Tektronix 7a15a User manual

Other Tektronix Amplifier manuals

Tektronix

Tektronix 2A61 User manual

Tektronix

Tektronix AM 502 User manual

Tektronix

Tektronix 7A16 User manual

Tektronix

Tektronix Z User manual

Tektronix

Tektronix 11A52 Owner's manual

Tektronix

Tektronix TYPE CA User manual

Tektronix

Tektronix 7A16A User manual

Tektronix

Tektronix TEKFAX ADA400A User manual

Tektronix

Tektronix 7K11 User manual

Tektronix

Tektronix TEKFAX ADA400A User manual

Tektronix

Tektronix 7A13 User manual

Tektronix

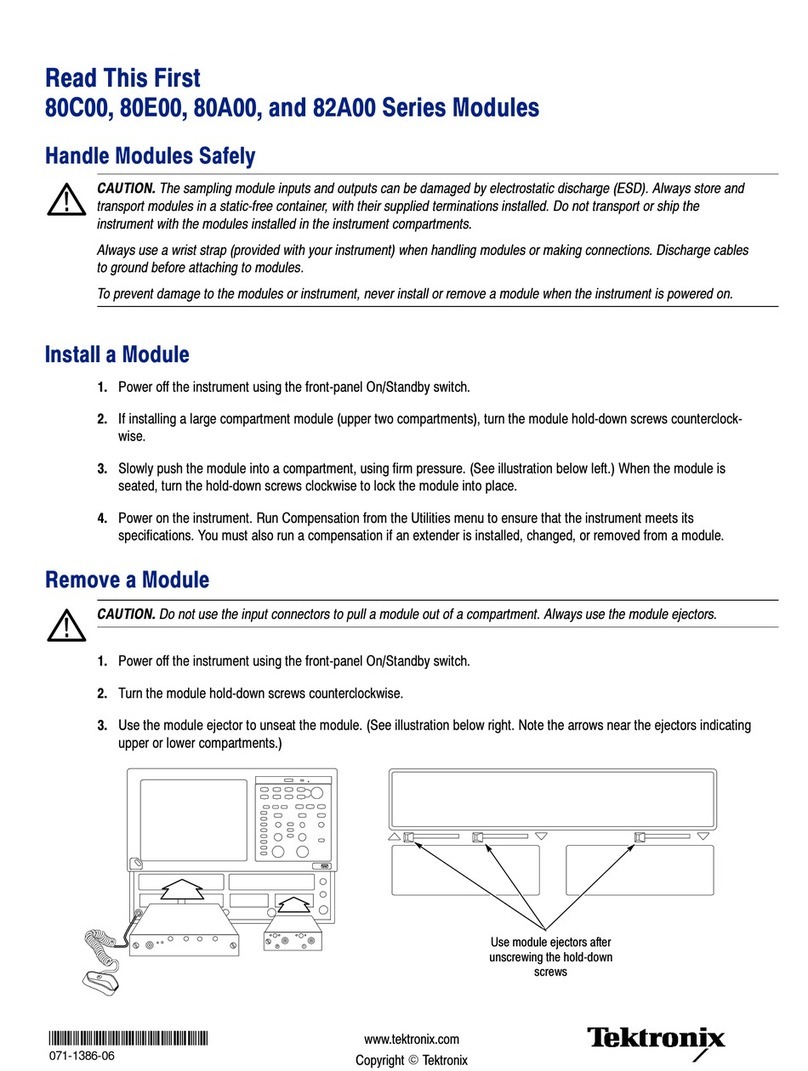

Tektronix 80C11 User manual

Tektronix

Tektronix 5A15N User manual

Tektronix

Tektronix 11A32 Assembly instructions

Tektronix

Tektronix 7A18 User manual

Tektronix

Tektronix 1A7 User manual

Tektronix

Tektronix 7A18A User manual

Tektronix

Tektronix 7A24 User manual

Tektronix

Tektronix 7A16A User manual

Tektronix

Tektronix 7A29 User manual