Tektronix 3B5 User manual

Other Tektronix Control Unit manuals

Tektronix

Tektronix 73A-851 User manual

Tektronix

Tektronix TDS3TMT User manual

Tektronix

Tektronix 80E02 User manual

Tektronix

Tektronix VX4286 User manual

Tektronix

Tektronix 73A-270 User manual

Tektronix

Tektronix DPO3PWR User manual

Tektronix

Tektronix 80A01 User manual

Tektronix

Tektronix 80E01 User manual

Tektronix

Tektronix ECO8000 Series User manual

Tektronix

Tektronix TM 501 User manual

Tektronix

Tektronix 80A05 User manual

Tektronix

Tektronix TM 515 User manual

Tektronix

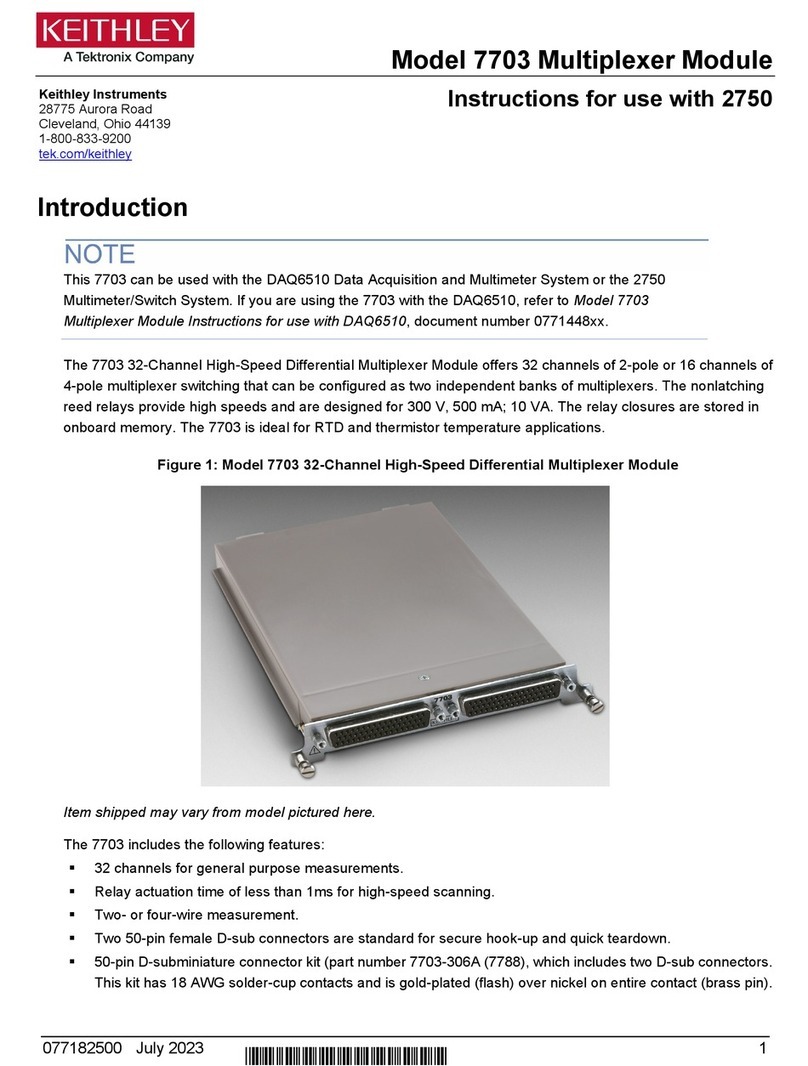

Tektronix KEITHLEY 7703 User manual

Tektronix

Tektronix TDS200 Series User manual

Tektronix

Tektronix VX4790A User manual

Tektronix

Tektronix 80A02 User manual

Tektronix

Tektronix 7A21N User manual

Tektronix

Tektronix TM 502A User manual

Tektronix

Tektronix DAS MTIF User manual

Tektronix

Tektronix VX4342 User manual

Popular Control Unit manuals by other brands

Clean Water Systems

Clean Water Systems Fleck 2510 Installation & start?up guide

Fairchild

Fairchild FSB44104A user guide

LEGRAND

LEGRAND Wattstopper LMIN-104 installation instructions

PMK

PMK ATT10BNCS instruction manual

Woodward

Woodward easYgen Technical manual

Balluff

Balluff BNI EIP-502-105-R015 user guide