Teledyne Cetac Technologies ASX-560 User manual

ASX-560 / ASX-280 Autosampler

Manual Part Number 480215 Rev2

Operator’s Manual

COPYRIGHT

© 2004-2015Teledyne Technologies

Incorporated. All rights reserved.

480215 Rev2, September, 2015

Teledyne CETAC Technologies authorizes its

customers to reproduce, transmit, or store

this document in its entirety, including this

page, for the express purpose of installing,

operating, or maintaining the product

described herein.

Teledyne CETAC Technologies

Customer Service & Support

14306 Industrial Road

Omaha, Nebraska 68144, USA

Phone (800) 369-2822 (USA only)

Phone (402) 733-2829

Fax (402) 733-1932

E-mail custserv@cetac.com

REVISIONS

Teledyne CETAC Technologies strives to

provide the scientific community with an

unparalleled combination of effective

technology and continuing value. Modular

upgrades for existing instruments will

continue to be a prime consideration as

designs progress.

Teledyne CETAC Technologies reserves the

right to revise this document and improve

products described herein at any time without

notice or obligation.

TRADEMARK ACKNOWLEDGEMENTS

Windows is a registered trademark of

Microsoft Corporation in the United States and

other countries.

PharMed and Tygon are registered

trademarks of Saint-Gobain Performance

Plastics.

DuPont™, Kapton®, Teflon®, Tefzel®and

Viton®are trademarks or registered

trademarks of E.I. du Pont de Nemours and

Company.

Superthane is a registered trademark of

NewAge Industries, Inc.

KYNAR® is a registered trademark of Arkema

Inc.

KIMWIPES is a registered trademark and

KIMTECH SCIENCE is a trademark of

Kimberly-Clark Worldwide, Inc

All other marks are the property of their

respective owners.

3

Contents

1Introduction ..............................................................................................................7

Overview.................................................................................................................................... 7

About This Manual ................................................................................................................ 7

Who Should Read This Book...................................................................................... 7

Autosampler Standard Components............................................................................. 8

Additional Equipment Required ...................................................................................10

Optional Accessories ..........................................................................................................11

Chemical Compatibility.....................................................................................................12

Where to Go for More Information..............................................................................13

2Preparing for Installation ................................................................................. 15

Choosing a Location............................................................................................................15

Space Requirements....................................................................................................15

Work Surface Requirements....................................................................................16

Rinse Solution Requirements...................................................................................16

Liquid Waste Routing Requirements ...................................................................16

Power Requirements...................................................................................................16

Unpacking the Autosampler ...........................................................................................17

3Installing the Autosampler ............................................................................... 19

Mounting the Tray and Rinse Station .........................................................................20

Mounting the Z-Drive.........................................................................................................21

Attaching the Z-Drive to the Autosampler Arm...............................................21

Connecting the Rinse Station..........................................................................................26

Waste Rinse Solution ..................................................................................................26

Tubing Considerations...............................................................................................26

Pumped Drain Arrangement...................................................................................27

Gravity Drain Arrangement.....................................................................................31

Dual-Rinse Gravity Drain Arrangement .............................................................34

Dual-Rinse Pumped Drain Arrangement............................................................36

Assembling and Placing the Sample Vial Racks .....................................................38

Installing the Sample Probe ............................................................................................39

Connecting to the Analytical Instrument’s Sample Port ....................................41

Enclosure Connections...............................................................................................41

Connecting the Autosampler to the Power Supply...............................................42

ASX-560 / ASX-280 Autosampler Operator’s Manual

Contents

4

Connecting the Autosampler to the Host Computer............................................43

Connecting a Serial Cable.................................................................................................43

Connecting a USB Cable....................................................................................................44

4Verifying Installation (IQ and OQ)..................................................................47

Basic Verification.................................................................................................................47

Installation Qualification (IQ)........................................................................................48

Inventory of Supplied Equipment.......................................................................... 48

Operating Environment Checklist......................................................................... 48

Visual Inspection.......................................................................................................... 48

Installation Checklist .................................................................................................49

Communication Test .................................................................................................. 49

X/Y/Z Movement and Alignment Test.................................................................49

Peristaltic Pump Test.................................................................................................50

Saving the Test Record .............................................................................................. 50

Clearance Inspection.................................................................................................. 50

Operational Qualification (OQ) .....................................................................................51

Performance Qualification (PQ)....................................................................................51

Autosampler IQ Checklist ................................................................................................52

Autosampler OQ Checklist...............................................................................................55

5Using the Autosampler .......................................................................................59

Establishing Optimal Operating Conditions ............................................................59

Creating the Lab Environment............................................................................... 59

Replacing Autosampler Components................................................................... 60

Purchasing Supplies ................................................................................................... 60

Arranging the Sample Vial Racks .................................................................................61

Starting the Autosampler.................................................................................................61

Shutting Down the Autosampler ..................................................................................62

Flushing the Rinse Station and Flow Path................................................................62

6Using the Autosampler Utility..........................................................................65

Installing the ASX Dashboard Software.....................................................................65

Starting the ASX Dashboard ...........................................................................................66

Changing the Movement Speed and Rinse Pump Speed....................................67

Dual Rinse...............................................................................................................................68

Dual Rinse Timing ....................................................................................................... 68

Pump Speed.................................................................................................................... 68

7Maintaining the Autosampler ..........................................................................69

Cleaning the Autosampler ...............................................................................................69

Daily External Cleaning ............................................................................................ 69

Weekly Cleaning........................................................................................................... 70

Cleaning the Sample Probe .............................................................................................71

Checking for Leaks..............................................................................................................71

Replacing Peristaltic Pump Tubing .............................................................................71

Aligning the Autosampler................................................................................................73

Checking the Home Position Alignment ............................................................. 73

Setting the Z-Axis Travel..................................................................................................74

Replacing the Z-Drive ........................................................................................................75

How Does the Z-Drive Work? .................................................................................. 75

How Should I Care for the Z-Drive? ...................................................................... 76

Removing the Old Z-Drive ........................................................................................ 76

ASX-560 / ASX-280 Autosampler Operator’s Manual

Contents

5

Installing the New Z-Drive .......................................................................................76

Replacing the Rinse Station.............................................................................................80

Replacing the Sample Tray..............................................................................................81

Replacing the Home Flag/Guide Plate........................................................................81

8Troubleshooting the Autosampler ................................................................ 83

Power System Problems...................................................................................................83

Communications Interface Problems .........................................................................84

RS-232 Serial Cable Problems.................................................................................84

USB Cable Problems....................................................................................................84

Software Configuration Problems.........................................................................85

Z-Drive Problems.................................................................................................................85

Contamination and Carryover Problems ..................................................................86

Saving a Log File...................................................................................................................86

Using the C-Term™ Terminal Program ......................................................................87

Installing C-Term .........................................................................................................87

Starting C-Term............................................................................................................87

Overview of the C-Term Window...........................................................................87

Configuring C-Term ....................................................................................................88

Autosampler Commands...........................................................................................88

Returning the Product to CETAC for Service...........................................................89

Shipping the Product..................................................................................................89

Product Warranty Statement .................................................................................89

Returned Product Procedures.................................................................................90

Returned Product Warranty Determination ....................................................91

9Safety and Regulatory Information ............................................................... 92

Characteristics ......................................................................................................................92

Environmental Characteristics...............................................................................92

Electrical Characteristics..........................................................................................93

Safety Notices ........................................................................................................................94

Power Cord Set Requirements ................................................................................94

Power Cord Safety Maintenance............................................................................94

Mains Disconnect .........................................................................................................94

Cleaning Instructions .................................................................................................95

Mechanical Hazards ...................................................................................................95

Operating Environment.............................................................................................96

Explanation of Caution and Warning Notices..................................................97

Electromagnetic Interference ........................................................................................97

Explanation of Regulatory Marks .................................................................................98

10 Glossary ................................................................................................................... 99

ASX-560 / ASX-280 Autosampler Operator’s Manual

Contents

6

This page is intentionally blank.

7

1Introduction

Overview

The CETAC ASX-560 and ASX-280 autosamplers are designed to be sturdy,

reliable, and easy to use. It provides automated sample introduction that

enables you to perform other tasks while the autosampler runs. The ASX-560

autosampler automatically introduces up to 360 samples when fully loaded;

the ASX-280 has a capacity of 180 samples. It contains a microprocessor that

allows sequential or random sampling, providing flexibility.

The autosampler is typically interfaced to and controlled by the analytical

instrument host computer using a serial or USB connection. You can also

connect the autosampler to other devices, such as an autodilutor, or use it with

accessory equipment, such as a syringe pump or the CETAC ASXPRESS PLUS

rapid sample introduction system.

About This Manual

This manual describes the procedures for installing, using, and maintaining

your CETAC ASX-560 or ASX-280 autosampler. It also provides information

about troubleshooting minor problems and describes the design of the

autosampler.

This manual shows common versions of the ASX-560 autosampler. Your

autosampler may have different racks, a different probe, or other minor

differences from what is shown.

Who Should Read This Book

The primary audience for this manual consists of analytical chemists and lab

technicians. To use this manual effectively, you should have a basic knowledge

of chemistry, a basic knowledge of electronic sampling equipment, at least a

beginning level of computer experience, and working knowledge of the

analytical instrument used with the autosampler.

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

8

CHEMICAL INJURY HAZARD

The autosampler is intended for use only by qualified operators who have

been trained in safe laboratory practices. Make sure you know the hazards

associated with all of the chemicals you are using, and take the appropriate

precautions. Exposure to laboratory chemicals may result in serious injury.

Autosampler Standard Components

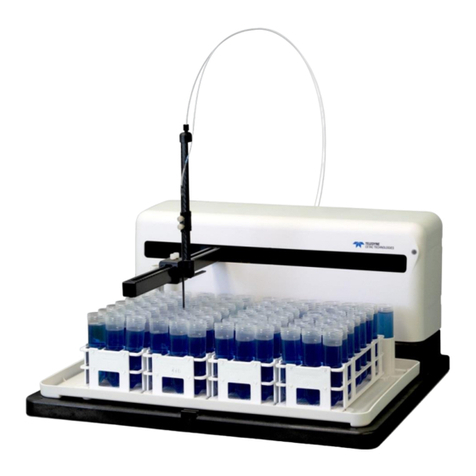

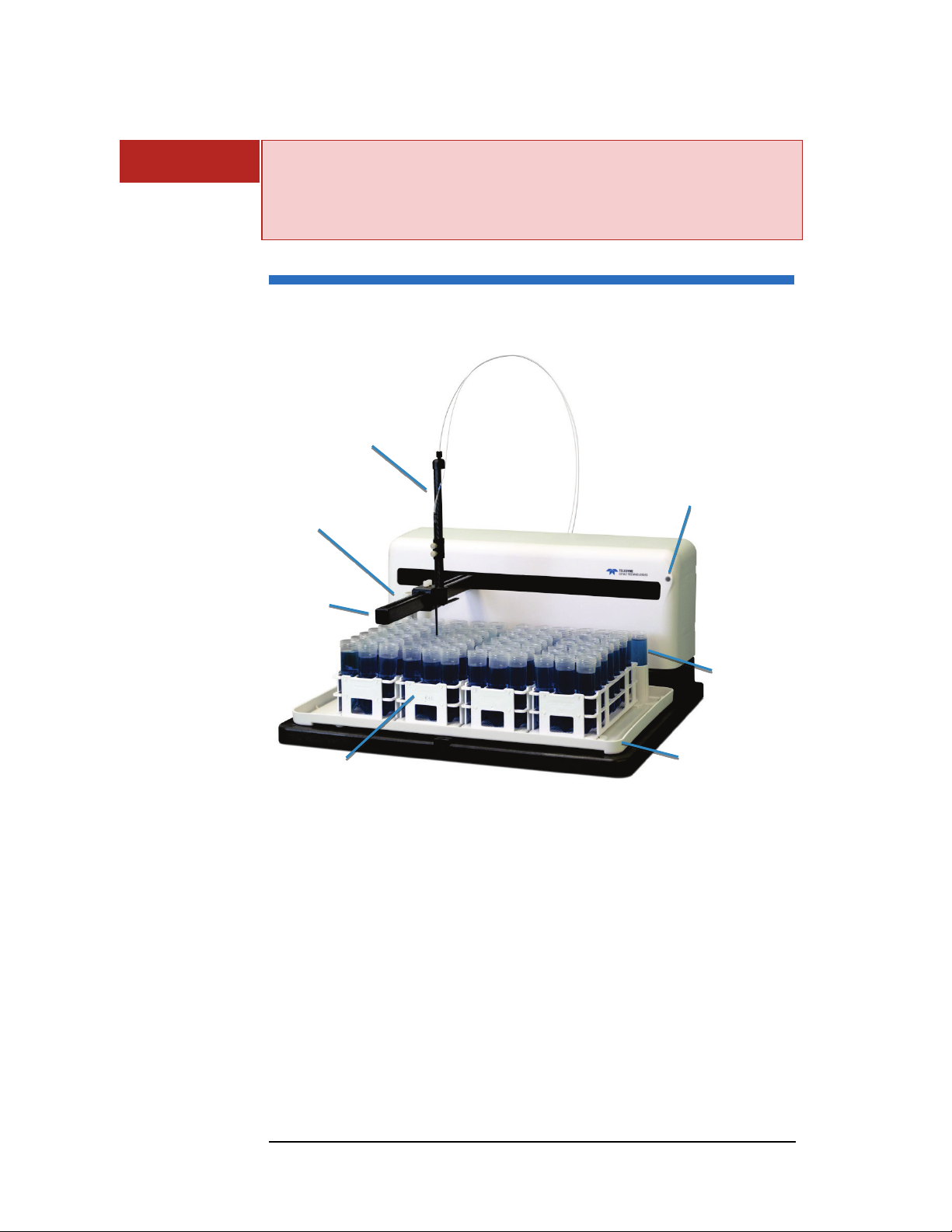

Figure 1-1 ASX-560 Autosampler—Front View

The following components are located on the front of the autosampler and are

shipped with the autosampler (see Figure 1-1).

Sample Tray. The sample tray holds the rinse station, sample racks, and

standards vials in place. The tray also contains small spills.

Sample Vial Racks. The ASX-560 includes four sample vial racks; the ASX-

280 includes two racks. You can choose from different rack sizes (common

sizes fit 21, 24, 40, 60 or 90 vials per rack). You can combine racks of

different sizes as long as the host computer’s software accepts the

combination.

Standards Vials. Ten standards vials are included with the autosampler.

The standards vials, which fit into the standards positions at the back of

the sample tray, are 50-milliliter conical centrifuge vials with caps.

Rinse Station. The flowing rinse station is located at the left end of the

standards positions at the back of the sample base. It comes with tubing

WARNING

Sample Tray

Standards Vials

Sample Vial Racks

Rinse Station

Arm

Z-Drive Assembly

Power

Indicator Lamp

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

9

used to connect the rinse station to the rinse source and the waste

container.

Arm. The arm moves the sample probe horizontally.

Z-Drive. The Z-drive moves the sample probe vertically. The Z-drive

assembly includes a Y-axis slider block and guide plate as well as the

sample probe. The Z-drive attaches onto the autosampler arm.

Power Indicator Lamp. The LED indicates that the autosampler is

connected to a power source and turned on.

Figure 1-2 ASX-560 Autosampler—Back View

The following components are located on the back of the autosampler and are

shipped with the autosampler.

On-board peristaltic pump. A two-channel peristaltic pump moves the

rinse solution from the rinse source through the flowing rinse station.

Serial Ports. The COM1 port connects the autosampler with the analytical

instrument’s host computer. The COM2 port connects the autosampler to

other external devices, such as an autodilutor.

USB Port. The USB port can be used to interface the autosampler with the

host computer.

The following standard components are also shipped with the autosampler:

Power Supply. A desktop "brick" transformer powers the autosampler.

Sample Probe Kit. The kit includes the sample probe. The sample probe

fits into the Z-drive.

Communication Cables. The contents of the kit depend on the version of

the autosampler. Most kits include a 1.828-meter serial cable and a USB

cable.

Power Switch

Serial Ports

USB Port

Power Connector

Z-Drive Motor

Peristaltic Pump

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

10

CD. The CD contains, if applicable:

Utility software

USB device drivers

Manuals

Other application-specific information

Supplied components depend on the application and the exact version of the

autosampler. See the packing list in the shipping container to see exactly which

components are supplied.

Additional Equipment Required

In addition to the provided equipment, you will need:

A host computer which has been configured with the control software for

your instrument. This computer must have an additional free USB or serial

port beyond the ports required to control the instrument and other system

components.

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

11

Optional Accessories

You may need optional accessories in addition to the standard components

included with the autosampler. See the ASX-560 / ASX-280 Autosampler Spare

Parts and Accessories Catalog for details. Available accessories include:

Sample Vials and Racks.

Sample Probes. Extra probes are available in a variety of diameters. See

table below for common probe sizes.

0.3 mm ID Black band

0.5 mm ID Blue band

0.8 mm ID Red band

0.9 mm ID Yellow band

1.0 mm ID 2 Blue bands

Table 1: Sample Probe Sizes and Color Coding

Dual Rinse Station. The dual-rinse option allows more thorough rinsing

to reduce sample contamination and carryover.

Enclosure. The enclosure protects samples from contamination and

contains and exhausts fumes.

ASXPRESS PLUS Rapid Sample Introduction System. 6-port valve system

which enables rapid sample loading and probe wash out.

NOTE:

Contact Teledyne CETAC Technologies if you need additional accessories not

listed, need added features to integrate the autosampler into your analytical

system, or have unique requirements. Research and development of new

features and accessories for the autosampler, often inspired by customer

requests, is a continuing activity at Teledyne CETAC Technologies.

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

12

Chemical Compatibility

The autosampler operates reliably under a wide variety of conditions. No

metallic components are exposed above the sample vials. The top cover and

base are made from polypropylene. The arm and Z-drive are made from carbon

fiber.

The back and frame are made from a high-strength aluminum alloy that is

treated with a RoHS-compliant chemfilm and finished with an epoxy powder

coating. Long-term exposure to aqueous acids greater than 15% may cause

discoloration or bubbling of the epoxy coating.

Internal splash shields protect against occasional exposure to corrosive

chemicals. The covers are not sealed against liquid or vapor intrusion. Long-

term exposure of the internal components to corrosive materials may cause

damage.

Exposure to corrosive vapors can be minimized by using an enclosure with

airflow directed down and away from the electronic components.

Components in the sample flow path are made of polyetherimide (PEI) and

polytetrafluoroethylene (PTFE). When these inert, non-metallic materials are

used at temperatures less than 135 °C, they can withstand repeated exposure

to the following substances:

Predominantly aqueous solutions of strong acids (less than 20%)

Predominantly aqueous solutions of strong bases (less than 10%)

Common organic solvents such as acetone, alcohols, ethyl acetate,

methylethylketone (MEK), petroleum oils and derived fuels, and kerosene.

DAMAGE FROM CHEMICAL EXPOSURE

Prolonged or repeated exposure to temperatures greater than 135 °C and to the

following substances can cause failure of the flow path components:

• Solutions of concentrated acids (greater than 40%).

• Solutions of concentrated bases (greater than 10% potassium, ammonium, or

sodium hydroxides).

• Partially halogenated hydrocarbons or extremely aggressive organic solvents

(chloroform, methylene dichloride, 1,1,2-trichloroethane).

Prolonged exposure to carbon tetrachloride can damage the autosampler.

CHEMICAL HAZARD

Do not use the autosampler with substances which could pose a hazard of

serious injury to the operator if spilled or injected, such as biological

substances or formic acid.

CAUTION

WARNING

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

13

Where to Go for More Information

In addition to this manual, you can refer to the following resources:

New versions of this manual may be available under “Support” on CETAC’s

Web site:

www.cetac.com

ASX-560 / ASX-280 Autosampler Spare Parts and Accessories Catalog,

available on the CETAC Web site.

CETAC Autosampler Safety Guide provides basic safety-related information

in a variety of languages.

Online help within the ASX Dashboard software.

Teledyne CETAC Technologies Customer Service and Support:

Phone: 1 (800) 369-2822 (USA only)

1 (402) 733-2829

Fax: 1 (402) 733-1932

E-mail: custserv@cetac.com

The software manual for the instrument you are using.

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 1: Introduction

14

This page is intentionally blank.

15

2 Preparing for

Installation

Installing the autosampler requires preparation. Before you install the

autosampler, you should evaluate the physical arrangement of the laboratory

to choose a suitable location.

Choosing a Location

For the system to function optimally, the location you select must meet specific

requirements.

Space Requirements

Most analytical applications benefit from using the shortest sample flow path.

Therefore, you should place the autosampler in close proximity to the

analytical instrument. The recommended footprint for the autosampler is

shown in the following tables.

Height 28 cm (14")

without Z-Drive

62 cm (24.4")

with Z-drive and tubing

Width 58 cm (232.5)

Depth 55 cm (21.6") 59 cm (23.5")

with cables and tubing

Weight 11.7 kg (26 lbs) without racks or vials

Table 2: Physical Characteristics – ASX-560

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 2: Preparing for Installation

16

Height 28 cm (14")

without Z-Drive

66 cm (26")

with Z-drive and tubing

Width 36 cm (14.0”)

Depth 54 cm (21.0") 58 cm (22.8")

with cables and tubing

Weight 8.1 kg (17.8 lbs) without racks or vials

Table 3: Physical Characteristics – ASX-280

The weight shown is that of the autosampler itself, without the desktop power

supply, tray, vials, sample probe, or tubing.

Allow at least 5 cm behind the autosampler for cable egress and access to the

power switch. Always position the equipment so that it is easy to disconnect

the power cord.

Work Surface Requirements

The autosampler must be placed on a sturdy countertop or table. Do not place

the autosampler on a wheeled cart or folding table.

During operation, the autosampler produces both vertical and horizontal

forces. If the work surface is allowed to shake or wobble, the autosampler may

“walk” across the surface, liquids may spill, or data quality may be affected.

Rinse Solution Requirements

For most applications, deionized water or kerosene is used as the rinse agent.

Place the rinse agent source within two meters of the autosampler.

Liquid Waste Routing Requirements

Ensure that there is a liquid waste receptacle within two meters of the

autosampler. The waste receptacle inlet should be 30 to 60 centimeters lower

than the autosampler rinse station outlet and set up so that the rinse drain

tubing drops directly into the waste receptacle with no coiling and without

being submerged below the liquid level of the waste receptacle.

SUBMERGED DRAIN TUBING MAY CAUSE EQUIPMENT DAMAGE

Ensure that the rinse drain tubing is not submerged in the waste liquid. If the

tubing is submerged, waste liquid can back up in the rinse station, flooding the

sample tray.

Power Requirements

The autosampler is powered by the supplied external desktop "brick" power

supply. Place the autosampler within 1.2 meters of a power outlet.

SHOCK AND FIRE HAZARD

Use only the provided power supply. The power supply must be plugged

into an outlet which has a protective ground connection.

The autosampler is intended to operate from DC power supplied through the

provided power supply. The power supply is provided power through an AC

CAUTION

WARNING

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 2: Preparing for Installation

17

power source that will not apply more than 240 VAC between the supply

conductors and ground. A protective ground connection by way of the

grounding connector in the power cord is required for safe operation.

Ensure that you position the autosampler so that the location where the power

supply cord plugs into it is easily accessible (is not blocked) so that it can be

quickly disconnected if needed. In case of hazard, the autosampler should be

disconnected from the power source.

The power supply socket is on the back of the autosampler below the power

switch. Connect the power supply to the autosampler first and then connect a

line cord to the power supply. Do not apply power to the power supply until

ready to operate the autosampler.

Unpacking the Autosampler

Inspect external packaging upon receipt for signs of shipping damage. Inspect

all items during unpacking and notify the carrier immediately of any concealed

damage. Check for kinked or bent tubing.

If the system is shipped or removed from storage during cold weather, allow

the packaged equipment to equilibrate to room temperature before opening

and exposing to warm, humid air. It is usually sufficient to provide four to eight

hours for this purpose.

EQUIPMENT DAMAGE FROM CONDENSATION

If condensation forms on or inside the autosampler, allow it to dry thoroughly

before connecting it to a power source and operating it. Failure to do so may cause

equipment damage.

Remove the packing checklist from the shipping container, and check off items

against it. Leave accessories in the packing until you are ready to install them.

NOTE

Keep the factory packaging for use in case the product ever needs to be

returned or shipped to another location.

CAUTION

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 2: Preparing for Installation

18

This page is intentionally blank.

19

3 Installing the

Autosampler

The autosampler can be installed with minimal effort; no tools are required.

You can remove thumbscrews with tools if necessary, but do not tighten them

with anything other than your fingers.

To install the autosampler, you must complete the following tasks. Each of

these tasks will be discussed in detail later in this chapter.

Mount the Z-drive.

Connect the rinse station.

Assemble the sample vial racks.

Connect the sample tubing to the analytical instrument.

Connect the autosampler to the power supply and to the host computer.

PINCH/PUNCTURE HAZARD

Ensure the power switch is off and the power cord is unplugged before

proceeding with installation. If the power is left on, motors may move

unexpectedly and cause injury.

WARNING

ASX-560 / ASX-280 Autosampler Operator’s Manual

Chapter 3: Installing the Autosampler

20

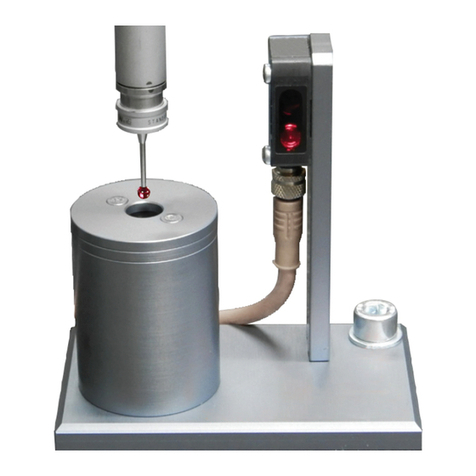

Mounting the Tray and Rinse Station

1Place the tray on the base of the autosampler.

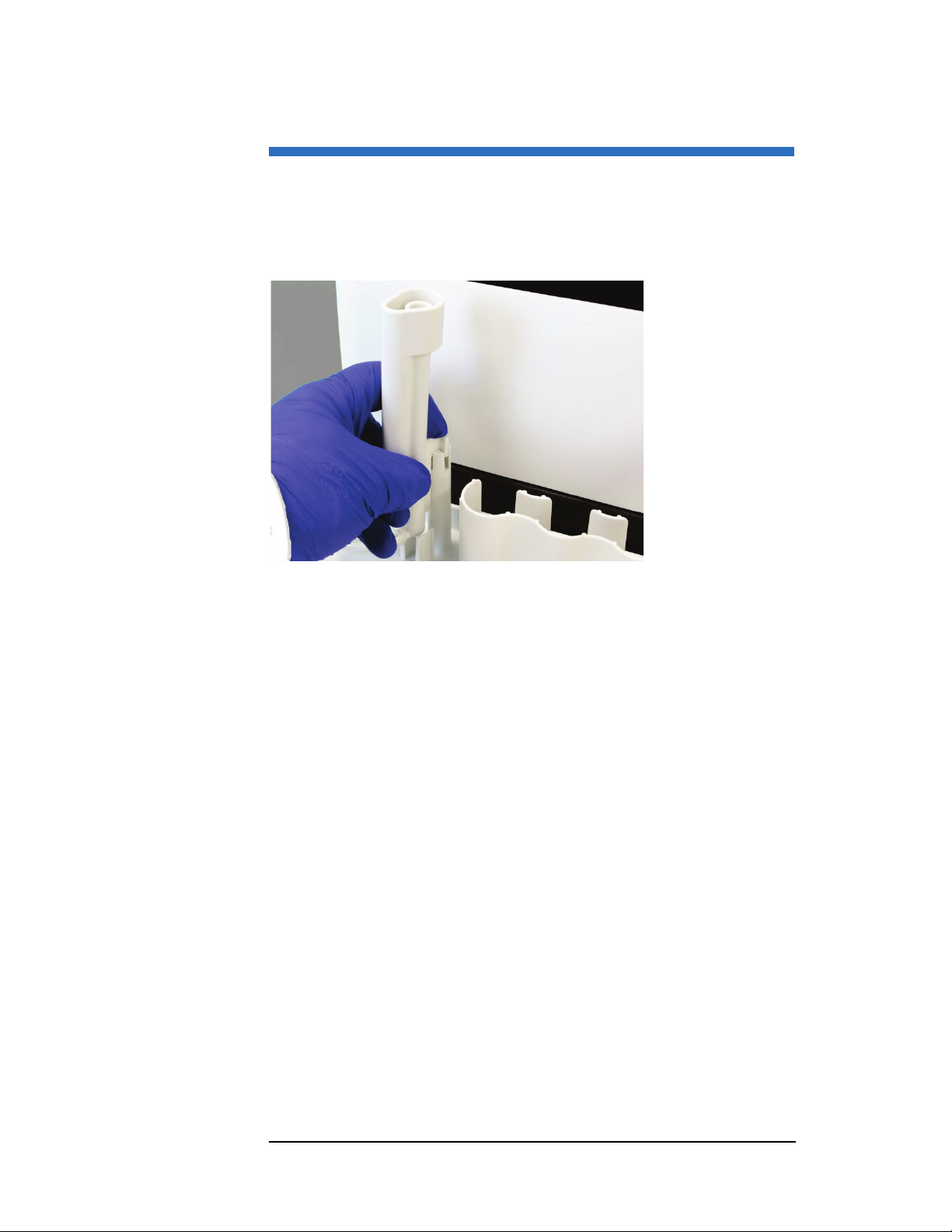

2Place the rinse station on the post on the back left corner of the tray. Press

straight down until it is fully seated.

Figure 3-1 Mounting the Rinse Station

Other manuals for ASX-560

1

This manual suits for next models

1

Table of contents

Other Teledyne Cetac Technologies Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Harvard Bioscience

Harvard Bioscience DSI Buxco E-cigarette, Vapor, & Tobacco (EVT) Smoke... Application guide

overhoff

overhoff TASC-HTO-HT-C14 Operation & maintenance manual

Tektronix

Tektronix Keithley 2380-500-30 Performance Verification Manual

Novus

Novus NV-100PS user manual

GYROZEN

GYROZEN 2236R user manual

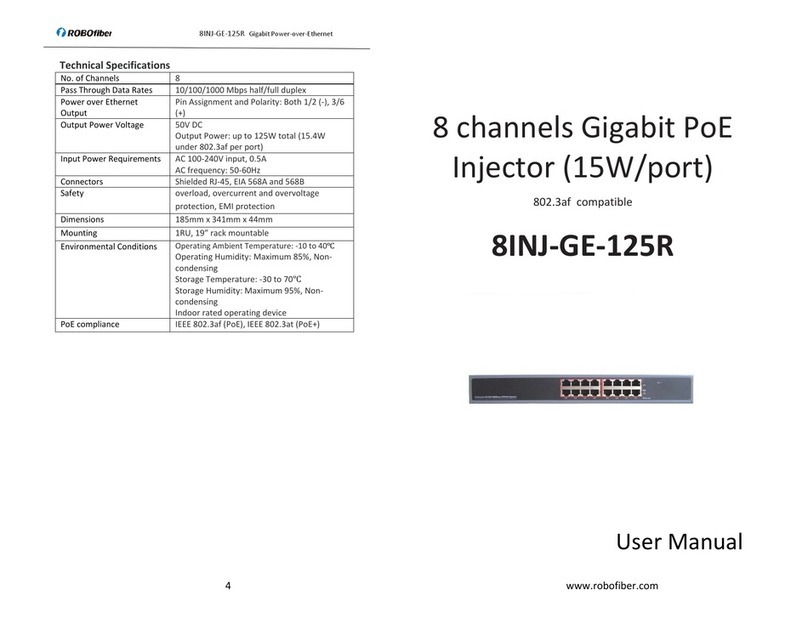

ROBOfiber

ROBOfiber 8INJ-GE-125R user manual