User Manual

A110D0001 Rev 1.2 for the A-110 Series

MRe, 28-Nov-2016

Page 3 of 29

PI (Physik Instrumente) L.P.

16 Albert Street, Auburn, MA 01501

Tel: 508-832-3456 Fax: 508-832-0506

Email: air@pi-usa.us

Table of Contents

1. About this Document ____________________________________________________________________5

1.1. Objective and Target Audience of this User Manual ________________________________________5

1.2. Symbols and Typographic Conventions __________________________________________________5

1.3. Other Applicable Documents __________________________________________________________5

2. Safety ________________________________________________________________________________6

2.1. Intended Use ______________________________________________________________________6

2.2. General Safety Instructions ___________________________________________________________6

2.3. Warnings and Safety Notices __________________________________________________________6

2.4. Organizational Measures _____________________________________________________________7

3. Product Description _____________________________________________________________________8

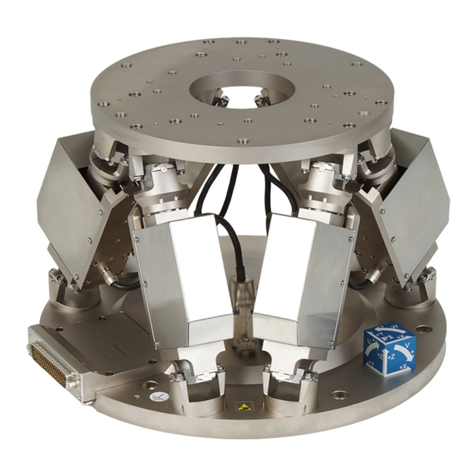

3.1. Model Overview and Part Numbering ___________________________________________________8

3.2. Product Features ___________________________________________________________________8

3.3. Product Labeling__________________________________________________________________ 10

3.4. Scope of Delivery _________________________________________________________________ 11

3.5. Accessories ______________________________________________________________________ 11

3.6. Controllers ______________________________________________________________________ 11

4. Technical Features ____________________________________________________________________ 12

4.1. Air Bearing ______________________________________________________________________ 12

4.2. Linear Motor_____________________________________________________________________ 12

4.3. Linear Encoder ___________________________________________________________________ 12

4.4. Limits and Index Mark (incremental encoders only) ______________________________________ 12

5. Unpacking and Handling________________________________________________________________ 13

6. Installation __________________________________________________________________________ 14

6.1. Mounting Surface Quality and Preparation _____________________________________________ 14

6.2. Mounting Procedure ______________________________________________________________ 14

6.3. Removing the shipping lock(s) _______________________________________________________ 15

6.4. Air Supply _______________________________________________________________________ 15

6.5. Affixing the Payload to the Stage _____________________________________________________ 16

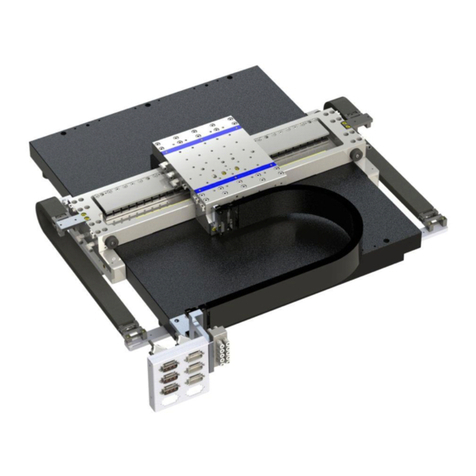

6.6. XY Configurations _________________________________________________________________ 17