2105 Interface Module

Table of Contents

vi

Section 4 Maintenance

4.1 Overview ..........................................................4-1

4.1.1 Cleaning .....................................................4-1

4.2 Desiccant ..........................................................4-1

4.2.1 Replacing the Desiccant ........................................4-2

4.2.2 Reactivating the Desiccant ......................................4-2

4.3 Hydrophobic Filter ..................................................4-3

4.4 O-Rings ...........................................................4-3

4.5 How to Obtain Service ...............................................4-3

Appendix A Replacement Parts List

A.1 Replacement Parts Diagrams and Listings...............................A-1

A.1.1 2105 Interface Module .........................................A-2

A.1.2 2191 Battery Module ...........................................A-7

A.1.3 2105Ci Antenna ...............................................A-9

Appendix B Accessories

B.1 How to Order.......................................................B-1

B.2 General Accessories .................................................B-1

B.3 Cables ............................................................B-2

Appendix C Material Safety Data Sheets

List of Figures

1-1 2105 Components - Top View .........................................1-2

1-2 2105 Components - Bottom View .......................................1-3

1-3 Battery Module Components, Top View .................................1-4

1-4 Battery Module Components, Bottom View ..............................1-5

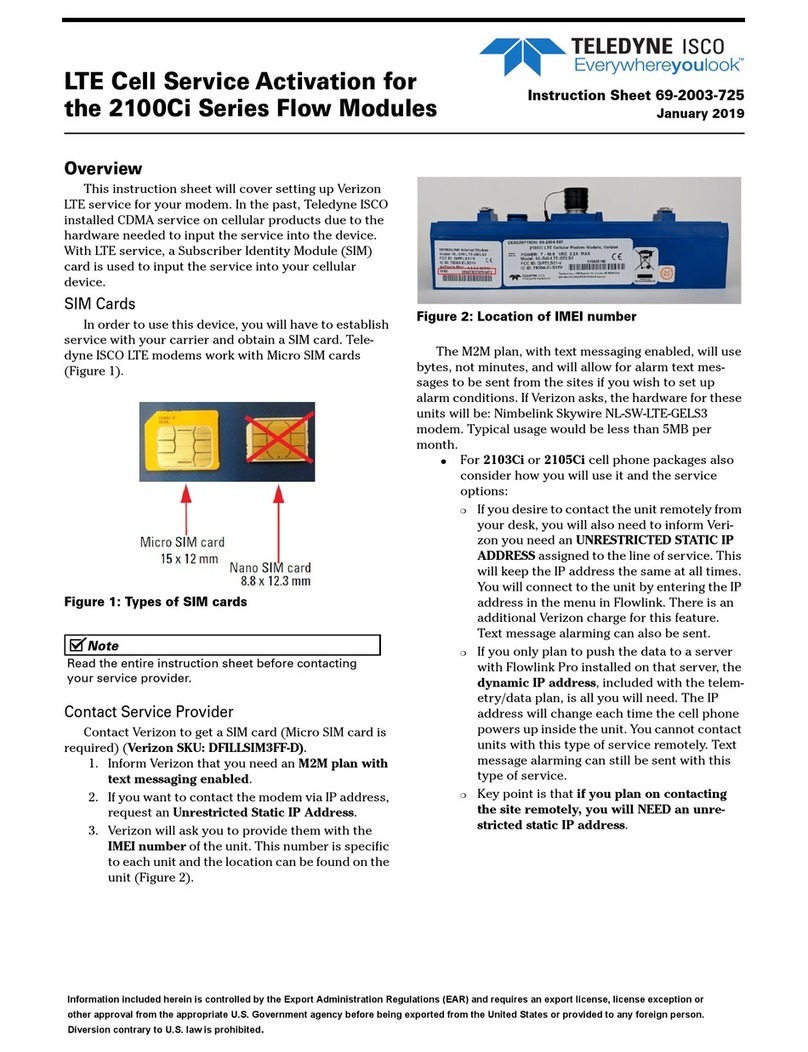

2-1 2105Ci serial label ..................................................2-1

2-2 Identifying the 2150 voltage specification ...............................2-2

2-3 Identifying the voltage specification on the DB9 cable .....................2-3

2-4 Unlocking the Latch .................................................2-4

2-5 Locking the Latch ...................................................2-5

2-6 Insert Battery in Carrier .............................................2-6

2-7 Battery Module - Inserting Carrier .....................................2-6

2-8 Battery Module - Aligning the Door ....................................2-7

2-9 Battery Module - Closing the Door .....................................2-7

2-10 Unlock latch and stow the cap ........................................2-8

2-11 Aligning the modules ...............................................2-8

2-12 Antenna connected to 2105Ci ........................................2-9

2-13 Flowlink connect screen (version 5.10.616) ............................2-10

2-14 Site resolution screen ..............................................2-11

2-15 Site Information screen ............................................2-12

2-16 Devices screen - connected to site ....................................2-13

2-17 Modem screen - configuring the cellular modem ........................2-14

2-18 Devices screen - configuring the modem for Serial-Over-IP communication . . 2-15

2-19 Devices screen - configuring the modem for CSD communication ..........2-16

2-20 Setting up text messaging and alarm conditions ........................2-17

2-21 Wireless power control window ......................................2-19

2-22 Equation Builder for power control ...................................2-20

2-23 Condition Builder .................................................2-20