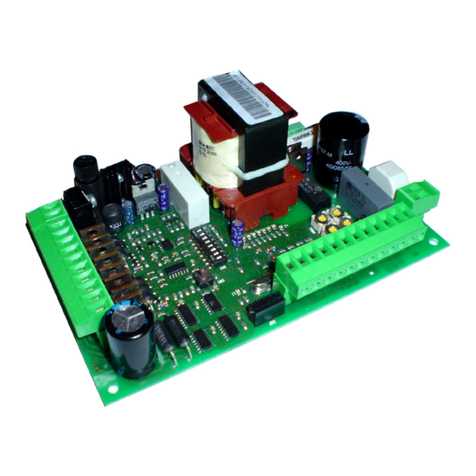

SETTINGS

Rv1

Rv2

Rv3

MOTOR SPEED REGULATION

Trimmer turned completely anti-clockwise = minimum speed

Trimmer turned completely clockwise = maximum speed

ATTENTION: Pay very much attention, when adjusting the maximum slowdown speed,

as it must be apropriated to the mechanical structure of the gate on which the

automation is installed and respect the security laws in force.

SLOW DOWN SPEED REGULATION

Trimmer turned completely anti-clockwise = minimum speed

Trimmer turned completely clockwise = maximum speed

ATTENTION: Pay very much attention, when adjusting the maximum slowdown speed,

as it must be apropriated to the mechanical structure of the gate on which the

automation is installed and respect the security laws in force.

REGULATION OF INTERVENTION THRESHOLD OF THE ANTI-CRUSHING DETECTOR

Trimmer turned completely anti-clockwise = maximum sensitivity (minimum thrust in case of

obstacle).

Trimmer turned completely clockwise = minimum sensitivity (maximum thrust in case of

obstacle).

After two consecutive interventions of the anti-crushing detector, even if in automatic logic, the

automation rests opened waiting for commands.

Adjust the sensitivity according to the security laws in force.

NOTICE: The setting of Trimmers and Dip Switches are read when the automation stops.

Do not hold the slowdown speed on the minimum with ammeter sensitivity on the minimum.

P1P1

English

http://www.seateam.com

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

67410618

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

17/52

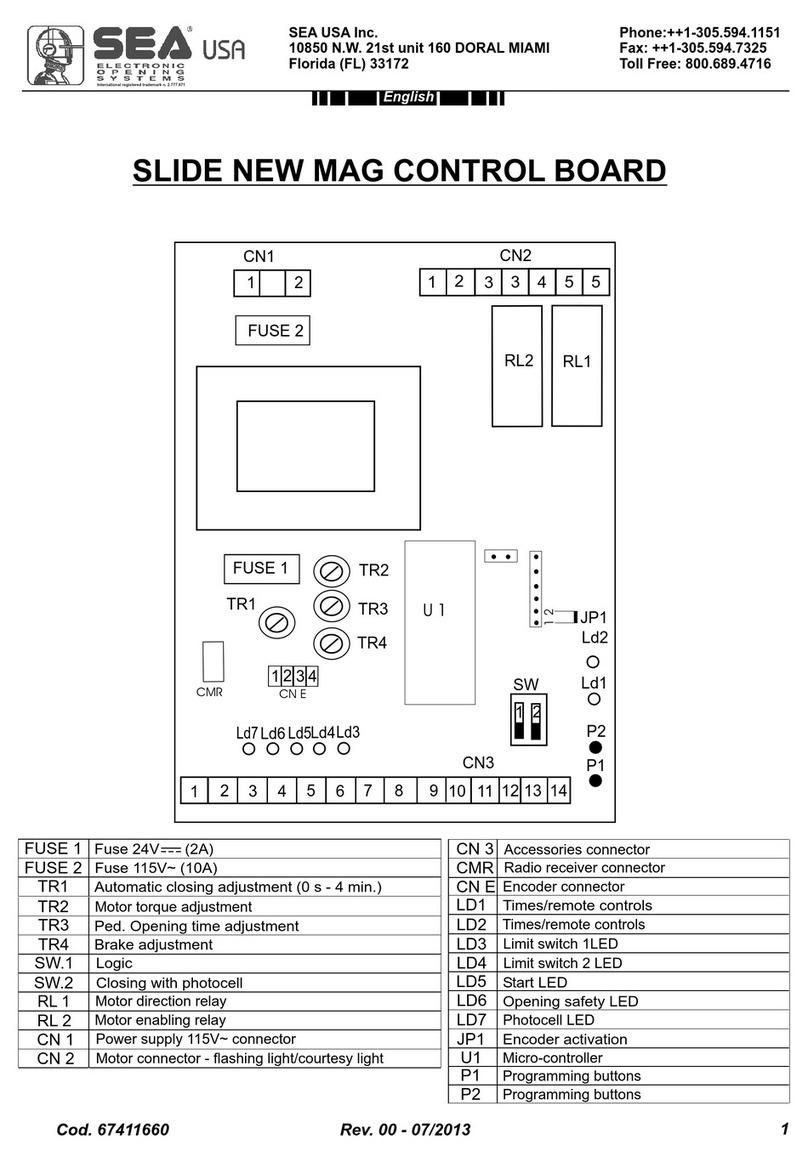

After having checked the right sliding of the gate and the electric connexions on the imputs/outputs, execute

the following procedures:

1.Release the gate and put it manually in closing.

2.Restore the mechanical stop and manually move the gate until the lock has mechanically re-engagement.

3. Power supply the control unit keeping pressed P1 for 3 sec. until the motor starts in closing or in opening.

4. During closing /opening phase push P1 at the point where you want to fix the beginning of the slowdown.

5. At the end of the opening/closing phase the calculation of the pausing time will begin, now attend the

desired pausing time and press pushbutton P1 again (every flash of the programming led corresponds to

more or less 1 sec. of pausing time).

6. Now the closing/opening will be executed, during this phase push P1 again at the point where you want

to fix the beginning of the slowdown in closing/opening.

7. Now the gate will reach the limit switch of closing/opening and will automatically finish the learning.

If at the end of the selflearning the gate is open instead of closed set DIP8 on ON.

Note: If you want to exclude the slowdown skip the phases 4 and 6 during programming.

Keep pressed while power suppling the control unit to start the selfprogramming procedure.

Make sure that the gate during programming phase correctly reaches both limit switches. If

this does not happen, increase the slowdown speed and/or decrease the ammeter

sensitivity and repeat the self-programming starting from point 3.

SELF-PROGRAMMING PROCEDURE OF THE CONTROL UNIT

Rev. 09 - 12/2009

Intelligent Security & Fire Ltd.