Section 2 Preparation

Detailed information about each of these optional devices is provided in Section 2.12

Plumbing Optional Modules To Torrent.

2.6.1 Cabling: Sample Load Pump

To connect a Sample Load Pump to the Torrent, attach the pump’s power cable to the

Torrent’s back panel connector labeled “SAMPLE LOAD PUMP.”

2.6.2 Cabling: Solvent Select Valve

To connect a Solvent Select Valve to the Torrent,

attach the valves power cable to the back panel

connector labeled “SAMPLE LOAD PUMP” and

connect the USB cable to the USB port on the back

panel.

2.6.3 Cabling: Fractionation Valve

To connect a Fractionation Valve to the Torrent,

attach the valve’s 9-pin power/control cable between

the port on the back of the Fractionation Valve to

the Torrent’s back panel connector labeled

“FRACTION VALVE.”

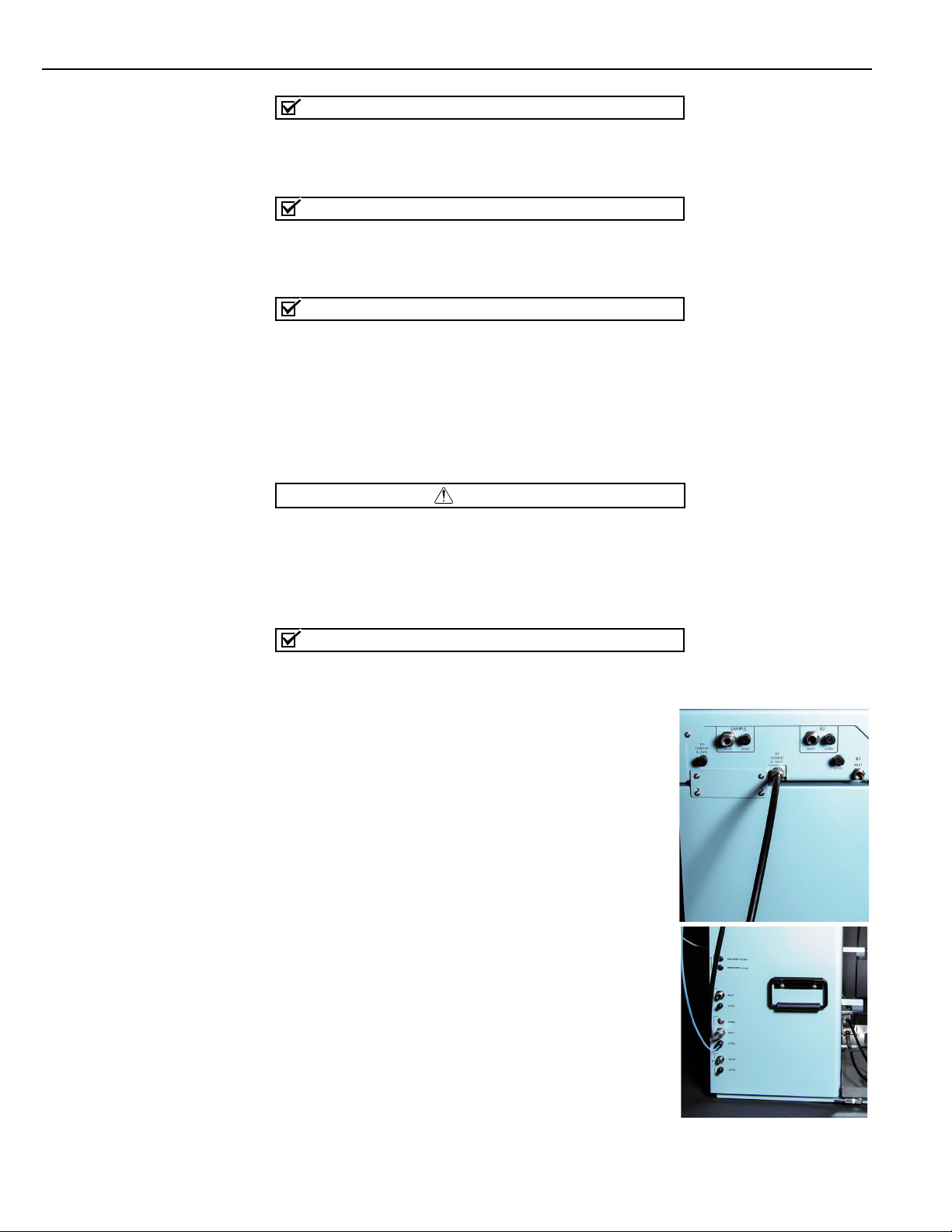

2.6.4 Cabling: Foxy R2 High Flow Fraction Collector

The Torrent can control up to four Foxy R2 High Flow fraction collectors via an

Ethernet network.

To connect one, or the first of multiple Foxys,

connect a standard straight-through network cable

between the Ethernet ports on the Torrent and a

Foxy. The second Ethernet port on the Foxy can be

used to add the next Foxy. See section 2.11.2 for

more details.

The Torrent can supply AC power to one Foxy.

Connect one end of the cable to the female IEC

connector on the Torrent. Connect the other end to

the Foxy power connector.

2.6.5 Cabling: Network Connection

The Torrent can be added to a network or directly

connected to a computer for remote control.

To add the Torrent to a network, connect a standard

straight-through network cable between the

Torrent’s Ethernet port and your network.

To connect the Torrent directly to a computer,

connect a “crossover” cable between the Ethernet

ports on the Torrent and a stand-alone computer.

To connect to a network, you will need access to IP

addresses and network information from your IT

department. For more information on network

guidelines, see TN28 Networking Guidelines for

CombiFlash Products, available at www.isco.com.