ii

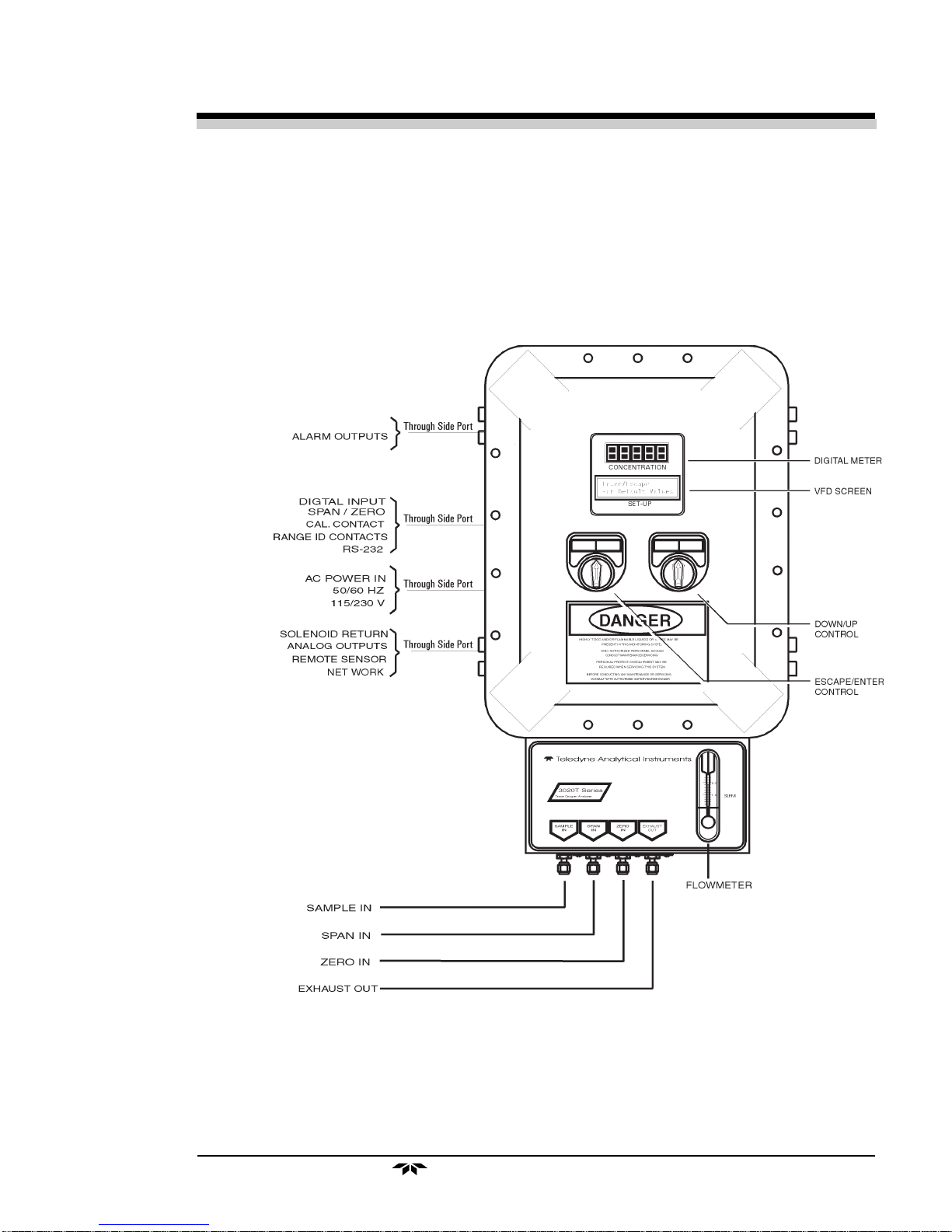

Model 3020T

Teledyne Analytical Instruments

Copyright©1999TeledyneAnalyticalInstruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, tran-

scribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

TeledyneAnalyticalInstruments,16830ChestnutStreet,CityofIndustry,CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, neglect or repairs other than those performed by Teledyne or an autho-

rized service center. We assume no liability for direct or indirect damages of any kind and

the purchaser by the acceptance of the equipment will assume all liability for any damage

which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

ImportantNotice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumenta-

tion related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent danger,

it has no control over process conditions, and it can be misused. In particular, any alarm or

control systems installed must be tested and understood, both as to how they operate and

as to how they can be defeated. Any safeguards required such as locks, labels, or redun-

dancy, must be provided by the user or specifically requested of Teledyne at the time the

order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the manufactur-

er or its agents, is to be construed as a warranty of adequate safety control under the

user’s process conditions.