Tab 6

Tab 7

Tab 8

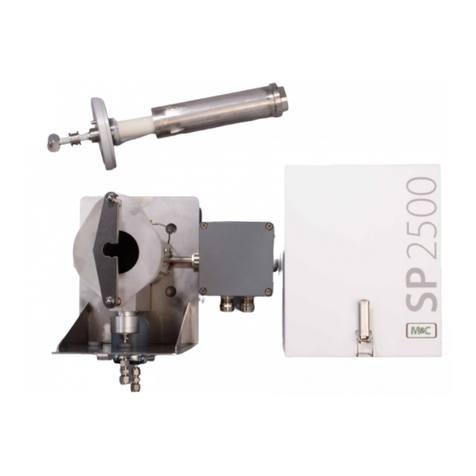

Isco 4700 Refrigerated Sampler

Table of Contents

5.2.8 Refrig Temperature 5-10

5.2.9 PCB Temperature 5-10

5.2.10 Input Voltage 5-11

5.2.11 Battery Voltage 5-11

5.2.12 Loaded Battery Volts 5-12

5.3 Temperature Verification 5-13

5.4 Major Assembly Removal and Replacement 5-14

5.4.1 General Instructions 5-14

5.4.2 Pump Module 5-16

5.4.3 Control Panel Module 5-17

5.4.4 Distributor Module 5-19

5.4.5 Refrigeration Module 5-20

Appendix A Replacement Parts

A.l Overview A-I

Appendix B General Safety Procedures

B.l Hazards B-1

B.2 Planning B-2

B.3 Adverse Atmospheres B-2

B.4 Entering Manholes B-2

B.4.1 Traffic Protection B-3

B.4.2 Removing the Covers B-3

B.4.3 Other Precautions B-3

B.4.4 Emergencies B-4

B.4.5 Field Equipment B-4

B.5 Lethal Atmospheres in Sewers B-4

List of Figures

1-1 4700 Sampler features 1-2

2-1 Minimum space requirements 2-3

2-2 Installing the distributor arm (A) and discharge tube (B) 2-5

2-3 Insert the keyed end first so that it faces the back of the

refrigerated compartment 2-7

2-4 The 24-bottle rack is held in place by a latch on the left side 2-7

2-5 Installing the locating base 2-8

2-6 One 20 liter bottle configuration with discharge tube through the bottle cap .. 2-10

2-7 Attaching the vinyl suction line with a tube coupler 2-11

2-8 Releasing a tube coupler clamp 2-12

2-9 Connecting FEP-lined suction line (A) to pump tube (B) 2-12

2-10 Strainers 2-13

2-11 External device connection at rear of sampler 2-15

2-12 4700 Sampler to Isco flow meter cable 2-15

2-13 4700 Sampler unterminated connect cable 2-16

2-14 Quick disconnect box 60-2004-228 2-16

3-1 Control panel buttons 3-1

3-2 Suction line length 3-4

3-3 Time paced sampling program flow chart 3-11

3-4 Flow paced sampling program flow chart 3-12

3-5 Suction Head Height 3-19

4-1 4700 Sampler to RS-232 serial communication cable 4-6

4-2 Sample temperature report 4-6

4-3 Sliding the 24-bottle rack out 4-7

5-1 4700 Pump 5-2

xi