TELink FR1 Instruction Manual

Telink FR1 PCB Design Guideline

AN-22051900-E1

Ver.1.0.0

2022/05/19

Keyword

Layout, FR1, PCB

Brief

This is Telink FR1 PCB design guideline which mainly introduces considerations when designing FR1 boards.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

2

Published by

Telink Semiconductor

Bldg 3, 1500 Zuchongzhi Rd,

Zhangjiang Hi-Tech Park, Shanghai, China

© Telink Semiconductor

All Rights Reserved

Legal Disclaimer

This document is provided as-is. Telink Semiconductor reserves the right to make improvements without

further notice to this document or any products herein. This document may contain technical inaccuracies or

typographical errors. Telink Semiconductor disclaims any and all liability for any errors, inaccuracies or

incompleteness contained herein.

Copyright © 2022 Telink Semiconductor (Shanghai) Co. , Ltd.

Information

For further information on the technology, product and business term, please contact Telink Semiconductor

Company (www.telink-semi.com).

For sales or technical support, please send email to the address of:

telinksales@telink-semi.com

telinksupport@telink-semi.com

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

3

Revision History

Version Change Description Date Author

V1.0.0 Initial release. 2022/05 Junyao MAO,

Weixiang WANG

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

4

Table of Contents

Revision History ................................................................................................................................3

Table of Contents..............................................................................................................................4

List of Figures ...................................................................................................................................5

1. Overview ...................................................................................................................................6

2. Application Board Structure ID ...................................................................................................7

2.1 Single-layer board.................................................................................................................7

2.2 Doulbe-layer board ...............................................................................................................8

2.2.1 Component and copper wire layer + carbon film alignment layer ...........................................8

2.2.2 Component and copper wire layer + carbon film and copper wire layer...................................9

3. Key Points of FR1 Board Design................................................................................................ 10

3.1 Board layer ........................................................................................................................ 10

3.1.1 Board thickness selection ............................................................................................... 10

3.1.2 Introduction of board structure........................................................................................ 10

3.2 Carbon film routing ..............................................................................................................11

4. Layout Regulations................................................................................................................. 13

4.1 Package............................................................................................................................. 13

4.2 Solder pads and vias............................................................................................................ 13

4.3 Notes ................................................................................................................................ 15

5. Routing Notes........................................................................................................................ 18

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

5

List of Figures

Figure 2-1 Single-layer board........................................................................................................7

Figure 2-2 Component layer + carbon film layer ..............................................................................8

Figure 2-3 Double layer routing + carbon film routing ......................................................................9

Figure 3-1 Stack structure .......................................................................................................... 10

Figure 3-2 Carbon film routing.................................................................................................... 12

Figure 4-1 Package forms........................................................................................................... 13

Figure 4-2 Package design for Telink IC ....................................................................................... 14

Figure 4-3 Via hole on carbon film .............................................................................................. 15

Figure 4-4 Layout for RF circuit................................................................................................... 16

Figure 4-5 Layout for power capacitors ........................................................................................ 17

Figure 5-1 Routing example 1 ..................................................................................................... 19

Figure 5-2 Routing example 2 .................................................................................................... 19

Figure 5-3 Routing example 3 ....................................................................................................20

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

6

1. Overview

With the same PCB size and the same quantity of components, generally the fewer the number of PCB

layers, the more difficult the design.

Due to cost concern, PCB designs are increasingly preferred to use FR1 boards, single-layer boards, which

leads to more obvious problems in wireless communication, including power interference, RF high harmonics,

and etc.

This document uses the Telink SoC chips as a basis and the remote control design as an example to illustrate

how to guide the design of FR1 boards to achieve fast development and avoid multiple iterations.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

7

2. Application Board Structure ID

According to the complexity of the components, taking into account cost and the difficulty of routing, the the

PCB design for Telink chips can be divided into single-layer boards or double-layer boards.

2.1 Single-layer board

In single-layer board design, make sure that all components and keys can be placed on the same side and

there should be enough space for the PCB antenna. This is suitable for boards with a small number of

components and routings.

The remote control board shown below can be designed as a single-layer board.

Figure 2-1 Single-layer board

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

8

2.2 Doulbe-layer board

2.2.1 Component and copper wire layer + carbon film routing layer

One layer of this double-layer board is used to place components and route copper wire, and the other layer

is for carbon film routing. For example, in a remote control design, we place the components on one layer

and the keys on the other layer. The keys need to be designed as carbon film keys and the keys routing is

connected to the component layer via carbon film via holes. Note that carbon film vias are chosen for cost

concerns.

The remote control board shown below can be designed as this type of double-layer board.

Figure 2-2 Component layer + carbon film layer

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

9

2.2.2 Component and copper wire layer + carbon film and copper wire layer

One layer of this double-layer board is used to place components and copper wire routing, and the other

layer is for carbon film routing + copper wire routing. For example, in a remote control design, we place the

components on one layer and the keys on the other layer. The keys need to be designed as carbon film keys

and the keys routing is connected to the component layer via carbon film via holes. When there are many

components and the routing is complex, if the design shown in 2.2.1 cannot be completed routing, then in

addition to the carbon film routing on another layer, it is necessary to add copper routing and connect the

component side routing through the carbon film via holes. Note that carbon film vias are chosen for cost

concerns.

The board shown below can be designed as this type of double-layer board.

Figure 2-3 Double layer routing + carbon film routing

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

10

3. Key Points of FR1 Board Design

3.1 Board layer

3.1.1 Board thickness selection

In order to reduce cost, FR1 or CEM-1 boards are generally used to produce PCB boards.

•The thickness of FR1 board is recommended to be 1.6mm.

•The thickness of CEM-1 board is recommended to be 1.2mm or 1.0mm.

Note:

1)

CEM-1 is more suitable for making thinner boards than FR1, and CEM-1 is less likely to warp boards

than FR1 over wave soldering.

2)

Whether FR1 or CEM-1 is used, the rules and notes for PCB design are the same.

3.1.2 Introduction of board structure

In general, FR1 circuit board is single surface board, however, we need create another layer in addition to the

Top layer and Bottom layer, called the carbon film layer. As shown in the figure below, the Key layer is the

carbon film layer.

Figure 3-1 Stack structure

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

11

3.2 Carbon film routing

Carbon film routing is generally 1mm width routing, and the process of carbon film via hole is shown in the

table below.

Table 3-1 Design of carbon film via hole

No. Item Requirement and

description

Process limit capabilities, which can lead to

reduced yields or increased production difficulties

109 Carbon grouting board Preferred FR1

thickness 1.6mm board

When using 1.2mm or 1.0mm thickness for card

type remote control, it is recommended to use

CEM-1 board to ensure the strength and avoid

board warping.

110 Drilling diameter of carbon

grouting hole 0.7mm

111 Diameter of copper plate for

carbon grouting hole 1.4mm

Copper plates at least 0.35mm larger than the hole

on one side, design as 15mm or 1.6mm if there is

enough space.

112 Diameter of weld-resistant

openings 1.3mm Copper plate with green oil on one side 0.05mm

113 Diameter of insulated opening 1.6mm 0.1mm greater than copper plate on one side when

insulated

114 Diameter of the carbon film on

the surface of the grouting hole 1.8mm

When there is no protective oil, in principle the

carbon film is required to be 0.2mm larger on one

side of the copper plate to avoid revealing copper.

When it is not possible to meet the carbon film

single-side is 0.2mm larger than copper, set the

carbon film and copper have the same width or

single-side is 0.05mm larger, but in this case we

need to print protective oil.

115 Diameter of the carbon film on

the skimmer surface 1.8mm

Minimum 1.6mm; when there is no protective oil,

in principle, it requires that one side carbon film is

0.3mm larger than copper plate to avoid revealing

copper

116 Diameter of carbon hole

protection oil 2.3mm Minimum 2.0mm, one side is larger than copper

0.2mm at least

117

Width of back carbon grouting

hole edge from carbon bridge

edge

≥2.3mm

Optimum 2.5 mm. The back carbon coverage width

is at least 2.1 mm due to oil spillage of 0.65 mm on

one side of the hole.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

12

No. Item Requirement and

description

Process limit capabilities, which can lead to

reduced yields or increased production difficulties

118

Distance between the edges of

adjacent copper plates on

different networks

≥1.0mm

At least 0.9mm, distance from the edge of the

carbon plate to the edge of the carbon plate is at

least 0.5mm.

119

Distance between the edges of

adjacent copper plates on the

same network

≥0.5mm

At least 0.4mm: the distance between the copper

wire and the adjacent non-connecting carbon

surface is 0.4mm or more (if the joint is a carbon

point to be filled through, it must be kept at

0.7mm or more).

120

Distance between the edge of

the carbon plate and the edge of

the green oil covered wire

≥0.5mm

The principle is to avoid short circuits caused by

carbon oil seepage in case of pinholes in the single

layer of green oil; the edge of the carbon plate is at

least 0.1mm from the insulation layer covering the

wire when there is an insulation layer underneath

the carbon film.

121 Carbon hole resistance <100 ohms/hole

122 Carbon hole reliability design

Designed for parallel

connection of two

holes when space is

available

Reduce open circuit scrap and reduce circuit

resistance.

Carbon film wire and carbon film via hole impedance are relatively high, so the carbon film wire should not

be less than 1mm. Due to the manufacturing process for carbon film via hole, the carbon film wires are easy

to short circuit with other holes and wires, so the routing around the carbon film hole should avoid the hole

more than 1mm, as shown in the figure below.

Figure 3-2 Carbon film routing

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

13

4. Layout Regulations

4.1 Package

The package forms of battery, LED, and MIC are shown in the figure below.

Figure 4-1 Package forms

4.2 Solder pads and via holes

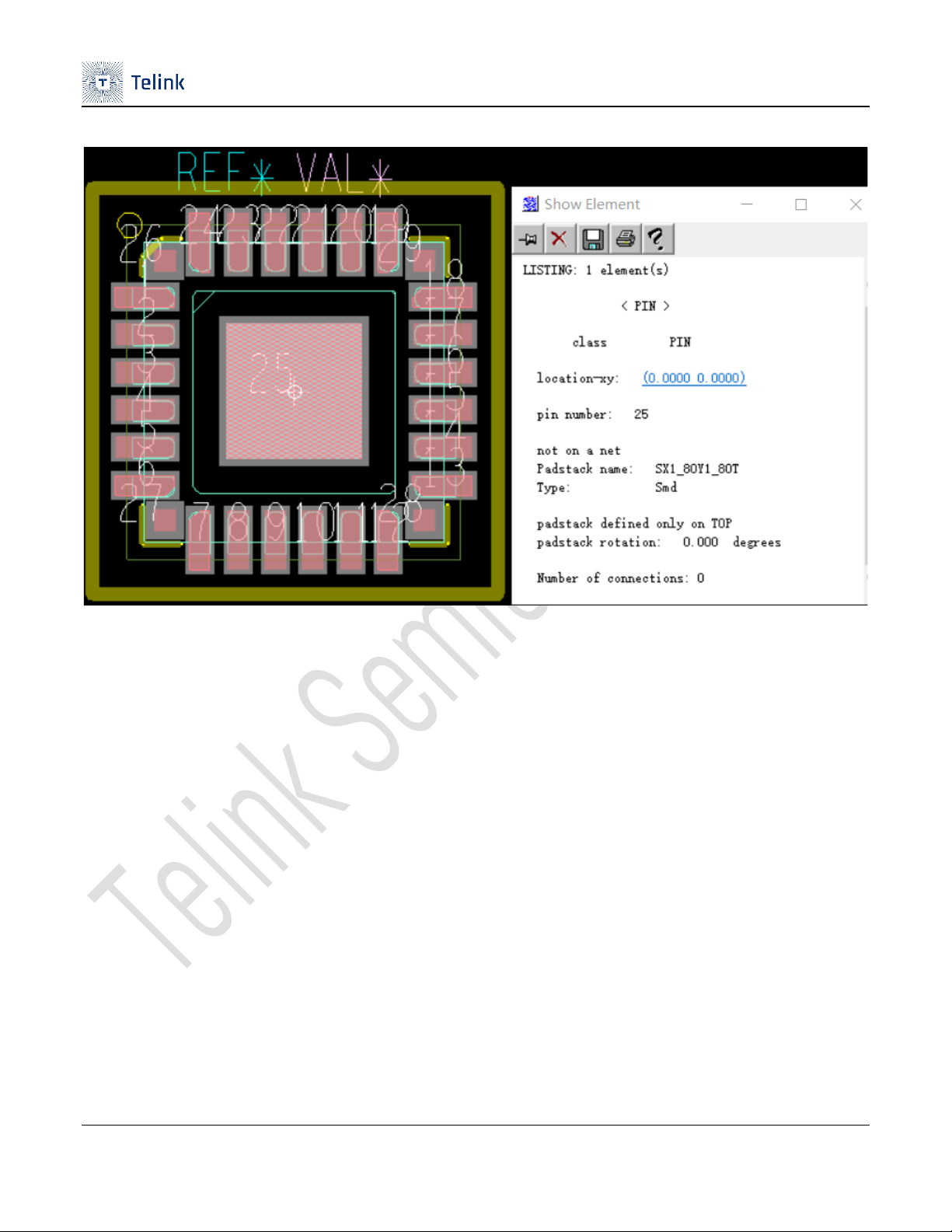

The PCB package design of Telink IC is as shown in Figure 4-2.

The carbon film via hole is shown in Figure 4-3, the hole diameter is greater than 0.7mm, outer diameter

1.4mm. The air gap between carbon film hole and copper wire is 2.5mm or more.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

14

Figure 4-2 Package design for Telink IC

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

15

Figure 4-3 Via hole on carbon film

4.3 Notes

First of all, the layout should consider the placement of the chip, based on the antenna, and reserve

enough space for the antenna first, so as to determine the location of the chip.

According to the board structure requirement, place the components (battery holder, keys, MIC, and

etc., while paying attention that do not place components in the location column area).

The components used for RF matching are close to the RF pins. The ANT circuit is isolated from the

chip and other circuits by ground to avoid signal crosstalk. The capacitors of the LC filter are placed

on both sides of the RF routing as shown in Figure 4-4. The purpose of placing on both sides of the

RF routing is to allow better harmonic regulation. It is best to place a 0R (0 ohm) resistor at its RF

end to improve ground return on both sides of the RF circuit, as shown in Figure 4-4.

The placement of the various capacitors needs to be arranged as suggested below, as shown in Figure

4-5.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

16

Before supplying power to the chip, the power must be filtered through a capacitor. The

power supply route is: the positive end of the battery spring tab →the filter capacitor →the

power pin of the chip.

The filter capacitor for the chip's power pin should be placed as close as possible to the

corresponding pin of the chip.

Figure 4-4 Layout for RF circuit

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

17

Figure 4-5 Layout for power capacitors

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

18

5. Routing Notes

Please be noted of the following routing points.

Prioritize the power and RF circuit routings, power wires should be as thick as possible (0.5mm ~ 1mm),

as close as possible to the power supply components or chip end in the use of star alignment

respectively power supply.

Then comes the normal routing, prioritize to route audio lines, and audio lines should have complete

copper on both sides, as shown in Figure 5-1.

For via hole, carbon film hole is needed, pay attention that put the carbon film hole as far as possible

with the routing and other carbon film hole, at least 1mm, to prevent short circuit.

Keep the width of the carbon film routing at 1mm or more to reduce carbon film impedance.

The ground is the main focus for FR1 board design.

Due to the high current jumps during RF operation, the smaller the GND impedance, the better, to

help reduce RF noise. For single-layer board, we should connect each component's ground with

wires after the power routing is completed, giving priority to ensuring that the ground line can go

through, and adding the 0R cross-line resistor at locations where it has blocks.

Ground wire should be as thick as 1mm and above, and routed in a ground shape.

Routing does not require excessive division of the ground plane, that is, the same direction routing

is together, and the routing distance should not be too long to affect the ground backflow. Priority

to ensure that the chip center ground and the power supply negative ground has a good ground

connection.

The crystal should be grounded as much as possible, and the RF components should be completely

grounded and covered with solid copper, as shown in Figure 5-1.

Avoid large areas of solid copper, in the wave soldering process, abnormal heat dissipation, the board is

easy to bulge. When encountering large areas of copper coverage, choose a mesh structure to facilitate

heat dissipation. For key circuits, such as RF, crystal, audio lines, and etc., the complete copper coverage

can be used directly. In addition, for some areas of narrow space, the complete copper should be laid out

to strengthen the ground reflow, as shown in Figure 5-1.

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

19

Figure 5-1 Routing example 1

In order to make a good connection between the chip and the ground and improve the RF performance,

it can be connected to the system ground through the chip's four corner ground, as shown in the location

of the red arrow in Figure 5-2.

Figure 5-2 Routing example 2

Telink FR1 PCB Design Guideline

AN-22051900-E1 Ver. 1.0.0

20

After the overall routing is complete, for the copper plates where the ground plane is disconnected from

the chip ground or power ground due to the routing, we should use 1206 package resistor to across the

line to make it connected with the chip ground or power ground copper, as shown in Figure 5-3.

Figure 5-3 Routing example 3

Table of contents

Other TELink Control Unit manuals

Popular Control Unit manuals by other brands

Xylem

Xylem Lowara Gen Series Installation and operating instructions

AUMA

AUMA AUMATIC AC 01.2 manual

GO Systemelektronik

GO Systemelektronik BlueConnect manual

Aprimatic

Aprimatic T2 installation instructions

Whelen Engineering Company

Whelen Engineering Company CenCom Core-R CEM4HC installation guide

Elko

Elko EST3 manual

Nordson

Nordson Encore HD Customer product manual

WIN Enterprises

WIN Enterprises MB-73240 user manual

Alcad

Alcad 905-ZA Quick programming guide

SMC Corporation

SMC Corporation EX250-SCN1 Technical specification

Beckmann

Beckmann EMS-8 -DU Series user manual

SMART Embedded Computing

SMART Embedded Computing PrAMC-7311 Installation and use