Telwin TIG-165 Setup guide

cod. 988250

inverter

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND REPAIR MANUAL

“trouble-free repair !”

TECHNOLOGY TIG

INVERTER REPAIR

LABORATORY

INVERTER REPAIR

LABORATORY

7

5426

8

13

2

TECHNOLOGY TIG

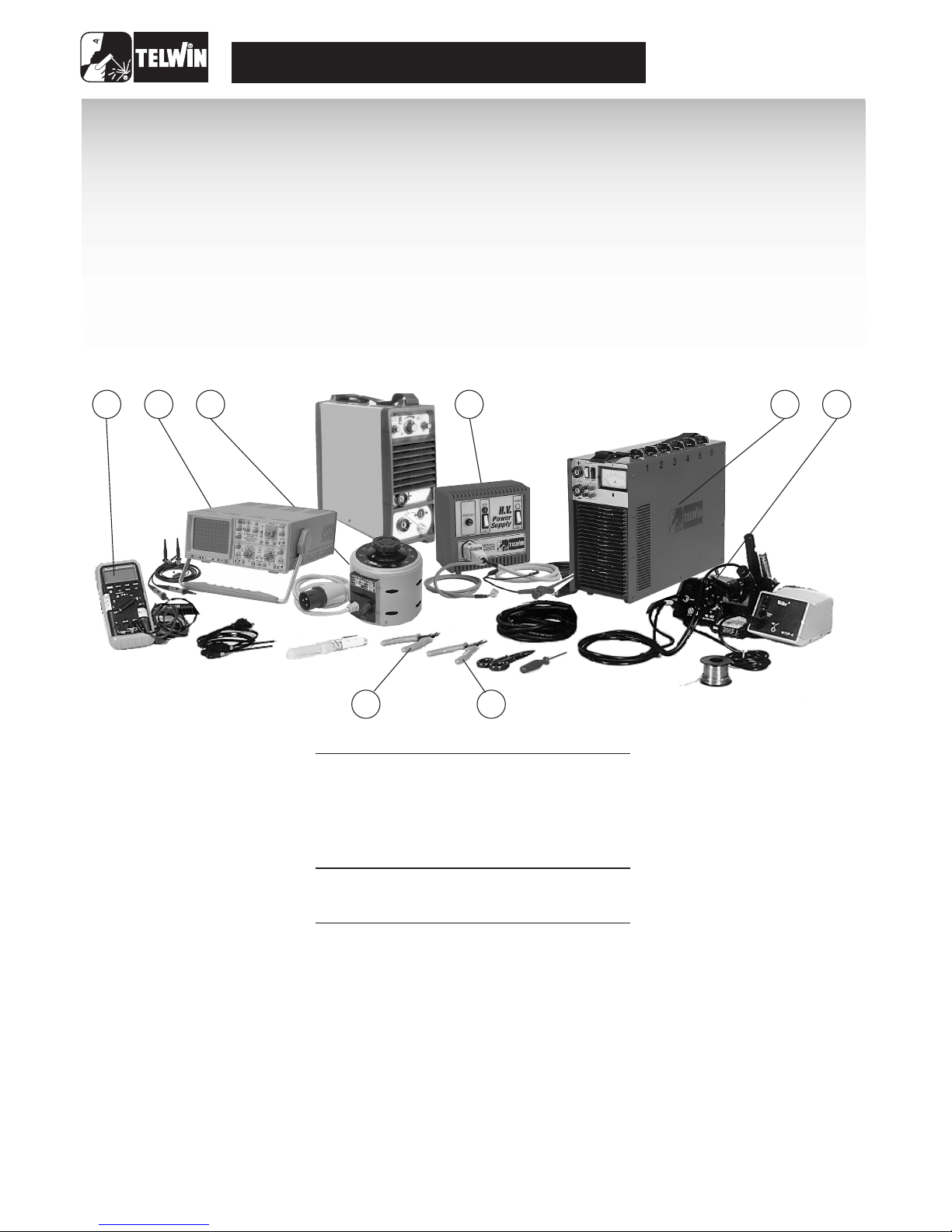

ESSENTIAL INSTRUMENTS

USEFUL INSTRUMENTS

MISCELLANEOUS

1 Oscilloscopio 20Mhz dual-trace cod. 802401

2 Static load generator cod. 802110

3 Variac 0 - 300v 1Kw cod. 802402

4 Power supply unit HV cod. 802403

5 Digital multimeter

6 Unwelding station

7 Flat-jaw pincers

8 Cutting nippers

(*)

(*)

(*)

(*)

Dismantling the inverter (see fig. 8)

A) Ensure that the power supply cable is disconnected from the mains..

B) Unscrew the 12 screws located at the four corners of the two blak plastic shells.

C) Slide out firstly the upper shell and then the lower shell.

D) Unscrew the two screws located below the wording "Technology TIG 165 "on the inverter side panel (13 , 14).

E) Slide out the casing by gently pulling it upwards.

F) Once you have completed the repair, proceed in reverse order to re-fit the casing and the shells, ensuring that the fold on the

upper part of the shell is fitted inside the frame and the lower part of the side walls is fitted outside the frame.

(*) The instruments with codes can be supplied by TELWIN. Sale price on request.

3

TECHNOLOGY TIG

1) Clean and visually check the

inverter

2) Checking the power and signal

cables.

3) Electrical measurements while the

machine is off.

Open the inverter shell and clean thoroughly using

compressed air.

Dirt is dangerous mainly in the power areas of the inverter

which are subject to high voltage or for those components

galvanically separating the primary from the secondary.

Thus, check carefully the following components:

Clean and check whether on the primary coil there are cuts or

cracks which could jeopardize the insulation of the secondary.

(Tig 165 DC/HF version.).

code 112478

(Tig 165 DC/HF version)

with high silicone insulation which connect the

H.F. transformer to the filter board and from the filter board to

the inverter shunt. (Tig 165 DC/HF 165 version.)

Check whether on the power transformer T1 or near

connector Jp1 there are signs of burns.

Visually check the post-gas and the gradual decreasing

of current potentiometers, the 2-4 phases electrode

and relays k1, k2.

These components must NOT have signs of dents, in

particular, the rotation of the potentiometers shaft

must be perfect and free from mechanical slacks.

(see Technology Repairs Manual)

(see Technology Repairs Manual)

( seeTechnology Repairs Manual )

(see Technology Repairs Manual)

check the cables fasten on connectors

J1, J2, J3. Specifically, check carefully the wires of connector

Jp1 in that there are subject to alternating network voltage.

check Cn01, Cn02, Fs01, Fs02

(See Technology Repairs Manual.)

1) H.F.Transformer:

2) H.F. Filter

3) H.F. Box

4) Electrovalve

5) Check cables

(See figure 2.)

A)

B)

7) Primary board:

8) Secondary board:

(See Figure 3-5)

1) Primary board:

2) Secondary board:

3) Tig control board:

4) Filter board:

(see Figure 2).

cod. 1124886) Control board Tig:

4) Electrical measurements while the

machine is in operation.

1)

(see figure 2).

2)

(See Figure 1.)

3)

4)

Warning!

the technology 114187 primary board cannot be mounted

on this machine.

5)

6)

- Jp1 Connector

- J2 Connector

- J1 Connector

7) Checking the operation of H.F. filter board, code 112478.

8) Checking the operation of tig control board, code 112488.

Disconnect the power supply cables of H.F. Box

Shortcircuit Jp2 on the primary board by means of a jumper

(placed between the SMD board and the electrolytic

condensers.

Remove all connectors from the tig control board. The inverter

is now set to work as a technology 165 with the switch located

on the front panel, in a central position ("hard welding").

Now follow the repair and test procedures of the inverter,

keeping in mind the following information:

1) the yellow led is not present on the board

2) the inverter carries the arc force and hod start functions.

Although the repair and test procedure are similar,

Remove the shortcircuit from Jp2 and put the connectors,

which were previously taken off from the tig control board, in

their places.

Switch the inverter on and check the following power supplies

on the tig control board:

Tester set in Vac

1) Place test prods on pins 1, 2 and you should have

220 Vac */- 10%

Tester set in Vac

Place test prods on pins 7, 8 and you should have 9

Vac +/- 10%.

1) Place negative test prod on pin 2 (mass) and

positive test prod on pin 1. The voltage should be +12

V +/- 3%.

2) Place negative test prod on pin 2 and positive test

prod on pin 3. The voltage should be -12 V +/- 3%.

- Ensure that the trimmer of pre-gas R 64 is rotated

counterclockwise.

Insert the tig torch and set the tig at two phases, press the torch

push-button. The electrovalve should be excited and, after a

short delay, the high frequency should be excited too. If this does

not happen, shortcircuit pins 1, 2 on connector J2.

If both the electrovalve and the high frequency are excited, it

means that there a failure on the filter board, probably due to the

following components:

a) Bridge rectifier P01.

b) Relay Rl 1

c) The alternating voltage 9 V on connector Cn 01 pin 7,

8 is missing.

d)The wire on the torch is cut off.

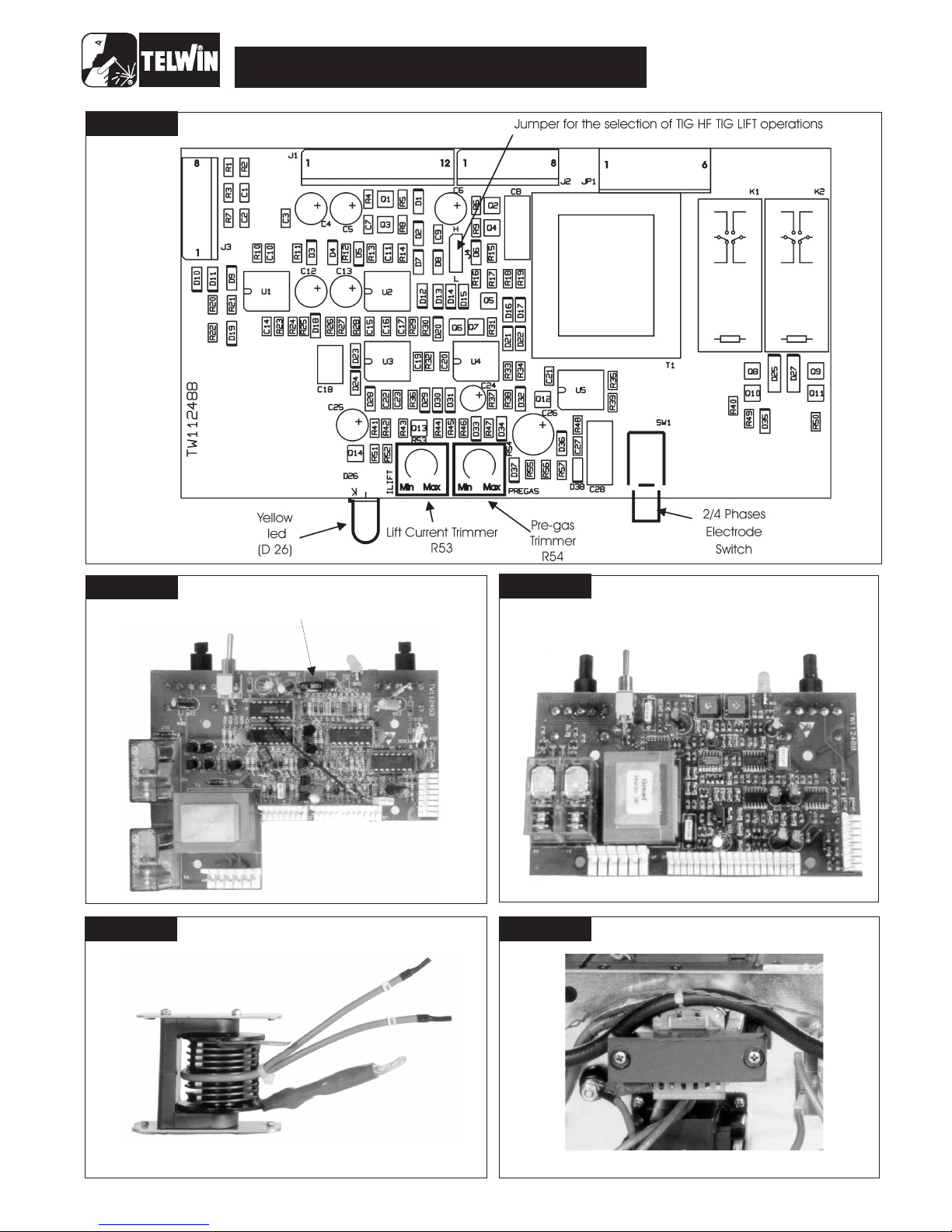

A J4 jumper is mounted on this board (see Figure 3), which

allows you to select two operation modes:

precedentemente tolti dalla scheda controllo tig.

Guide to repair of the inverter Tig

TECHNOLOGY TIG

4

R53) is properly set, the welding arc should strike.

b) Release the torch push-button, check the gradual

decreasing of current and the post-gas potentiometers.

a) Set the switch located on the front panel at 4-phase

position ( ).

b) Bring the tugsteno electrode in contact with the element to

be welded, press and release the torch push-button then lift

the electrode for about 2 mm; the welding arc should strike.

In order to obtain a gradual decreasing of current, you must

press and release the torch push-button for the second

time.Finally, check whether there is a post-gas.

Switch the remote control on (code 802109) and ensure that it

works correctly.

Warning! The following remote control adjusts the current in

function of the current set on the front panel; thus, if we set a

value of 50 A on the inverter, we could adjust this value from 5

A to 50 A by acting on the remote control.

Switch the "tig pulse" box on (code 802320) and ensure that

it works correctly by checking the current parameters relative

to peak, pause and work phases.

If striking a welding arc by means of high frequency proves to be

difficult (weak high frequency), the failure could be due to the

following components:

-Torch

- High frequency box

- High frequency transformer

- High frequency filter

- Primary coil with inverted polarity

If after having replaced these components the failure persists, we

suggest to check carefully the high frequency silicone insulated

cable as well as the high frequency transformer connection on the

positive inverter, which must NOT touch the carpentry or the wire

of the torch push-button. Furthermore, we suggest you

disassemble the positive dinse plug and check for signs of

discharges due to high frequency.

There are two types of tig control board and high frequency

transformers:

Tig control board

High frequency transformer

- The two tig control boards are perfectly compatible insofar as the

tig 165 DC-HF is concerned (high frequency striking).The board

with code 112453 instead, cannot be mounted on tigs with lift

striking (tig 161 DC-LIFT).

- The high frequency transformer in Figure 8 is equipped with a

different mechanical fastening system thus, should you need to

make a replacement on a tig mounting a transformer like the one

in Figure 5, you must drill three new holes on the carpentry

3) Checking the 4-phase cycle.

Checking the remote control.

1)

2)

High frequency striking

(See Figure 4-5)

(See Figure 6-7)

(see

Figure 6).

5) Changes and Updates

Jumper set towards connectors J1, J2 (H),

high frequency striking (tig 165 DC-HF).

Jumper set towards pre-gas and lift trimmers (L),

"lift" striking (tig 161 DC-LIFT).

Ensure that the aforementioned jumper is in H position.

Set the machine in electrode through the commutator.

Through static load or directly in welding, ensure the correct

operation of the inverter. (See "Final Testing" in Paragraph 5 of

the Technologic Repairs Manual.)

Set the inverter up for tig welding. (Connect torch and

argon gas bottle.)

Set the switch at two phases ( ) down slope and post-

gas potentiometers at the middle of the scale, the pre-

gas trimmer at the minimum (the trimmer is inside the

board).

Press the torch push-button:

The high frequency and the gas electrovalve should excite.

If after two seconds the welding arc does not strike, the

high frequency will automatically disexcite. On the other

hand, if the arc strikes, the current should reach the

value of about 80 A; when releasing the torch push-

button the current decreases gradually for about 2-3

seconds. From this time on, the electrovalve remains

excited for about 3 seconds.

Repeat the same testing procedure, however turning the pre-

gas trimmer clockwise and setting it at the maximum. By

pressing the torch push-button, the electrovalve will excite

but the high frequency will set off after a 4-second delay.

Set this trimmer as to have a 2-second delay or

according to the customer's needs.

Set the commutator at 4 phases ( ).

Repeat the preceding testing procedures, keeping in mind

that, in order to strike the arc you must press the torch push-

button.When releasing it, the welding current will remain at

the preset value (80 A).If the operator presses and releases

the torch push-button for a second time, the gradual

decreasing of current and the post-gas phases will begin.

Bring the electrode in contact with the element to be welded; if

you do not press the torch push-button, the yellow led

(D26) located on the front panel should switch on.

Set the welding current of the post-gas and the gradual decreasing

of current potentiometers as you did for the two-phase cycle.

A) Set the switch on front panel at two-phase( ) bring the

tugsteno electrode in contact with the element to be

welded, the led located on the front panel will switch on,

press the torch push-button. Through the plier-shaped

amperometer connected to the mass cable, check whether

there is a flow of current of about 20 A +/- 3 A. Should you

need to reset this value, act on trimmer R53. (In this phase,

the yellow led is switched off.)

a) Bring the tugsten electrode in contact with the element to

be welded, press the torch push-button and lift the

electrode by about 2 mm. If the lift current (20 A trimmer

A)

B)

1)

2)

3)

4)

A) Checking the Tig 165 DC/HF machine cycle

1)

2)

3)

4)

5)

B) Checking the Tig 161 DC-LIFT machine cycle

1) Checking the lift current:

2) Checking lift striking and the 2-phase cycle.

TECHNOLOGY TIG

5

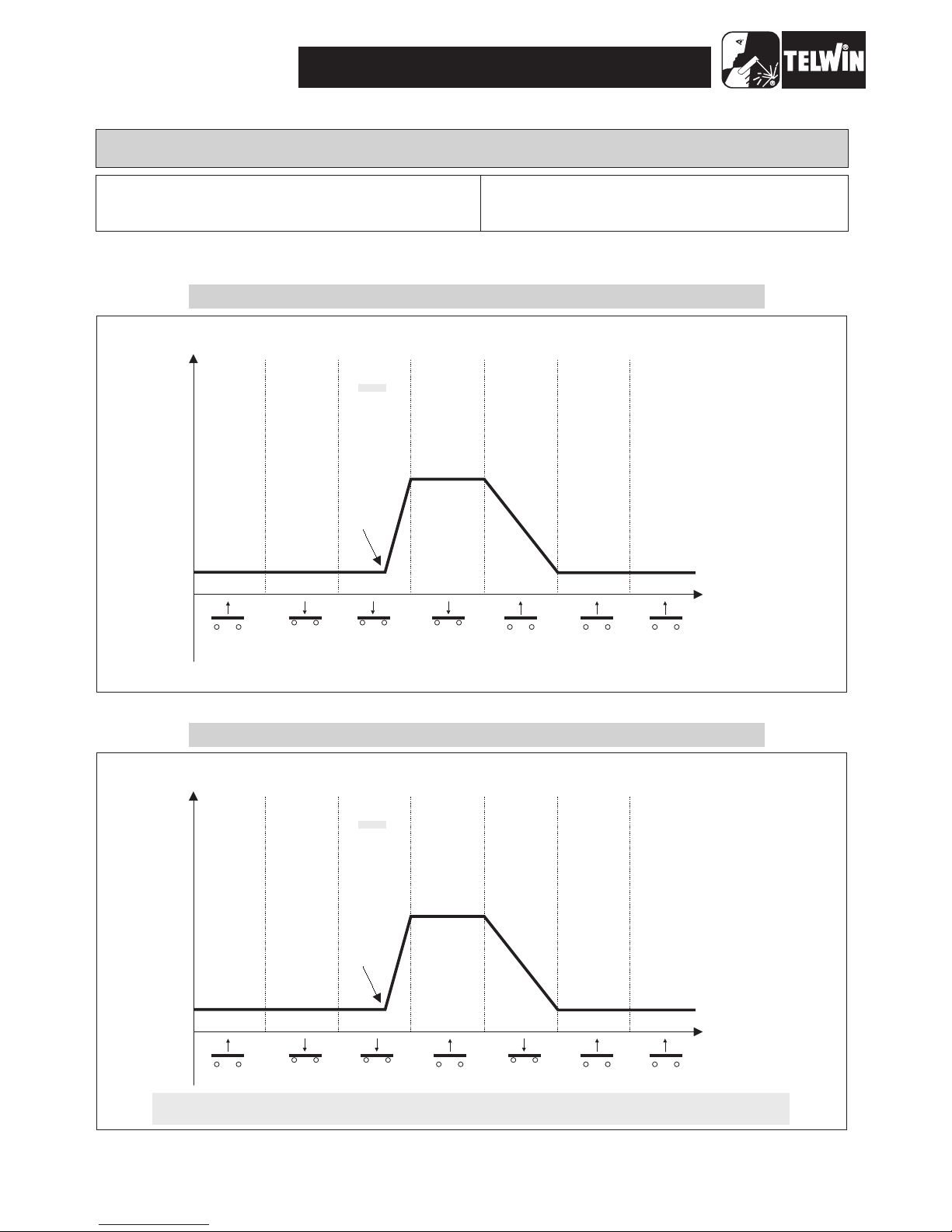

TWO-PHASE MACHINE CYCLE AT HIGH FREQUENCY

I

O

PRE GAS STRIKING

WELDING CURRENT

DOWN SLOPE POST GAS END OF CYCLE

EV= OFF

HF=OFF

I=Ø

EV= ON

HF= OFF

I=0

EV= ON

HF= ON

ARC

ARC STRIKING

EV= ON

HF= OFF

EV= ON

HF= OFF

EV= ON

HF= OFF

I=0

EV= OFF

HF= OFF

I=0

P.T. OFF P. T. ON P. T. ON P.T. ON P. T. OFF

P.T. OFF P. T. OFF

I

O

EV= OFF

HF=OFF

I=Ø

EV= ON

HF= OFF

I=0

EV= ON

HF= ON

ARC

EV= ON

HF= OFF

EV= ON

HF= OFF

EV= ON

HF= OFF

I=0

EV= OFF

HF= OFF

I=0

P.T. OFF P. T. OFF

P.T. OFF P. T. ON P. T. ON P.T. OFF P. T. ON

LEGEND

EV =Electrovalve

HF =High frequency

I=Welding current

D26 =Yellow led located on Tig front

D26: This led will switch on when between the electrode and the element to be welded there is direct current

thus stopping the inverter operation.

FOUR-PHASE MACHINE CYCLE AT HIGH FREQUENCY

PRE GAS STRIKING

WELDING CURRENT

DOWN SLOPE POST GAS END OF CYCLE

ARC STRIKING

TECHNOLOGY TIG

6

I

O

EV= OFF EV= ON EV= ON EV= ON EV= ON EV= ON EV= OFF

P.T. OFF P. T. ON P. T. ON P.T. ON P. T. OFF

P.T. OFF P. T. OFF

D26 ON D26 ON D26 OFFD26 OFF D26 OFF D26 OFFD26 OFF

I=0 I=0 I=0 I=0I=20A

TWO-PHASE MACHINE CYCLE LIFT STRIKING

I

O

EV= OFF EV= ON EV= ON EV= ON EV= ON EV= OFF

P.T. OFF P. T. ON P. T. OFF P.T. OFF

P.T. ON P. T. OFF

D26 ON D26 ON D26 OFFD26 OFF D26 OFF D26 OFFD26 OFF

I=0 I=0 I=0 I=0I=20A

P.T. ON

MINIMUM

TIME

PRE GAS

TRIMMER

R54

POST GAS

POTENTIOMETER

R58

DOWN SLOPE

POTENTIOMETER

R59

LIFT CURRENT

R53

CURRENT

MINIMUM (A)

CURRENT

MAXIMUM (A)

@0

@0

@0

@0

@45

@11

@8

@40

EV= ON

(s) (s)

PRE GAS STRIKING

WELDING CURRENT

DOWN SLOPE POST GAS END OF CYCLE

PRE GAS STRIKING

WELDING CURRENT

DOWN SLOPE POST GAS END OF CYCLE

FOUR-PHASE MACHINE CYCLE LIFT STRIKING

MAXIMUM

TIME

TECHNOLOGY TIG

7

Illustrated references

Jumper P 2

J1

J2

J3

Post-gas

(R58)

Yellow led

(D26)

Main current

supply

MMA Selector

2/4 Phases

Down

slope

(R59) Relay

k1,k2 JP 1

Figure n° 1

Remote control

connector

Figure n° 2

Cn 01

HF Filter

Fs 01

Supply cable

HF Box

HF Box

Primary plug

HF Silicone Cable

Positive

dinse

plug

Torch push-button

connector

HF Transformer

Fs 02

Cn 02

Electrovalve

Figura n° 2

Figure n° 3

Figura n° 2

Figure n° 4 Figure n° 5

PRE-GAS

TRIMMER

Figura n° 2

Figure n° 6 Figura n° 2

Figure n° 7

TECHNOLOGY TIG

8

9

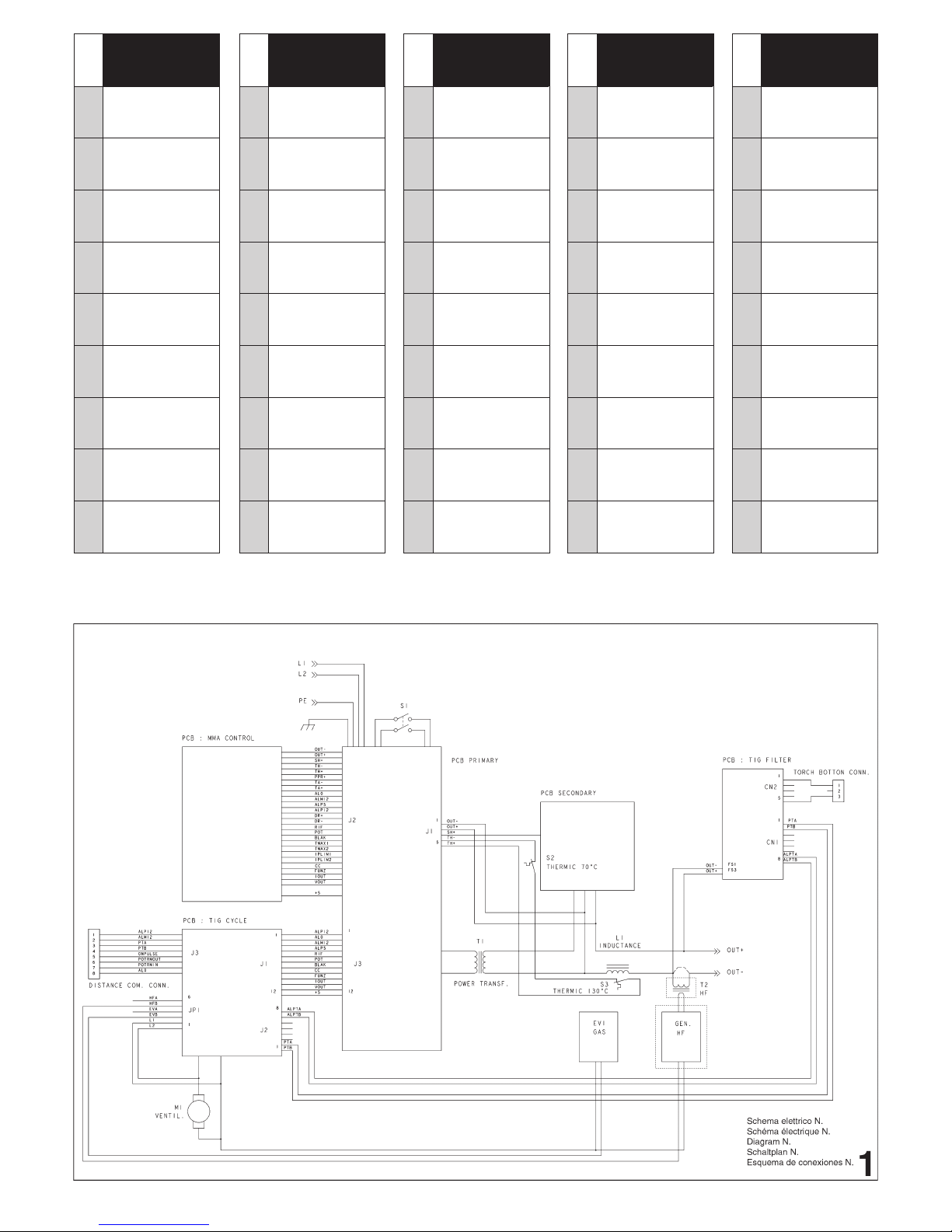

ELENCO PEZZI DI RICAMBIO - LISTE PIECES DETACHEES

SPARE PARTS LIST - ERSATZTEILLISTE

PIEZAS DE REPUESTO

Per richiedere i pezzi di ricambio senza codice precisare: codice della saldatrice; il numero di matricola; numero di riferimento del particolare sull'elenco ricambi.

Pour avoir les pieces detachees, dont manque la reference, il faudra preciser: modele, logo et tension de I'appareil; denomination de la piece; numero de matricule

When requesting spare parts without any reference, pls specify: model-brand and voltage of machine; list reference number of the item; registration number

Wenn Sie einen Ersatzteil, der ohne Artikel Nummer ist, benoetigen, bestimmen Sie bitte Folgendes: Modell-zeichen und Spannung des Geraetes; Teilliste Nuemmer; Registriernummer

Por pedir una pieza de repuesto sin referencia precisar: modelo-marca e tension de la maquina; numero di riferimento de lista; numero di matricula

Esploso macchina, Dessin appareil, Machine drawing, Explosionszeichnung des Geräts, Diseño seccionado maquina.

22

1

8

2

26

27

23

11

34

14

28

24

12 21 7 3330 3 6 18 4 29 16

201913 5 1025 35173032 9 15

10

(I) XX

(F) XX

(GB) XX

(D) XX

(E) XX

Per individuare lo schema elettrico corrispondente alla vostra macchina, rifarsi all'ultima cifra "/ " del numero di matricola (N. 0000/ ) riportato sul frontale.

Pour reperer le schema electrique correspondant a votre appareil, verifier le dernier chiffre"/ " du numero de serie (N. 0000/ ) reporte sur la partie frontale.

In order to find the electrical diagram corresponding to your model, check the last number "/ " of the serial number (N. 0000/ ) printed on front panel.

Um den schaltplan, der ihrem gerät entspricht, ausmachen zu können, müssen sie die letzte ziffer "/ " der matrikelnummer (N. 0000/ ), die auf der frontseite angebracht ist, beachten.

Para la identificacion del esquema eléctrico, correspondienten, a su máquina, refierase a la última cifra "/ " del número de placa (N. 0000/ ) instalado sobre el frontal.

REF. REF. REF. REF. REF.

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

Potenziometro

Potentiometre

Potentiometer

Potenziometer

Potenciometro

Potenziometro

Potentiometre

Potentiometer

Potenziometer

Potenciometro

Rele'

Relais

Relais

Relais

Relais

Raddrizzatore Monofase

Redresseur Monophase

Single-phase Rectifier

Einphasiger Gleichrichter

Rectificador Monofasico

Scheda Filtro

Platine Filtre

Filter Card

Filterkarte

Tarjeta Filtro

Resistenza

Resistance

Resistor

Wiederstand

Resistencia

Condensatore

Condensateur

Capacitor

Kondensator

Capacitor

Manopola

Poignee

Knob

Knopf

Manija

Generatore H.f.

Generateur H.f.

H.f. Generator

H.f. Generator

Generador H.f.

Elettrovalvola

Electrovanne

Electrovalve

Elektroventil

Elektrovalvula

Deviatore

Gareur

Switch

Schalter

Interruptor

Interruttore

Interrupteur

Switch

Schalter

Interruptor

Termostato 10,0A

Thermostat 10,0A

Thermal Switch 10,0A

Thermostat 10,0A

Termostato 10,0A

Cablaggio Presa

Prise Cablee

Socket Wiring

Steckdose Mit Kabel

Cableado Enchufe

Assieme Condensatore

Condensateur

Capacitor Assembly

Kondensatorsatz

Grupo Capacitor

Cavo Alimentazione

Cable De Reseau

Mains Cable

Netzkabel

Cable De Alimentation

Motoventilatore

Ventilateur

Fan

Ventilator

Ventilador

Trasformatore Di Corrente

Transformateur De Courant

Current Transformer

Stromwandler

Transformador De Corriente

Trasformatore H.f.

Transformateur H.f.

H.f. Transformer

H.f. Transformator

Transformador H.f.

Assieme Trasformatore

Transformateur

Transformer Assy

Transformatorsatz

Grupo Transformador

Pressacavo

Presse Cable

Cable Bushing

Kabelhalter

Prensa Cable

Fibbia Per Cinghia

Boucle Pour Courroie

Belt Buckle

Gurtschnalle

Hebilla Para Correa

Cinghia

Courroie

Belt

Gurt

Correa

Cornice

Cadre

Frame

Rahmen

Marco

Fondalino

Chassis

Bottom

Bodenteil

Base

Mantello

Capot

Top Cover

Gehaeusedeckel

Tapa

Presa Dinse

Prise Dix

Dinse Socket

Dinse Steckdose

Enchufe Dinse

Raccordo Entrata Gas

Raccord Entree Gaz

Gas Pipe Connector

Gaseintritt

Racor Entrada Gas

Kit Igbt

Kit Igbt

Kit Igbt

Kit Igbt

Kit Igbt

Kit Diodo

Kit Diode

Kit Diode

Kit Diode

Kit Diodo

Kit Scheda Controllo Tig

Kit Platine De Control Tig

Tig Control Pcb Kit

Wig Steurungskarte Kit

Kit Tarjeta De Controlo Tig

Kit Scheda Secondario

Kit Fiche Secondaire

Kit Secondary Pcb

Kit Sekundaertrafokarte

Kit Tarjeta Secundario

Kit Scheda Primario

Kit Fiche Primaire

Kit Primary Pcb

Kit Primaertrafokarte

Kit Tarjeta Primario

Manopola Piccola

Poignee Petite

Small Knob

Kleiner Griff

Manija Pequena

Presa

Fiche

Plug

Stecker

Espina

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

TECHNOLOGY TIG

11

Official servicing centers

Repairing card

Date:

odel :

Serial number:

Company:

Technician:

Inverter m

In which place has the inverter been used domanda:

Building yard

Workshop

Others:

Supply:

Power suply

From mains without extension

From mains with extension m:

Mechanichal stresses the machine has undergone to

Description:

Dirty grade.

Dirty inside the machine

Description:

Kind of failure Component ref.

Substitution of primary circuit board: yes no

Troubles evinced during repair:

Rectifier bridges

Electrolytic capacitors

Relays

Pre-charge resistor

Snubber networks

Secondary diodes

Potentiometer

Potentiometer

IGBT

TECHNICAL REPAIR CARD

In order to improve our service, each servicing centre is requested to fill in the technical card above at the end

of every repair job.

Please fill in the card as accurately as possible and return in to Telwin.

Thank you in advance!

SINCERT

ACCREDITAMENTOORGANISMI CERTIFICAZIONE

SISTEMAQUALITA' CERTIFICATO

UNI EN ISO 9001

TGA-ZQ-002/92-00

Deutscher

Akkreditierungs

atR

CERTIFIED QUALITY SYSTEM

ISO

9001

TELWIN S.p.A.

800 801

- Via della Tecnica, 3

36030 VILLAVERLA (Vicenza) Italy

Tel. +39 - 0445 - 858811

Fax +39 - 0445 - 858 / 858

Table of contents

Other Telwin Inverter manuals

Popular Inverter manuals by other brands

Maxeon

Maxeon Sunpower E Series Safety and installation instructions

ABB

ABB UNO-DM-3.3-TL-PLUS-US-Q Quick installation guide

Giandel

Giandel PS-4000QAR user manual

Kaco

Kaco blueplanet gridsave 50.0TL3-S Series manual

Hitachi

Hitachi L200 Series Quick reference guide

Black & Decker

Black & Decker PI100BB instruction manual

Sunerg Solar Energy

Sunerg Solar Energy TENDAEVO 1T installation manual

Gallagher

Gallagher i Series manual

Parkside

Parkside PS 2900 A1 Translation of the original instructions

Hitachi

Hitachi J300 Series instruction manual

Siemens

Siemens SINAMICS G120P operating instructions

Analytic Systems

Analytic Systems IPSi2400-40-220 Installation & operation manual