Telwin TECHNOLOGY TIG 172 Operating instructions

cod. 988647

inverter

TECHNOLOGY TIG 172

AC/DC - HF/LIFT

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND REPAIR MANUAL

“reparation no problem !”

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND REPAIR MANUAL

CONTENTS PAGE

OPERATION AND WIRING DIAGRAMS................ 2

REPAIR GUIDE.......................................................13

SPARE PARTS LIST...............................................26

REPAIR SHEET......................................................28

- Block diagram 2

- Analysis of the block diagram 3

- Illustrations 5

- Wiring diagrams 7

- Equipment required 13

- General repair instructions 14

- Troubleshooting and remedies 14

- Testing the machine 18

- Illustrations 21

15

TECHNOLOGY TIG 172 AC/DC

-2-

TIG & MMA

CYCLE CONTROL

31

678

245

1

13

17

33

11

3

23

29

32

30

34

12

19

V

t

16

20

PROTEZIONE

SOVRATENSIONE

V

t

14

IGBT DRIVER

21

SEPARAZIONE

GALVANICA

22

INDUCTANCE

THERMOSTAT

27

SCR DRIVER

25

SHUNT AMPLIFIER

+|

26

MAXIMUN

CURRENT REGOLATOR

18

CONTROL PANEL

24

10

+

-

9

AC/ DC CURRENT

CONVERTER

28

BLOCK DIAGRAM

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

HF TRANSFORMER

SHUNT INDUCTANCE

PRIMARY

EMC FILTER

POWER

TRANSFORMER

PRE-CHARGE

RECTIFIER BRIDGE FILTER CHOPPER

SECONDARY

DIODES

SECONDARY

EMC FILTER

CURRENT

TRANSFORMER

FAN POWER SUPPLY

LED

PRIMARY CURRENT

READER

MICROCONTROLLER

UNDERVOLTAGE

SAFEGUARD

DUTY CYCLE

MAKER

ADDER

TORCH BUTTON

SOLENOID VALVE

RELAY

HF GENERATOR

SOLENOID VALVE

TORCH BUTTON

RELAY

AUXILIARY

TRANSFORMER

SECONDARY

DIODE THERMOSTAT

OUTPUT

INPUT

-3-

ANALYSIS OFTHE BLOCK DIAGRAM

Block 1

Block 2

Block 4

Block 5

Block 6

Block 7

NOTE:Unless indicated otherwise, it should be assumed that

thecomponentsareassembledontheweldingmachine.

Consistingof:C3,C8,C9,L1 .

Preventsnoisefromthemachine frombeingtransmittedalong

themainpowerlineandviceversa.

Consistingof:D3,D5 .

Convertsthe mains alternating voltageinto continuous pulsed

voltage.

Consistingof:C2,C4,C5,C6,C7 .

Converts the pulsed voltage from the rectifier bridge into

continuousvoltage.

Consistingof:Q1,Q2 .

Converts the continuous voltage from the filter into a high

frequency square wave capable of piloting the power

transformer.

Regulates the power according to the required welding

current/voltage.

Consistingof:T2.

TheC.T.isusedtomeasurethecurrentcirculatinginthepower

transformer primary and transmit the information to block 14

(primarycurrentreaderandlimiter).

Consistingof:T1 .

Adjusts the voltage and current to values required for the

welding procedure. Also forms galvanic separation of the

primary from the secondary (welding circuit from the power

supplyline).

EMC Filter

Rectifier bridge

Filter

Chopper

Current transformer

Power transformer

(primaryboard)

(primaryboard)

Consistingof:K1,K2,R1(primaryboard).

Prevents the formation of high transient currents that could

damage the main switch, the rectifier bridge and the

electrolyticcapacitors.

When the power source is switched on relays K1 and K2 are

de-energised, capacitors C2, C4, C5, C6, C7 are therefore

charged via R1. When the capacitors are charged the relays

willbeenergised.

(primaryboard)

(primaryboard)

(primaryboard)

Consisting of: D1, D2, D3, D4, D5, D6, D7, D8, D9, D10

(secondaryboard)

D1, D2 convert the current circulating in the positive OUT of

the power transformer to a single direction, preventing

saturationofthenucleus.

D3, D4, D5 recirculate the inductance output current (block 9)

during the time when the IGBT's are not conducting,

bypassingthepowertransformer(block7).

Block 3

Block 8

Pre-charge

Secondary diodes

Positivepolaritydiodesinthecircuit:

Negativepolaritydiodesinthecircuit:

D9, D10 convert the current circulating in the negative OUT of

the power transformer to a single direction, preventing

saturationofthenucleus.

D6, D7, D8 recirculate the inductance output current (block 9)

duringthetimewhentheIGBT'sarenotconducting,bypassing

thepowertransformer(block7).

The positive polarity diodes in the circuit are

involved. The positive and negative polarity diodes in the

circuitareinvolvedalternately.

Consistingof:SCR(secondaryboard)

The SCR module is piloted by block 18 (microcontroller) and

block 27 (SCR driver), transforming the secondary output

currentfromDCtoACwhenTIGACweldingisrequired.

Consistingof:L1,R2,(secondaryboard)

The inductance levels the output current from the secondary

board diodes making it practically direct.The shunt detects

the current circulating in the secondary and sends a voltage

signal to block 25 (shunt amplifier), which will process it.

(primaryboard)

(primaryboard)

Consistingof:D16,R81,R82,R83,R84,R85(controlboard).

Detectsandlimitsthesignal from block6 (current transformer)

and, via trimmer R85, adjusts the maximum allowable primary

current. The signal is also redimensioned so that it can be

processedandcomparedinblock16(dutycyclemaker).

Consistingof:U14(controlboard).

Processes the information arriving from block 17 (adder) and

block 15 (primary current reader and limiter), producing a

square wave with variable duty cycle, limiting in any case the

primarycurrenttoamaximumpresetvalue.

DC Operation:

AC Operation

Block 9

Block 10

Block 15

Block 16

Primary current reader and limiter

Duty cycle maker

AC/DC current converter

Inductance and Shunt

Secondary EMC Filter

HF Transformer

Flyback power supply

IGBT Driver

Block 11

Block 12

Block 13

Block 14

Consistingof: CY1.

Prevents noise from the power source from being transmitted

throughtheweldingcablesandviceversa.

Consistingof:T2.

The HF transformer boosts the signal from block 34 (hf power

source), raising the voltage impulse in the secondary at the

instantwhenarcstrikeisgenerated.

Italsoisolatestheweldingcircuitfromtheprimarycircuit

Consistingof:T2,U2 .

Uses switching methods to transform and stabilise the voltage

obtained from block 4 (filter) and supplies auxiliary voltage to

powerblock14(driver)andthecontrolboardcorrectly.

Consistingof:ISO1,ISO2 ..

Takes the signal from block 13 (flyback power supply) and,

controlled by block 16 (duty cycle maker), makes the signal

suitableforpilotingblock6(chopper).

TECHNOLOGY TIG 172 AC/DC

-4-

Block 26

Block 27

Block 28

Block 29

Block 31

Block 32

Block 33

Block 35

Maximum current regulator

SCR Driver

Auxiliary transformer

Torch button

Solenoid valve relay and HF

Solenoid valve

HF generator

Consisting of: R105 (control board).

Processes the information arriving from block 25 (shunt

amplifier) and, via trimmer R105, allows calibration of the

maximum welding current that can be supplied by the power

source. The signal is re-dimensioned so that it can be

processedandcomparedwithblock17(adder).

Consisting of: ISO1,ISO5, Q1, Q2 and ISO2, ISO6, Q3, Q4

(secondaryboard)

Receives the signals arriving from block 18 (microcontroller)

and makes them appropriate for piloting block 9 (AC/DC

currentconverter).

Consisting of:T1, D2 (torch button board).

Its purpose is to supply a redimensioned, rectified voltage to

power block 30 (torch button relay).

(torchbuttonboard).

Consisting of:TIG Torch

When the torch button is operated, a separate signal is sent to

block 18 (microcontroller), to achieve arc strike and enable the

solenoidvalve.

Consisting of: K2 (secondary board).

When the torch button is pressed, block 18 (microcontroller)

activates relay K2 which supplies the mains voltage needed to

powerblock33(solenoidvalve)andblock34(HFgenerator).

Consisting of:Y1

Supplies an appropriate amount of the desired gas mixture

to strike the arc in the torch and the quantity needed to

operate and cool the torch itself.

Consisting of: HF generator board

Using the signal sent by block 32 (s ), the

generator produces a high frequency signal that is sufficient

for powering block 12 (HF transformer).

olenoid valve relay

Fan

HF safeguard

Consistingof:V1.

Powered directly by block 13 (flyback transformer) and cools

thepowercomponents.

Consistingof: K1,R1

The HF safeguard also separates the control board from the

high frequency so as to prevent the residual signal from the

torchbuttoncablesfromenteringtheboard.

Block 30

TECHNOLOGY TIG 172 AC/DC

Block 17

Block 18

Block 21

Block 22

Block 23

Block 24

Block 25

Adder

Microcontroller

Galvanic separation

Inductance thermostat

Secondary diode thermostat

Control panel

Shunt Amplifier

Consistingof:U13A,U13B(controlboard).

Collects the information from block 26 (maximum current

regulator) and block 18 (microcontroller), producing a voltage

signal that is suitable for processing by block 16 (duty cycle

maker).

Consistingof:U4(controlboard)

Control logic, which manages typical timing for the TIG and

MMA cycles. Also drastically limits power source output

currentwhen itdetectsanalarm event.Intheeventofanalarm

it acts directly on block16 (duty cycle maker) and directly

changes the reference signal obtained from block 23 (control

panel).

Consistingof:U3A,R62,U68(primaryboard).

Consistingof:U3B,R61,U67(primaryboard).

Consistingof:ISO3(primaryboard).

The signal arriving from blocks 19 and 20 (over- and under-

voltage safeguard) is separated galvanically and sent to block

18(microcontroller)fordetectionofapossiblealarmevent.

Consistingof:ST2.

When the temperature of the inductance is too high the

thermostat cuts in, sending an alarm signal to block 18

(microcontroller). It is reset automatically when this alarm

conditionisnolongerpresent.

Consistingof:ST1(secondaryboard).

Whenthetemperatureofthesecondarydiodedissipatoristoo

highthethermostatcutsin,sendinganalarmsignaltoblock18

(microcontroller). It is reset automatically when this alarm

conditionisnolongerpresent.

Consistingof:Controlpanelboard

Panel for setting and displaying the parameters and operating

modes of the power source, all controlled by block 18

(microcontroller).

Consistingof: U12(controlboard).

Amplifies the signal arriving from block10 (shunt inductance),

and makes it appropriate for block 26 (maximum current

regulator).

Block 19

Block 20

Undervoltage safeguard

Overvoltage safeguard

If the main supply voltage falls below the minimum allowed

value this safeguard triggers (a tolerance of approx. ±15% of

the power supply voltage is allowed: outside this range the

safeguardtriggers).

If the main supply voltage exceeds the maximum value this

safeguard triggers (a tolerance of approx.±15% of the power

supply voltage is allowed: outside this range the safeguard

triggers).

(14)

IGBT

DRIVER

(5)

CHOPPER

(18)

MICROCONTROLLER

(17)

ADDER

(26)

MAXIMUN CURRENT

REGULATOR

(25)

AMPLIFIER

SHUNT

(3)

PRE-CHARGE

(16)

DUTY CYCLE

MAKER

-5-

Primary board

TECHNOLOGY TIG 172 AC/DC

Control board

(19 - 20)

UNDERVOLTAGE/OVERVOLTAGE

SAFEGUARD

(2)

RECTIFIER

BRIDGE

(13)

FLY-BACK

TRASFORMER

(4)

FILTER

(1)

EMC

FILTER

(21)

GALVANIC

SEPARATION

(6)

CURRENT

TRASFORMER

ILLUSTRATIONS

(15)

PRIMARY CURRENT

READER AND LIMITER

(8)

SECONDARY

DIODES

(9)

AC/DC

CURRENT

CONVERTER

(30)

SOLENOID VALVE

RELAY

(29)

AUXILIARY TRASFORMER

-6-

Secondary board

Torch button board

(27)

SCR DRIVER

(10)

SHUNT

TECHNOLOGY TIG 172 AC/DC

(32)

SOLENOID VALVE

RELAY AND HF

-7-

TECHNOLOGY TIG 172 AC/DC

WIRING DIAGRAMS

General wiring diagram

-8-

TECHNOLOGY TIG 172 AC/DC

Wiring diagram primary board - Power

Wiring diagram primary board - Driver

-9-

TECHNOLOGY TIG 172 AC/DC

Wiring diagram control board - Micro

Wiring diagram primary board - power supply

-10-

TECHNOLOGY TIG 172 AC/DC

Wiring diagram control board - Digital

Wiring diagram control board - Analogyc

-11-

TECHNOLOGY TIG 172 AC/DC

Wiring diagram control board - In / Out

Wiring diagram secondary board - Power

-12-

Wiring diagram HF board Wiring diagram PT board

TECHNOLOGY TIG 172 AC/DC

Wiring diagram secondary board - Driver

TECHNOLOGY TIG 172 AC/DC

4

38

12

9

5

76

-13-

(*)The instruments with codes can be supplied by Telwin. The sale price is available on request.

REPAIR GUIDEREPAIR GUIDE

REPAIR GUIDEREPAIR GUIDE

EQUIPMENT REQUIRED

ESSENTIAL INSTRUMENTS

USEFUL INSTRUMENTS

1 Dual trace oscilloscope cod. 802401 (*)

2 Static load generator cod. 802110 (*)

3 Variac 0 - 300v 1500 VA cod. 802402 (*)

4 Digital multimeter

6 Unsoldering station

7 Miscellaneous tools

5 Differential probe 1/200

6 Hall Probe cod. 802406

cod. 802403

(*)

(*)7 HV Power supply

WARNING:

WARNING:

WARNING:

BEFORE PROCEEDING WITH REPAIRS TO

THE MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY.

EXTRAORDINARY MAINTENANCE SHOULD

BE CARRIED OUT ONLY AND EXCLUSIVELY

BY EXPERT OR SKILLED ELECTRICAL-

MECHANICAL PERSONNEL.

ANY CHECKS CARRIED OUT INSIDE THE

MACHINE WHEN IT IS POWERED MAY

CAUSE SERIOUS ELECTRIC SHOCK DUE TO

DIRECT CONTACT WITH LIVE PARTS.

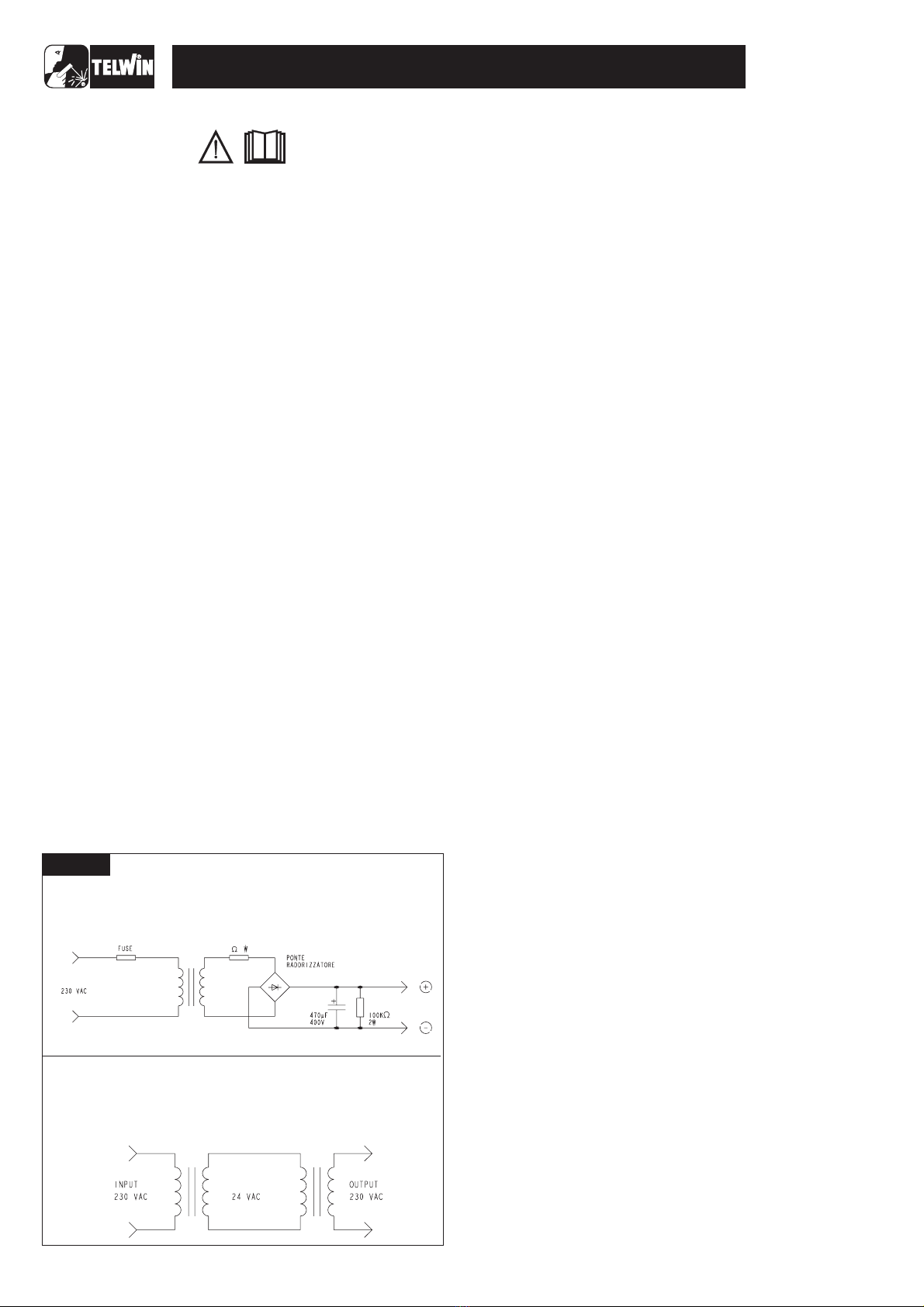

HV POWER SUPPLY MODULE

THE HV POWER SUPPLY is used to ensure operation of the

switching power supply (the circuit on the primary board supplying

auxiliary voltages), even when the machine is operating at low

voltage.

It is easy to build using the electrical diagrams in fig. A for

reference and using the following components or, alternatively, it

can be ordered from Telwin.

T1 = insulation transformer 230-230V 50VA(*)

D1 = rectifier bridge 36MB 80 (cod. 112357)

C1 = electrolytic capacitor 470uF 400V ALL

(cod.112514)

R1 = resistor 10 ohm 5W 5%

R2 = resistor 100K ohm 2W 5%

F1 = delayed action fuse 1.5 A Fuse holder 5X20mm

Female red and black faston

Plastic box.

The following is a list of practical rules which must be strictly

adhered to if repairs are to be carried out correctly.

A) When handling the active electronic components, the IGBT's

and Power DIODES in particular, take elementary antistatic

precautions (use antistatic footwear or wrist straps, antistatic

working surfaces etc.).

B) To ensure the heat flow between the electronic components

and the dissipator, place a thin layer of thermo-conductive

grease (e.g. COMPOUND GREASIL MS12) between the

contact zones.

C) The power resistors (should they require replacement) should

always be soldered at least 3 mm above the board.

D) If silicone is removed from some points on the boards, it should

be re-applied. Use only non-conducting neutral or oximic

reticulating silicones (e.g. DOW CORNING 7093). Otherwise,

silicone that is placed in contact with points at different

potential (rheophores of IGBT's, etc.) should be left to

reticulate before the machine is tested.

E) When the semiconductor devices are soldered the maximum

temperature limits should be respected (normally 300 C for no

more than 10 seconds).

F) It is essential to take the greatest care at each disassembly

and assembly stage for the various machine parts.

G) Take care to keep the small parts and other pieces that are

dismantled from the machine so as to be able to position them

in the reverse order when re-assembling (damaged parts

should never be omitted but should be replaced, referring to

the spare parts list given at the end of this manual).

H) The boards (repaired when necessary) and the wiring should

never be modified without prior authorisation from Telwin.

I) For further information on machine specifications and

operation, refer to the Instruction Manual.

J) When the machine is in operation there are

dangerously high voltages on its internal parts so do not touch

the boards when the machine is live.

Every operation should be carried out in complete

safety with the power supply cable disconnected from the mains

outlet:

After completing the repairs, proceed in the reverse order to re-

assemble the cover and do not forget to insert the toothed washer

on the ground screw.

Using suitably dried compressed air, carefully clean the

components of the power source since dirt is a danger to parts

subject to high voltages and can damage the galvanic separation

between the primary and secondary.

To clean the electronic boards we advise decreasing the air

pressure to prevent damage to the components.

GENERAL REPAIR INSTRUCTIONS

TROUBLESHOOTING AND REMEDIES

N.B.

WARNING!

WARNING!

°

1.0 Disassembling the machine

2.0 Cleaning the inside of the machine

- Undothe8screwsfasteningthe2plasticcovers(4each)tothe

frontandback .

- Undo the 8 screws fastening the top cover to the structure

.

- Slideoutthetopcoverbypullinggentlyoutwards .

- Undothe4 screwsfasteningthe bottomtothestructure

.

(figure1A)

(figure1B) (figure1B)

(figure

1B)

- Separate the top metallic structure from the base and put

it on the work bench(figure 3).

NOTE: Because the base is an integral part of support

structure it

should be removed if it is necessary to gain access to

internal boards.

-14-

TECHNOLOGY TIG 172 AC/DC

10 5

F1 R1

R2

D1

T1

Figure A

ELECTRICAL DIAGRAM FOR POWER SUPPLY (HV OUTPUT):

THE INSULATION TRANSFORMER CAN BE REPLACEDWITH

TWO TRANSFORMERS OF THE SAME POWER,

CONNECTING THE SECONDARIES ACCORDING TO THE

FOLLOWINGDIAGRAM:

It is therefore important to take special care when cleaning the

following parts

Check whether dirt has been deposited on the front and back air

vents or has damaged the correct rotation of the blades, if there is

still damage after cleaning replace the fan.

Make sure there is no mechanical deformation, dent, or damaged

and/or disconnected connector.

Make sure the power supply cable has not been damaged or

disconnected internally and that the fan works with the machine

switched on. Inspect the components and cables for signs of

burning or breaks that may endanger operation of the power

source. Check the following elements:

Use the multimeter to check whether the contacts are stuck

together or open. Probable cause:

- mechanical or electric shock (e.g. bridge rectifier or IGBT in

short circuit, handling under load).

Probable cause:

- see main power supply switch. If the relay contacts are

stuck together or dirty, do not attempt to separate them and

clean them, just replace the relay.

Probable cause:

- mechanical shock;

- machine connected to power supply voltage much higher than

the rated value;

- broken rheophore on one or more capacitor: the remainder will

be overstressed and become damaged by overheating;

- ageing after a considerable number of working hours;

- overheating caused by thermostatic capsule failure.

Probable cause:

- discontinuation in snubber network,

- fault in driver circuit

- poorly functioning thermal contact between IGBT and

dissipator (e.g. loosened attachment screws: check),

- excessive overheating related to faulty operation

Probable cause:

- excessive overheating related to faulty operation.

Probable cause:

- mechanical shock.

Probable cause:

- discontinuation in snubber network;

- poorly functioning thermal contact between IGBT and

dissipator (e.g. loosened attachment screws: check);

- faulty output connection.

Probable cause:

see the main power supply switch; If the relay contacts are

stuck together or dirty, do not attempt to separate or clean them,

just replace the relay.

Check it for colour changes.

Probable cause:

overheating due to loosening of the screws connecting the shunt

to the PCB.

Probable cause:

see the main power supply switch; If the relay contacts are

stuck together or dirty, do not attempt to separate or clean them,

just replace the relay.

Make sure the fuse is correctly inserted into the fuse holder and

that it has not blown (blackened in colour). Use the multimeter to

check whether the fuses have blown. Probable cause:

excessive current absorption from the main supply.

Inspect the windings for colour changes.

Probable causes:

- aging after a substantial number of working hours;

- excessive overheating related to faulty operation.

Inspect the windings for colour changes. Probable causes:

- aging after a substantial number of working hours;

- excessive overheating related to faulty operation.

Check it for colour changes. Probable cause:

- overheating due to loosening of the screws connecting the

shunt to the PCB.

Check the solenoid valve to see if it opens. Probable causes:

- the solenoid valve does not open because of a mechanical

block; do not attempt to open the valve but used compressed air to

carry out thorough cleaning or replace the solenoid valve.

Maintenance status, referring to the instructions given in the

instruction manual. Condition of parts not subject to wear on the

connecting cable between torch and power source (insulation).

It is important to check that all the connections are in good

condition and the connectors are inserted and/or attached

correctly. To do this, take the cables between finger and thumb (as

close as possible to the fastons or connectors) and pull outwards

gently: the cables should not come away from the fastons or

connectors. N.B. If the power cables are not tight enough this

could cause dangerous overheating.

Fan fig. 2A

Main power supply switch fig. 2A

Relays K1, K2 primary board fig. 5

Electrolytic capacitors C2,C4,C6,C7 primary board fig. 5

IGBT's Q1, Q2, Q3, Q4 primary board fig. 5

Primary diodes D1, D4, D6, D8 primary board fig. 5

Mode selector switches SW2 and SW3 panel board (fig. 2A)

Secondary diodes D1...D10 secondary board fig. 2A

Relay K2 secondary board (fig. 6)

Shunt R2 secondary board (fig. 6)

Relay K1 torch button board (fig. 4)

Fuse F1 torch button board (fig. 4)

Power transformer and filter inductance (fig. 2A)

HF transformer (fig. 2A)

Shunt (fig. 2A)

Solenoid valve (fig. 3)

TIG Torch

()

()

()

()

()

.

()

()

Primary board (fig. 5:)

Secondary board (fig. 6):

Power transformer and inductance assembly (fig. 2A)

Parts fastened to the base (fig. 4)

5.0 Electrical measurements with the machine switched off

-

-

-

-

-

-

-

-

-

fig. 5

fig. 5

fig. 6

fig. 6

fig. 5

fig. 5

fig. 6

rheofores of IGBT's Q1, Q2, Q3, Q4;

rheofores of recirculating diodes D4, D8;

rheofores of snubber network diodes D1, D6;

rheofores of opto-couplers ISO1 and ISO2;

rheofores of connectors J4 and J6;

rheofores of secondary power diodes D1…D10;

bump contacts on top of and under the printed circuit of the

SCR Q5 module;

thermostat ST1 on secondary diode dissipator;

rheofores of opto-couplers ISO1, ISO2, ISO3, ISO4;

Do this if it is necessary to remove the primary board, otherwise it

is possible to clean the part superficially from the side of the

secondary board.

If the primary and secondary boards are removed (with the

diaphragm), carefully clean all the parts fastened to the base, or

clean the base partially from the sides of the machine.

A) With the multimeter set on diode testing check the following

components (joint voltages not less than 0.2V):

- rectifier bridges D3, D5 ( );

- IGBT's Q1, Q2, Q3, Q4, (no short circuits between collector-

gate and collector-emitter ( ));

- secondary diodes D1…D10 between anode and cathode

( ). SCR Q5 module (no short circuits between anode

and cathode ).

B) With the multimeter in ohm mode check the following

components:

- resistor R1: 47 ohm (pre-charge ).

- resistors R2, R6: 10 ohm (primary snubber ).

- resistors R1, R2, R3, R4: 10 ohm (secondary snubber ).

- thermostat continuity test on inductance: disconnect fastons

3.0 Visual inspection of the machine

4.0 Checking the power and signal wiring

N.B.

- N.B.

-

- N.B.

-

-15-

TECHNOLOGY TIG 172 AC/DC

J15 and J16 from the control board and make sure the

resistance is approx. 0ohm ( ).

- thermostat continuity test on secondary dissipator:

disconnect fastons J13 and J14 from the control board and

make sure the resistance is approx. 0 ohm ( ).

Switch on the HV power supply (HV OUT) and make sure that

(fig. 5):

- pre-charge relays K1 and K2 close;

- the fan starts to turn for the power transformer;

Make sure the waveform shown on the oscilloscope

resembles .

if there is no signal it may be necessary to replace the

integrated circuit U2 or IGBT Q10 on the primary board ( ).

C) Set up the multimeter in volt mode and make sure the primary

board has the following voltages: ( ):

- between the cathode of diode D32 (+) and the negative of

diode bridge D5 (-): equal to +16.5Vdc 3%;

- between pin 3 (+) and the dissipator (-) of U5: equal to +5Vdc

5%;

- between pin 3 (+) and the dissipator (-) of U4: equal to +12Vdc

5%;

- between pin 3 (+) and pin 1 (-) of U6: equal to -12Vdc 5%;

- between pin 8 (+) and pin 7 (-) of ISO1: equal to +30Vdc 5%;

- between pin 8 (+) and pin 7 (-) of ISO2: equal to +30Vdc 5%;

- between pin 4 (+) and pin 5 (-) of J4: equal to +18Vdc 10%;

- between pin 9 (+) and pin 8 (-) of J4: equal to +18Vdc 10%;

D) Switch off the HV power supply, reposition the control board

and reconnect the wiring.

E) On the front panel set switch SW2 to MMA (as low as it will go)

and switch SW3 to DC-LIFT (in the centre).

F) Switch on the HV power supply (HV out) and make sure that

(fig. 2A):

- the green power supply LED D6 lights up;

- the green LED D7 indicating voltage over the torch lights up;

- the yellow alarm LED D8 is off;

- the display shows a numeric value that varies between 5 and

140 when the encoder is turned.

- with the oscilloscope probe connected as in point 6.1 F) the

wave form resembles ;

- the frequency is equal to 60KHz ±5%; if the frequency reading

on the oscilloscope is not 60KHz ±5%, calibrate the frequency

when the machine is being tested (see point 1.2 A).

if the signal is not present it may be necessary to replace the

integrated circuit U2 or IGBT Q10 on the primary board

G) Switch off the HV power supply.

H) Set up the oscilloscope with the voltage probe x10 connected

between the gate (probe) and the emitter (earth) of IGBT Q4

on the primary board ).

I) Switch on the HV power supply (HV out) and make sure the

waveform displayed on the oscilloscope resembles .

fig. 7

fig. 7

A)

B)

Fig. B

N.B.

fig. 5

fig. 5

fig. C

N.B.

(fig. 7).

(fig. 5

fig. D

6.0 Electrical measurements with the machine in

operation

WARNING!

fig. 3

fig. 4

fig. 5

WARNING!

Before proceeding with faultfinding, we should

remind you that during these tests the power source is powered

and therefore the operator is exposed to the danger of electric

shock.

The tests described below can be used to check the operation of

the power and control parts of the power source.

A) Do not connect the gas mixture source.

B) Disconnect all connectors and fastons from the control board

and remove it from the primary board.

C) From the primary board, disconnect fastons CN3 (XF+) and

CN10 (XF-) for the power transformer ( ), and disconnect

faston J1 from the support board (fig. 5).

D) On the primary board disconnect the jumper on JP1.

E) Connect the HV power supply OUT (code 802403) on the

primary board as follows ( ):

- (+) Positive (clamp) to rheofore of resistor R35 towards

JP1 (after removing jumper JP1);

- (-) Negative (faston) to negative faston of diode bridge D3.

F) Set up the oscilloscope with the voltage probe x100

connected between the rheofore of R40A (collector Q10)

towards JP1 (probe) and the negative of diode bridge D3

(earth) to the primary board ( ).

G) Disconnect fastons J1 and J3 from the HF board (fig. 4).

H) Connect the power supply cable to a single phase variac with

variable output 0-300 Vac.

during testing prevent contact with the metal part of

the torch because of the presence of high voltages that are

hazardous to the operator.

6.1 Preparation for testing

6.1 Scheduled tests

only

-16-

TECHNOLOGY TIG 172 AC/DC

SETTINGS:

· PROBE x10

· 100mV/Div;

· 10 sec/Div.

VERIFY THAT:

· THE FREQUENCY IS

60KHz ±10%;

· AMPLITUDE IS

450V ±10%.

µ

FIGURE C

SETTINGS:

· PROBE x100;

· 100 V/Div;

· 10 sec/Div.

· THE FREQUENCY

IS 35KHz ±15%;

· AMPLITUDE IS

450V ±10%;

µ

VERIFY THAT

FIGURE B

SETTINGS:

· PROBE x10;

· 100mV/Div;

· 5 sec/Div.

TIME TOLLERANCE ± 20%

· POSITIVE AMPLITUDE

IS +18V ±10%;

· NEGATIVE AMPLITUDE

IS -10V ±10%.

µ

VERIFY THAT

FIGURE D

J) Repeat this test on Q1, Q2, Q3 as well. if the signal is not

present there could be a fault in the IGBT driver circuit,

specifically ISO1 and ISO2 ( ), or in the control board (

, in which case we recommend replacing the board).

K) Switch off the HV and replace the 2 fastons connecting the

primary board and the power transformer (CN3 and CN10).

L) Switch on the HV and the variac (initially set to 0V), close the

main power supply switch on the machine and gradually

increase the voltage generated by the variac until it reaches

26Vac.

M) Set up the oscilloscope with the voltage probe x100

connected between the collector (probe) and the emitter

(earth) of IGBT Q4 on the primary board ( ).

N) Make sure the waveform shown on the oscilloscope

resembles

O) Repeat this test on Q2 as well, using the differential probe.

If the signal is not present there may be a fault in the IGBT's

().

P) Return the variac voltage to 0V, switch off the machine and the

HV power supply.

Q) Disconnect the HV power supply, replace jumper JP1 on the

board.

R) Switch the machine on again and gradually increase the

voltage generated by the variac to 150Vac 5% then make sure

an alarm is registered with yellow LED D8 on and alarm “AL.1”

shown on the display.

S) Increase the voltage on the variac to 230Vac and make sure

the alarm ceases (yellow LED D8 goes off).

T) Increase the voltage on the variac yet again to 300Vac 5% and

make sure the machine registers an alarm again. Return the

variac voltage immediately to 230Vac and switch off the

machine.

if an alarm persists (and is not caused by a fault in the control

board) there could be a fault in opto-isolator ISO3 or integrated

circuit U3 on the primary board ( ).

N.B.

fig. 5 fig.

3

fig. 5

fig. E.

N.B.

fig.5

N.B.

fig. 3

7.0 Repairs, replacing the boards

If repairing the board is complicated or impossible, it should be

completely replaced.

The board is identified by a 6-digit code (printed in white on the

component side after the initials TW). This is the reference code

for requesting a replacement: Telwin may supply boards that are

compatible but with different codes.

before inserting a new board check it carefully for

damage that may have occurred in transit. When we supply a

board it has already been tested and so if the fault is still present

after it has been replaced correctly, check the other machine

components. Unless specifically required by the procedure, never

alter the board trimmers.

If the fault is in the control board remove it from the primary board

as follows:

- with the machine disconnected from the main power supply

disconnect all the wiring from the control board;

- cut any bands restricting the board;

- remove the control board from the spacers attached to the

primary board;

for assembly proceed in the reverse order.

If the fault is in the control board we strongly advise replacing it

without further intervention.

If the fault is in the primary board remove it from the machine

structure as follows:

- with the machine disconnected from the main power supply

and after removing the control board, disconnect all the wiring

from the primary board;

- cut any bands restricting the board (e.g. on the power supply

cable and primary connections);

- undo the screws fastening the front and back panels and

remove the panels from the machine structure;

- undo the screws fastening the primary board to the machine

structure;

- remove the primary board by lifting it upwards.

for assembly proceed in the reverse order.

The 4 IGBT's are attached to 2 different dissipators and whenever

a replacement is required, both IGBT's should be replaced.

Before making the replacement make sure the components

piloting the IGBT's are not also damaged:

- with the multimeter set in mode make sure there is no

short circuit on the PCB between the 1 and 3 bump contacts

(between gate and emitter) corresponding to each

component;

- alternatively, resistors R3, R4, R7, R8 could have burst and/or

diodes D11, D12, D15, D16 may be unable to function at the

correct Zener voltage (this should have shown up in the

preliminary tests);

- clean any irregularity or dirt from the dissipators. If the IGBT's

have burst the dissipators may have been irreversibly

damaged: in this case they should be replaced;

- apply thermo-conductive grease following the general

WARNING!

N.B.

N.B.

Please read the procedure for replacing the IGBT's

carefully: (fig. 5).

ohm

7.1 Removing the control board (fig. 3)

7.2 Removing the primary board (fig. 3)

- Unscrew the four (4) nuts that fix the dissipator onto the

card;

- unscrew the four (4) screws that fix the four (4) IGBT onto

the dissipator;

- unscrew the two (2) screws that fix the two diode bridges

onto the dissipator;

- remove the four (4) IGBT and the two (2) diode bridges by

unwelding the reophores, then remove tin from the

printed plates;

- remove dissipator from card.

st rd

-17-

TECHNOLOGY TIG 172 AC/DC

SETTINGS:

· PROBE x10;

· 10V/Div;

· 5 sec/Div.

±

.

· AMPLITUDE IS:

35V ±20%.

µ

TIME TOLLERANCE 20%.

VERIFY THAT

FIGURE E

instructions.

- Prepare the components for replacement. For the IGBT's,

bend the rheofores at 90 (never bend and/or place the parts

under tension near the case).

- Position the components on the dissipator with the fastening

screws, but do not tighten the screws completely

- Join the dissipator/component assembly to the printed board,

inserting all the rheofores in the bump contacts and the

threaded spacers on the 4 attachment holes.

- Attach the dissipators with the nuts and lock them once and for

all in the following order:

- the nuts fastening the dissipators to the printed circuit with a

torque wrench setting of 2 Nm ±20%;

- the screws fastening the rectifiers to the dissipators with a

torque wrench setting of 2 Nm ±20%;

- the screws fastening the IGBT's to the dissipators with a

torque wrench setting of 1 Nm ±20%.

- Solder the terminals taking care not to let the solder run along

them.

- On the component side cut away the protruding part of the

rheofores and check they are not shorted (especially the gate

and emitter).

The 4 IGBT's should belong to the same selection kit

supplied by Telwin.

If the fault is in the secondary board, it should be specified that to

remove it, it is necessary to separate the base from the machine

structure as follows:

- with the machine disconnected from the main power supply

and after removing the control and primary boards, separate

the base from the machine structure by undoing the 4 screws;

- disconnect all wiring connected to the secondary board;

- undo the 4 screws fastening the dissipator to the machine

structure;

- extract the secondary board from the machine structure;

for assembly proceed in the reverse order.

The 10 secondary DIODES are attached to the dissipator and to

reach them it is necessary to remove the boards above and below.

Whenever one diode is replaced, they should all be replaced.

- undo the 3 screws fastening the SCR module to the top board;

- disconnect the 4 fastons connected to the SCR module;

- undo the 2 screws fastening the aluminium connections to the

bottom board;

- remove the top board;

- undo the 4 nuts fastening the bottom board to the dissipator;

- undo the 10 screws attaching the diodes to the dissipater;

- remove the 10 diodes by unsoldering the rheofores and also

remove the solder from the bump contacts on the PCB;

- clean any irregularities or dirt from the dissipators. If the diodes

have burst the dissipator may be irreparably damaged: in such

a case it should be replaced;

- apply thermoconductive paste following the general

instructions; for diodes D6, D7, D8, D9 and D10

remember to insert nomex insulation between the dissipator

and the diode.

- place the dissipator with the new components on the bump

contacts of the PCB and fasten it down with the screws (torque

wrench setting 1 Nm 20%);

- solder the terminals taking care not to let the solder run along

them;

- on the soldering side cut the protruding part of the rheofores

and make sure they have not shorted (between cathode and

anode).

make sure that resistors R1, R2, R3, R4 and capacitors C1,

C2, C3, C4 on the snubber are soldered correctly to the bottom

board.

The SCR module is attached to the dissipator and to reach it, it is

necessary to remove the top board:

- undo the 3 screws fastening the SCR module to the top board;

- disconnect the 4 fastons connected to the SCR module;

- remove the top board;

- remove the SCR module by undoing the 2 screws at the side;

- clean any irregularities or dirt from the dissipators. If the SCR

module has blown the dissipator may be irreparably damaged:

in such a case it should be replaced;

- apply thermoconductive paste following the general

instructions;

- place the new SCR module on the dissipator and fasten it with

the screws (torque wrench setting 5 Nm 20%);

make sure that resistors R1, R6, diodes D22, D5 and

capacitors C1, C5 on the snubber are soldered correctly to the top

board.

Tests should be carried out on the assembled machine before

closing it with the top cover. During tests with the machine in

operation never commute the selectors or activate the ohmic load

contactor.

Before proceeding to test the machine, we should

remind you that during these tests the power source is powered

and therefore the operator is exposed to the danger of electric

shock.

The tests given below are used to verify power source operation

under load.

A) Do not connect the gas mixture source.

B) Connect the machine to the static load generator (code

802110) using cables fitted with the appropriate dinse

connectors (802110)

C) Set up the dual trace oscilloscope with the voltage probe

CH1x100 connected between the collector (probe) and the

emitter of Q4 (earth) on the primary board ( ).

D) Pass the current probe of the Hall effect transducer along the

cable connecting the power transformer at faston CN10 with

the reference arrow pointing into CN10.

E) Lastly, connect the Hall Probe and the current probe to the

oscilloscope.

F) Set up a multimeter in DC volt mode and connect the prods to

the OUT+ and OUT- dinse connections.

G) On the front panel set switch SW2 to MMA (as low as it will go)

and switch SW3 to DC-LIFT (in the centre).

H) Keep fastons J1 and J3 disconnected from the HF board (fig.

3).

the high frequency voltage will permanently damage

any instrument connected to the generator. Before proceeding

make very sure that the fastons listed above are disconnected and

completely isolated from one another.

I) Connect the power supply cable to the 230Vac power supply.

during testing prevent contact with the metal part of

the torch because of the presence of high voltages that are

hazardous to the operator.

Switch on the machine, gradually increase the power supply

voltage from 0V to 230Vac and make sure that:

- the pre-charge relays on the primary board close;

- the fan starts operating correctly;

- the green power supply LED D6 lights up;

- the waveform displayed on the oscilloscope resembles

and the frequency is equal to +60KHz ±5%; if the frequency

°

NOTE.

N.B.

Take special note of the procedure for replacing the

secondary diodes (fig. 6):

Warning!

N.B.

Please take careful note of the procedure for replacing the

SCR module (fig. 6):

N.B.

WARNING!

fig. 5

WARNING!

WARNING!

A) Loadless test:

Fig. F

7.3 Removing the secondary board (fig. 6)

TESTING THE MACHINE

1.1 Preparation for testing

1.2 Scheduled tests

-18-

TECHNOLOGY TIG 172 AC/DC

reading on the oscilloscope is not 60KHz ±5%, adjust the

frequency using trimmer R162 on the control board;

- the output voltage over dinse + and dinse is equal to 110Vdc

15%.

- set up the ohmic load with the switch settings as in the table in

;

- on the front panel use the encoder to position the current at

15A;

- switch on the main switch;

- start up on the ohmic load and make sure that:

- the waveforms displayed on the oscilloscope resemble

those in ;

- the output current is equal to +15Adc 20% and the output

voltage is equal to +15Vdc 5%.

- switch off the ohmic load and switch off the main switch.

- set up the ohmic load with the switch settings as in the table in

;

- on the front panel position with the encoder the current at 140A;

- start up the ohmic load and make sure that:

- the waveforms displayed on the oscillscope resemble those

in ;

- the output current is equal to +80Adc 10% and the output

voltage is equal to +23.2.Vdc 10%.

- switch off the ohmic load and switch off the main switch.

- set up the ohmic load with the switch settings as in the table in

;

- on the front panel position with the encoder the current at 140A;

- start up on the ohmic load and make sure that:

- the waveforms displayed on the oscilloscope resemble

those in ;

- the output current is equal to +140Adc 5% and the output

voltage is equal to +26Vdc 5%; if the output current reading is

not 140A ±3%, adjust the current using trimmer IMAX R105

on the control board ( ).

- switch off the ohmic load and switch off the main switch.

- on the front panel set switch SW2 to TIG/2T (as high as it will

go) and switch SW3 to AC (as low as it will go).

- connect the TIG torch to the machine.

- set up the dual trace oscilloscope, connecting probe CH1 x10

to pin 1 of connector J3, on the control board ( ), and probe

CH2 x 10 to pin 2. The earths are connected together to pin 3

on the same J3 connector;

- set up the ohmic load with the switch settings as in the table in

- on the front panel use the encoder to position the current at

15A;

- start up the ohmic load, press the torch button and make sure

B) Rated load test:

fig. G

Fig. F

C)Intermediate load test:

fig. H

Fig. H

D) Rated load test:

fig. I

Fig. I

fig. 7

E) Testing operation of SCR module

fig. 7

Fig. J;

±

±

±

±

-19-

TECHNOLOGY TIG 172 AC/DC

FIGURE F

FIGURA E

FIGURE G

6

3

2

145

110000Number switch

Number switch

Number switch

Position switch

Position switch

Position switch

FIGURA E

6

3

2

145

222210

FIGURE H

FIGURA E

6

3

2

145

333222

FIGURE I

SETTINGS

· THE FREQUENCY IS

60KHz ±5%;

· AMPLITUDE CH1 IS

340V ±10%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =1A;

· 10mV/Div;

· 5 sec/Div.µ

VERIFY THAT

SETTINGS

· THE FREQUENCY IS

60KHz ±5%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS 7A

±20%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =5A;

· 10mV/Div;

· 5 sec/Div.µ

VERIFY THAT

SETTINGS

· THE FREQUENCY IS

60KHz ±5%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS

26A ±20%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =10A;

· 10mV/Div;

· 5 sec/Div.µ

VERIFY THAT

SETTINGS

· THE FREQUENCY IS

60KHz ±5%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS

46A ±10%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =20A;

· 10mV/Div;

· 5 sec/Div.µ

VERIFY THAT

the waveforms displayed on the oscilloscope resemble those

in .

- switch off the ohmic load and switch off the main switch.

If one of the two signals is absent the control board should be

replaced ( Otherwise, if the machine does not supply AC

current the SCR module should be replaced, or if the worst comes

to the worst replace the secondary board.

Set switch SW2 to TIG/2T (toward to the top) and switch SW2 to

LIFT (in the centre). Connect the TIG torch and press the button to

verify that relay K1 closes ; if not check whether:

After checking operation for point 1.3 A), press the button and

check whether:

- the solenoid valve closes (fig. 2A); if not check whether:

- the voltage over the female fastons ( ) is equal to 230Vac

±10%. If voltage is present this means the solenoid valve is

faulty, otherwise check the operation of relay K2 on the

secondary board;.

-

- the voltage over pin 1 (+) and pin 25 of J9 (control board) is

equal to +15Vdc ±20%, otherwise replace the control board.

Set switch SW2 to TIG/2T (as high as it will go) and switch SW3 to

AC (as low as it will go). Now reconnect only fastons J1 and J3 to

the HF generator board ( ) and faston J1 on the support

board.

The high frequency voltage will permanently damage

any instrument connected to the generator.

With the TIG torch still connected and pressing the button check

whether:

- the HF generator board starts to hum for about 2 seconds

(high frequency in torch); otherwise make sure the voltage

over female fastons J1 and J3 ( ), disconnected from the

HF board, is equal to 230Vac ±10%; if voltage is present the

HF board is faulty; if not check the operation of transformer T1

and SCR Q1;

On the front panel set switch SW2 to MMA (as low as it will go),

switch SW3 to DC-LIFT (in the centre) and the welding current to

maximum. Under the load conditions shown in , switch on the

machine and leave it in operation until the thermostatic capsules

trigger (machine in alarm). After making sure the internal wiring is

positioned correctly re-assemble the machine once and for all.

with the machine set up according to the instructions in the

handbook make a test weld with an electrode diam. 2.5 and the

current setting at 80A. Monitor the dynamic behaviour of the

power source, also checking for the presence of the Arc Force, by

first operating key SW1 and then the encoder.

with the machine set up according to the instructions in

the handbook make a test weld with a grey electrode diam. 2.4

and an argon gas bottle (gas flow at 4.5 litres/minute). Make a

weld on iron or steel with a current setting of 80A, monitor the start

and arc stability and make sure the piece melts properly. Also

check all the main properties of the machine that can be set from

the digital panel (see TAB.1).

with the machine set up according to the instructions in

the handbook make a test weld with a green electrode, diam.

1.6mm, and the argon gas bottle (gas flow at 10 litres/minute).

Make a weld on aluminium with a current setting of 40A and

Duty Cycle 80%, monitor the start and arc stability and make

sure the piece melts properly. Also check all the main properties

of the machine that can be set from the digital panel (see

TAB.1).

Fig. J

N.B.

fig. 3).

A) Checking torch button operation

(fig. 4)

B) Checking solenoid valve operation

fig.4

on the secondary board relay K2 closes (fig. 6); if not check

whether:

C)Checking HF generator operation

fig. 4

WARNING!

fig.4

D) Running time test and closing the machine

fig. I

E) Welding test

MMA:

TIG/DC:

TIG/AC:

1.3 Operational tests

- Operation of the torch button;

- Operation of diode bridge D2 on the torch button board;

- Operation of transformer T1 on the torch button board;

- 20-

TECHNOLOGY TIG 172 AC/DC

FIGURA E

6

3

2

145

110000

FIGURE J

SETTINGS

· THE FREQUENCY ON

CH1 AND CH2 IS

45KHz ±10%;

· AMPLITUDE ON CH1

AND CH2 IS 12V ±10%;

:

· PROBE CH1 x10;

· 5 V/Div;

· PROBE CH2 =10;

· 5V/Div;

· 10 sec/Div.µ

VERIFY THAT

Number switch

Position switch

Table of contents

Other Telwin Inverter manuals