Page <3> V1.027/12/19

Newark.com/exclusive-brands

Farnell.com/exclusive-brands

Element14.com/exclusive-brands

Rules For Safe Operation

Warning

To avoid possible electric shock or personal injury, and to avoid possible damage to the Meter or to the equipment

under test, adhere to the following rules:

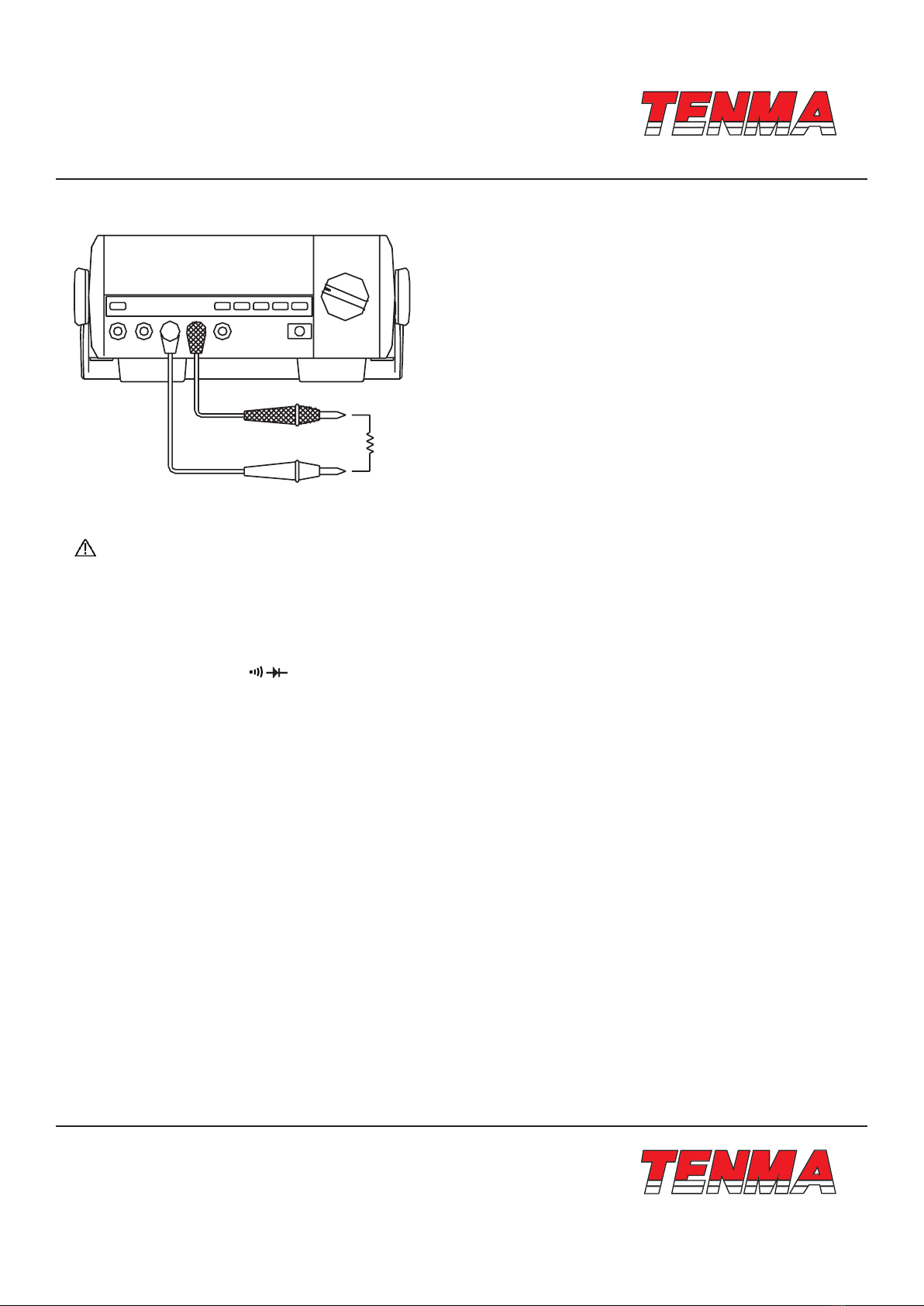

• Before using the Meter inspect the case. Do not use the Meter if it is damaged or the case (or part of the case) is removed.

Look for cracks or missing plastic.

• Pay attention to the insulation around the connectors.

• Inspect the test leads for damaged insulation or exposed metal. Check the test leads for continuity. Replace damaged test

leads with identical model number or electrical specications before using the Meter.

• Do not apply more than the rated voltage, as marked on the Meter, between the terminals or between any terminal and

ground.

• Prior to measurement, ensure the rotary selector switch is in the proper position. To prevent potential damage to the meter,

do not change range or mode during measurement.

• When the Meter working at an effective voltage over 60V DC, or 30V RMS AC, special care should be taken for there is

danger of electric shock.

• Use the proper terminals, function, and range for your measurements.

• If the value to be measured is unknown, use the maximum measurement position and reduce the range step by step until a

satisfactory reading is obtained.

• Do not use or store the Meter in an environment of high temperature, humidity, explosive, ammable gas or strong magnetic

eld. Do not use the meter if allowed to get wet. Even after complete drying, incorrect readings could occur, causing a po-

tentially hazardous condition.

• When using the test leads, keep your ngers behind the nger guards.

• Disconnect circuit power and discharge all high-voltage capacitors before testing resistance, continuity, diodes, current, or

capacitance.

• Before measuring current, check the Meter’s fuses and turn off power to the circuit before connecting the Meter to the circuit.

• Replace the battery as soon as the battery indicator appears. With a low battery, the Meter might produce false

readings that can lead to electric shock and personal injury.

• Remove test leads, temperature probe, RS232C interface cable, and alligator clip from the Meter and turn the Meter power

off before opening the Meter case.

• When servicing the Meter, use only the same model number or identical electrical specications replacement parts.

• The internal circuit of the Meter shall not be altered at will to avoid damage of the Meter and any accident.

• Soft cloth and mild detergent should be used to clean the surface of the Meter when servicing. No abrasive and solvent

should be used to prevent the surface of the Meter from corrosion, damage and accident.

• The Meter is suitable for indoor use only.

• Turn the Meter power off when it is not in use. Remove batteries from meter if use of battery power is not anticipated for long

periods of time.

• Routinely check installed batteries for leaking. Remove immediately if evidence of leaks exist.