10

• Pay attention to electric shocks when measuring high voltage.

• After completing all measurement operations, disconnect the test pen from the

measured circuit.

• When the measured voltage is higher than the safety voltage of 30V AC, the meter

LCD displays the high voltage warning prompt.

• When inputting overvoltage, higher than 750V AC gear range, the meter will

automatically sound intermittent buzzing and the high voltage warning prompt will

automatically ash.

• AC conversion adopts the AC coupling true RMS response mode, sinusoidal input

for correction.

• The accuracy of non-sinusoidal wave shall be adjusted as follows:

- Crest factor 1.4~2.0, accuracy should be increased 1.0%,

- Crest factor 2.0~2.5, accuracy should be increased 2.5%,

- Crest factor 2.5~3.0, accuracy should be increased 4.0%.

DC VOLTAGE MEASUREMENT

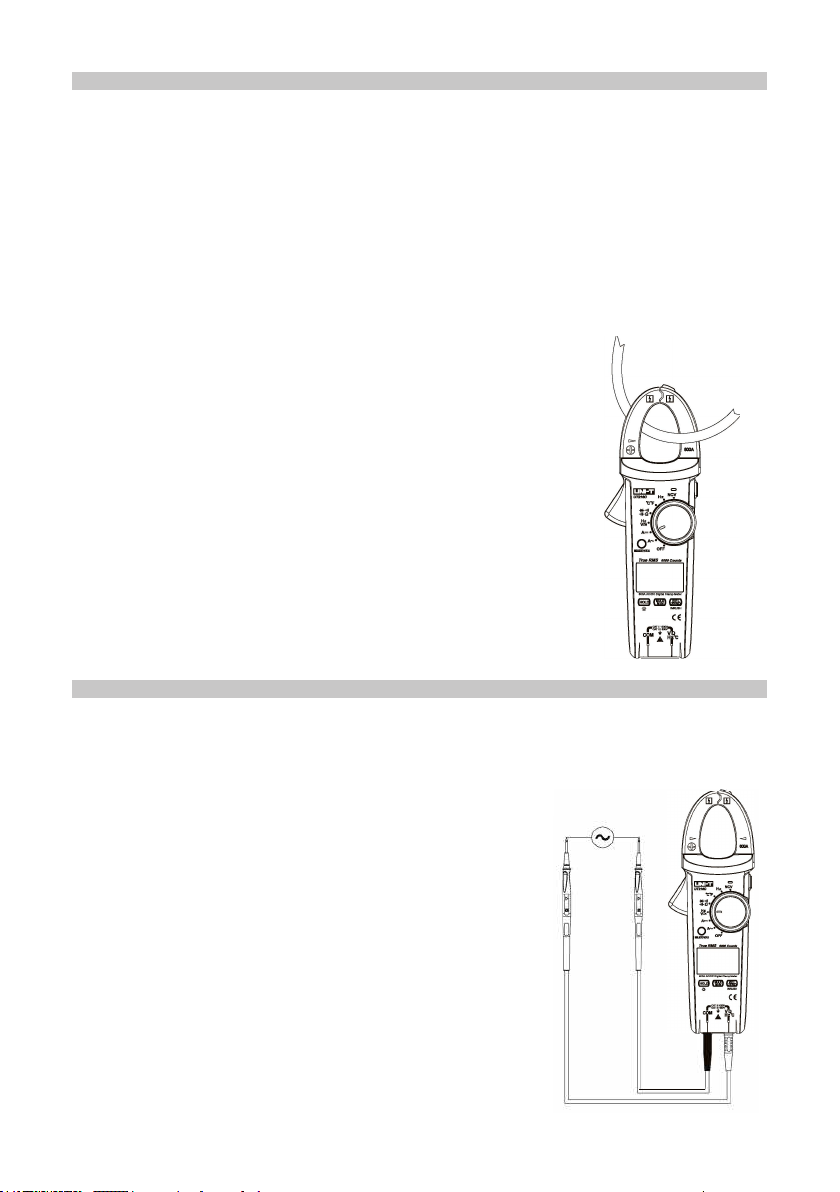

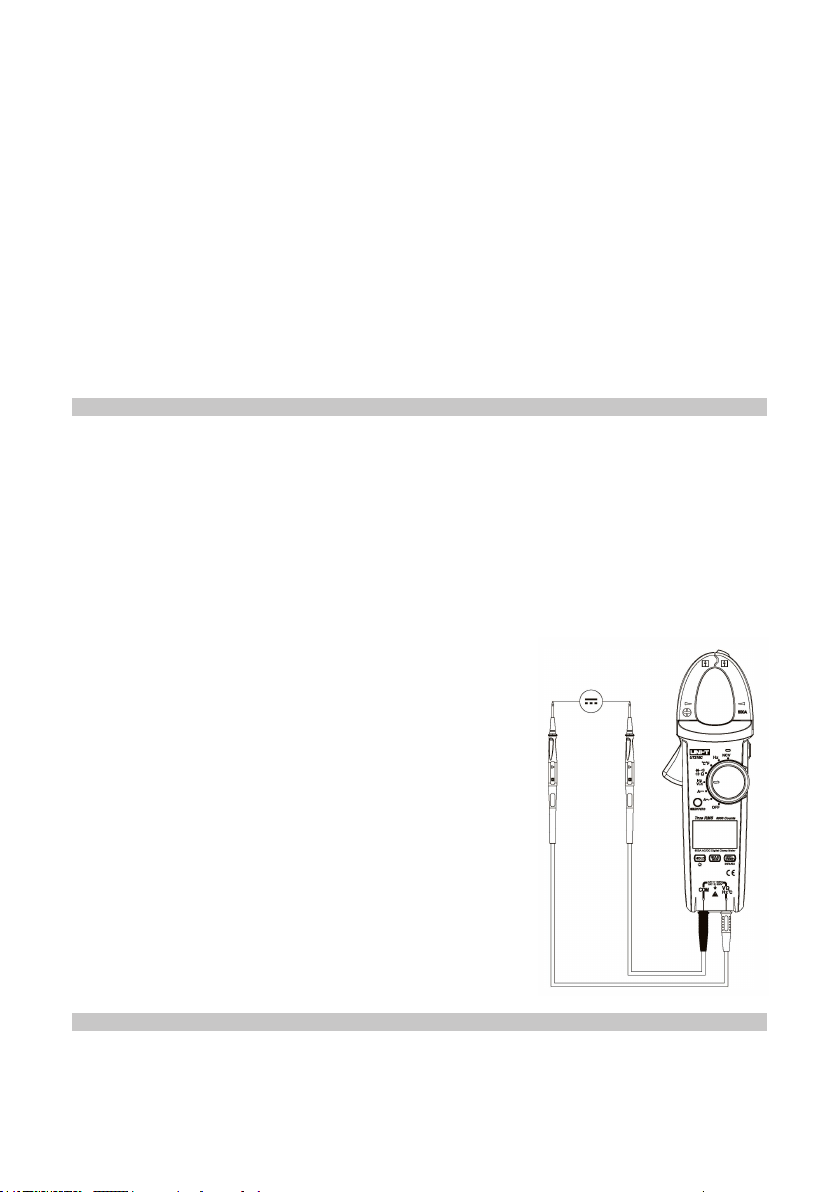

• Insert the red test pen into the “V” jack and the black test pen into the “COM” jack.

• Push the function range switch to the DC voltage measurement and connect the

test pen in parallel with the power or load to be measured.

• Directly read the measured resistance value from the display.

Note:

•Insert the red test pen into the “Ω” jack and the black test pen into the “COM” jack.

•Push the function range switch to the measurement gear “Ω”, press SELECT to

RESISTANCE MEASUREMENT

•

•

•

•

•

•

Do not input voltage higher than 1000V. It may be feasible to measure higher

voltage, but damage will be caused to the meter.

In order to obtain a precise reading when measuring at 600mV gear, the relative

measurement function can be adopted.

Firstly, input the test pen under the short-circuit

condition, press the REL button and read the

resistance measurement value. Afterwards, the meter

automatically deducts the test pen displayed value

under short-circuit condition.

Watch out for electric shocks when measuring high

voltage. After completing all measurement operations,

disconnect the test pen from the measured circuit.

When the measured voltage is higher than the safety

voltage of 30V DC, the meter LCD will display the

warning prompt.

When inputting overvoltage higher than 1000V

DC gear range, the meter will automatically sound

intermittent buzzing and the high voltage warning

prompt will automatically ash.