Tenney TJR Manual

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 1

Tenney Junior

Environmental Test Chamber

OPERATION & MAINTENANCE MANUAL

Model No. TJR, Serial No. 3xxxx

Chamber Type: Temperature

Controller: Watlow 942

CHAMBER OPTIONS

GTempGard IV - Watlow 93 GGN2 Purge

GBoost Heat - Watlow 147 GData Communications

GLN2 Boost Cooling GLinkTenn32 Software

GCO2 Boost Cooling GChart Recorder

GDry Air Purge GAlternate Controller - Watlow F4

TPS - Thermal Product Solutions

2121 Reach Road

Williamsport, PA 17701

570-326-1770 Fax: 570-326-7304

Rev. 04/30/04

The Tenney Junior Family

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 2

SECTION Page

INFORMATION

1.0 COMPANY INFORMATION & ASSISTANCE ____________________________________ 4

2.0 SAFETY WARNINGS & SYMBOLS ___________________________________________ 5,6

3.0 PRODUCT SPECIFICATIONS & OVERVIEW ___________________________________ 7,8

4.0 DRAWINGS, INFORMATION, and VENDOR INSTRUCTION LISTINGS ______________ 9

5.0 INSTALLATION INSTRUCTIONS

5.1 Delivery and Uncrating of Unit ________________________________________________ 10

5.2 Location and Installation of Unit ______________________________________________ 10

5.3 Air Supply Connection - - - (for optional equipment) _______________________________ 11

5.4 GN2 Connection - - - (for optional equipment) ___________________________________ 11

5.5 LN2 Connection - - - (for optional equipment) ____________________________________ 12

5.6 CO2 Connection - - - (for optional equipment) ____________________________________ 12

5.7 Electrical Specifications ____________________________________________________ 13

5.8 Power Connection _________________________________________________________ 13,14

5.9 Application of Power _______________________________________________________ 14

5.10 Operating With an Active Heat Load ___________________________________________ 14

SYSTEMS and CONTROL

6.0 AIR CIRCULATION SYSTEM ________________________________________________ 15

7.0 TEMPERATURE CONTROL

7.1 Controller Features ________________________________________________________ 16,17

7.2 Watlow 942 Control Functions _______________________________________________ 18,19

7.3 Watlow F4 Control Functions (Alternate Controller) _______________________________ 19

8.0 HEATING DESCRIPTION ___________________________________________________ 20

9.0 CHAMBER OVERTEMPERATURE PROTECTION _______________________________ 20-22

10.0 CASCADE REFRIGERATION SYSTEM ________________________________________ 23,24

TABLE OF CONTENTS

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 3

OPTIONAL EQUIPMENT and FEATURES

11.0 ALARM and SHUTDOWN CIRCUIT - TempGard IV (Optional)

11.1 System Description ________________________________________________________ 25

11.2 Special Hookup of TempGard IV for Model TJR ONLY _____________________________ 26

11.3 Circuit Operation __________________________________________________________ 27

11.4 TempGard IV Alarm Setpoint Entry ____________________________________________ 28

12.0 BOOST HEAT (Optional) __________________________________________________ 29

13.0 DRY AIR PURGE SYSTEM (Optional) ________________________________________ 30

14.0 GN2 PURGE AIR SYSTEM (Optional) ________________________________________ 31

15.0 LN2 BOOST COOLING SYSTEM (Optional) ___________________________________ 32

16.0 CO2 BOOST COOLING SYSTEM (Optional) ___________________________________ 33

17.0 LinkTenn32 SOFTWARE (Optional) __________________________________________ 34

18.0 CHART RECORDER (Optional) _____________________________________________ 35

CHAMBER OPERATION & MAINTENANCE

19.0 SEQUENCE of OPERATION ________________________________________________ 36,37

20.0 PREVENTATIVE MAINTENANCE ____________________________________________ 38,39

21.0 SERVICING CASCADE REFRIGERATION SYSTEMS ____________________________ 40-43

22.0 CHAMBER TROUBLESHOOTING GUIDE ______________________________________ 44,45

SUPPLEMENTAL INSTRUCTIONS

Revision History

♦Original Document Dated 04/27/04

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 4

Congratulations on purchasing a chamber from one of the fine divisions of TPS - Thermal Product Solutions.

You probably already know us as Lunaire Limited. We’ve changed our name and expanded our vision with

the intent to provide you with more diversified solutions to your thermal product process requirements.

We truly hope that every aspect of chamber design and quality will measure up to your strictest standards.

Your chamber has been designed to operate with the reliability you expect for the demands you impose on

your product and research testing.

Headquartered in Williamsport, Pennsylvania, which is located in the North-central part of the state, TPS

includes the following four divisions that manufacture environmental test chambers and industrial ovens.

Tenney Environmental - - - - - - Lunaire Environmental - - - - - - Gruenberg Oven - - - - - - Blue M

Parts and service inquiries for equipment within each division should be directed to Lunaire Limited by any of

the following methods.

Important! Please have the Model and Serial Numbers of your unit available when contacting us.

TPS

2121 Reach Road

Williamsport, PA 17701

Phone: 570 - 326 - 1770

Fax - Parts Dept. 570 - 320 - 2160

Fax - Service Dept. 570 - 326 - 3372

Fax - Main: 570 - 326 - 7304

Web site: www.thermalproductsolutions.com

Parts Replacement

Your equipment has been designed and manufactured to provide years of reliable service. In the event a

component should fail, it is recommended that only OEM approved parts be used as replacements. Please

contact the Parts Department for component replacement, or repair.

1.0 COMPANY INFORMATION & ASSISTANCE

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 5

1. Read this entire Operation Manual, as well as the vendor manuals and cut-sheets provided before

operating this equipment! Failure to adhere to any Safety Warning, or failure to follow the proper

operating procedures listed throughout any of the information provided, could cause damage to your

equipment, personal injury, or death.

2. Do not use this equipment in any manner not specified in this manual. Improper use may impair the

safety features employed and will void your warranty.

3. For chambers that are not rated Explosion Resistant: The air conditioning section contains low mass,

open wire heating elements. Due to this low mass, the heater elements can readily attain temperatures

sufficiently high to ignite gas vapors. Do not install test articles that may release explosive or

flammable vapors in the chamber.

4. Only qualified service personnel should ever be permitted to perform any service-related procedure on

this equipment!

5. Do not place the unit near combustible materials or hazardous fumes or vapors.

6. Do not install unit in a corrosive environment. A corrosive environment may lead to poor performance

and deterioration of unit.

7. Make sure the chamber and any remote equipment provided are leveled when installed.

8. A main power disconnect may not be provided with your unit. If not provided, we recommend that a

fused disconnect switch on a separate branch circuit be installed as the power source in accordance

with all National and Local Electrical Codes. If your unit is equipped with a power cord and plug, you

must utilize a receptacle with the appropriate rating, which is on a branch circuit of its own.

9. Do not position the chamber in a manner that would make it difficult to operate your main power

disconnect switch.

10. Your power supply line voltage may be too low or too high to properly and safely operate your

equipment. Before making the power supply connection to your equipment, you must follow the

specific directions stated under “Power Connection” in the Installation Instructions section. Failing to

perform the directions stated may damage your equipment and void your warranty!

11. Control panels, gauge boxes, the conditioning compartment, etc., contain exposed electrical

connections. Keep panels in place properly when the unit is in operation. Disconnect and Lock-Out /

Tag-Out all electrical power from the unit at its source before servicing or cleaning.

12. Refrigerant under high pressure is used. Only qualified refrigeration mechanic personnel should ever

be permitted to perform any service-related procedure on the refrigeration system.

13. Do not adjust any mechanical components such as refrigeration valves or any electrical components

except as directed in this manual.

14. Human exposure to temperature extremes can cause injury. Take appropriate precautions before

opening chamber doors and upon handling test specimens.

15. Do not modify any component on this unit. Use only original equipment manufactured (OEM) parts as

replacement parts. Modifications to any component, or the use of a non-OEM replacement part could

cause damage to your equipment, personal injury, or death.

2.0 SAFETY WARNINGS & SYMBOLS

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 6

INTERNATIONAL WARNING / SAFETY SYMBOL DEFINITIONS

Obey all “DANGER”, “WARNING”, and “CAUTION” labels shown in the manual and mounted on the

equipment. Do not remove any labels mounted on the equipment.

“WARNING OF HAZARDOUS AREA”

“WARNING OF DANGEROUS ELECTRIC VOLTAGE”

“WARNING OF HOT SURFACE”

“EARTH (GROUND) PROTECTIVE CONDUCTOR TERMINAL”

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 7

Application:

This manual applies to the following reach-in temperature test chambers, which employ a capillary tube type

refrigeration system.

Model TJR: Tenney Junior - Benchtop Unit

Model TU-JR: Tenney Junior - Upright Unit

Specifications:

♦Temperature Range: -75 to +200 degrees Celsius, ±0.3 degrees Celsius

♦Workspace: 15-5/8" W x11" D x11-3/4" H (40 W x28 D x30 H Centimeters)

Note: This manual may also apply to special chambers with alternate model numbers (listed below).

For Model XXXX, S/N xxxxx, the following custom specifications apply:

♦Temperature Range: - xx° to + xxx° C, +/- xx deg. after stabilization

Environmental Conditioning Functions:

♦Heating of the chamber is achieved by recirculating chamber air through open-air nichrome wire heater

elements.

♦Cooling of the chamber is achieved by recirculating chamber air through a refrigerated cooling coil in

the chamber conditioning section. The chamber is equipped with a cascade refrigeration system. Non-

CFC refrigerants are used.

♦Air circulation is generated by a propeller type fan, which is driven by an externally mounted motor.

Temperature Controller:

Either the standard Watlow 942 Controller or the optional Watlow F4 Controller is used for temperature

control. The type used is indicated on the manual cover page.

♦Watlow 942 (Standard): The Watlow 942 Controller is a ¼ DIN profiling type controller. Profile

operations include 24-step program capability, time/temperature profile - rate, or time - based

programming, guaranteed soak deviation, and program looping. The W942 can also be used for simple

single, or fixed set point operation.

An RTD sensor is used for temperature measurement. Dual outputs are configured in the time

proportioned, On/Off, or switched dc modes. Two optional auxiliary outputs can be set up as alarms, or

3.0 PRODUCT SPECIFICATIONS & OVERVIEW

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 8

time-based events. Optional retransmit output allows the retransmit of set point or process variable.

Data communications is optional using RS232/RS423, RS422, EIA-485, or IEEE interface.

♦Watlow F4 (Optional): The Watlow F4 Controller is a ¼ DIN profiling type controller, which is

designed for demanding ramp and soak applications. Up to 256 steps can be programmed into as

many as 40 variable-length, nameable profiles. A four line high definition LCD interface display

enhances guided software to make profile programming and controller configuration faster and easier.

A 16-bit microprocessor provides this operational versatility, along with precise process control. The F4

can also function as a static set point controller. EIA-232 and EIA-485 serial communications with

Modbus RTU protocol is standard.

Chamber & Product Over/Under Temperature Protection:

Chamber overtemperature protection is provided with a thermal cutoff device. Product over/under

temperature protection may be provided with an optional alarm output from the main controller. The optional

TempGard IV feature with the Watlow 93 Controller may be used for redundant product over/under

temperature protection. These devices are configured in a comprehensive alarm and shutdown circuit.

Additional Options:

Your Tenney chamber may include many other options such as boost heating, boost cooling using LN2 or

CO2, a purge air system using compressed air or GN2, a chart recorder, and LinkTenn32 software.

LinkTenn32 is an enhanced software program that provides centralized remote monitoring, and the control of

multiple process controllers / chambers simultaneously.

As you can see, Tenney Environmental Test Chambers are diversified tools designed to encompass a wide

range of operating conditions and functions. If you come upon any questions as you continue on through the

manual, please contact our Service Department.

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 9

The following drawings are provided:

Electrical Schematic - Model TJr. (Std. with Watlow 942 Controller) E - 2684 - 4

Electrical Schematic - Model T-U Jr. (Std. with Watlow 942 Controller) E - 2686 - 4

Electrical Schematic (Std. with Watlow F4 Controller) E - 2515 - 4

Electrical Schematic (Special Chambers with any controller) E - 2xxx - 4

Power Transformer Options - Electrical Schematic (with option only) E - 2340 - 3

Boost Heat Option - Electrical Schematic (with option only) E - 1873 - 3

Refrigeration Schematic R - 904 - 4

The following vendor manuals and information are provided:

Watlow 942, or F4 Controller Manual

Test Report

Optional Equipment – Vendor manuals will be supplied when the option is included.

Data Communications Manual (W942 - Data Com. is separate, WF4 - Data Com. is integrated in main mnl.)

LinkTenn32 Software

Watlow 93 Controller Manual (TempGard IV Feature)

Watlow 147 Limit Controller Manual

Chart Recorder Manual

Heatless Dryer Manual (with dry air purge option)

4.0 DRAWINGS

,

INFORMATION

,

and VENDOR INSTRUCTION LISTINGS

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 10

Read this section completely before attempting to install, or operate the equipment.

5.1 Delivery and Uncrating of Unit

Inspect equipment and shipping crate immediately upon receipt. If any damage is apparent, you should

discuss it with the trucking delivery person and contact the transportation company immediately. Make notes

of any damage on the Bill Of Lading. Retain all shipping materials for inspection. Any claims for damage

must start at the receiving point. Check packing slip carefully and make sure all materials have been

received as indicated on the packing ticket. Unless otherwise noted, YOUR ORDER HAS BEEN SHIPPED

COMPLETE.

Chambers and any remote machinery skids or control cabinets should be handled and

transported in an upright position. They must never be carried on their back, front, or any side.

Important! Inspect the circulation fan inside the chamber. The fan is driven by a motor that is mounted in

isolation bushings. Sometimes during shipping, the motor is pushed out of vertical alignment. If this has

occurred, the fan blade will strike the casing. Eliminate the interference by pushing the motor back into

alignment on its rubber mounts. However, be sure that the shipping abuse was not so great that the

extension shaft on the fan has been bent.

Important! Do to the vibration incurred during shipping and handling, it is possible that mechanical

connections could become loose. Check all connections to make sure they are secure.

5.2 Location and Installation of Unit

Your equipment has been fully operated, tested, and balanced in our plant prior to shipment, unless notified

otherwise. Follow the installation requirements below.

♦Chamber Weight: Approximately 260 lbs.

♦Environmental Specifications (For CE European Marked Chambers Only)

Pollution Degree 2, Installation Category III

♦Do not place the unit near combustible materials or hazardous fumes or vapors.

♦Ventilation: The chamber should be installed in an area where there is good air ventilation, especially if

an air-cooled condenser is used. Allow a minimum of 18 inches between any wall and chamber side, or

to any equipment mounted to the chamber side.

♦Do not install unit in a corrosive environment. A corrosive environment may lead to poor performance

and deterioration of unit.

♦Do not position the chamber in a manner that would make it difficult to operate your main power

disconnect switch. See “Power Connection” below.

♦Make sure the chamber is leveled when set up.

5.0 INSTALLATION INSTRUCTIONS

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 11

GN2 Purge System

5.3 Air Supply Connection (For Optional Equipment)

Your chamber will require a compressed air supply for the Dry Air Purge System option. The system is

mounted on the back side of the chamber. The supply should be clean and dry, and range from 80 PSIG

min. to 100 PSIG max. The connection type is ¼” FPT. Make sure the connection is secure. Reference the

corresponding “Option” section in this manual, or your chamber specifications for more details.

Flow Adjustments:

Adjust the flow

adjustment valve at the

supply connection to

maintain 100 PSIG max.

Adjust the flowmeter

metering valve to

approximately 300 cubic

feet per hour.

5.4 GN2 Connection (For Optional Equipment)

Your chamber will require a supply of gaseous nitrogen

for the GN2 Purge System option. The supply may range

up to 100 PSIG maximum. The connection is type 1/8”

NPT. Make sure the connection is secure. Reference the

corresponding “Option” section in this manual and your

chamber specifications for more details.

Flow Adjustment:

Adjust the metering valve to maintain approximately 300

cubic feet per hour.

Vent Port

Checkvalve

Chamber

A

ccess Port

Metering

Valve

GN2 Supply

Connection

1/8” NPT

Warning! Gaseous nitrogen displaces

oxygen. Make sure the area surrounding the

chamber is well ventilated to dilute the gas

vented from the chamber vent port

checkvalve.

Dry Air Purge System

Metering Valve

Flow Adjustment Valve

Twin Tower

Heatless Dryer

Vent Port

Checkvalve

Back Side o

f

Chamber (TJR)

Compressed Air Supply

Connection Input 1/4” FPT

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 12

5.5 LN2 Connection (For Optional Equipment)

Your chamber will require a supply of liquid nitrogen for the LN2 Boost Cooling option. The supply may range

up to 40 PSIG maximum. The connection is type 1/8” NPT. Make sure the connection is secure. Reference

the corresponding “Option” section in this manual and your chamber specifications for more details.

Warning! Gaseous nitrogen resulting from

vaporized LN2 displaces oxygen. Make sure the

area surrounding the chamber is well ventilated to

dilute the gas vented from the chamber vent port

checkvalve!

LN2 Flow Adjustment:

LN2 systems are provided with a manually set flow adjusting

valve, which permits the adjustment of nitrogen flow to avoid

incomplete evaporation at varying LN2 supply pressures. As

the chamber cools to the extreme cold temperature limit,

complete evaporation of liquid nitrogen may not occur if the

supply pressure is allowed to drop. Incomplete evaporation

will cause droplets of liquid to fall to the chamber floor and

cause puddling.

Do not allow liquid nitrogen to contact the door

gasket. Exposure to LN2 will damage the gasket

and violate the seal.

A setting of 4 turns open of the valve generally provides good

performance at a supply pressure of 20 to 25 PSIG. This valve may be readjusted as necessary to

accommodate the supply pressure at the end use point.

Note: Your equipment configuration may be slightly different from what is shown.

5.6 CO2 Connection (For Optional Equipment)

Your chamber will require a supply of liquid carbon dioxide for the CO2 Boost Cooling option. The supply

may range up to 1000 PSIG. The connection is type 1/8” NPT. Make sure the connection is secure.

Reference the corresponding “Option” section in this

manual and your chamber specifications for more details.

Warning! Carbon Dioxide gas displaces

oxygen. Make sure the area surrounding the

chamber is well ventilated to dilute the gas

vented from the chamber vent port checkvalve!

Note: There is no flow adjustment for the CO2 supply. A

fixed orifice on the injection port inside the chamber

regulates the supply.

Note: Your equipment configuration may be slightly

different from what is shown.

CO2 Boost Cooling

CO2 Supply

Connection

Vent Port

Checkvalve

Chamber

A

ccess Port

LN2 Boost Cooling

Chamber

A

ccess Port

Vent Port

Checkvalve

LN2 Supply Connection &

Flow Adjustment Valve

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 13

- 50 HERTZ SUPPLIES -

LINE VOLTAGE MIN. / MAX. TABLE

Nominal

Voltage

Minimum

Voltage

Maximum

Voltage

200 180 220

220 198 242

50 Hz

Supply

Operation outside these

limits can result in damage

to the system's motors.

- 60 HERTZ SUPPLIES -

LINE VOLTAGE MIN. / MAX. TABLE

Nominal

Voltage

Minimum

Voltage

Maximum

Voltage

120 108 127

208 198 218

230 207 253

60 Hz

Supply

Operation outside these

limits can result in damage

to the system's motors.

5.7 Electrical Specifications

18 A, 100 / 120 V, 50 / 60 Hz, 1 PH

Your main power fused disconnect switch should be fused at 20 Amps.

5.8 Power Connection

Warning! Before making the power supply connection to your unit, you must perform the

following procedure:

1. Verify the power supply voltage rating established for your chamber (listed above). The voltage rating

is also found on the serial tag on the side of the oven. Note the rated value here:

2. Measure and record the intended voltage source. Note the measured value here:

3. Reference the “Line Voltage Min/Max Tables” below. Verify that the power supply voltage source you

measured and recorded is within the minimum and maximum allowable operating voltages for your

chamber rating. If it is not within this operating range, do not make the power connection! Otherwise,

erratic operation and damage may occur to your equipment, which may void your warranty. If you have

any questions, please call the Lunaire Service Department.

Important! One of the most common causes of equipment malfunction is low line voltage as the power

source to the unit. Ordinarily in this condition, the heat output would be reduced and the system's motors

would operate erratically, eventually overheat, and shut down. You must be certain that your equipment is

connected to a circuit with an adequate voltage and current source. An oversupply voltage would also cause

erratic operation and eventual shutdown, or damage to your equipment.

For CE European Marked Chambers Only: Chamber Fuse Type and Rating

1FU (Qty. 1) Gould Model GDG1/2 .5 A, 250 VAC Time-Lag

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 14

Making the Power Supply Connection to the Chamber:

A main power disconnect is not provided with your chamber. We recommend that a fused disconnect switch

on a separate branch circuit be installed as the power source to your chamber, in accordance with all

national and local electrical codes. Reference your Electrical, or Power Schematic for all electrical

requirements.

The power connection is made via a cord and plug for standard units. Connect the plug to a receptacle that

has the appropriate power supply on a branch circuit of its own. If the TempGard IV option is included,

refer to the “Alarm and Shutdown Circuit - TempGard IV” section for the connection procedure.

For special units that have the power supply hard-wired to the chamber, connect incoming lines to the main

input connections provided in the control section.

Warning! High Accessible Current – An Earth connection is essential before connecting the

power supply. Make sure equipment is properly grounded in accordance with all codes.

5.9 Application of Power

♦Before energizing any equipment, make a visual inspection for loose components, electrical

connections, fittings, etc. Shut all operating switches to the “OFF” position before energizing.

♦Have trained personnel start and check out the equipment before its first cycle.

Motor Rotation Check: Units with three phase motors must be checked to insure proper motor rotation. A

red arrow is located on the motor housing to show proper rotation. If it is opposite, shut down the oven and

disconnect the main power supply source. Perform Lock-Out / Tag-Out Procedures established by your

company. Reverse two of the line feeds to obtain proper operation. Failure to check motor rotation may result

in DAMAGE TO THE EQUIPMENT due to opposite airflow, or no airflow.

5.10 Operating With an Active Heat Load

Note: This feature is only available with the TempGard IV option.

When operating with an active heat load, such as introduced by a powered test unit, this heat must be

removed or the chamber temperature will rise. The internal logic of the controller will automatically turn on

the refrigeration system to maintain a set temperature. Although a cooling system failure is not likely to

occur, it is always a possibility when mechanical systems are used. In the event of a cooling system failure

that results in an out of limit over temperature condition, one or more of the system safeties will remove

power from the system. However, heating will continue if power remains applied to the active load. To guard

against this continued heating, the product should be powered through the spare contacts of the Master

Contactor (CON) from the TempGard IV circuitry. This is described in the Alarm And Shutdown Circuit

section.

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 15

Temperature Sensor -

TUJR Location

Tenney Junior Test Chambers are provided with an efficient airflow system that maintains maximum

temperature uniformity.

Chamber air is conditioned in the ceiling plenum where the circulation fan, heater elements, and refrigeration

coil are located. A propeller type fan driven by an externally mounted motor generates airflow. The plenum

cover prevents direct heat radiation to the workspace.

Process air is drawn up into the left side of the plenum. It flows through the heater elements and the

refrigeration coil and is discharged by the fan down into the workspace. The cycle repeats. A 100 ohm

Platinum RTD sensor mounted below the fan measures discharge air temperature.

6.0

A

IR CIRCUL

A

TION SYSTEM

Air Circulation

Air

C

ir

cu

l

a

ti

o

n

Circulation Fan & Guard

Heaters &

Refrigeration

Coil

Plenum

Conditioning Section

Heating

Elements

Refrigeration

Cooling Coil

Fan Blade

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 16

7.1 Controller Features

Temperature conditions are controlled with the standard profiling type Watlow 942 Controller. The alternate

Watlow F4 Controller may be used for more demanding applications. Both controllers are described below.

Watlow 942 Controller:

The Watlow 942 is a profiling type ¼ DIN controller with ramping and auto-tuning control. The following main

features are employed.

♦Single Channel

♦Profiling: Multiple Profiles, 24 Steps Max.

♦Automatic & Manual Control

♦1 Input: Universal Type (RTD is Std.)

♦2 Control Outputs: Time Proportioned, or On / Off Control

♦2 Auxiliary Outputs - Optional: 1 or 2 Events, or 1 or 2 Alarms, or 1Retransmit w/Alarm, or w/Event

♦Guaranteed Soak - Standard

♦Communications: Serial - Optional

Watlow F4S Controller:

The Watlow F4S is a profiling type ¼ DIN controller with ramping and auto-tuning control. The following main

features are employed.

♦Single Channel

♦Profiling: Forty Profiles, 256 Steps

♦Automatic & Manual Control

♦1 Input: Universal Type (RTD is Std.)

♦4 Digital Inputs

♦2 Auxiliary Analog Inputs - Optional

♦2 Control Outputs: Time Proportioned, On/Off, or 4-20 ma

♦2 Alarm Outputs

♦8 Digital Event Outputs

♦2 Retransmit Outputs - Optional

♦Communications: EIA-232 and EIA-485 with Modbus RTU protocol

7.0 TEMPERATURE CONTROL

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 17

DATA COMMUNICATIONS - WATLOW 942

As an option, your chamber may include data communications with the main controller's serial port. When

employed, a Data Communications manual will be included in the Supplemental Instructions Section. As a

reference, the available data types are listed and briefly described below.

RS232C / RS423A: Both interfaces are compatible and use 3 wires: a single transmit wire; a single receive

wire; and a common line. The maximum wire length is 50 feet. Only a single chamber may be connected to

your computer. Data signals are measured as plus and minus 12 Volts to common with RS232C, and plus

and minus 5 Volts to common with RS423A.

RS422A: This interface uses 5 wires: a transmit pair; a receive pair; and a common line. Up to ten

chambers may be connected to your computer on a multi-drop network up to 4,000 feet long. Data signals in

each pair are measured as a plus or minus 5 Volt differential.

EIA-485: This interface uses only 2 wires. Both wires are used for transmitting and receiving data, and

therefore, only one device may talk at a time. Up to 10 chambers may be connected to your computer on a

multi-drop network up to 4,000 feet long. Data signals are measured as a plus or minus 5 Volt differential. An

EIA-485 card must be installed for signal conversion.

IEEE-488: This is a parallel multi-drop interface with several control and data lines. Each device connected

must be set to a unique address. Data from other test devices may also be collected. An IEEE-488 to serial

converter card must be installed. Maximum cable length is approx. 33 ft.

DATA COMMUNICATIONS - WATLOW F4

Data communications utilizes EIA-232 and EIA-485 serial interface with Modbus RTU protocol. Modbus RTU

enables a computer or PLC to read and write directly to registers containing the controller's parameters.

These data interface types are briefly described below.

Controller Configuration:

The pre-programmed controller configuration for your chamber is documented in the Test Report, which is

located in the Supplemental Instructions Section. Refer to the controller’s user manual for more information.

Important! The configuration set-up is mainly provided for your reference. Not all of the parameters shown

apply to your chamber. Changes to some of the set-up parameters may drastically affect your chamber

performance and void your warranty. Contact the Lunaire Service Dept. before attempting any changes.

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 18

7.2 Watlow 942 Control Functions:

The Main Power switch 1SS must be turned ON to enable the conditioning control circuitry. 1SS will also turn

on the chamber conditioner fan.

The following descriptions detail the functions of the various outputs. Event outputs (user entered) are

provided mainly for special applications. These features are normally described in the “Options” section of

the manual.

- HEAT CONTROL -

1C - 01 - - This time proportioned output will trigger triac 1TRC to conduct and provide power to the electric

heaters.

- COOLING CONTROL -

1C - 02 - - This On/Off output will trigger triac 2TRC to conduct and energize the refrigeration system. The

high stage compressor will immediately start. The low stage compressor will start after a slight

delay from the Low Pressure Cut-In Switch PS2.

- EVENT OUTPUTS - (Optional)

1C - 03 - - This is Event No. 1, which serves as a compressor shutoff when going from a very low to a vary

high setpoint. In this scenario, any cycling of the compressors is not desired, and a heat

overshoot is tolerated. 1C-03 contacts are normally closed. They will open when the event is

turned ON to disable the Cooling Control Output.

For Model XXXX, SN xxxxx Only:

Event No. X - - Output 1C-0x:

WATLOW 942 COMPRESSOR TURN-ON LOGIC

In determining when to turn the refrigeration system On or Off, the controller’s logic will compare the

following signals and setpoints.

1. Actual Chamber Temperature 3. Hysteresis

2. Setpoint Temperature 4. Deadband

Hysteresis (HYS) and deadband (db) are parameters entered at the factory. Hysteresis is the temperature

change necessary to change the output from full ON to full OFF, and is detailed in the Setup Menu section in

the Watlow 942 Manual. Deadband is the span in which Output 1C-02 will remain ON below the controller’s

low setpoint, and is detailed in the Operation Menu section of the Watlow Manual. HYS and db are entered

in degrees Celsius. Deadband is always entered as a (-) minus. The logic is:

♦Measured temperature rises above setpoint: Refrigeration turn-on = hysteresis minus deadband.

♦Measured temperature falls below setpoint: Turn-on is always above setpoint.

♦Turn-off is always below setpoint: Turn-on is always above setpoint.

Example Settings For HYS and db: See Next Page

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 19

Example Settings For HYS And db

HYS db Turn-On (Above SP) Turn-Off (Below SP)

Standard 4 -3 1 3

5-3 2 3

5-1 4 1

No Good 3 0 3 0

Chambers are shipped with HYS = 4, and db = - 3, as shown on the top line in the above examples. It is

unlikely a change to these settings will be required. Fortunately, these settings are not subject to “cold start”

default, and will remain valid after a power interruption. They are held in EEROM, not battery-backed RAM.

7.3 Watlow F4 Control Functions (Alternate Controller): The Main Power switch 1SS must be turned

ON to enable the conditioning control circuitry. 1SS will also turn on the chamber conditioner fan.

- HEAT CONTROL -

Output 1A - - This time proportioned output will trigger triac 1TRC to conduct and provide power to the

electric heaters.

- COOLING CONTROL -

Dig. Out #8 - - This digital On/Off output will energize solid state relay SSRxand a control relay, which

triggers triac 2TRC to conduct and provide power to the entire refrigeration system. The

high stage compressor will immediately start. The low stage compressor will start after a

slight delay from the Low Pressure Cut-In Switch PS2.

Note: Digital Output No. 8 serves as a Compressor Control output, which can save wear

on a compressor and prevent it from locking up from short cycling. Compressor On %

Power sets the power level that will switch this output (compressor & control circuitry) on.

Compressor Off % Power sets the power level that will switch the compressor off.

The compressor(s) will not turn on until the output power exceeds the Compressor On %

Power for a time longer than the Compressor On Delay. The compressor will not turn off

until the output power exceeds the Compressor Off % Power for a time longer than the

Compressor Off Delay.

To Clear an Alarm or Error:

In an alarm condition, an alarm message will appear on the Main Page (if this option has been selected on

the Setup Page). To silence it, move the cursor to the alarm message and press the Right Key >. A pop-up

message will confirm the silencing of the alarm, and the indicator light will go off.

When the condition causing the error or alarm is corrected, return to the error or alarm message on the Main

Page, and press the Right Key again. A pop-up message confirms the alarm is unlatched.

Cascade Temperature Control (Optional):

Note: Tenney chambers are set up to run in the “No Cascade” mode because of the many variations in

customer products that require special tuning with this option.

TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4 Page 20

Heating of the chamber is accomplished with the use of open air low mass nichrome wire heating elements.

These elements have low thermal lag and provide rapid response to the controller's demands. The elements

are mounted in the plenum conditioning section. This isolates them from the workspace and prevents direct

radiation to the product. The heater bank is rated 500 Watts, consisting of two 250 Watt elements.

Heater Control:

The heaters are controlled by a time proportioned output from the main controller. This output triggers a triac

to conduct and provide power to the elements.

Note: The Boost Heat option may be provided to increase the rate of heating. Reference the “Boost Heat”

option section for details.

9.1 Overview

A thermal cutoff (labeled as Heat Limiter HL) is provided to protect the chamber against overtemperature

conditions. This is an axial leaded one-shot protection device, which is connected in-line with the mains

power supply Neutral Line, directly to the heater rack. The thermal cutoff will permanently open and remove

power from the heater elements when the surrounding air temperature reaches 240°C. Once the thermal

cutoff opens, it must be replaced.

Note: The thermal cutoff is not used when the Boost Heat option is employed. This option uses a Watlow

147 Limit Controller for overtemperature protection. Reference the “Boost Heat” option section for details.

8.0 HEATING DESCRIPTION

Heater Element Rack

Thermal Cutoff is installed

in the Neutral Line, and is

wrapped in glass cloth

electrical tape.

9.0 CHAMBER OVERTEMPERATURE PROTECTION

Thermal Cutoff

This manual suits for next models

2

Table of contents

Popular Laboratory Equipment manuals by other brands

Fluke

Fluke 2031A user guide

Labconco

Labconco Purifier Class 2 Biological Safety Cabinet Operation manual

cytiva

cytiva 420100 Instructions for use

YOKOGAWA

YOKOGAWA FF20 instruction manual

Kinematics

Kinematics 4400/VC operating instructions

Thermo Scientific

Thermo Scientific Applied Biosystems GeneChip 645 user guide

Integra

Integra PIPETBOY acu 2 operating instructions

Helmer

Helmer QuickThaw DH2 Operation manual

Waters

Waters Xevo TQ-S Operator's, overview and maintenance guide

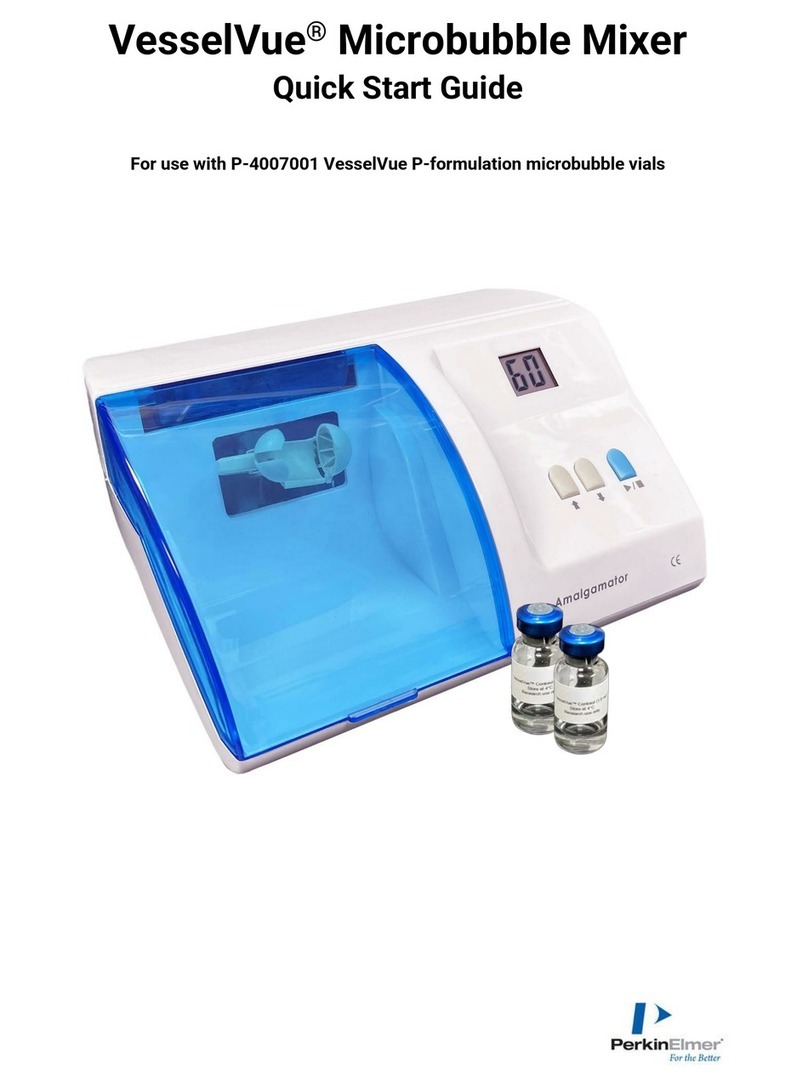

PerkinElmer

PerkinElmer VesselVue quick start guide

YIC Technologies

YIC Technologies EMS8000 user manual

Aqua Medic

Aqua Medic Helix Max 11 W Operation manual