Tense DT-96 User manual

TENSE Elektronik

1

DT-96 / DT-72 / DT-48

AUTO-TUNE PID TEMPERATURE CONTROLLER

General Specification:

µP based, PID temperature controller with OUT and ALARM outputs

Auto-tuning for PID parameters

Sensor type: T/C (J,K,T,S,R), Pt100, selectable, multi-input

Selectable control type: P, PI, PD, PID or ON-OFF

Automatic “Overshoot” elimination in PID mode

“Anti-windup”

Upper and Lower limit for SET and ALARM settings

Selectable relative, absolute or band alarm

ON-delay for OUT in cooling mode

Displays SET and PROCESS values

Cold-junction compensation for T/C

Line compensation for Pt100

Excellent linearity with oC/mV and oC/look-up tables

Input “Offset” feature

Password protection

High accuracy

EEPROM memory to store settings

Optional SSR output

Easy connection with plug-in connectors

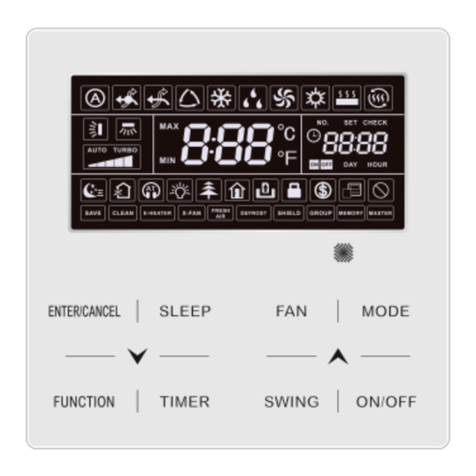

CONNECTION

no: normally open

nc: normally closed

Warning: if 2 wire Pt100 is used, connect

compansation lead to measuring lead

(DT-96: 17-18,DT-72: 13-14,

DT-48: 10-11)

1

2

310

411

512

6

7

Out

Alarm

no

nc

+

100 ... 240VAC

50/60Hz 6VA

Out & Alarm;

250V max.2A

resistive load

AC

T/C

Pt100

Out & Alarm;

250VAC

max. 2A

resistive load

17

18

19

T/C

Pt100

3

4

5

8

6

9

7

10

Out

Alarm

no

no

nc

nc

100 ... 240VAC

50/60Hz 6VA

13

14

15 T/C

Pt100

+

Out & Alarm:

250V max.2A

resistive load

AC

3

4

5

8

6

9

7

10

Out

Alarm

no

no

nc

nc

100 ... 240VAC

50/60Hz 6VA

TENSE Elektronik

2

TECHNICAL SPECIFICATION

Dimensions : DT-96:96x96, DT-72:72x72, DT-48:48x48mm

Display : 4 Digits 7 Segment (PV), 4 digits 7 Segment (SV)

Sensor Type : J,K,T,S,R type T/C, Pt100 selectable

Measuring Scale : -100 .. 600 oC, J type T/C, (Inpt=J)

-100 .. 1300 oC, K type T/C, (Inpt=k)

-100 .. 400 oC, T type T/C, (Inpt=t)

0 .. 1750 oC, S type T/C, (Inpt=S)

0 .. 1750 oC, R type T/C, (Inpt=r)

-100 .. 600 oC, Pt100, (Inpt=Pt)

-99.9 .. 600.0 oC, Pt100, (Inpt=Pt.0)

Resolution : ± 1 oC or ± 0.1 oC

Accuracy : ±% 0.3 (Over full scale)

Control Form : ON-OFF or P,PI,PD,PID - selectable

OUT Output : Relay (NO + NC), 250VAC, 2A, Resistive load, (optional SSR)

Alarm Output : Relay (NO + NC), 250VAC, 2A, Resistive load, (only NO for DT48)

Heat SET : Lower Limit .. Upper Limit oC (H.Set)

Alarm SET : AL.tY = Abs,-Abs; Lo.L .. UP.L oC (A.Set)

AL.tY = rel, -rel, bnd, -bnd, bn.i, -bn.i; -100 .. +100 / -10.0 .. +10.0 (Pt.0)

Heat Hysteresis : 0 .. 50 / 0.0 .. 5.0 oC (H.Hys); PID is active if set to 0

Alarm Hysteresis : 1 .. 50 / 0.1 .. 5.0 oC (A.Hys)

Proportional Band : 1 .. 130 oC (Pb.C)

Integral Time : 0 .. 30,0 min. (OFF if set to 0)

Derivative Time : 0.. 10,0 min. (OFF if set to 0)

Control Period : 4 .. 200 sec. (Ct)

Offset : -100..+100 oC / -10.0 .. +10.0 (oFFS)

Heating/Cooling : selectable (only ON-OFF control form is active for cooling)

Cold. Junc. Comp. : 0 .. 50 oC (T/C)

Line Comp. : 10 Ohm max. (3 wire Pt100)

Operation Temp. : 0 .. 50 oC

Supply Voltage : 230VAC +10%, -20%, 50 - 60Hz

Power Consumption : < 8VA

Altitude : < 2000 m

Failure : ALARM output is always OFF, OUT output is active according to P.Err and

Ct parameters in case of sensor failure, measurement out of range or

hardware fails to measure input signal (OUT output is OFF if Perr is 0)

Error Message:

FAIL : Displays “FAiL” message in case of sensor failure,measurement out

of range or hardware fails to measure input signal.

Err : Hardware failure.

Warning:

Use shielded and twisted signal cables and connect shield to ground on device side. Use

correct compensation cables for T/C sensors. Connect T/C cable directly to the device

connectors. Keep all signal cables away from contactors, devices/cables emitting electrical

noise, power cables.

Keep device away from contactors, devices/cables emitting electrical noise, power cables.

Take precautions agains environmental conditions like humidity, vibration, pollution and

high/low temperature during installation.

Use fuse (F250mA 250VAC) on mains/supply input of the device. Use appropriate cables

for mains connections. Apply safety regulations during installation.

TENSE Elektronik

3

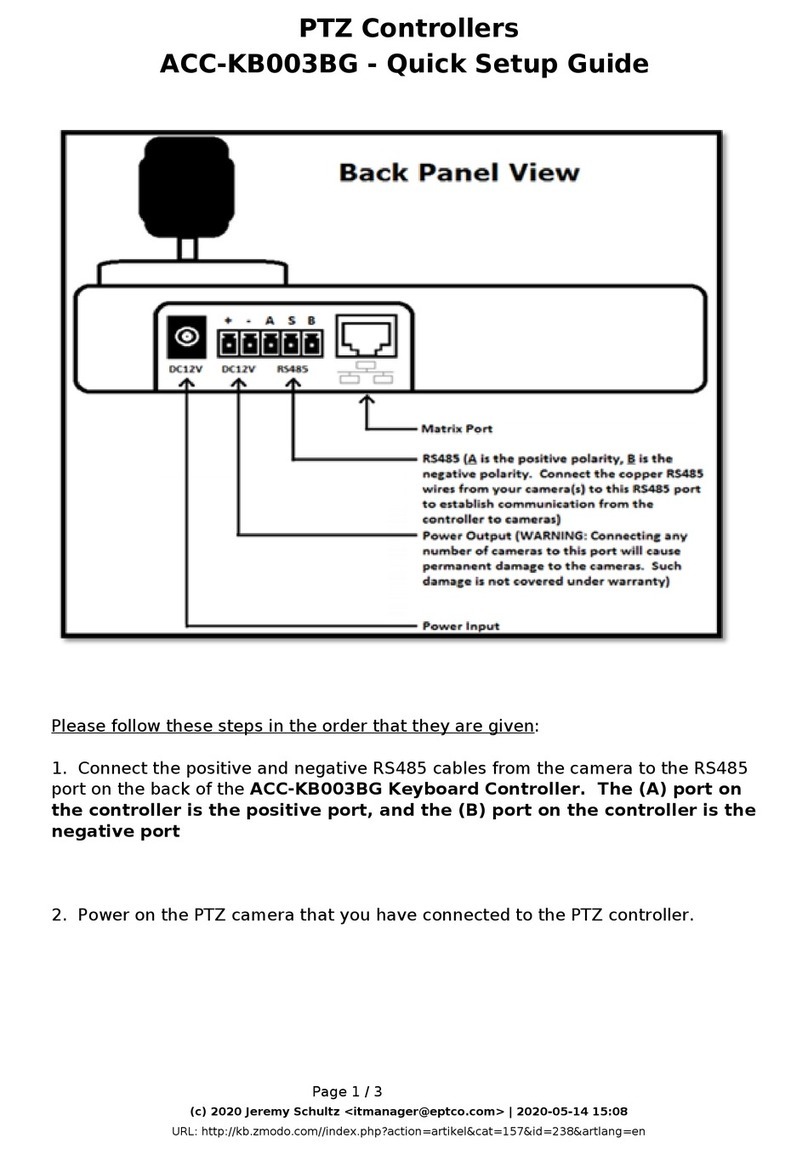

Programming Parameters:

SETSET

H.hys /

C.hys 0..50 /

0.0 .. 5.0oC (3)

End Prog.

SETSET

Heat/Cool Hysteresis (oC):

PID is active if set to 0

(for H.Hys) (oC)

A.hys 1..50 /

0.0 .. 5.0oC (3)

SETSET

Pb.C 10..130 oC

SETSET

Ct 4..200 sec

SETSET

oFFS -100 .. +100 /

-10.0 .. +10.0 oC (3)

SETSET

td 0..10.0 min

SETSET

+

CodE Enter 162

SETSET

UP.L Lo.L ..

Upper Scale (oC)

SETSET

Upper limit value for Lo.L,

H.SET and A.SET. Upper Scale value

differs according to the selected

sensor type.

AL.tY

SETSET

r.ALr/

b.ALr -100 .. +100 /

-10.0 .. +10.0 oC (3)

SETSET

ti 0..30.0 min

SETSET

AL.tY=

Abs,-Abs

Inpt Sensor Type (1)

SETSET

J: J type T/C

K: K type T/C

t: T type T/C

S: S type T/C

r: R type T/C

Pt: Pt100

Pt.0: 0.1oC resolution Pt100

h-C Select

function (2)

SETSET

HeAt: heating function

Cool: cooling function

Lo.L Lower Scale ..

UP.L (oC)

SETSET

Lower limit value for UP.L,

H.SET and A.SET. Lower Scale value

differs according to the selected

sensor type.

P.Err % 0..100

SETSET

Determines the duty cycle of OUT output

when “Fail” message is displayed. If 0, OUT is always

OFF. If 100, OUT is always ON, when device “fails”.

Period is Ct.

C.Hys/

H.Hys

not 0

(1) When sensor type is changed, Up.L, Lo.L, H.Set or A.Set may be set to a new value

automatically, if any of them violates measuring scale of the selected sensor.

(2) ON-OFF control is the only option for Cooling function

(3) If sensor type is selected as Pt.0.

Back

Press “Back”

to return to the

top of

parameters

programming

block

Integral Time:

In minutes. If set to 0,

P, PD is active (integral OFF).

Derivative Time:

In minutes. If set to 0,

P, PI is active (derivative OFF).

Alarm Hysteresis (oC)

Proportional Band in (oC)

Control period (sec)

Offset Value; Offset is directly added

to the measured value. This feature shall

be used for user calibration. Normally set to 0.

Enter 162 to pass

to parameter prog. mode

Relative or band Alarm

Value. Displayed if AL.ty is

other then Abs or –Abs.

Press for 2 sec.

Upper Display

C.dLY 0..30 sec

SETSET

Active only in cooling mode.

Minimum delay before OUT

becomes ON after it becomes OFF.

Abs,rel,bnd,bn.i

-Abs,-rel,

-bnd,-bn.i

Alarm Type:

Abs: Absolute -Abs: Absoloute, invert out

rel: Relative -rel: Relative, invert out

bnd: band -bnd: band, invert out

bn.i: band inhibit -bn.i: band, invert out

h-C=

heat

CodE Enter 262

to start

auto-tune

SETSET

Upper Display

“tunE”

flashes

•Before starting Auto-tune, adjust H.SET.

•Auto-tune does not start in “cooling” mode.

•Process value may exceed H.Set during auto-tuning.

•After auto-tuning, control form automatically switches

to PID mode.

•Auto-tuning is stopped (interrupted) any time by

pressing any key. In this case, the parameters before

auto-tuning is valid.

•Auto-tuning may not always determine the best values

for your process.

Factory SET Values:

H.SEt: 100 oC

A.SEt: 400 oC

Inpt : J

H-C : Heat

H.hys: 3 oC

A.hys: 3 oC

Pb.C: 30 oC

Ct: 4 sec

ti: 5.0 min

td: 1.0 min

UP.L: 400 oC

Lo.L: 0 oC

oFFS: 0 oC

AL.tY : rel

r.ALr: 3 oC

C.dLY: 15 sec

P.Err: 0

TENSE Elektronik

4

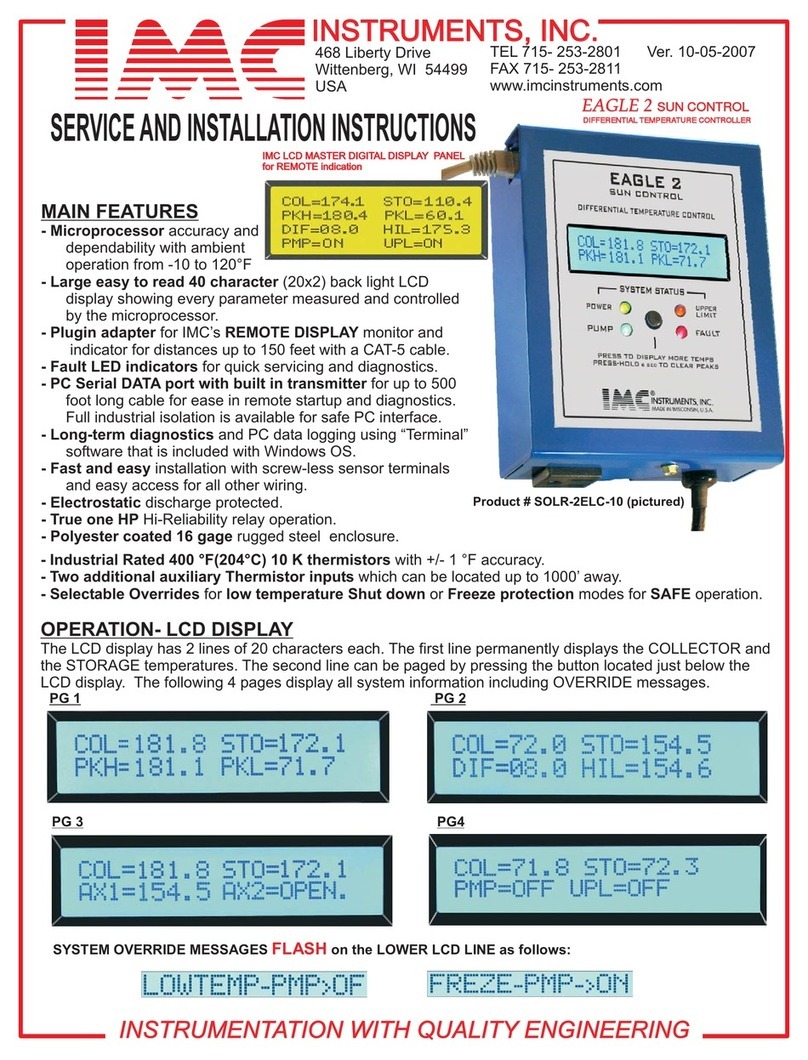

Programming Heat SET ve Absolute Alarm SET:

Press 2 sec. SETSET

H.SEt Lo.L .. UP.L oC

Prog. end

Upper Display

SETSET A.SEt Lo.L .. UP.LoC

SETSET

Heat SET;

(Process SET)

value is

set Lo.L .. UP.L

Displayed if Ab.AL=Yes;

Absolute Alarm SET

Value is set Lo.L .. UP.L

AL.tY

= rel, -rel

bnd, -bnd

bn.i, -bn.i

ALARM Output:

PV

ALARM AL.tY= -Abs, -rel

AL.tY = Abs, -Abs; X = A.SEt

AL.tY = rel, -rel ; X = H.SEt + r.ALr

X(X+A.hys)

PV

ALARM AL.tY=Abs, rel

X

(X-A.hys)

ONON

C

PV

A = H.Set-b.Alr, B = H.SET-b.Alr+A.hys, C = H.SEt+b.Alr-A.hYS, D = H.SET+b.Alr

DBA

ON

C

PV

DBA

ON

AL.tY= bnd, bn.i (*) AL.tY= -bnd (**)

ON

H.SEt H.SEt

ALARM ALARM

(*) AL.tY = bn.i is same as bnd except that if AL.tY = bn.i, ALARM is never ON before PV is in band.

(**) AL.tY = -bn.i is always same as -bnd.

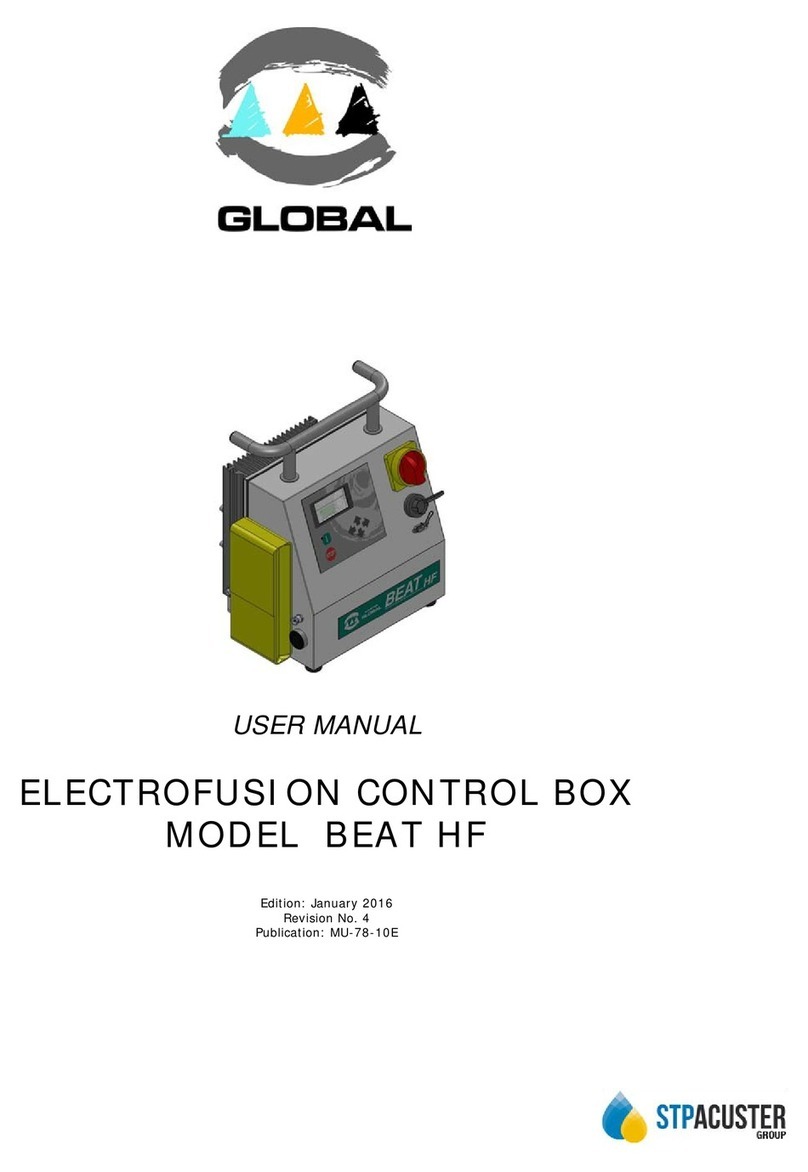

OUT output (ON-OFF Control):

ON-OFF is active when “H.Hys” is other then 0

H.SET(H.SET-H.Hys) PV

OUT

H.SET (H.SET+C.Hys)

HeatingCooling

PID Parameters:

P,PI,PD,PID is active when “H.Hys” is set to 0 (only for heating; h-C is set to ”HEAt”)

PbC: Proportional band in oC

Ct: Control period for PID control. Prefer 4-10 sec.

Ti: Integral time; Set in minutes. Determines how fast controller reacts to compansate the

offset between SET point and the process value. If set to 0, integral part is OFF. If set too

low, process value may oscillate.

Td: Derivative time; Set in minutes. If set to 0, derivative part is OFF. Determines how

sensitive the controller is to changes of the offset between SET point and the process value.

If set too high, process value may oscillate or overshoot.

This manual suits for next models

2

Other Tense Controllers manuals