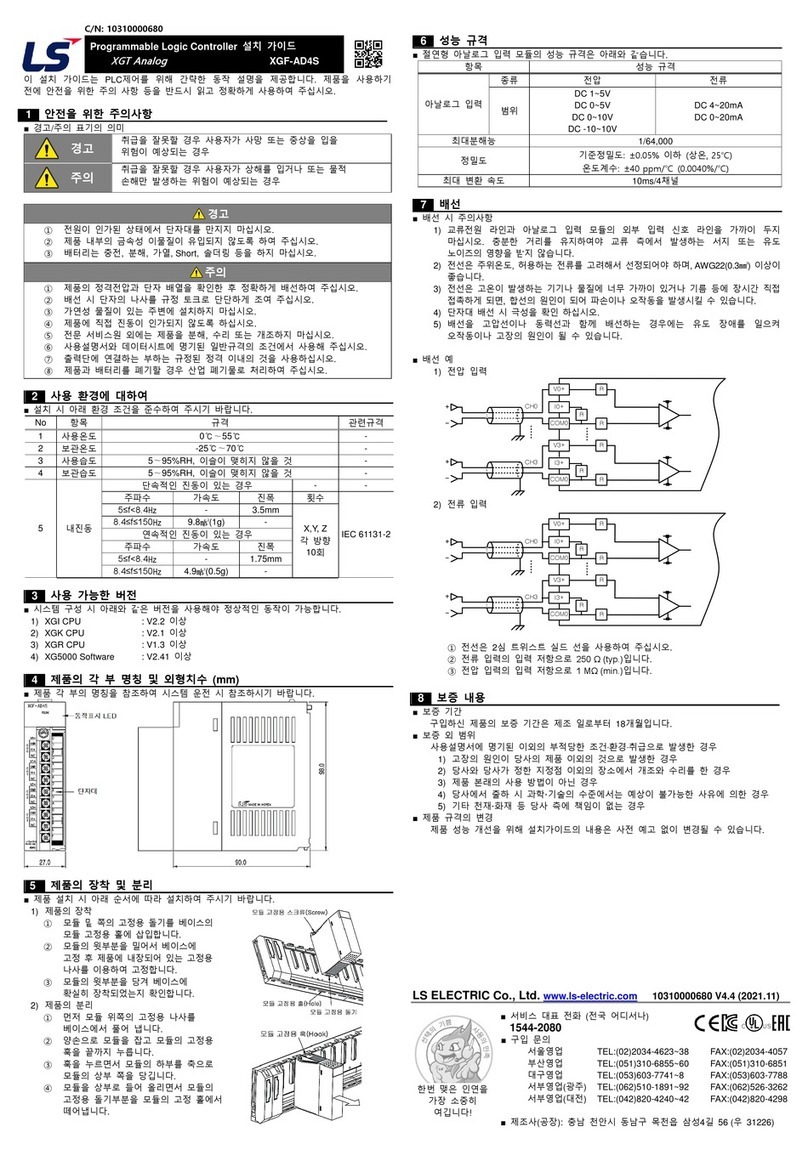

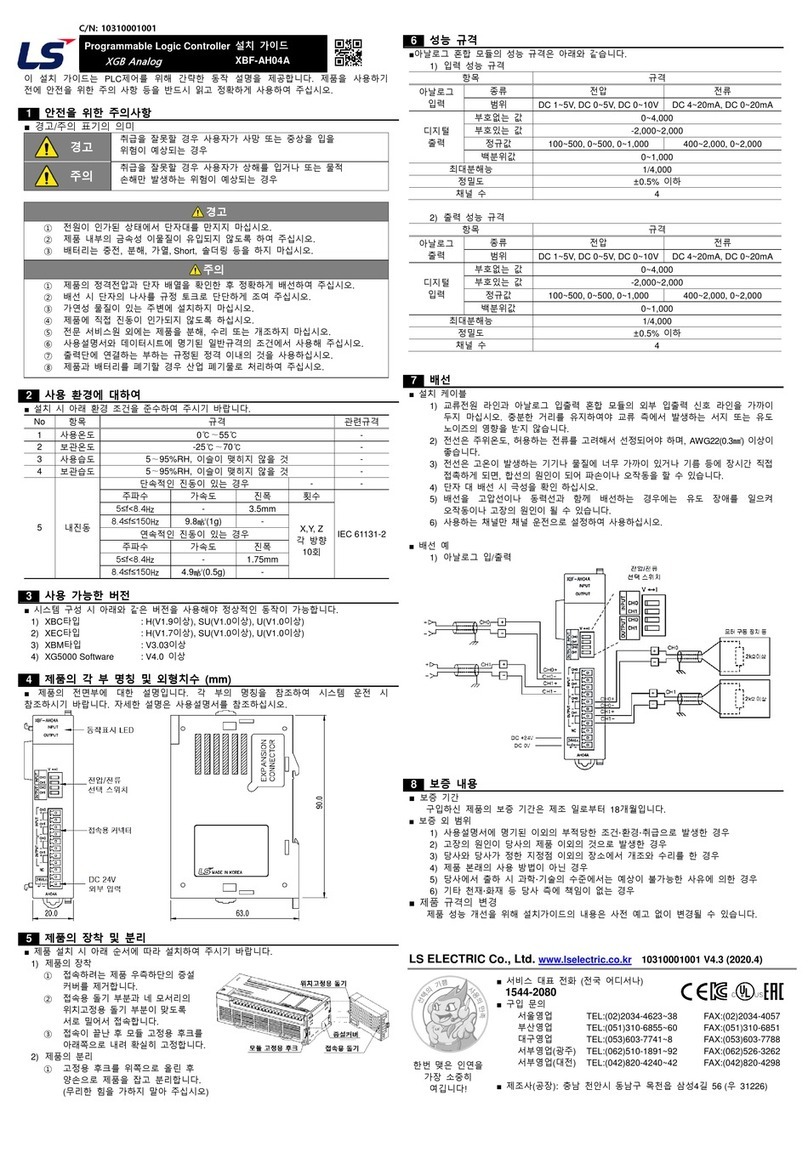

Programmable Logic Controller Installation Guide

XGF-TC4S

This installation guide provides simple functioninformation of PLC control. Please readcarefully

this data sheet and manuals before using products. Especially read safety precautions and

handle the products properly.

■ Meaning of warning and caution inscription

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

①Do not contact the terminals while the power is applied.

②Protect the product from being gone into by foreign metallic matter.

③Do not manipulate the battery(charge, disassemble, hitting, short, soldering).

①Be sure to check the rated voltage and terminal arrangement before wiring.

②When wiring, tighten the screw of terminal block with the specified torque range.

③Do not install the flammable things on surroundings.

④Do not use the PLC in the environment of direct vibration.

⑤Except expert service staff, do not disassemble or fix or modify the product.

⑥Use the PLC in an environment that meets the general specifications contained

in this datasheet.

⑦Be sure that external load does not exceed the rating of output module.

⑧When disposing of PLC and battery, treat it as industrial waste.

To install, observe the below conditions.

5 ~ 95%RH, non-condensing

5 ~ 95%RH, non-condensing

10 times in

each

direction

for

X, Y, Z

■ For system configuration, the following version is necessary.

1) XGI CPU : V2.2 or above

2) XGK CPU : V2.1 or above

3) XGR CPU : V1.3 or above

4) XG5000 Software : V2.41 or above

This is front part ofthe CPU. Refer to each name when driving the system.For more information,

refer to user manual.

■ Here describes the method to attach each product to the base or remove it.

1) Attachment of product

①Slide the upper part of module to fix

to the base, and then fit it to the base

byusing the module fixed screw.

②Pull the upper part of module to check

if it is installed to the base completely.

2) Detachment of product

①Loosen the fixed screws of the upper

part of module from the base.

②Hold the module by both hands and press

the fixed hook of module thoroughly.

③Bypressing the hook, pull the upper

part of module from the axis of the lower

part of module.

④By lifting the module upward, remove

the fixed projection of module from the fixing hole.

Performance Specifications

■Performance specifications are as follows.

Range of input

temperature

±0.1%

(allowable for some section up to 1% of

measurable temperature range by sensors)

Temperature coefficient

(range of operating

temp)

Cold junction

compensation

Automatic compensation by RJC sensing (PT100)

■ Installation of cable

1) Don’t let AC power line near to module’s signal line. With an enough distance kept

away between, it will be free from surge or inductive noise.

2) Don’t let the cable too close to hot device and material or in direct contact with oil for

long, which will cause damage or abnormal operation due to short-circuit.

3) Check the polarity when wiring the terminal.

4) Wiring with high-voltage line or power line may produce inductive hindrance causing

abnormal operation or defect.

5) It is available 9 kinds of thermocouple sensor

(K / J / E / T / B / R / S / N / C)

■ Wiring Example

■ Warranty period

18 months after the production date.

■ Scope of Warranty

18-month warranty is available except:

1) The troubles caused by improper condition, environment or treatment except the

instructions of LS ELECTRIC.

2) The troubles caused by external devices

3) The troubles caused by remodeling or repairing based on the user’s own discretion.

4) The troubles caused by improper usage of the product

5) The troubles caused by thereason which exceeded the expectation from science and

technology level when LS ELECTIC manufactured the product

6) The troubles caused by natural disaster

■ Change in specifications

Product specifications are subject to change without notice due to continuous product

development and improvement.

LS ELECTRIC Co., Ltd. www.lselectric.co.kr 1031000696 V4.3 (2020.3)

Headquarter/Seoul Office

Tel: 82-2-2034-4033,4888,4703

LS ELECTRIC Shanghai Office (China)

LS ELECTRIC (Wuxi) Co., Ltd. (Wuxi, China)

LS-ELECTRIC Vietnam Co., Ltd. (Hanoi, Vietnam)

LS ELECTRIC Middle East FZE (Dubai, U.A.E.)

LS ELECTRIC Europe B.V. (Hoofddorf, Netherlands)

LS ELECTRIC Japan Co., Ltd. (Tokyo, Japan)

LS ELECTRIC America Inc. (Chicago, USA)

Factory: 56, Samseong 4-gil, Mokcheon-eup, Dongnam-gu, Cheonan-si, Chungcheongnam-

do, 31226, Korea

Parts Name and Dimension (mm)