April 2017

8 GTH-1256 Part No. 57.0009.0662

First Edition - Second Printing

Work Area Safety

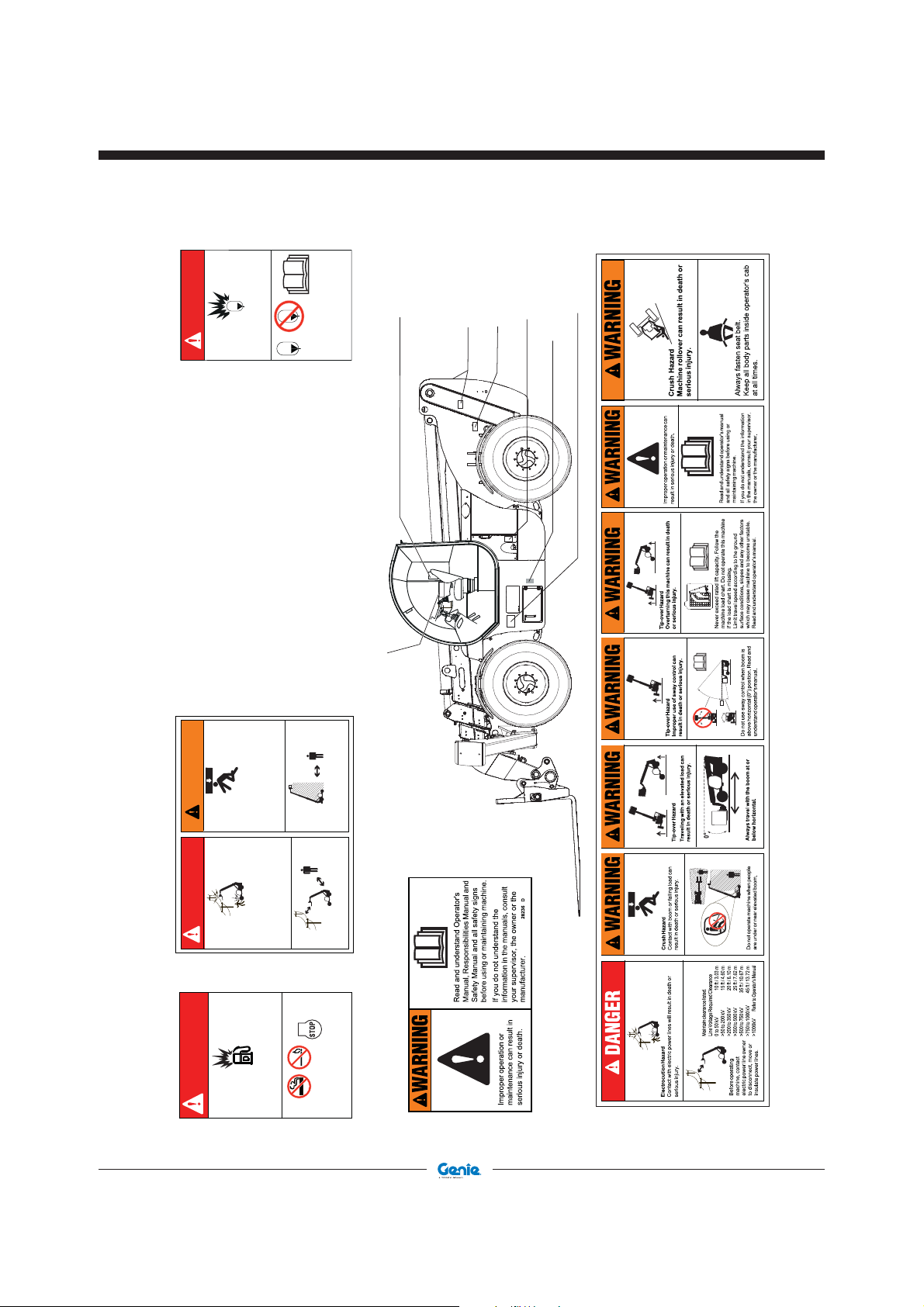

Overturning Hazards

Using the load chart, confirm that

the load is within the rated capacity

of the machine. Do not exceed the

rated load.

The load center of the fork (if equipped) must be

equal to or less than the load center indicated on

the load chart.

All loads shown on the load chart are based on

the machine being on firm ground, the frame being

level, the forks being positioned evenly on the

carriage, the load being centered on the forks, the

tires being properly sized and properly inflated, and

the telehandler being in good operating condition.

If using accessories, read, understand and obey the

decals, instructions and manuals with the accessory.

Do not raise the load unless the ground can support

all forces imposed by the machine.

Do not lower a load without retracting the boom first.

Do not operate the machine if the load chart is missing.

Do not exceed the rated capacity for each

configuration.

Do not raise the boom unless the

machine is level. The machine level

indicator should be at zero degrees.

Do not level the machine using the frame sway

control unless the boom angle indicator is at zero

degrees or less.

Do not use the sway control to position

an elevated load.

Do not raise a load and then drive to position it.

When driving, keep the boom at

or below horizontal and keep the

load close to the ground.

Operate the machine at speeds that will keep the

load under control. Start and stop movements

smoothly.

Do not raise a load unless the load

is properly positioned or secured on

the forks or approved attachment.

Do not operate the machine in strong or gusty winds.

Do not increase the surface area of the carriage or

load. Increasing the area exposed to the wind will

decrease machine stability.

Use extreme care and slow speeds while driving the

machine in the travel position across uneven terrain,

debris, unstable or slippery surfaces and near holes

and drop-offs.

Do not alter or disable machine components that in

any way affect safety and stability.

Do not replace items critical to machine stability with

items of different weight or specification.

Do not replace factory-installed tires with tires of

different specification or ply rating.

If using accessories, read, understand and obey the

decals, instructions and manuals with the accessory.

Lateral inclination allowed during working

phase ± 0,5°