Terumo T-SEAL III User manual

T-SEAL®III

Terumo Tube Sealing Device

Version 1.0

Operator’s Manual

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 1of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

T-SEAL III

Terumo Tube Sealing Device

Operator’s Manual

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 2of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

1. Warnings and Cautions 3

2. Scope 4

Introduction 4

Performance and Specifications 4

2.1 Symbols/Markings Description 9

3. Installation 10

Unpacking and Inspection 10

Environmental Requirements 10

3.1 Installation Procedure 10

Stand-Alone Setup 10

Cascade Setup 10

4. Functional Description 11

4.1 Description of Sealing 11

5. Operating Instructions 11

5.1 Preparation Before Use 12

5.2 How to Seal Tubes 12

6. Cleaning 12

6.1 Sealing Head 13

7. Troubleshooting 13

7.1 Sealer 13

8. Warranty and Service 14

8.1 Warranty 14

8.2 Service 14

8.3 Product Disposal 15

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 3of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

1. Warnings and Cautions

The general safety information in the Operator’s Manual is for operating personnel. Specific notes, cautions, and

warnings are found throughout this document where applicable. Please read the Operator’s Manual carefully before

using this device.

Note! Identifies conditions that should be noted carefully.

Caution! Identifies conditions that could result in damage to the device.

Warning! Identifies conditions that could result in personal injury or loss of life.

Warning! T-SEAL III must be used in compliance with all specifications and operational procedures listed in the

Operator’s Manual.

Warning! T-SEAL III must be used under the control of trained personnel.

Warning! Follow the Operator’s Manual while operating T-SEAL III.

Warning! Cables and accessories other than those specified may result in increased emission or decreased

immunity of the equipment or system. Only accessories designed for use with T-SEAL III should be

used.

Warning! The device should not be used adjacent to or stacked with other equipment. If adjacent or stacked use

is necessary, verify normal operation of the device in the configuration in which it will be used.

Warning! If any of the components of T-SEAL III are exposed to blood, they must be cleaned with an

appropriate disinfectant solution.

Warning! The device must always be connected to a grounded outlet and with an appropriate alternating current

mains source, 100 or 240 V ~.

Warning! The device emits RF energy during the sealing procedure and movement of the electrode.

Warning! T-SEAL III is not intended for use in an oxygen-rich environment.

Warning! T-SEAL III is not intended to be used with flammable anesthetics or in conjunction with flammable

agents.

Caution! ELECTROMAGNETIC INTERFERENCE REGULATIONS

This device fulfills EN 60601-1-2:2014 Standards (Electromagnetic Compatibility). Nevertheless, this device uses

radiofrequency (RF) energy to generate heat while the tube is being sealed and can affect other Medical Electrical

Equipment. See Table 1 for guidance. If installation and use are not performed in accordance with the Operator’s

Manual, it could cause interference with radio, television, and instrument communications.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 4of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

2. Scope

This section contains a description of and specifications for T-SEAL III, a benchtop tube sealing device from Terumo

Blood and Cell Technologies (Terumo BCT).

Introduction

T-SEAL III is a fully automatic system for sealing polyvinyl chloride (PVC) tubes, especially those in blood pack

systems. Following the sealing procedure, the tube is easily pulled apart, due to the distinct sealing pattern, with no

damage to the blood inside the tube. Segments are formed by advancing the tube through the slot of the sealing head to

create a series of seals. Up to eight devices can be linked (cascaded) together for simultaneous sealing of segments.

T-SEAL III includes a built-in sealing head and is ready to operate. The front cover can be easily removed for cleaning.

T-SEAL III automatically adjusts the sealing time to suit different sizes and types of tubes.

T-SEAL III generates radio frequency (RF) energy for sealing. Be cautious of potential electrical shocks or hazards

while handling this device. Always turn the power switch off before disconnecting cables or cleaning.

Performance and Specifications

The table below lists the physical specifications.

Specification type

Value

Terumo BCT catalog

number

T3828

Description

T-SEAL III, a complete sealing system, which includes a built-in sealing head, a power

cord, and an operator’s manual

Type of tube

Polyvinyl chloride (PVC) tubes up to 6.2 mm (0.24 in) outer diameter with 4.4 mm

(0.17 in) inner diameter or 0.9 mm (0.04 in) wall thickness

Ethylene vinyl acetate (EVA) tubes up to 4.15 mm (0.16 in) outer diameter with 3.9 mm

(0.15 in) inner diameter or 0.9 mm (0.04 in) wall thickness

Sealing capacity

Up to 1000 seals/hour with PVC tubes up to 5 mm outer diameter (wall thickness

0.56 mm) at 20 °C (68 °F)

Sealing time

0.5 to 3 seconds, depending on tubing

Intended use

T-SEAL III is a fully automatic system for sealing blood bag system tubes. The sealing

is performed by means of a high-frequency dielectric heating system.

Input power

100-240 V ~, 50-60 Hz

Consumption

250 W

Power cord

Three-wire (10 A), 2.5-m cable with female plug (IEC 320)

RF output

80 W maximum/50 Ω/40.680 MHz

Size (W ×H ×D)

70 × 156 × 338 mm

Weight

2,8 kg (6,2 lb)

Temperature

Operating: 0 °C to 35 °C (32 °F to 95 °F)

Storage: -20 °C to 70 °C (-4 °F to 158 °F)

Humidity

Operating: 10% to 90% Rh (non-condensing)

Storage: 10% to 90% Rh (non-condensing)

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 5of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

Altitude

Operating: Maximum 3000 meters (9842 feet)

In compliance with

EN 60601-1: 2006, General Requirements for basic safety and essential performance

EN 60601-1-2: 2015, Collateral standards for Electromagnetic Compatibility

Electrical safety:

Class I

Waterproof

IPX0. Not waterproof

T-SEAL III is used in the same environment as medical equipment (hospitals and blood banks). It must be used by

highly qualified personnel.

Manufacturer Conroy Medical AB

According to MDR: Valhallavaegen 1, SE-194 63 Upplands Vaesby, Sweden

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 6of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

Table 1: Guidance and Manufacturer’s Declaration – Electromagnetic Emission

T-SEAL III is intended for use in the electromagnetic environment specified below. The customer or

the user of T-SEAL III should assure that it is used in such an environment.

Emission Test

Compliance

Electromagnetic Environment — Guidance

RF emission

CISPR 11

Group 2

T-SEAL III must emit electromagnetic energy in order to

perform its intended function. Nearby electronic equipment

may be affected.

RF emission

CISPR 11

Class B

T-SEAL III is suitable for use in all establishments, including

domestic establishments and those directly connected to the

public low-voltage power supply network that supplies

buildings used for domestic purposes.

Harmonic emission

IEC 61000-3-2

Class A

Voltage fluctuations/

Flicker emissions

IEC 61000-3-3

Complies

Table 2: Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

T-SEAL III is intended for use in the electromagnetic environment specified below. The customer or

the user of T-SEAL III should assure that it is used in such an environment.

Immunity Test

IEC 60601

Test Level

Compliance

Electromagnetic

Environment — Guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

± 8 kV contact

± 15 kV air

8 kV

15 kV

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Electrical fast

transient/burst

IEC 61000-4-4

± 2 kV for power

supply lines

2 kV

Mains power quality should be that of a

typical commercial or hospital

environment.

Surge

IEC 61000-4-5

± 1kV line(s)

to line(s)

± 2kV line(s)

to earth

1kV

2kV

Mains power quality should be that of a

typical commercial or hospital

environment.

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

< 5% Uτ

(> 95% dip in Uτ)

for 0.5 cycle

40% Uτ

(60% dip in Uτ)

for 5 cycles

70% Uτ

(30% dip in Uτ)

for 25 cycles

< 5% Uτ

(> 95% dip in Uτ)

for 5 sec

< 5% Uτ

(> 95% dip in

Uτ)

for 0.5 cycle

40% Uτ

(60% dip in Uτ)

for 5 cycles

70% Uτ

(30% dip in Uτ)

for 25 cycles

< 5% Uτ

(> 95% dip in

Uτ)

for 5 sec

Mains power quality should be that of a

typical commercial or hospital environ-

ment. If the user of the T-SEAL III

requires continued operation during

power mains interruption, it is re-

commended that the T-SEAL III be

powered from an uninterruptible power

supply or battery.

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m

3 A/m

Power frequency magnetic fields should

be at levels characteristic of a typical

location in a typical commercial or

hospital environment.

NOTE Uτis the

AC mains voltage

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 7of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

prior to application

of the test level.

Table 3: Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

T-SEAL III is intended for use in the electromagnetic environment specified below. The customer or

the user of T-SEAL III should assure that it is used in such an environment.

Immunity Test

IEC 60601 Test Level

Compliance

Level

Electromagnetic Environment —

Guidance

Portable and mobile RF communications equipment should be used no closer to any part of

T-SEAL III including cables than the recommended separation distance calculated from the

equation applicable to the frequency of the transmitter.

Recommended separation distance:

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

10 Vrms

150 kHz to 80 MHz

10 V/m

80 MHz to 2.5 GHz

10 V

10 V/m

Portable and mobile RF

communications equipment should

be used no closer to any part of the

sealer, including cables, than the

recommended separation distance

calculated from the equation

applicable to the frequency of the

transmitter.

Where P is

the maximum output power rating of the transmitter in watts (W) according to the

transmitter manufacturer and d is the recommended separation distance in meters (m).

Field strengths from fixed RF transmitters, as determined by an electromagnetic site survey,ashould

be less than the compliance level in each frequency range.b

Interference may occur in the vicinity of equipment marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

aField strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones

and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be

predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF

transmitters, an electromagnetic site survey should be considered. If the measured field strength in

the location in which T-SEAL III is used exceeds the applicable RF compliance level above, it

should be observed to verify normal operation. If abnormal performance is observed, additional

measures may be necessary, such as reorienting or relocating T-SEAL III.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 8of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

Table 4: Recommended Separation Distance Between Portable and Mobile RF Communications

Equipment and the T.3828 T-SEAL III

T-SEAL III is intended for use in the electromagnetic environment in which radiated RF

disturbances are controlled. The customer or the user of T-SEAL III can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and T-SEAL III.

For transmitters rated at a maximum output power, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where

P is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

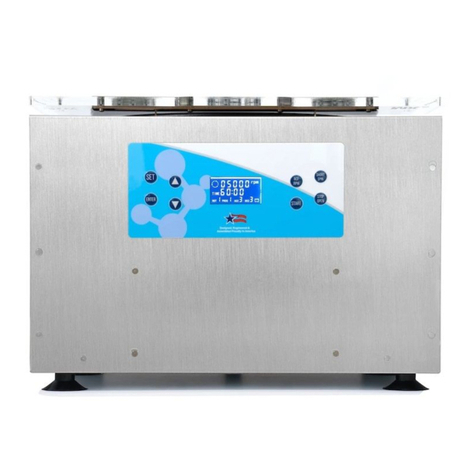

Front view

:

Rear view

:

1. LED indicator

2. Splash guard

3. Sealing indicator

4. Optic sensor

5. Front cover with tube slot

1. Power switch

2. Power inlet

3. COM ports

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 9of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

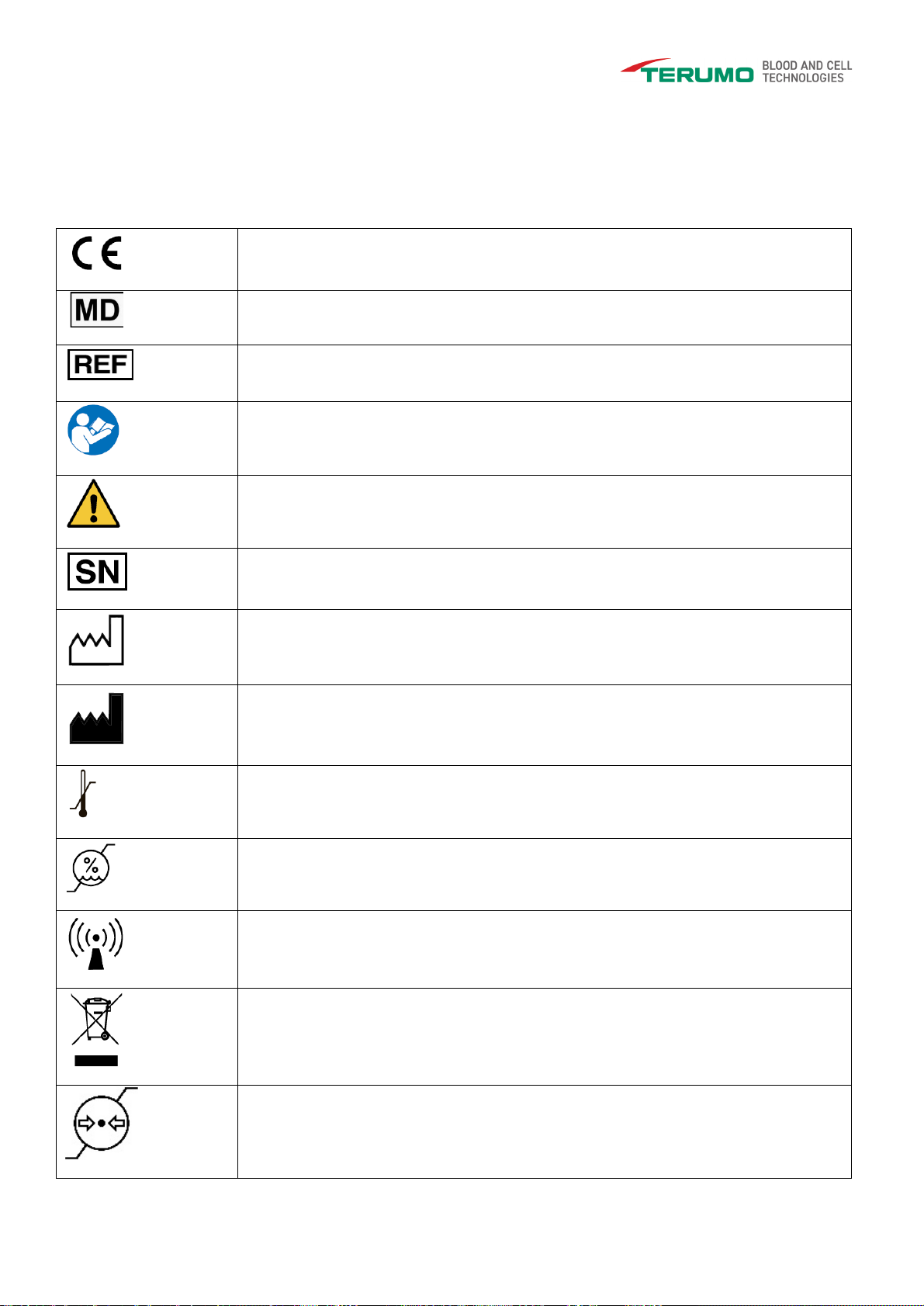

2.1 Symbols/Markings Description

On device and labels:

This marking reflects compliance with the Council Directive 93/42/EEC on Medical Devices

Symbol for “MEDICAL DEVICE”

Symbol for “CATALOGUE NUMBER”

Symbol for “FOLLOW INSTRUCTIONS”

Symbol for “WARNING”

Symbol for “SERIAL NUMBER”

Symbol for “DATE OF MANUFACTURE”

Symbol for “MANUFACTURER”

Storage conditions - Symbol for “TEMPERATURE”

Storage conditions - Symbol for “RELATIVE HUMIDITY”

Symbol for “NON-IONIZING RADIATION”

Symbol (WEEE to 2012/19/EU) — Do not dispose Product as municipal waste. Collect

Product separately. Use collection and return systems available to you. Product brought to EU

market after August 13, 2005.

Symbol for “MINIMUM AND MAXIMUM ATMOSPHERIC AIR PRESSURE”

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 10 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

3. Installation

This section involves unpacking, temperature requirements, and installation of the device.

Unpacking and Inspection

1. Visually inspect the cardboard box for damage. Report any damage immediately.

2. Lift the device out of the cardboard box and place it on a flat surface.

The device is shipped in one cardboard box that includes:

1 Sealing unit

2 Power cords

1 Operator’s manual

1 Operator’s manual in other languages: on CD-ROM/USB stick

3. The above list is subject to change; refer to the packing list for an accurate description of contents.

If any parts are missing or if the parts are damaged, report it immediately.

4. Please keep all shipping and packaging materials, as they may be required for later transportation, at least during the

warranty period.

Environmental Requirements

To keep the device operating at its best, please observe the following:

Place the device on a flat surface free from dust, solvents, and acidic vapor.

Use the instrument in a dry area free from vibration and with a room temperature of 0 °C to 35 °C

(32 °F to 95 °F) and relative humidity 10% to 90% non-condensing.

Handle the components with care in a clean environment.

3.1 Installation Procedure

Stand-Alone Setup

Preparing T-SEAL III for use.

1. Unfold the front and back support wings.

2. Place T-SEAL III on a flat surface, out of direct sunlight.

3. Connect the power cord to the receptacle at the rear of the device.

4. Plug the power cord into a grounded outlet.

5. Perform a test seal on an empty or water-filled tube to ensure proper operation.

Cascade Setup

Warning: This is a Class A product when in cascade mode. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take actions.

1. Unfold the positioning wing.

2. Fix the tube segment length by positioning the T-SEAL III devices in the correct slot of the positioning wing. The

segment length can be modified in increments of 1 cm. Minimum segment length is 7 cm (first slot position);

maximum segment length is 11 cm (last slot position)

3. The leader can be placed on the left side or the right side. The leader is selected by inserting a communication

termination plug into its COM IN. The last follower should have a communication termination plug into its COM

OUT.

Note: In a cascade setup with mixed T-SEAL II and T-SEAL III devices, the leader must be a T-SEAL III device.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 11 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

4. Connect the T-SEAL III devices to the power supply by connecting the AC power cord to the AC power inlet and

then to an earthed AC socket.

5. Make sure that the power switches are OFF.

6. Insert a communication termination plug into the COM IN of the leader.

7. Interconnect the next T-SEAL III device with the leader by utilizing the short communication cable. Connect the

short communication cable from the COM OUT of the leader to the COM IN of the first follower.

8. Interconnect the remaining followers by connecting the communication cables as described above.

9. Insert a communication termination plug into the COM OUT of the last follower.

10. Turn on all of the devices.

11. When the status LEDs are green and none of the error LEDs are illuminated, the devices are ready to make

segments.

12. Place the tube in the tube slot and slide the tube downward into the slots. Be careful not to stretch the tube or to

put any stress on it.

13. Each sealing head will separately detect its tube section, and cascade sealing will be activated only when all the

individual tube sections are detected. If the tube is not correctly detected in one or more of the sealing heads, the

error LED will be illuminated on the actual device and on the leader. In this case, remove the tube from all the

heads and start the procedure again.

14. All the T-SEAL devices will seal one by one.

15. During the sealing process the LEDs will turn yellow on each device. When the process is finished, they will turn

green again.

16. Remove the tube when all the LEDs have turned green.

4. Functional Description

This section describes how T-SEAL III works, where the connectors and the indications are placed on the unit, and

their functions.

4.1 Description of Sealing

The tube to be sealed is placed in the slot of the front cover, in between the electrodes. When the sensor detects the

tube, the sealing procedure begins automatically. The radio frequency (RF) generator starts and the energy is transferred

from the fixed electrode to the tube, which melts to a welding pattern.

During the entire sealing process, the yellow seal light on the display of the sealing unit is lit. When the light goes out,

the seal process is complete, the electrode opens, and the tube may be removed.

The sealing unit detects, controls, and adjusts the necessary sealing activity to give the best sealing quality for the type of

tube that is being used.

5. Operating Instructions

This section describes the use of the device.

Warning! T-SEAL III uses radio frequency (RF) energy to generate heat for sealing. Be cautious of potential electrical

shocks or hazards while handling this device. Always keep your fingers away from the electrodes in the slot. Never place

any object other than the tube between the electrodes.

Warning! This device emits a low level of electromagnetic (non-ionizing) radiation while sealing. It should not be used

near high-frequency sensitive electronic equipment. See Table 1 for guidance.

Caution! Inspect all parts of the device for defects before use.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 12 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

5.1 Preparation Before Use

1. Place the device on a flat surface near the work area. The front of the unit should be visible during the

sealing procedure. Ensure that the power cord can be easily disconnected from the mains supply.

2. Connect the power cord according to Section 3.1, “Installation Procedure.”

3. Check that the LED indicator lights up green when the power switch is turned on.

5.2 How to Seal Tubes

Note! The tube must be dry on the outside.

1. Put the tube to be sealed in the slot of the front cover.

2. The tube activates the sealing process. The sealing electrodes press the tube together and the sealing indicator lights

up. The sealing time is normally 0.5 to 3 seconds. Avoid stretching the tube during the sealing process.

Note! Keep the tube in position until the light goes out.

3. When the light goes out, the sealing is finished, and the electrodes move back to release the tube.

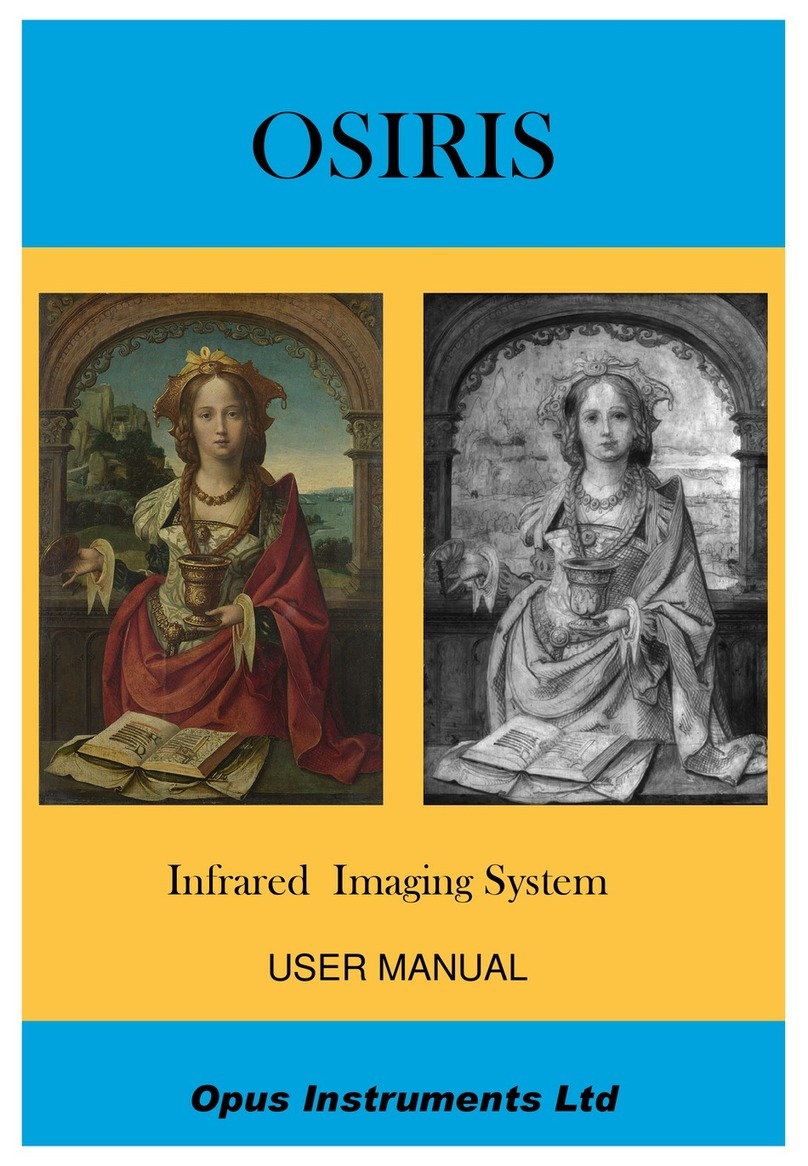

4. Lift up the sealed tube and verify that it matches the pattern shown in the photo below.

5. The center of the sealed pattern is very thin, and pulling both sides will divide the tube into two pieces.

When sealing EVA tubing, use clean scissors to separate the tubing at the center of the seal.

Caution! Do not make two or more seals within 1 cm (0.39 in) of each other, because the resulting pressure in the

tube may cause microscopic cracks and holes in the seals.

Caution! In the event of device malfunction (intermittent operation, poor seal quality, or the sealing time seems too

long or too short), contact your local Terumo BCT representative for assistance.

Caution! Periodically perform a visual check of the sealing pattern to ensure it matches the photo below.

Good sealing pattern Bad sealing pattern

6. Cleaning

This section gives information on the cleaning procedure and frequency for T-SEAL III, which requires minimal

maintenance for efficient operation. Follow the cleaning procedure below.

Warning! For your own safety, always turn off the power switch and disconnect the power cord.

Warning! Blood and blood products must always be treated as potentially infectious. In the event of blood leaks,

appropriate protective clothing should be worn during cleanup procedures.

After removing residual biological material, surfaces that have been in contact with blood or components must be

disinfected using a sterilizing agent, such as isopropanol 70%. Alternatively, a freshly prepared solution of diluted

sodium hypochlorite (household bleach) may be used to disinfect surfaces. Diluted solutions of 1 part bleach to 10 parts

water may be used.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 13 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

Regardless of the sterilizing or disinfection solution used, remove any residue to ensure that surfaces of the equipment

are not subject to corrosion or discoloration. Discard all materials that come into contact with blood according to

institutional policies regarding disposal of biohazardous materials.

Caution! Do not disinfect or sterilize any part of T-SEAL III using an autoclave or with ethylene oxide gas. Doing so

will make the device unusable and invalidate the warranty.

Do not use chemical or abrasive cleaners such as acetone or ammonia.

Do not use sharp-edged tools for cleaning, which could damage the finish of the units.

Caution! Do not allow liquid to flow into the electronics part of the device.

6.1 Sealing Head

Cleaning may be required as a result of a blood leak or when required after inspection.

If a blood leak occurs, immediately remove the device from service and clean it completely before resuming use.

Use a soft lint-free tissue, moistened with a mild detergent, to clean the outside of the sealing head and cover.

To clean the electrodes, remove the front cover of the sealing module.

Note! The front cover can be cleaned separately. Clean both electrodes with a soft lint-free tissue moistened with a

mild detergent. Dry carefully and ensure that the electrodes are completely dry to prevent sparks.

Note! After cleaning, inspect the electrodes for damage. Attach the cover, ensuring that it snaps into position.

Note! Some sealing tests can be made before resuming use. Compare the pattern against the photo in Section 4.2.

Caution! Do not submerge the sealing unit in fluid, as it is not waterproof. Fluid will cause malfunction and tiny arcs

and will reduce the life span of the device.

7. Troubleshooting

Maintenance performed by the user is limited to substituting one device or one power cord for another, and if used in

cascade, changing the communication cable and connectors. The following information covers possible problems and

offers suggested solutions.

7.1 Sealer

Problem

Probable Cause

Recommended Action

Power on indicator doesn’t light

up green.

No voltage.

Other cause.

Check power supply.

Ensure the power switch is turned on.

Contact your local Terumo BCT

representative.

Power on indicator lights up

green, but when the tube is

inserted, the seal indicator

doesn’t light up.

Sealing unit defective.

Other cause.

Ensure the front cover is correctly in

place.

If the device is used in a cascade, replace

it with a different device.

Contact your local Terumo BCT

representative.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 14 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

LED flashes red.

Sealing unit is too hot.

Turn the power switch off and wait about

10 minutes, and then try again.

If the LED is still flashing, contact your

local Terumo BCT representative.

LED doesn’t light.

Sealing unit defective.

Contact your local Terumo BCT

representative.

Sealing does not start.

Wet electrodes.

Leaky or wet tube.

Blocked optic sensor.

Other cause.

Clean the electrodes as described in

Section 6.1.

Dry the tube and try again.

Clean the optic sensor.

Contact your local Terumo BCT

representative.

Tube splits or breaks during

sealing.

Tube stretched during sealing.

Seals are too close together.

Incorrect adjustment of

electrodes.

Do not stretch the tube. See Section 5.2.

Leave a minimum of 1 cm (0.39 in)

between seals.

Contact your local Terumo BCT

representative.

8. Warranty and Service

If any serious incidents occur from the use of this equipment, please report the event, as soon as possible, to the closest

Terumo office.

Information on the warranty and the service provided by Terumo BCT is listed below.

8.1 Warranty

Terumo BCT guarantees that the equipment shall be free from defects in material and workmanship when delivered to

the original purchaser. Terumo BCT´s sole obligation shall be limited to repair or replacement, at Terumo BCT´s option

and expense, of the defective part or unit for the duration of the warranty.

The warranty extends only to the original purchaser and is not assignable or transferable and shall not apply to auxiliary

equipment or disposable accessories.

Terumo BCT guarantees that the equipment is fit for the purposes and indications described in the labelling when used

in accordance with the instruction for use. Unless the equipment is used in accordance with such instructions, this

warranty is void and of no effect. No other expressed or implied warranty exists, including any warranty of

merchantability or appropriateness for a particular purpose. Terumo BCT’s sole obligation and original purchaser’s

exclusive remedy for breach of warranty shall be limited to repair or replacement at Terumo BCT´s option.

Terumo BCT shall not be liable for proximate, incidental or consequential damages. Modifications, alterations,

recalibrations or abuse, and service by other than a Terumo BCT authorized representative will void the warranty.

8.2 Service

Service Under the Warranty Period

While under Terumo BCT warranty, the instrument must not be opened by unauthorized personnel.

Contact your Terumo BCT representative for service and repair information for all T-SEAL III instruments.

UNLOCKING POTENTIAL |TERUMOBCT.COM Page 15 of 15 Version 1.0 Rev 02/2021

©2021 Terumo BCT, Inc.

The unit must be packed in its original box. To ensure prompt return, a Terumo BCT representative must be notified

before shipping any unit for repair.

When contacting Terumo BCT, please be prepared to provide the part number and serial number of the unit. A service

request number will be issued and should accompany all communications. A brief written description of the problem

should be attached to the instrument when it is returned for service.

Terumo BCT will not be responsible for unauthorized returns or for units damaged in shipment due to improper

packing.

8.3 Product Disposal

For disposal of T-SEAL III (and accessories) at the end of the calculated life cycle of 10 years, please ensure the

following:

Do not dispose of T-SEAL III as unsorted municipal waste.

Recycle the T-SEAL III separately.

Use the collection and return systems available to you.

For more information on return, recovery, or recycling of T-SEAL III, please contact your local Terumo BCT Sales

Office.

Terumo BCT, Inc.

10811 West Collins Ave.

Lakewood, Colorado 80215-4440

USA

USA Phone: 1.877.339.4228

Phone: +1.303.231.4357

Fax: +1.303.542.5215

Terumo BCT Europe N.V.

Europe, Middle East and Africa

Ikaroslaan 41

1930 Zaventem

Belgium

Phone: +32.2.715.0590

Fax: +32.2.721.0770

Terumo BCT Asia Pte. Ltd.

89 Science Park Drive

#04-25 (Lobby B)

The Rutherford

Singapore 118261

Phone: +65.6715.3778

Fax: +65.6774.1419

Terumo BCT Latin America S.A.

La Pampa 1517–12th Floor

C1428DZE

Buenos Aires

Argentina

Phone: +54.11.5530.5200

Fax: +54.11.5530.5201

Terumo BCT Japan, Inc.

Tokyo Opera City Tower 49F,

3-20-2, Nishi-Shinjuku,

Shinjuku-ku, Tokyo 163-1450,

Japan

Phone: +81.3.6743.7890

Fax: +81.3.6743.9800

Document number: D0000011338

T-Seal®III

Terumo Tube Sealing Device

Version 1.0

Operator’s Manual

©2021 Terumo BCT, Inc.

Table of contents

Other Terumo Laboratory Equipment manuals