1 Contents

4

5.2.5. Switching on .................................................................................................. 35

5.2.6. Calling up the function ................................................................................... 36

5.2.7. Entering values.............................................................................................. 36

5.2.8. Printing / saving data ..................................................................................... 38

5.2.9. Search for boxes ........................................................................................... 38

5.2.10. Confirming an error message ........................................................................ 38

5.2.11. Switching off .................................................................................................. 38

5.3. Folder............................................................................................ 39

5.4. Measurement records ................................................................... 41

5.5. Instrument diagnosis..................................................................... 42

5.5.1. Error diagnosis .............................................................................................. 42

5.5.2. Gas path check.............................................................................................. 42

5.5.3. Sensor diagnosis ........................................................................................... 43

5.5.4. Device information......................................................................................... 43

6Using the product ................................................................................. 43

6.1. Performing settings ....................................................................... 43

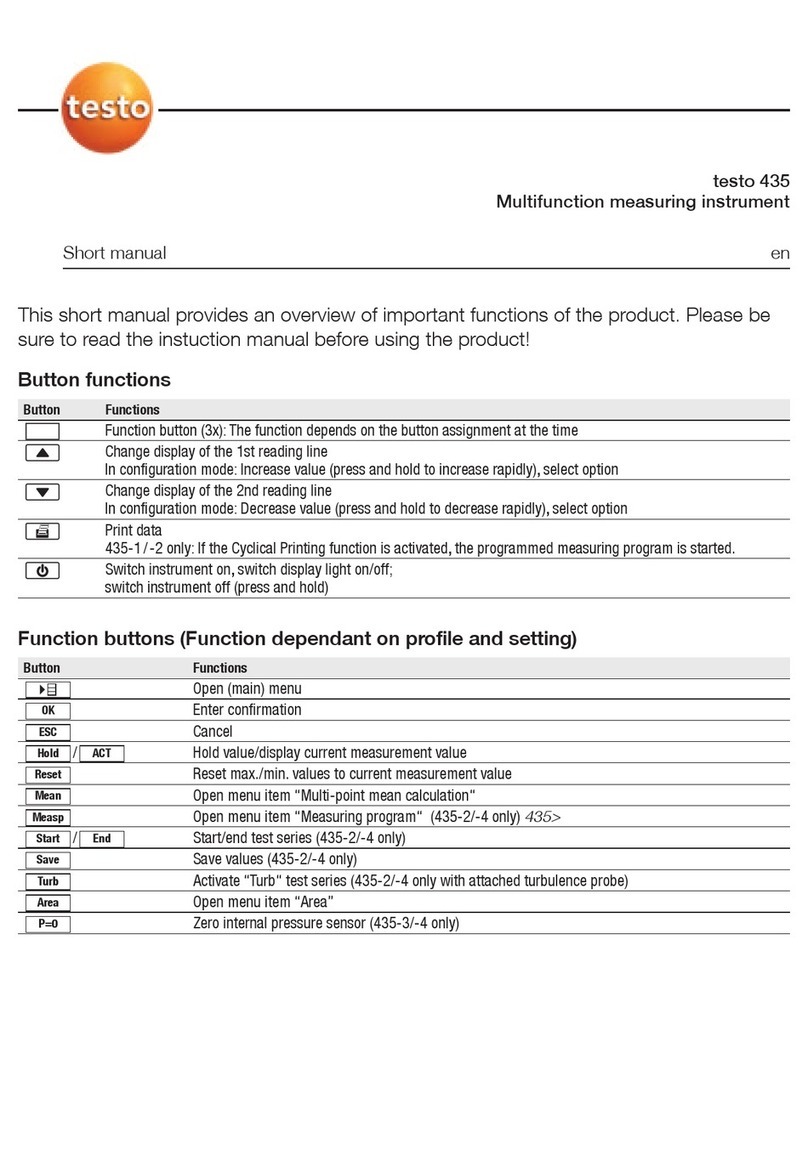

6.1.1. Assigning the right hand function key ............................................................ 43

6.1.2. Instrument settings ........................................................................................ 43

6.1.2.1. Measurement view .......................................................................... 43

6.1.2.2. Units................................................................................................ 45

6.1.2.3. Date / time....................................................................................... 46

6.1.2.4. Power options.................................................................................. 46

6.1.2.5. Display brightness ........................................................................... 46

6.1.2.6. Printer ............................................................................................. 47

6.1.2.7. Language ........................................................................................ 47

6.1.2.8. Password protection........................................................................ 47

6.1.2.9. Analog input .................................................................................... 48

6.1.2.10. Data bus.......................................................................................... 49

6.1.3. Fuels.............................................................................................................. 49

6.1.4. Sensor settings.............................................................................................. 50

6.1.4.1. Sensor protection ............................................................................ 50

6.1.4.2. Calibration / adjustment................................................................... 51

6.1.4.3. Calibration data ............................................................................... 53

6.1.4.4. Negative values............................................................................... 54

6.1.5. Programs....................................................................................................... 54

6.2. Measuring ..................................................................................... 56

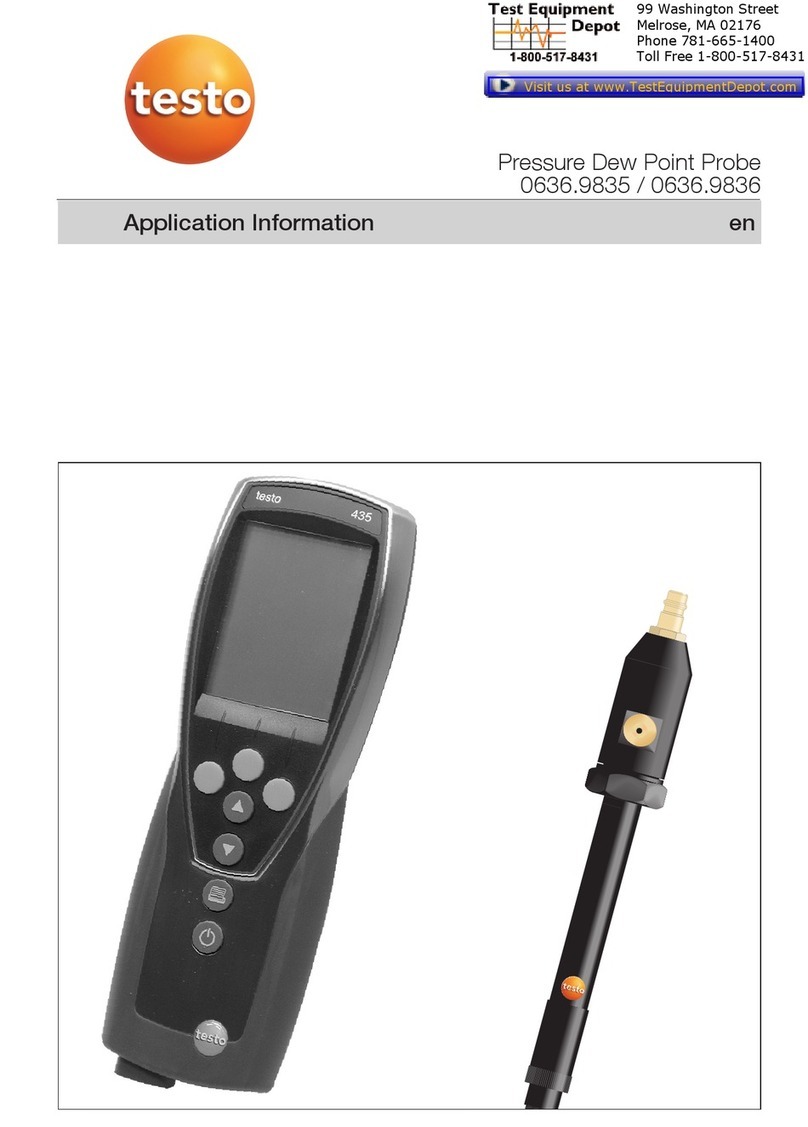

6.2.1. Preparing for measurement ........................................................................... 56

6.2.2. Position flue gas probe .................................................................................. 58

6.2.2.1. Flue gas flow with hot spot characteristics....................................... 58

6.2.2.2. Flue gas flow without hot spot characteristics.................................. 58

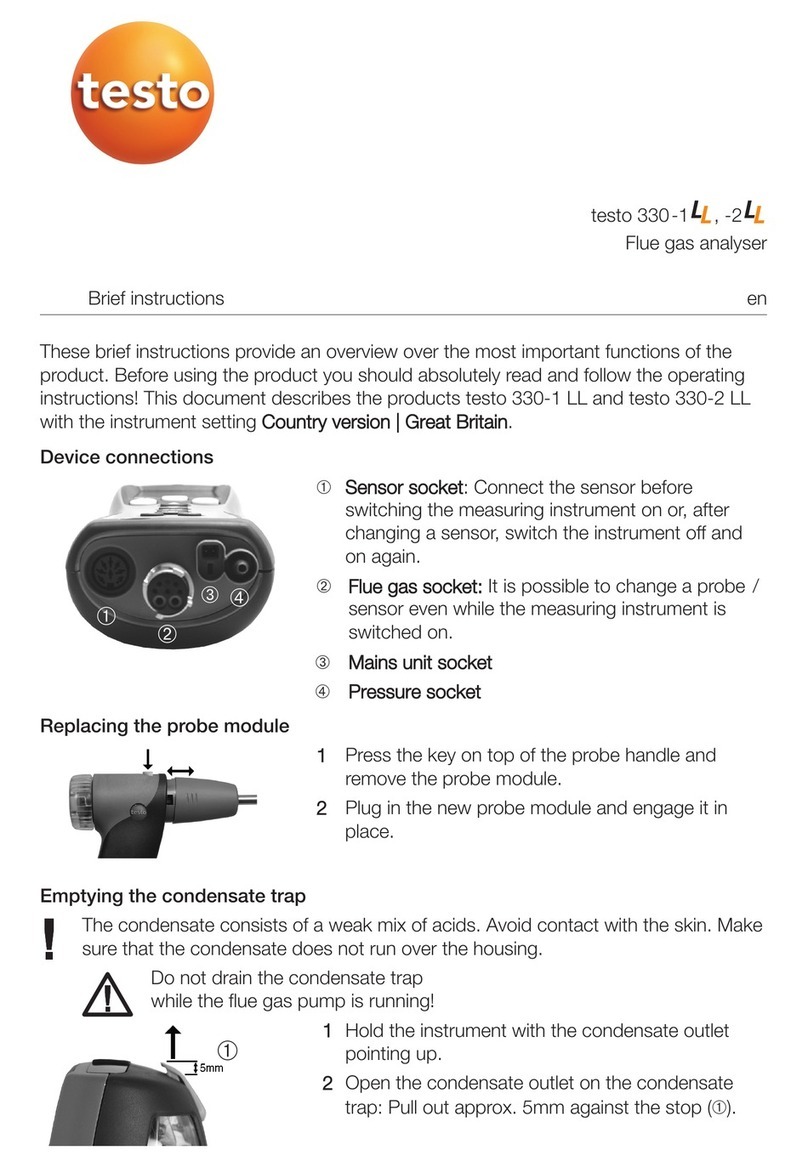

6.2.3. Attachment options for the flue gas probe...................................................... 59

6.2.3.1. Using the probe stop ....................................................................... 59

6.2.3.2. Using the welded pipe ..................................................................... 60

6.2.4. Vibrations ...................................................................................................... 60

6.2.5. Flue gas measurement .................................................................................. 61

6.2.6. Differential pressure measurement (determining the pressure in the flue gas

duct) .............................................................................................................. 63

6.2.7. EMDS measurement ..................................................................................... 64

6.3. Analog outputs .............................................................................. 65