TGW NBC Flat Belt Instruction manual

1118140rev102213

INSTALLATION,OPERATION,MAINTENANCE

MANUAL

NBC™ Flat Belt

Narrow Belt Conveyor

Accumulation with CRUZcontrol®

& Transportation

NBC™ Flat Belt

1118140rev102213 2

NBC Flat Belt Index

Purpose..................................................................................................................................... 7

TGW Systems Equipment Warranty.......................................................................................... 8

Warnings and Safety Instructions.............................................................................................. 9

NBC Flat Belt Accumulation and Transportation Conveyor..................................................... 13

Concept and Operation......................................................................................................... 14

NBC Application Selection....................................................................................................... 16

When to choose NBC........................................................................................................... 16

Application Notes.................................................................................................................. 16

NBC Technical Applications ................................................................................................. 17

Receiving and Site Preparation............................................................................................... 19

General................................................................................................................................. 19

Preparation of Site................................................................................................................ 20

Parts Inventory and Identification ......................................................................................... 20

General Procedures ................................................................................................................ 21

Dimensional Reference Points ............................................................................................. 21

Squaring Conveyor............................................................................................................... 21

Elevations............................................................................................................................. 22

Component Orientation......................................................................................................... 23

Installation Arrangements........................................................................................................ 24

Floor Supports...................................................................................................................... 24

Anchoring ............................................................................................................................. 24

Knee Braces......................................................................................................................... 25

Ceiling Hangers.................................................................................................................... 26

Anchoring Ceiling Hangers................................................................................................... 28

Connectors........................................................................................................................... 29

Line Straightness.................................................................................................................. 30

Setting Logic Modules............................................................................................................. 31

Installing the NBC Air Transportation Pilot Valve..................................................................... 32

NBC Belts................................................................................................................................ 33

Red Belt................................................................................................................................ 33

Black Belt.............................................................................................................................. 34

NBC QUIKmeld Unit................................................................................................................ 35

PN 1120200Threading Belt in NBC Accumulation Conveyor .................................................. 35

Threading Belt in NBC Transportation Conveyor..................................................................... 41

Belt Tensioning........................................................................................................................ 42

250 lb Drive Tensioning (Spring/Screw Take-up)................................................................. 42

500 lb and 250 lb-AT Drive Tensioning (Air Take-up)........................................................... 44

Wiring (Optional) Proximity Switch in the 500 lb & 250 lb-AT Drive Air Take-up .................. 45

NBC Cross Sections................................................................................................................ 46

Skewing NBC Rollers .............................................................................................................. 47

Factory Skew Charge Section.............................................................................................. 47

Maintenance Skew Section .................................................................................................. 48

Installation Steps for Field Installed Skewed Maintenance Pressure Assemblies ................... 49

2" Roller Centers .................................................................................................................. 49

3" Roller Centers .................................................................................................................. 51

CRUZ®channel to XenoROL®Channel Connections............................................................... 52

NBC™ Flat Belt

1118140rev102213 3

Guardrail Mounting on NBC..................................................................................................... 53

CRUZchannel to C6 Nose Piece............................................................................................. 55

Air Supply Requirements......................................................................................................... 56

General................................................................................................................................. 56

Low Pressure Switch............................................................................................................... 58

Pneumatic Requirements ..................................................................................................... 58

CRUZcontrol®.......................................................................................................................... 59

Definition of Terms .................................................................................................................. 60

CRUZcontrol Concepts............................................................................................................ 61

Basic and Progressive Logic ................................................................................................... 62

Basic Logic.............................................................................................................................. 63

Basic Logic Operation........................................................................................................... 63

Discharge from Basic Logic.................................................................................................. 63

Progressive Logic.................................................................................................................... 64

Progressive Logic Operation ................................................................................................ 64

Discharge from Progressive Logic........................................................................................ 64

Application – CRUZ®logic........................................................................................................ 66

Logic Modules and Release Rates....................................................................................... 66

Application – NBC Releasing Accessories .............................................................................. 68

CRUZcontrol Components....................................................................................................... 71

CRUZcontrol Logic Assembly............................................................................................... 71

Function Modules................................................................................................................. 73

Power Supplies..................................................................................................................... 81

Accessories.......................................................................................................................... 85

CRUZcontrol On Site Installation............................................................................................. 88

Pre-installed on the conveyor............................................................................................... 88

Field Installation.................................................................................................................... 88

Conveyor Flow...................................................................................................................... 89

Overview – TGW CRUZcontrol Logic Module .................................................................... 100

Conveyor Details ................................................................................................................ 100

Photoelectric Sensor........................................................................................................... 101

Standard Logic Module....................................................................................................... 102

Pneumatic Valve................................................................................................................. 108

Adaptor Cable for M12 Connector...................................................................................... 110

Conveyor Power Supply..................................................................................................... 111

Power Supply Technical Data............................................................................................. 114

Part Number Listing............................................................................................................... 115

Maintenance Schedule.......................................................................................................... 116

Daily.................................................................................................................................... 116

Weekly................................................................................................................................ 116

Monthly............................................................................................................................... 116

Semi-Yearly........................................................................................................................ 117

Yearly ................................................................................................................................. 117

Belt Splice Inspection ......................................................................................................... 117

Gearmotors......................................................................................................................... 117

Solenoid Valves.................................................................................................................. 118

Sensing Switches............................................................................................................... 119

NBC™ Flat Belt

1118140rev102213 4

Parts Identification................................................................................................................. 120

NBC 500 lb Drive Train.......................................................................................................... 121

NBC 250 lb Drive Train.......................................................................................................... 123

NBC 250 lb Manual Take-up and Drive Train........................................................................ 125

NBC Pressure Assembly....................................................................................................... 126

NBC Skewed Pressure Pan Assembly.................................................................................. 127

NBC Discharge Brake Assembly........................................................................................... 129

NBC End Pulley Assembly .................................................................................................... 131

NBC 12 ft Contact Accumulation........................................................................................... 132

NBC Logic Module Component............................................................................................. 133

NBC 12 ft Contact Accumulation Skewed Rollers ................................................................. 134

Appendix................................................................................................................................ 135

Troubleshooting Guide – Mechanical/Electrical.................................................................. 135

NBC Belt Routing Troubleshooting Guidelines................................................................... 137

Mission .................................................................................................................................. 138

Table of Figures

Figure 1: Basic Concept Layout..........................................................................................................61

Figure 2: Logic Assembly Mode & Alignment......................................................................................71

Figure 3: Function Modules.................................................................................................................78

Figure 4: Full Function Module Board Layout......................................................................................79

Figure 5: Full Function Module Circuit.................................................................................................79

Figure 6: Release Function Board Layout...........................................................................................80

Figure 7: Release Function Module Circuit .........................................................................................80

Figure 8: Two Logic Assemblies using a T Cable................................................................................82

Figure 9: Two Separate CRUZcontrol Sections...................................................................................83

Figure 10: One CRUZcontrol Section with Two Power Supplies .........................................................84

Figure 11: Discharge Logic Control.....................................................................................................86

Figure 12: Logic Assembly..................................................................................................................88

Figure 13: Left Hand Flow Conveyor Bed ...........................................................................................89

Figure 14: Right Hand Flow Conveyor Bed.........................................................................................89

Figure 15: Isolated Input Single Release.............................................................................................92

Figure 16: Non-Isolated Input Single Release.....................................................................................92

Figure 17: CRUZcontrol around a curve (low rate)..............................................................................93

Figure 18: CRUZcontrol around a curve. (High rate)...........................................................................95

Figure 19: Function Module Wiring .....................................................................................................95

Figure 20: Work Zone.........................................................................................................................96

Figure 21: Work Zone Using TB1........................................................................................................96

Figure 22: Work Zone Using TB4........................................................................................................96

Figure 23: TGW Conveyor C-Channel..............................................................................................100

Figure 24: Sensor Dimensional Data for 25° Cable Exit....................................................................101

Figure 25: Final TGW Logic Module Mechanical Design...................................................................103

Figure 26: Logic Module Wiring for Overmolded 2x2 Daisy Chain Cables......................................... 105

Figure 27: Basic Accumulation Logic................................................................................................106

Figure 28: Progressive Accumulation Logic......................................................................................107

Figure 29: M12 Sensor Connection Pin-out ......................................................................................108

Figure 30: “T”-Cable Wiring...............................................................................................................110

Figure 31: Power Interrupt Wiring .....................................................................................................111

Figure 32: Logic Interrupt Wiring.......................................................................................................111

NBC™ Flat Belt

1118140rev102213 5

Figure 33: Slug Interrupt Wiring........................................................................................................111

Figure 34: TGW PN 1117432 Dimensional Diagrams........................................................................ 112

Figure 35: TGW PN 1117432 Connection Diagrams.........................................................................112

Figure 36: TGW PN 1117431 Dimensional Diagram..........................................................................113

Figure 37: TGW PN 1117431 Connection Diagram ...........................................................................113

Table of Tables

Table 1: Logic Assemblies Functions..................................................................................................72

Table 2: Logic Assemblies Part Numbers ...........................................................................................72

Table 3: Function Module Types.........................................................................................................73

Table 4: Function Module Functions...................................................................................................73

Table 5: Terminal Block Descriptions..................................................................................................75

Table 6: Jumper Descriptions .............................................................................................................76

Table 7: Function Module Part Numbers.............................................................................................78

Table 8: Maximum Number of Logic Modules per String – 100-240 VAC............................................81

Table 9: Power Supply Part Numbers.................................................................................................84

Table 10: Photoelectric sensor............................................................................................................85

Table 11: Reflector .............................................................................................................................85

Table 12: Sensor Valve Assembly ......................................................................................................85

Table 13: Extension Cables................................................................................................................86

Table 14: Discharge Logic Assembly..................................................................................................87

Table 15: Conveyor Specification .....................................................................................................100

Table 16: Sensor Optical Specification .............................................................................................101

Table 17: Sensor Electrical Specification.......................................................................................... 102

Table 18: Logic Module Mechanical Specification.............................................................................104

Table 19: Logic Module Electrical Specification ................................................................................104

Table 20: Logic Function...................................................................................................................105

Table 21: Pneumatic Valve Specification..........................................................................................108

Table 22: Interconnection Types and Lengths ..................................................................................110

Table 23: Logic Module w/Sensor and 2x2 Daisychain.....................................................................115

Table 24: Accessories w/2x2 Connections........................................................................................115

Table 25: Logic Module w/MHL1 Sensor and M12 Daisychain for CRUZcontrol............................... 115

Table 26: Accessories w/M12 Connections for CRUZcontrol............................................................115

NBC™ Flat Belt

1118140rev102213 6

NBC™ Flat Belt

1118140rev102213 7

Purpose

It is the intent of TGW Systems, through this manual, to provide information that acts as a

guide in the installation, operation and maintenance of TGW Systems NBC Flat Belt

conveyors.

This manual describes basic installation practices, assembly arrangements, preventive

maintenance and assists in replacement parts identification.

This service manual is intended for use by personnel who are knowledgeable of installation

and safe working practices on conveyor systems.

Not all applications and conditions can be covered; therefore, this manual is to be used ONLY

as a guide.

If additional copies of this manual are needed or if you have any question concerning the

conveyor, please contact your Business Partner or TGW Systems Lifetime Services at 231-

798-4547 or Fax 231-798-4549.

NBC™ Flat Belt

1118140rev102213 8

TGW Systems Equipment Warranty

TGW Systems warrants that the material and workmanship entering into its equipment is

merchantable and will be furnished in accordance with the specifications stated.

TGW Systems agrees to furnish the purchaser without charge any part proved defective within

2 years from date of shipment or before the equipment has forty-one hundred (4100) hours of

running use, whichever period is shorter, provided the purchaser gives TGW Systems

immediate notice in writing and examination proves the claim that such materials or parts were

defective when furnished. For drive components specific to XenoROL®(i.e. Xeno belts, slave

Xeno belts, drive spools, standard and speed-up, and spacers), this warranty shall be

extended to five years or ten thousand (10,000) hours of running use, whichever period is

shorter, provided the conveyors are applied, installed and maintained in accordance with TGW

Systems published standards. Other than the above, there are no warranties which extend

beyond the description on the face hereof. Consequential damages of any sort are wholly

excluded.

The liability of TGW Systems will be limited to the replacement cost of any defective part. All

freight and installation costs relative to any warranted part will be at the expense of the

purchaser. Any liability of TGW Systems under the warranties specified above is conditioned

upon the equipment being installed, handled, operated, and maintained in accordance with the

written instructions provided or approved in writing by TGW Systems.

The warranties specified above do not cover, and TGW Systems makes no warranties which

extend to, damage to the equipment due to deterioration or wear occasioned by chemicals,

abrasion, corrosion or erosion; Purchaser's misapplication, abuse, alteration, operation or

maintenance; abnormal conditions of temperature or dirt; or operation of the equipment above

rated capacities or in an otherwise improper manner.

IMPORTANT

All equipment and components not manufactured by TGW Systems carry only such warranty

as given by the manufacturer thereof, which warranty TGW Systems will assign or otherwise

make available to Purchaser without recourse to TGW Systems, provided that such warranty is

assignable or may be made available.

For service on motors, reduction units, electrical components, controls, air or hydraulic

cylinders, contact the local authorized sales and service representative of respective

manufacturer. If none is available in your locality, contact the TGW Systems representative.

TGW Systems will not be responsible for units that have been tampered with or disassembled

by anyone other than the authorized representative of the respective manufacturer.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, EXTENDING BEYOND THOSE SET FORTH IN THIS STATEMENT OF

WARRANTY. Rev 08/22/2011

NBC™ Flat Belt

1118140rev102213 9

Warnings and Safety Instructions

Failure to follow the instructions and cautions throughout this book, and warning labels on the

conveyor may result in injury to personnel or damage to the equipment.

Your TGW Systems conveyor is powered by a motor and can be stopped only by turning off

electrical power to the motor. As with all powered machinery, the drive-related components –

including sprockets, chains, shafts, universal joints and pneumatic devices – can be

dangerous. We have installed or provided guards to prevent accidental contact with these

parts, along with warning labels to identify the hazards.

Special attention must be paid to the following areas of this manual:

•Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

•Indicates a situation which, if not avoided, could result in property

damage.

NOTE

This is where you will be notified of helpful information.

WARNING

CAUTION

NBC™ Flat Belt

1118140rev102213 10

•After maintenance, REPLACE guards immediately.

•Keep ALL warning labels clean and clear of any obstructions.

•Never remove, deface or paint over WARNING or CAUTION

labels. Any damaged label will be replaced by TGW Systems

at no cost by contacting Lifetime Services.

•It is very important to instruct personnel in proper conveyor

use including the location and function of all controls.

•Special emphasis must be given to emergency stop

procedures.

•It is important to establish work procedures and access areas

which do not require any part of a person to be under the

conveyor.

•It should be required that long hair is covered by caps or hair

nets.

•Loose clothing, long hair and jewelry must be kept away from

moving equipment.

•Maintain enough clearance on each side of all conveyor units

for safe adjustment and maintenance of all components.

•Provide crossovers or gates at sufficient intervals where

needed to eliminate the temptation for personnel to climb over

or under any conveyor.

•Walking or riding on a moving conveyor must be prohibited.

•Before performing maintenance on the conveyor, make sure

the start-up controls are locked out and cannot be turned on

by any person other than the one performing the maintenance.

•If more than one crew member is working on the conveyor,

EACH CREW MEMBER MUST HAVE A LOCK ON THE

POWER LOCKOUT.

•All pneumatic devices must be de-energized and air removed

to prevent accidental cycling of the device while performing

general maintenance.

•Make sure all personnel are clear of all conveyor equipment

before restarting the system.

WARNING

NBC™ Flat Belt

1118140rev102213 11

•Before servicing or performing any work in the motor control

panel, disconnect and lock out the main incoming service. If

only the panel disconnect is off, the incoming side will still be

hot.

WARNING

NBC™ Flat Belt

1118140rev102213 12

NBC™ Flat Belt

1118140rev102213 13

NBC™ Flat Belt

1118140rev102213 14

NBC Flat Belt Accumulation and Transportation Conveyor

NBC flat belt contact accumulation

Concept and Operation

NBC flat belt conveyor is offered in contact accumulation and transportation versions.

The conveyor differences are as follows:

Contact Accumulation

The NBC contact accumulation zones are 4' long, but operate in such a manner as to allow

mixed length product to dense pack accumulate. The products are allowed to touch and bump,

but are at zero-pressure after they stop. The minimum speed for dense packing of product is

90 FPM for totes and 125 FPM for corrugated product.

The product-carrying rollers are driven by a 2" wide belt. This belt is held in contact with the

underside of the carrying rollers by spring pressure roller channel assemblies, mounted on the

conveyor side channels.

Accumulation begins when a product blocks the first sensor from the discharge end. The first

product stops over the discharge sensor which “arms” the next sensor upstream while lowering

the belt pressure roller channel in that zone.

When a zone accumulates, each spring pressure roller channel assembly in that zone lowers

by the use of an air diaphragm. The belt is lowered away from the carrying rollers causing

them to become non-powered. Products are conveyed to the zone; then coast as they enter

the non-powered area and bump into the stopped downstream product. As accumulation takes

place from zone-to-zone, the accumulated products are at zero-line-pressure.

NBC contact accumulation

closes product gaps

NBC™ Flat Belt

1118140rev102213 15

NBC Logic Module Assembly

NBC Pressure Pan – spring-to-drive rollers, air-to-accumulate

Transportation

The NBC transportation has the same spring loaded pressure pans as the accumulation

versions, but no air diaphragm to disengage the pressure pan. A plastic cam can be manually

activated to lock the pressure pan in the down position for ease of belt installation. However,

once the plastic cam is manually deactivated, the pressure pan always drives.

Air Transportation

Air transportation uses air diaphragms to retract the pressure assemblies rather than the

plastic lockout cam. All the diaphragms are linked together to a central valve which is designed

to disengage the entire line at once. There are no logic modules for individual zone

accumulation.

Logic Module

Hidden air diaphragm

retracts pressure

channel

NBC™ Flat Belt

1118140rev102213 16

NBC Application Selection

When to choose NBC

•Accumulation or transportation as required

•Product-to-product contact is allowed

•Single product release is not required

•Product weight: 1-75 lbs (50 lbs/ft)

•Product height: 1" minimum

•Product may be same size and weight, or mixed

•Ambient temperature is +50° to 120°F for the black belt and +35° to 120° for the red belt.

•Air supply is dry

Application Notes

•Conveyor operations before and after NBC are vital to proper application decisions.

•The conveyor downstream from progressive release NBC must run at a speed which is greater

than or equal to the speed of the discharging NBC conveyor.

•There will not be a gap or means of detecting a specific product, directly at the end of NBC

without a speed-up bed.

•When feeding sortation from NBC, use a split metering belt to singulate individual products

when specific minimum gap is required.

•NBC cannot be fed from an upstream conveyor at a rate exceeding the NBC rate, especially

from a curve.

•Convey all products along one side of NBC unless products are nearly the same width and

closely match the conveyor width. Skewed roller beds are available to accomplish this.

•During accumulation, product density (packing) increases with product weight and speed.

•A discharge brake is not recommended for speeds over 129 FPM unless used with pivoting

blade stop.

•NBC conveyor requires a QUIKmeld Tool Kit for splicing the black belt for 500 lb drives ONLY.

These tool kits were developed by TGW and are available only from TGW.

•Limit the length of NBC conveyors to 150’. If you have a requirement beyond 150’ contact

Sales Support.

•For temperatures BELOW 50° for the black belt and 35° for the red belt, contact Sales Support

for details.

•Always locate the drive bed at the charge end of the primary conveyor.

•Totes may have up to a 2" taper on each end without affecting the function of the electronic

sensors. Customers who have tapered totes may request TGW to perform a product test with

test product supplied by the customer.

•Mechanical lacing is used for units up to 70’ with the 250 lb drive. Use the application

calculation sheet to determine belt pull, horsepower and drive requirements.

•Due to the direct drive train, speeds may vary +/- 10% from stated speeds.

•For all applications over 250 lbs of belt pull, the black welded belt shall be used.

•Under no circumstances shall a mechanical lace be used with a black belt.

NBC™ Flat Belt

1118140rev102213 17

NBC Technical Applications

Release Rates

Product delivery (release) following accumulation is always an important application

consideration. The product release rate depends on the release logic, conveyor speed, gaps

between products, and the product length. In all situations that require dense product

packing, the conveyor should NOT run below 125 FPM for cartons and 90 FPM for totes.

For applications with temperatures at or below 50° defined as cool applications, the minimum

conveyor speed of 150 FPM is required. This increase speed is due to the increase in viscosity

of the grease in the roller bearing which limits the rotation of the roller and minimizes the

distance of product coastability during accumulation.

Release efficiency is the ratio between conveyor speed (feet per minute) and the product

footage delivered (case feet per minute). One variable is the amount of gaps between products

before release. These gaps are due to product coast when accumulating. (See Coastability)

Additional gaps can occur at release dependent on the signal logic used.

Release Efficiencies

Overall release efficiency with a single continuous release may vary from:

Contact Accumulation

40% with Basic Logic (40% product / 60% air)

80% with Progressive Logic (80% product / 20% air)

Release efficiencies are dependent on whether there are mixed case sizes, weights and

conveyor speed, and also whether Basic or Progressive logic is used, and the release

operation is either singulate or slug release. When the speed to meet rate using Basic Logic is

over 150 FPM, consider using Progressive Logic

Discharge Zone

A function module is provided for the discharge bed to control product release. If the NBC line

is feeding another NBC line, a function module may not be required.

Horsepower Principles

The horsepower required for NBC conveyor is based on the effort (in pounds) to pull the belt

through the conveyor (belt pull), turning all the rollers and moving the product at a given speed.

Actual horsepower is based on "effective belt pull", which includes a factor for belt flexing,

bending, and snubbing.

Coastability

Product coast is affected by many factors involving the product and conveyor. When one

product does not coast up to the previous product, a gap occurs. Some gaps are likely within

a zone. This is not a problem if considered when determining the conveyor speed. Factors

NBC™ Flat Belt

1118140rev102213 18

determining coast are; product bottom - smoothness, firmness, straightness; product weight;

product weight distribution; product length relative to zone length; conveyor speed; roller

bearing friction, rollers still turning from previous product movement or rollers which have

stopped.

General Cautions on NBC

•Singulating individual product out of NBC requires a TGW application review. Consult

Sales Support for available options.

•Do not pitch NBC either up or down. When product accumulates, the conveyor turns to

gravity and product control is lost.

•Do not overfeed downstream conveyor with either Basic or Progressive release. This

will create line pressure.

•The minimum package length is 9". The minimum package height is 1". The maximum

product weight is 50 lbs/ft.

•Small light products that fit between a zone sensor and the end of the zone may rotate

and/or accumulate side by side. Consult Sales Support for available options.

•Do not skew rollers without a skew pressure pan properly installed in that zone. Any

NBC conveyor that has skewed rollers without proper installation will immediately and

permanently VOID ALL TGW WARRANTIES.

NBC™ Flat Belt

1118140rev102213 19

Receiving and Site Preparation

General

NBC flat belt conveyors are shipped in subassemblies. These subassemblies are packaged to

guard against damage in shipment when handled properly.

Examination immediately following unloading will show if any damage was caused during

shipment. If damage is evident, claims for recovery of expenses to repair damaged or replace

components must be made against the carrier immediately. While unloading, a check must be

made against the Bill of Lading, or other packing lists provided, to confirm full receipt of listed

items.

•TAKE CARE DURING THE REMOVAL OF EQUIPMENT FROM THE

CARRIER.

•Remove small items and boxes first.

•Pull and lift only on the skid, not on the frame, crossmember or any part

of the equipment.

•Be sure the skid is free of other materials which may be on top of or

against the side of the skid to be removed.

Conveyor ready for shipment

CAUTION

NBC™ Flat Belt

1118140rev102213 20

Preparation of Site

After the conveyor is received, move it to the installation site or designated dry storage area as

soon as possible. Clean up all packing material immediately before parts are lost in it, or

accidentally discarded. Loose parts should remain in the shipping boxes until needed.

Prior to starting assembly of the conveyor, carefully check the installation path to be sure there

are no obstructions that will cause interference. Check for access along the path needed to

bring in bed sections and components closest to the point where they are needed. It is often

necessary to give the area along the system path a general cleanup to improve installation

efficiency, access and accuracy.

Parts Inventory and Identification

Each subassembly is shipped completely assembled except typical loose parts. Drive

assemblies are shipped mounted to the appropriate drive bed frame. Segregate the conveyor

subassemblies by types for inventory and ease of locating during installation.

An identification label is attached to one side channel or on a crossmember, close to one end

of each conveyor bed and on all drive packages. This label contains: item number, description,

job number /segment number, tag number (if specified), assembler's initials and date of

manufacture. On supports, the tag is located on the bottom side of the foot. On special devices

it is located on a convenient flat surface that is not offensive to the appearance of the

equipment but is still accessible for viewing. These numbers can be cross-referenced against

the packing list. The illustrations in this manual and the part number stickers will assist you

with your inventory.

Loose parts are boxed and shipped separately. You should have all conveyor sections and

supports for a particular conveyor prior to installation. It is cost-effective to identify and procure

any missing parts before they are needed for assembly. Small items like nuts and bolts are

weigh-counted and packaged by size and type.

Identification labels

Table of contents

Other TGW Accessories manuals

Popular Accessories manuals by other brands

Sper scientific

Sper scientific 330001 instruction manual

Atmel

Atmel QTouch AT42QT1040 Operations

LEGRAND

LEGRAND WattStopper RS-350-N installation instructions

ABB

ABB ADS420 manual

Honeywell

Honeywell Notifier FST-851 Installation and maintenance instructions

Apogee Instruments

Apogee Instruments SU-300-SS owner's manual

Honeywell

Honeywell SEARCHLINE EXCEL PLUS quick start guide

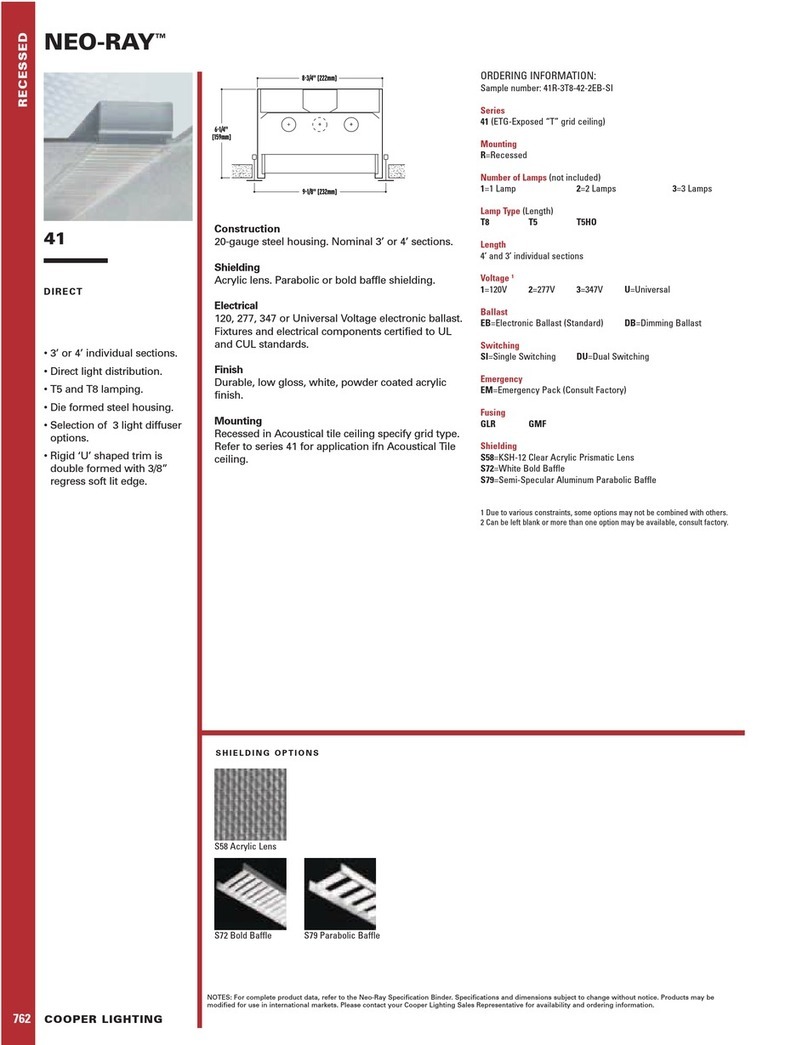

Cooper Lighting

Cooper Lighting NEO-RAY 41 specification

Philips

Philips HF3504 quick start guide

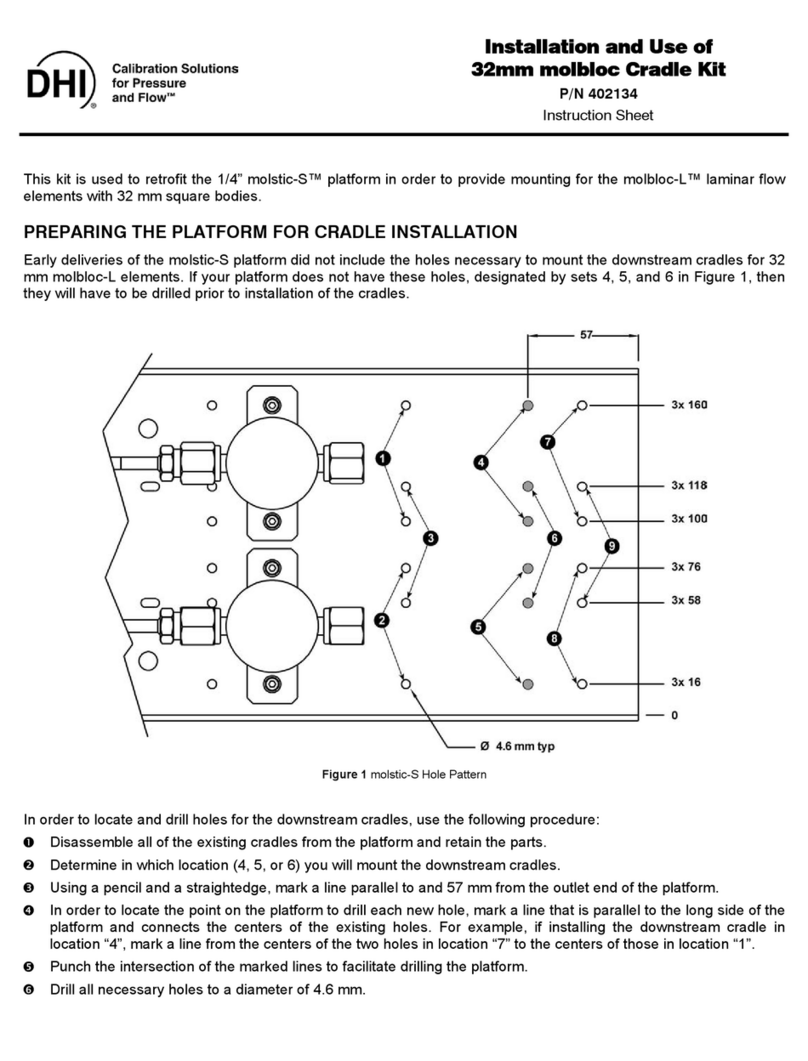

DH Instruments

DH Instruments 32MM MOLBLOC CRADLE KIT Installation and use

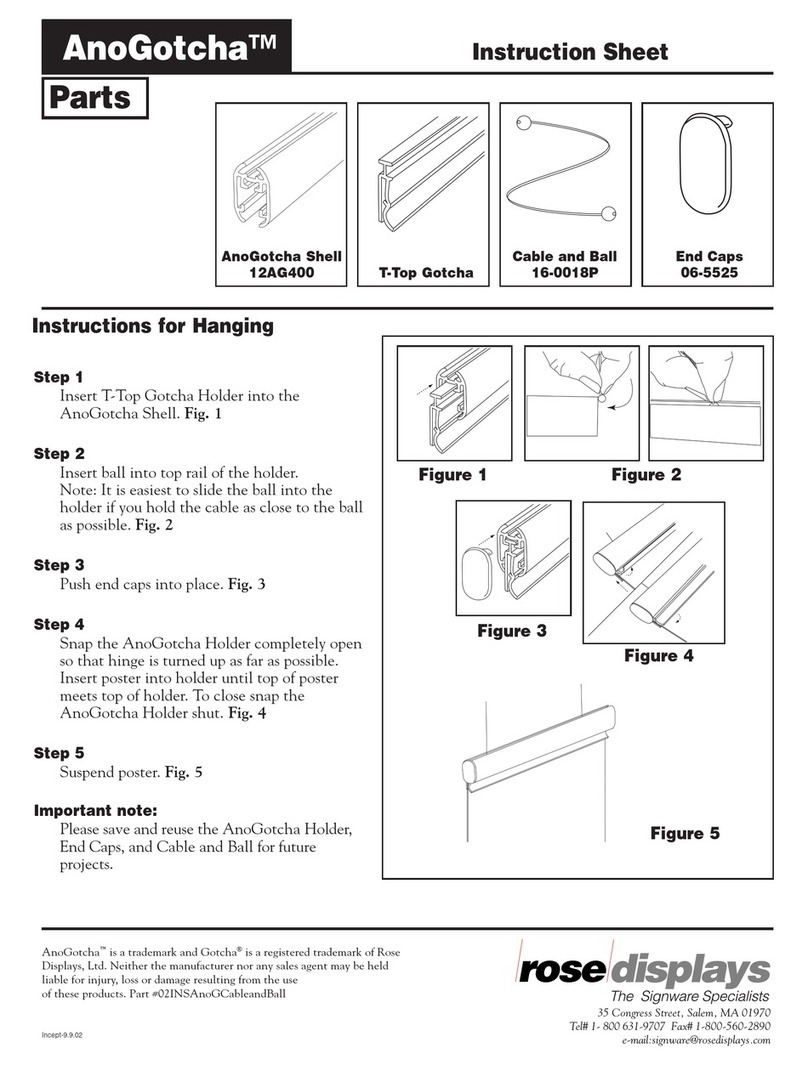

ROSE DISPLAYS

ROSE DISPLAYS ANOGOTCHA ROUND WITH CABLE AND BALL manual

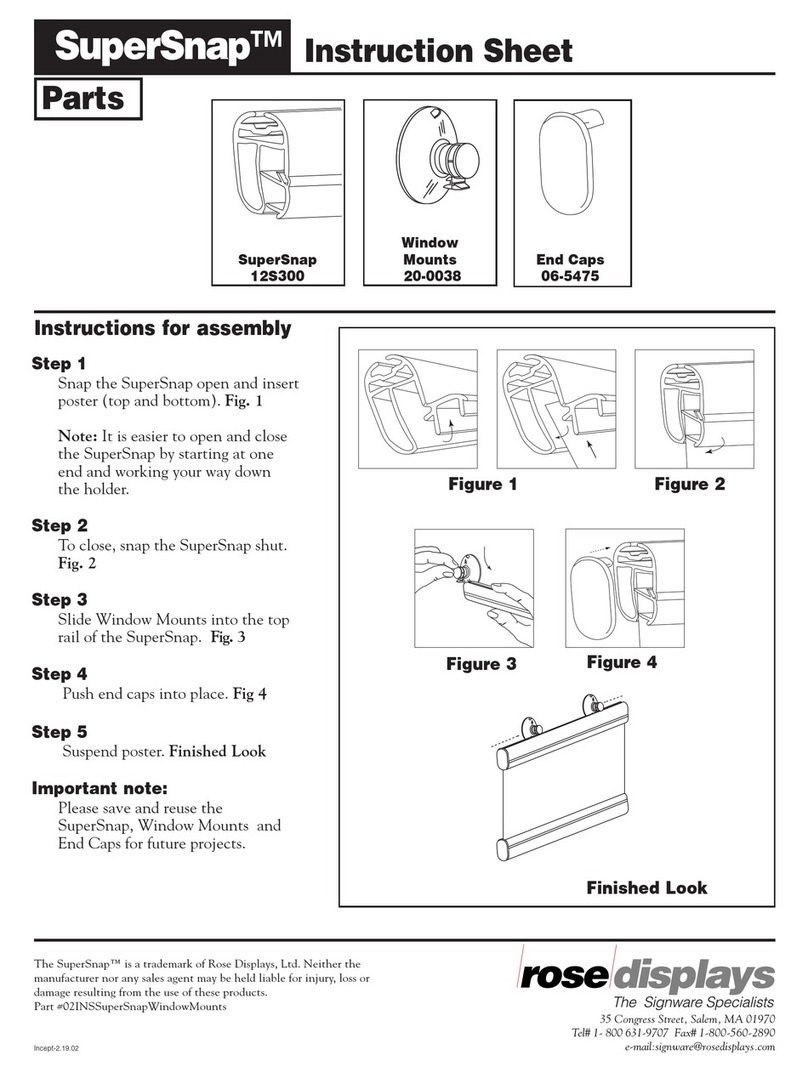

ROSE DISPLAYS

ROSE DISPLAYS SUPERSNAP WITH WINDOW MOUNTS instruction sheet