TGW XenoROL XR40 Instruction manual

INSTALLATION, OPERATION,

MAINTENANCE MANUAL

XenoROL®

XR40 and XR48

90480006rev101210

1

XR40 and XR48 IO0

PURPOSE ............................................................................................................................................................................. 3

EQUIPMENT WARRANTY ................................................................................................................................................... 4

XENOROL CONCEPT .......................................................................................................................................................... 5

WARNINGS & SAFETY INSTRUCTIONS ........................................................................................................................... 5

INTRODUCTION TO XENOROL .......................................................................................................................................... 5

PRECAUTIONS .................................................................................................................................................................... 5

DEFINITION OF TERMS ...................................................................................................................................................... 6

CAPACITY OF ROLLERS/FRAME ...................................................................................................................................... 7

MINIMUM PRESSURE ACCUMULATION ........................................................................................................................... 7

REDUCTION OF LINE PRESSURE ..................................................................................................................................... 7

GENERAL ............................................................................................................................................................................. 8

PREPARATION OF SITE ...................................................................................................................................................... 8

PARTS INVENTORY & IDENTIFICATION ........................................................................................................................... 8

RECEIVING & SITE PREPARATION ................................................................................................................................... 8

TYPICAL XENOROL® LOOSE PARTS ............................................................................................................................... 9

DIMENSIONAL REFERENCE POINTS ............................................................................................................................. 10

ELEVATIONS ...................................................................................................................................................................... 10

GENERAL PROCEDURES ................................................................................................................................................ 10

COMPONENT ORIENTATION ............................................................................................................................................ 10

TYPICAL LAYOUT/LEGEND .............................................................................................................................................. 11

LAYOUT DIMENSIONS ...................................................................................................................................................... 12

LINE-SHAFT TERMINATIONS ........................................................................................................................................... 13

FLOOR SUPPORTS ........................................................................................................................................................... 14

SUPPORTING ARRANGEMENTS..................................................................................................................................... 14

CONNECTORS ................................................................................................................................................................... 15

KNEE BRACES .................................................................................................................................................................. 15

CEILING HANGERS ........................................................................................................................................................... 16

SWAY BRACING (CEILING HANGER).............................................................................................................................. 17

DIAGONAL SWAY BRACE (FLOOR SUPPORT) .............................................................................................................. 17

MULTI-LEVEL XENOROL® SUPPORT ............................................................................................................................. 18

GENERAL ........................................................................................................................................................................... 19

BASICS OF XENOROL® INSTALLATION ....................................................................................................................... 19

DRIVES ............................................................................................................................................................................... 22

SUBASSEMBLY INSTALLATION ...................................................................................................................................... 22

CURVES ............................................................................................................................................................................. 22

JUMP CHAINS/BELTS ....................................................................................................................................................... 23

MERGE ASSEMBLY .......................................................................................................................................................... 24

SPURS ................................................................................................................................................................................ 24

TRAFFIC CONTROLLER ................................................................................................................................................... 25

XENOSWITCH ASSEMBLY ............................................................................................................................................... 25

WHEEL DIVERTER ASSEMBLY ....................................................................................................................................... 26

URETHANE BELT TRANSFER (UBT) ............................................................................................................................... 27

UBT XENOBRAKE ............................................................................................................................................................. 28

PIVOTING ROLLER STOP ................................................................................................................................................ 28

RIGHT ANGLE CONNECTION / URETHANE BELT TRANSFER MODULE (RAC/UBT MODULE) ................................ 29

XENOBRAKES ................................................................................................................................................................... 30

POWERED GATE ASSEMBLY .......................................................................................................................................... 31

ROLLERS ........................................................................................................................................................................... 32

LINE-SHAFT GUARDS ...................................................................................................................................................... 33

GUARD RAILS ................................................................................................................................................................... 34

GENERAL ........................................................................................................................................................................... 35

AIR SUPPLY REQUIREMENTS ......................................................................................................................................... 35

AIR CONSUMPTION .......................................................................................................................................................... 35

PRESSURE SWITCH ......................................................................................................................................................... 35

GENERAL ........................................................................................................................................................................... 36

ELECTRICAL ..................................................................................................................................................................... 36

SAFETY GUIDELINES ....................................................................................................................................................... 36

GENERAL ........................................................................................................................................................................... 38

COMMON ADJUSTMENTS ............................................................................................................................................... 38

90480006rev101210

2

COMMISSIONING OF EQUIPMENT .................................................................................................................................. 38

DRIVE BELT BREAK-IN .................................................................................................................................................... 38

GENERAL ........................................................................................................................................................................... 39

MOTOR AND GEARCASE ................................................................................................................................................. 39

PREVENTIVE MAINTENANCE .......................................................................................................................................... 39

CHAINS AND SPROCKETS .............................................................................................................................................. 39

TIMING BELT & PULLEYS................................................................................................................................................. 40

TIMING BELT TAKEUP & TENSION.................................................................................................................................. 40

ROLLERS ........................................................................................................................................................................... 41

DRIVE BELTS & LINE-SHAFT BEARINGS....................................................................................................................... 42

SUPPORTS/FRAMEWORK................................................................................................................................................ 42

UNIVERSAL JOINTS.......................................................................................................................................................... 42

COUPLER SPROCKETS/CHAINS .................................................................................................................................... 43

GUIDE POSTS .................................................................................................................................................................... 43

AIR SYSTEMS .................................................................................................................................................................... 43

MAINTENANCE SCHEDULE ............................................................................................................................................. 44

LUBRICATION GUIDE ....................................................................................................................................................... 45

TROUBLESHOOTING GUIDE ........................................................................................................................................... 46

TROUBLESHOOTING GUIDE-MECHANICAL .................................................................................................................. 47

TROUBLESHOOTING GUIDE-MECHANICAL .................................................................................................................. 48

TROUBLESHOOTING GUIDE-MECHANICAL .................................................................................................................. 49

TROUBLESHOOTING GUIDE-MECHANICAL .................................................................................................................. 50

TROUBLESHOOTING GUIDE-MOTOR/REDUCER .......................................................................................................... 51

TROUBLESHOOTING GUIDE-MOTOR/REDUCER .......................................................................................................... 52

TROUBLESHOOTING GUIDE-ELECTRICAL ................................................................................................................... 53

REPAIR PROCEDURES .................................................................................................................................................... 54

COUPLER CHAINS ............................................................................................................................................................ 54

CHAIN & SPROCKETS ...................................................................................................................................................... 54

UNIVERSAL JOINTS ......................................................................................................................................................... 55

LINE-SHAFT BEARINGS (STANDARD) ............................................................................................................................ 55

LINE-SHAFT ....................................................................................................................................................................... 56

REDUCERS/GEARMOTORS ............................................................................................................................................. 56

RIGHT ANGLE CONNECTION .......................................................................................................................................... 56

DRIVE BELTS ..................................................................................................................................................................... 57

XENOBRAKES ................................................................................................................................................................... 58

SOLENOID VALVES .......................................................................................................................................................... 58

MOTOR CONTROLS .......................................................................................................................................................... 59

SENSING SWITCHES ........................................................................................................................................................ 59

PARTS IDENTIFICATION .................................................................................................................................................. 60

INTERMEDIATE BEDS ...................................................................................................................................................... 60

CURVES ............................................................................................................................................................................. 60

DRIVE PACKAGE AND BED ............................................................................................................................................. 62

LOW PROFILE DRIVE PACKAGE AND BED ................................................................................................................... 62

URETHANE BELT TRANSFERS ....................................................................................................................................... 63

URETHANE BELT TRANSFER OPTIONS ........................................................................................................................ 63

JUMP CHAIN ASSEMBLY ................................................................................................................................................. 64

RIGHT ANGLE CONNECTION / URETHANE BELT TRANSFER MODULE .................................................................... 64

WHEEL DIVERTER ASSEMBLY ....................................................................................................................................... 65

MERGE ASSEMBLY .......................................................................................................................................................... 65

GATE .................................................................................................................................................................................. 66

XENOSWITCH ASSEMBLY ............................................................................................................................................... 66

XENOBRAKE ..................................................................................................................................................................... 67

LOCATING STOP AND PIVOTING ROLLER STOP .......................................................................................................... 67

ROLLER DATA ................................................................................................................................................................... 68

PARTS IDENTIFICATION LIST .......................................................................................................................................... 69

PARTS IDENTIFICATION LIST .......................................................................................................................................... 70

ADDITIONAL REPLACEMENT PARTS............................................................................................................................. 71

XR40/48 DRIVE BELT DATA .............................................................................................................................................. 72

DRIVE PARTS IDENTIFICATION ...................................................................................................................................... 73

LOW PROFILE DRIVE DATA ............................................................................................................................................. 74

90480006rev101210

3

90480006rev101210

It is the intent of TGW Systems Inc., through this manual, to provide

information that acts as a guide in the installation, operation and mainte-

nance of TGW Systems XenoROL ® conveyors.

This manual describes basic installation practices, assembly arrange-

ments, preventive maintenance, repair procedures, troubleshooting, ser-

vice intervals and assists in replacement parts identification.

If additional copies of this manual are needed or if you have any question

concerning the conveyor, please contact Customer Service at

231/798-4547 or Fax 231/798-4146.

PURPOSE

90480006rev101210 4

EQUIPMENT WARRANTY

TGW Systems warrants that the material and workmanship entering into its equipment is merchantable

and will be furnished in accordance with the specifications stated.

TGW Systems agrees to furnish the purchaser without charge any part proved defective within 2 years

from date of shipment or before the equipment has forty-one hundred (4100) hours of running use,

whichever period is shorter, provided the purchaser gives TGW Systems immediate notice in writing

and examination proves the claim that such materials or parts were defective when furnished. For drive

components specific to XenoROL® (i.e. Xeno belts, slave Xeno belts, drive spools, standard and

speed-up, and spacers), this warranty shall be extended to five years or ten thousand (10,000) hours of

running use, whichever period is shorter, provided the conveyors are applied, installed and maintained

in accordance with TGW Systems published standards. Other than the above, there are no warranties

which extend beyond the description on the face hereof. Consequential damages of any sort are

wholly excluded.

The liability of TGW Systems will be limited to the replacement cost of any defective part. All freight

and installation costs relative to any warranted part will be at the expense of the purchaser. Any liability

of TGW Systems under the warranties specified above is conditioned upon the equipment being

installed, handled, operated, and maintained in accordance with the written instructions provided or

approved in writing by TGW Systems.

The warranties specified above do not cover, and TGW Systems makes no warranties which extend to,

damage to the equipment due to deterioration or wear occasioned by chemicals, abrasion, corrosion or

erosion; Purchaser's misapplication, abuse, alteration, operation or maintenance; abnormal conditions

of temperature or dirt; or operation of the equipment above rated capacities or in an otherwise improper

manner.

All equipment and components not manufactured by TGW Systems carry only such warranty as given

by the manufacturer thereof, which warranty TGW Systems will assign or otherwise make available to

Purchaser without recourse to TGW Systems, provided that such warranty is assignable or may be

made available.

IMPORTANT

For service on motors, reduction units, electrical components, controls, air or hydraulic cylinders,

contact the local authorized sales and service representative of respective manufacturer. If none is

available in your locality, contact the TGW Systems representative. TGW Systems will not be

responsible for units that have been tampered with or disassembled by anyone other than the

authorized representative of the respective manufacturer.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EXTENDING

BEYOND THOSE SET FORTH IN THIS STATEMENT OF WARRANTY.

Rev 04/08/2009

5

90480006rev101210

WARNINGS & SAFETY INSTRUCTIONS

Failure to follow the instructions, warnings, cau-

tions (throughout this booklet) and warning labels

(on the conveyor) may result in injury to personnel

or damage to the equipment.

Never remove, deface or paint over WARNING or

CAUTION labels. Any damaged label will be replaced

by Ermanco Inc. at no cost by contacting the Distributor

Services Department.

It is very important to instruct personnel in proper con-

veyor use including the location and function of all con-

trols. It is important to establish work procedures and

access areas which do not require any part of a person

to be under the conveyor. It should be required that

long hair be covered by caps or hair nets and the wear-

ing of loose clothing or jewelry when working at or near

the conveyor be prohibited.

Maintain enough clearance on each side of the unit for

safe adjustment and maintenance of components.

Provide crossovers or gates at sufficient intervals to

eliminate the temptation to climb over or under any con-

veyor. Prohibit riding or walking on conveyor by any-

one.

REMOVE ALL UNUSED COUPLER SPROCKETS.

AT OPEN ENDS (TERMINATION) OF XenoROL

CONVEYORS, ADD THE SET COLLAR PROVIDED

TO THE END OF THE LINE-SHAFT AND INSTALL

THE LINE-SHAFT END COVER. THE SET COLLAR

AND ORANGE END COVER ARE FOUND IN THE

LOOSE PARTS BOX.

INTRODUCTION TO XenoROL

XENOROL CONCEPT

XenoROL rollers are driven by pretensioned polyure-

thane belts which pull the drive spools against the line-

shaft. Each spool delivers a fixed amount of torque

from the line-shaft to the rollers. This torque is based

on the drive belt tension and coefficient of friction be-

tween the spool and line-shaft. If the torque require-

ment to drive the load on the rollers exceeds the fixed

torque of the spool, the spool slips on the line-shaft like

a clutch.

PRECAUTIONS

TEMP. RANGE (AMBIENT): 35°F to 100°F. For tem-

perature applications outside this range, consult the

Distributor Services Department.

ULTRAVIOLET RAYS: Avoid exposure of polyure-

thane belts to sunlight.

OILY OR WET CONDITIONS: Will impair frictional

drive characteristics between spool and line-shaft.

CORROSIVE OR ABRASIVE SUBSTANCES: Will

adversely affect various components, voiding the war-

ranty.

XenoROL conveyor allows unequaled versatility with

high speed, complete reversibility and minimum pres-

sure accumulation. A major benefit of XenoROL line-

shaft driven conveyor is the ability to power straight

sections and curves plus auxiliary devices from a single

drive. Auxiliary equipment includes: transfers, spurs,

adjoining parallel sections, merges, switches, sortation

devices, powered guard rails, etc.

Your XenoROL® line-shaft driven live roller conveyor is

powered by a motor and can be stopped only by turning

off electrical power to the motor. As with all powered

machinery, the drive and driven sprockets, chains, line-

shafts, universal joints and pneumatically actuated de-

vices present a danger. We have installed or provided

guards to prevent inadvertent contact with these com-

ponents along with warning labels to identify the haz-

ards. After maintenance, REPLACE guards imme-

diately. Keep ALL warning labels clean and clear

of any obstructions.

Warnings and Cautions are included throughout this

manual and are defined as follows:

WARNING - A notice which, if not followed, could

result in a serious injury to

personnel.

CAUTION - A notice which, if not followed, could

result in damage to equipment.

6

90480006rev101210

DEFINITION OF TERMS

Accessory - A device which receives power from and

contributes to the horsepower requirement of the line-

shaft.

Accumulation (Minimum Pressure) - Act of queuing,

holding, or backing up of product on a conveyor.

Carrying Roller - The conveyor roller upon which the ob-

ject being transported is supported. It has a circumfer-

ential groove near one end to allow the drive belt to ride

below the carrying surface.

Coefficient of Friction - A numerical expression of the

ratio between the force of contact between two sur-

faces and the resistant force tending to oppose the

motion of one with respect to the other.

Conveyor Width - The dimension outside to outside of

frame rails. For the inside dimension, the abbreviation

used is "BF" (between frames).

Coupler - A mechanical device which connects seg-

ments of the line-shaft.

Coupler Chain - A double wide chain, plastic or metal,

which performs the function of connecting one sprocket

to an adjacent sprocket.

Coupler Sprocket - A sprocket located at the extreme

end of a line-shaft, positioned to allow connection to a

second sprocket on another line-shaft by using a cou-

pler chain.

Crossmember - Structural member which is assembled

between two side channels of a conveyor bed.

Drive - An assembly of mechanical, electrical, and

structural components to provide power to line-shaft.

Drive Belt - An endless round belt manufactured from

elastic material, typically urethane, connecting spools to

carrying rollers for transmitting rotation of line-shaft.

Drive Sprocket - The sprocket which propels the chain

or synchronous belt.

Driven Sprocket - The sprocket which is propelled by

the chain or synchronous belt.

Frame - The structure which supports the components

of a conveyor bed consisting of formed channel rails

bolted together with square tubing crossmembers.

Guard Rail - Members paralleling the path of a conveyor

and limiting the unit loads to movement in a defined

path.

Jump Chain - A drive chain or belt which transmits

power from one line-shaft to an adjacent parallel line-

shaft. A crossover between adjacent line-shafts within

a common conveyor frame is called an internal jump

chain. A crossover between a line-shaft in one con-

veyor frame and a line-shaft in an adjacent parallel con-

veyor frame is called an external jump chain.

Line-shaft - Shaft which runs longitudinally within line-

shaft conveyor to provide power transmission to carry-

ing rollers and accessory equipment.

Line-shaft Bearing - The pillow block style bearings in

which the line-shaft rotates.

Line-shaft Curve - A curved conveyor section equipped

with a line-shaft segmented with universals to change

the direction of product travel horizontally. The curve

radius is measured to the inside face of the inside frame

rail.

Line-shaft Guard - Provided to prevent entanglement in

rotating parts.

Roller Centers - Distance between center lines of adja-

cent rollers. For curves, roller centers are measured at

the inside radius.

Roller Groove - The groove that is fabricated into the

carrying roller to provide a seat for the drive belt below

the carrying surface.

Speedup Spool - (See spool) A spool of larger diameter

than adjacent spools assembled to the line-shaft. The

difference in diameters causes those carrying rollers

powered by the speedup spools to rotate faster than

those driven by the smaller spools when driven by the

same line-shaft.

Spool (Pulley) - A sheave or concave cylinder as-

sembled on the line-shaft with slip fit to provide friction

drive to carrying rollers but also “slip” in case of stalled

carrying rollers. Also contains and protects drive belt.

Sprocket Ratio - The ratio of the number of teeth of the

driven sprocket to the drive sprocket.

Tapered Roller - A conical conveyor roller for use in a

curve with end and intermediate diameters proportional

to their radius.

Universal Joints - A device used to connect two inter-

secting line-shafts whose axes are not in a straight line.

XenoBRAKE® - Pneumatically operated pad mounted

below the conveyor rollers used to stop the carrying roll-

ers upon signal by a sensor.

7

90480006rev101210

Average lbs. pressure per roller.

MINIMUM PRESSURE ACCUMULATION

When conveyed product is stopped, the friction between

the product and the roller stops the roller, drive belt and

spool. Though the shaft continues to turn, only mini-

mal friction exists between the inner surface of the spool

and the line-shaft surface. The pressure of accumu-

lated product is independent of its weight and is deter-

mined by the belt tension.

Long lengths of accumulated product must be zoned

with stop devices. This reduces the total line pressure

into several smaller increments. Stopping devices are

also used to accumulate product prior to the curves. Air

or electrical sensor controls can be supplied to activate

the stop device. Always consult the Distributor Services

Department.

REDUCTION OF LINE PRESSURE

Pressure of accumulated articles can be reduced by

removing belts at specified intervals on the conveyor.

For example, accumulated pressure can be reduced

25% by removing every fourth belt. CAUTION: THE

DRIVE CAPACITY IS ALSO REDUCED 25%.

OPTIONAL BELTS: Consider the optional drive belts

for lighter loads. This will increase conveyor length on

a single drive while reducing horsepower requirements.

CAPACITY OF ROLLERS/FRAME

DRIVE PER ROLLER BY TYPE OF BOTTOM

Product Bottom

(Conveying Surface)

Drive Capacity per Roller (lbs.)

XR40 XR48

1-4" Dia. Belts

3/16"

Std.

5/32"

Option

1/8"

Option

12-3/4"

Std.

13-1/2"

Option

Soft, weak bottom, load unbalanced, uneven bottom, with noticeable

bumping. Ex.: plastic totes, wire or steel baskets, lightweight

corrugated (always use 3" centers).

15 10 630 25

Slight indentation, less than even loading. Ex.: normal corrugated and

plastic totes (includes most applications). 20 14 940 34

Firm, flat bottom and uniform loading. Ex.: heavy wall corrugated,

double wall corrugated and stiff treated materials. 25 17 11 50 42

Hard & flat bottom, retaining some flexibility, uniform load distribution.

Ex.: plywood and fiberboard. 30 20 13 60 50

Note: Optional bearings with seals may reduce the roller drive capacity.

If product conveys hard against the guard rail (ex. where a transfer is used to square product against the guard rail),

reduce the capacity by 25%.

FRAME CAPACITY

Frame

Channel

Depth

Support Centers (lbs./ft.)

10' 9' 8' 7' 6' 5'

XR40

4-1/2" Deep 60#/ft. 90#/ft. 145#/ft. 235#/ft. 395#/ft. 710#/ft.

XR40/XR48

9" Deep 215#/ft. 305#/ft. 450#/ft. 670#/ft. 1115#/ft. 1960#/ft.

Note: The 4-1/2" deep frame has more capacity when supported on 8' centers than XR40 roller drive

capacity. The 9" deep frame has more capacity when supported on 9' centers than XR40 or XR48 roller

drive capacity.

XR40 XR48

3/16"

Std.

5/32"

Option

1/8"

Option

1/4" x

12-3/4"

Std.

1/4" x

13-1/2"

Option

1# 0.7# 0.5# 2# 1.7#

8

90480006rev101210

RECEIVING & SITE PREPARATION

CAUTION

TAKE CARE DURING THE REMOVAL OF EQUIP-

MENT FROM THE CARRIER. Remove small

items and boxes first. Pull and lift only on the

skid, not on the frame, crossmember or any part

of the equipment. Be sure the skid is free of

other materials which may be on top of or

against the side of the skid to be removed.

PREPARATION OF SITE

After the conveyor is received, move it to the installation

site or designated dry storage area as soon as possible.

Clean up all packing material immediately before parts

get lost in it. Loose parts should remain in the shipping

boxes until needed.

Prior to starting assembly of the conveyor, carefully check

the installation path to be sure there are no obstructions

that will cause an interference. Check for access along

the path needed to bring in bed sections and compo-

nents closest to the point where they are needed. It is

often necessary to give the area along the system path a

general cleanup to improve installation efficiency, access

and accuracy.

Ceiling-hung conveyor header steel should be installed well

ahead of the conveyor frame installation to minimize conges-

tion.

PARTS INVENTORY & IDENTIFICATION

Each subassembly is shipped completely assembled

except typical loose parts which are listed on page 9.

Drive assemblies are shipped mounted to the drive con-

veyor frame.

Segregate the conveyor subassemblies by types for

inventory and ease of locating during installation.

GENERAL

XenoROL® line-shaft driven live roller conveyors are

shipped in subassemblies. These subassemblies are

packaged to guard against damage in shipment.

Examination immediately following unloading will show

if any damage was caused during shipment. If dam-

age is evident, claims for recovery of expenses to

repair damage or replace components must be made

against the carrier immediately. While unloading, a

check must be made against the Bill of Lading, or other

packing lists provided, to confirm full receipt of listed

items.

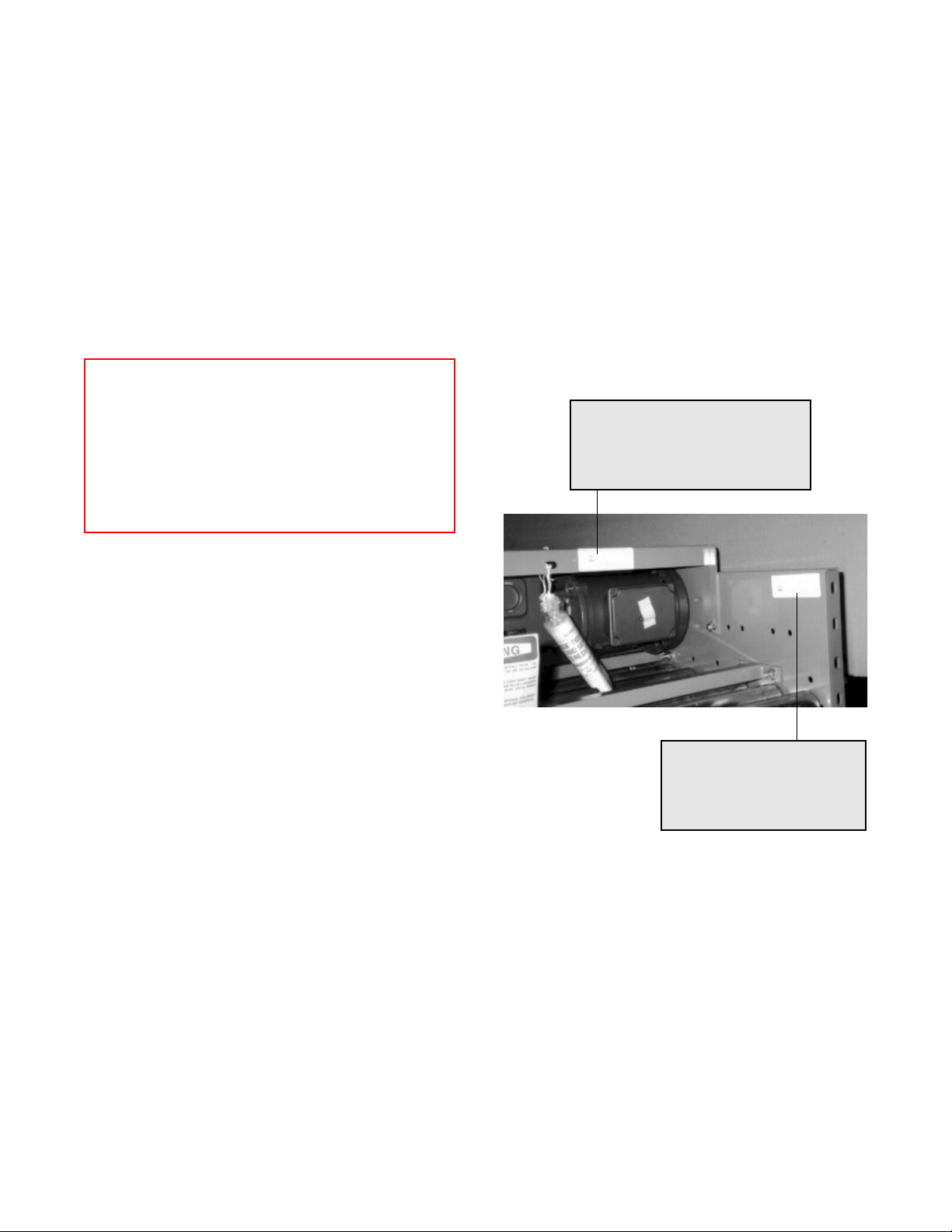

An identification label is attached to the inside of one

side channel close to one end of each conveyor bed

and on all drive packages. (See below.) This label

contains: job number, part number, order number, tag

number (if specified), assembler's initials and date of

manufacture. On supports, the tag is located on the

bottom side of the foot. On special devices it is located

on a convenient flat surface that is not offensive to the

appearance of the equipment but is still accessible for

viewing. These numbers can be cross-referenced

against the packing list. The illustrations in this manual

and the part number stickers will assist you with your

inventory.

Identification labels on

bed and drive package

IT#: 40084360

DSC: DR,CTR 24XR40 3/4 HP 60 B

JOB: C003325 11/10/96

mt

Loose parts are boxed and shipped separately. You

should have all conveyor sections and supports for a

particular conveyor prior to installation. It is cost-

effective to identify and procure any missing parts

before they are needed for assembly. Small items

like nuts and bolts are weigh-counted and packaged by

size and type.

IT#: X9503463

DSC: BED 24XR40-3D-X 10'

JOB: C003325 11/10/96

TAG: 101E

O-RINGS 90530005 90530009

9

90480006rev101210

TYPICAL XenoROL® LOOSE PARTS

Part Number Item Use Illustration

41700910

Line-shaft Guard End Cover

with Set Collar Kit

COVER with Set Collar, Kit

Cover End of Lineshaft at Termination of

Conveyor See WARNING Page 13

90140001 Safety Caps Cover End of Line-shaft Keyway See WARNING Page 20

90314510 Line-shaft Guard, 10' straight Guard Line-shaft See Page 33

41701000 Attaching Bracket Fasten Line-shaft Guard See Page 33

95200001 Spring Clip Nut 1/4 - 20 Fasten Line-shaft Guard See Page 33

95000021 Hex Head Flange Bolt 1/4-

20x3/4 Fasten Line-shaft Guard See Page 33

95300036 Rubber Washer Isolate Guard See Page 33

90480028 U-joint Cover Guard Horizontal to Incline, Straight Beds

90140025 Coupler Chain Line-shaft Coupling Bed to Bed See Page 20

Varies by Size Floor Support Support Conveyor Frames See Page 14

80400002 KBA Knee Brace Brace Frame to Support Leg See Page 15

80400003 KBB Knee Brace Brace Frame to Support Leg See Page 15

80400004 KBC Knee Brace Brace Frame to Support Leg See Page 15

80700001 Guard Rail Arm Support Adjustable Channel G.R. See Page 34

80700006 Guard Rail Upper Bracket Fasten Adjustable Channel G.R. to Arm See Page 34

80700007 Guard Rail Lower Bracket Fasten Arm to Frame See Page 34

80700011 Guard Rail Splice Angle Support Rail to Rail Joint See Page 34

95000027 1/4-20 Bolt x 2" Hex Head Upper Bracket to Channel G.R. See Page 34

95000075 3/8-16 x 1" Hex Head Bolt Lower Bracket to Frame and Brackets to

Arm See Page 34

95000020 1/4-20 x 3/4" Hex Head Bolt Splice Angle to Channel Guard See Page 34

95200050 1/4-20 Nuts Adjustable Channel G.R. See Page 34

80700112 Spacer Channel Ceiling Hanger See Page 16

80700013 V-Bracket Ceiling Hanger See Page 16

Varies b y

Length Cross Pipe Ceiling Hanger See Page 16

80701011 Standhead Connector Bed Joints See Page 15

40700051 Butt Bolt Connectors Bed Joints See Page 15

Special Connector Devices Per Application

Electrical Components Per Application

Special Device Parts Per Application

95000072 3/8-16 x 3/4 Hex HD Bolts Butt Bolts, Braces, Supports

95000074 3/8-16 x 3/4 Truss HD Bolts Angle Guard Rail

95200061 3/8-16 Nuts Angle Guard Rail

90530009 O-ring Drive Belts Rollers on discharge end of beds 24" wide

or more

90530005 O-ring Slave Belts Roller to roller belts at bed joints

80701002 2" Angle Guard Rail Straight conveyor

Varies by width Inside & Outside Angle G.R. Curves

Varies by width Rollers for beds 24" wide or

more*

Carrying rollers mounted in hex frame

holes

* Rollers for 30" wide conveyor and wider are shipped as loose parts.

Components for pneumatic options, including solenoid valves, fittings, air lines and mounting brackets are shipped as loose parts.

10

90480006rev101210

GENERAL PROCEDURES

After the first elevation is established at a critical point,

the elevation of all other points shall be relative to

this first point. Normal practice is to dimension the

layout and measure elevations from the floor at each

point of support. As the conveyor system proceeds

onto another floor or into another building or room, a

new elevation will be measured from the floor at that

point. This new elevation will then become the

reference for subsequent elevations.

When installing an overhead system, the first eleva-

tion is measured from the floor and becomes the

reference elevation point until a change in elevation is

shown on the layout. Any new elevation is also

measured from the floor and becomes the new refer-

ence point. The process is repeated each time an el-

evation change occurs.

The following procedures are to be used as guidelines

only for conveyor installation. Specific methods will vary

somewhat depending on available equipment on site

and each installer's preferences based on past experi-

ence.

WARNING

The Installation Supervisor must be experi-

enced with conveyor and qualified in the

mechanics of the equipment and enforce

safe working procedures for the protection

of the crew, customer, and customer's prop-

erty.

CAUTION

Consult the building architect or a struc-

tural engineer regarding ceiling loading or

structural limitations of the building if any

conveyor is ceiling hung.

COMPONENT ORIENTATION

Using your conveyor system layout drawing and the

numbers on the I.D. tags on each component, position

and orient the conveyor sections. You must know:

• The direction of product flow

• The elevation height

• How the drive is positioned

• Conveyor drive shaft location

• Any speed differential in jump chains

• Drive termination points

Note: IMPORTANT! Use extreme care when initially

orienting line-shaft conveyor components. Each line-

shaft conveyor section must be properly oriented to

ensure correct coupling to the next conveyor section.

For example, using the wrong jump chain bed or wrong

orientation may cause the following conveyor to run at

the wrong speed.

IMPORTANT! Do not make alterations to the equip-

ment without consulting with user's representative and

Ermanco. Unauthorized modifications to the equipment

may impair its function, create a hazardous condition,

affect its useful life and/or void the warranty. IMPOR-

TANT! At drive termination points, the coupler sprock-

ets must be removed before the section is installed.

DIMENSIONAL REFERENCE POINTS

The path of each conveyor in the system is determined

by establishing a reference point at each end. The cen-

ter line of the conveyor is established and a chalk line is

snapped between these points.

Conveyors should be installed with the center line of

the bed matching the center line of the conveyor path.

Locate and mark the center of the crossmembers at

each end of the conveyor. Use a plumb line or other

acceptable means to ensure accuracy to the chalk line.

Always carry out a thorough check for any obstructions

such as building columns, manholes, etc. It may be

necessary to reroute the conveyor to avoid the obstruc-

tion. In this case it would be advisable to begin installa-

tion at this point, using the obstruction as a reference

point (Datum), and install the sections in either direc-

tion as required.

All conveyor sections must be checked for squareness

prior to installation as "racking" or being knocked out of

square may have occurred during shipping and han-

dling. (Reference page 19.)

ELEVATIONS

All conveyors should be installed in accordance with

the elevations shown on the drawings. In addition, all

conveyors must be level across the frame width and

length (if horizontal). Leveling of the frames is best

done using a rotating laser level or a builder's level.

11

90480006rev101210

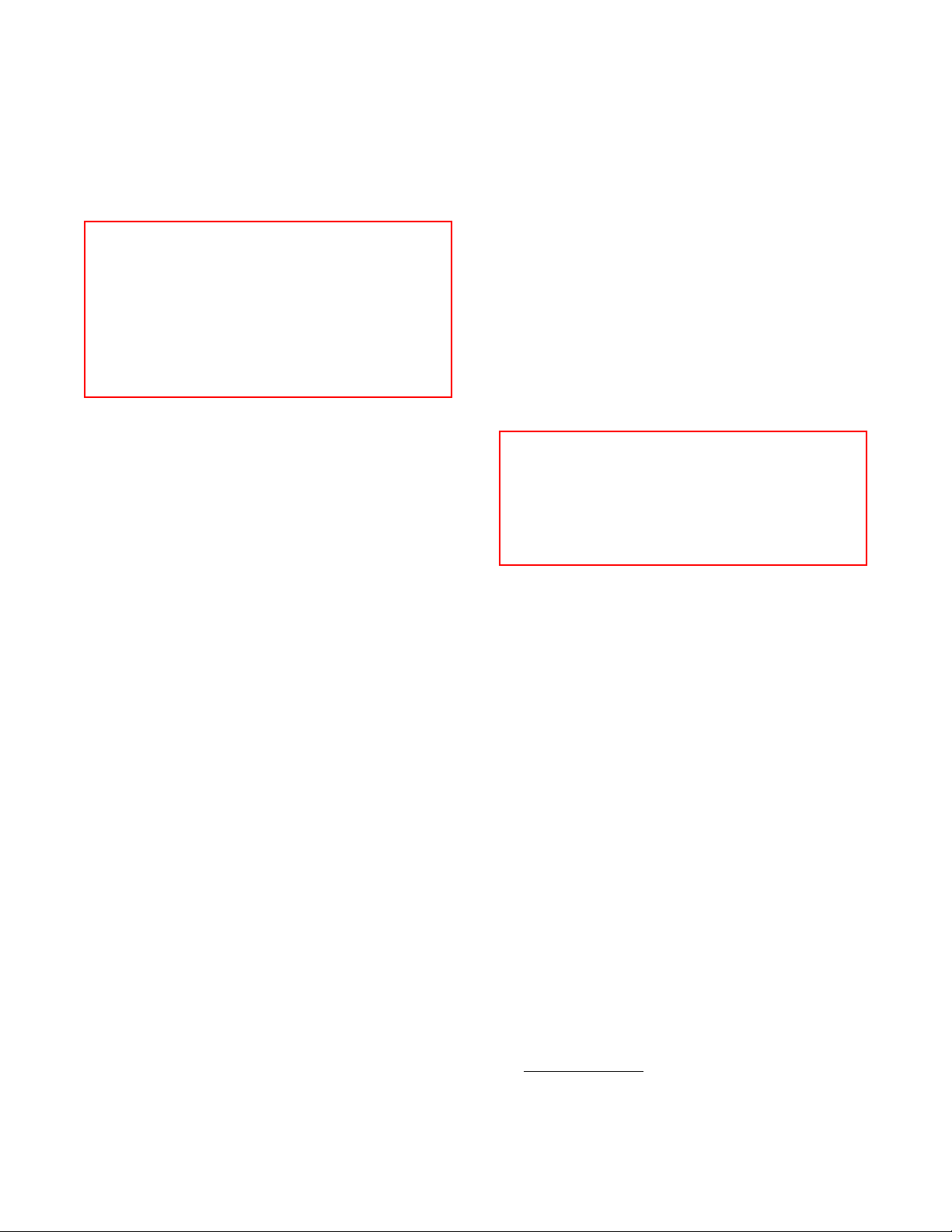

TYPICAL LAYOUT/LEGEND

Illustrated below is a hypothetical layout of an Ermanco

conveyor system. The dimensional data has been left

off for clarity. This layout is made up of a combination

of symbols from the legend as found on TGW Systems'

TECAP program layout software. This is typical of a lay-

out that would be received from Ermanco or any dis-

tributor using this software.

The layout you have received may or may not have the

match mark tag numbers as indicated in the balloons.

If your layout is tagged, these ballooned numbers will

match the tag number on each bed assembly or device.

(Ref. pg. 8). If the layout is not match marked, care must

be taken to see that the right device or drive, etc. is lo-

cated properly. Drive information, including horsepower

and speed, should be noted on the layout. Also shown

symbolically are positions of line-shafts, jump chains,

zero pressure zones, transfer flow direction, etc.

LAYOUT

LEGEND

12

90480006rev101210

LAYOUT DIMENSIONS

In laying out the conveyor path, the dimensions shown on

this page indicate the relative position between parallel or

perpendicular conveyors in utilizing a spur. For example,

dimension "G" indicates the center-to-center distance of

two parallel conveyors offset through a specific spur de-

gree and width when used with a corresponding curve.

As shown in the chart, dimension "E", the length of the

spur, is determined by the conveyor width which directly

affects dimensions "G" and "D" or "J" and "H". Normally,

merging takes place at 45° while most diverting devices uti-

lize 30°. Reference the overall layout to determine which

set of dimensions to use.

Since the original system layout will have already taken

these dimensions into account, they are most useful in

making future changes to the system. Note: These dimen-

sions do not include the wheel diverter. (Ref. page 26).

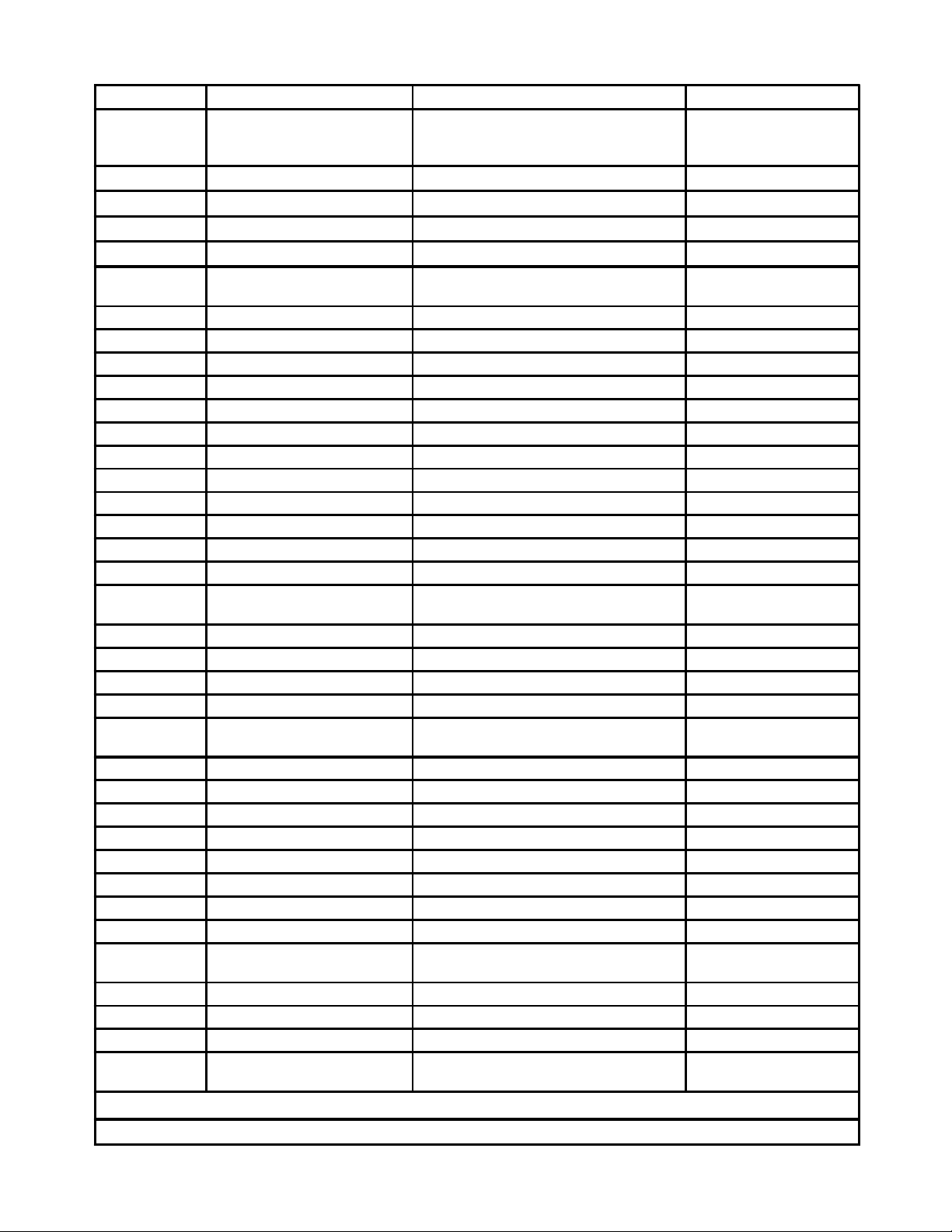

30° SPUR DIMENSIONS (In Inches)

A" B" C" D" E" F" G" H" I" J"

15-1/2

18-1/2

24-1/2

72

72

96

26

26-1/4

27-1/4

80-1/4

81-3/4

95-1/8

36

36

48

19

19-3/4

25-1/2

24-3/4

25

32

56

57-3/8

66-1/4

59

59-3/4

71-1/2

80-1/4

81-3/4

95-1/8

30-1/2

36-1/2

42-1/2

96

120

120

28

28-3/4

29-3/4

108-1/2

122

135-3/8

60

72

84

32

38-1/2

44-7/8

38-3/4

45-3/4

52-3/8

75-1/4

84-1/2

93-3/8

83-1/2

95-1/4

107-1/2

18-1/2

122

135-3/8

45° SPUR DIMENSIONS (In Inches)

A" B" C" D" E" F" G" H" I" J"

15-1/2

18-1/2

24-1/2

72

72

96

27-1/4

27-3/4

29

76-1/2

87-1/8

91-3/8

24

36

36

19-1/4

28

28-1/4

31-3/4

41

42-3/4

49-1/2

59-1/4

62-1/4

46-1/2

56

58-1/4

59

69

72

30-1/2

36-1/2

42-1/2

96

120

120

30-1/2

31-1/2

32-3/4

104

108-1/4

121

48

48

60

38-1/2

39-1/2

48-3/4

53-1/4

54-3/4

65-1/4

73-3/4

76-3/4

88-1/2

69

71

81-1/2

83-1/2

86-1/2

97-3/4

13

90480006rev101210

Never leave unused sprockets on line-shaft.

WARNING

Safety caps are required on ends of all ad-

joining line-shaft conveyor beds not

coupled together.

When continuing drive, install coupler

chain per instruction on pages 19 and 20.

LINE-SHAFT TERMINATIONS

End

Cover

in position

Set Collar

At joint between adjacent drive units, remove

sprockets and add white plastic safety caps.

WARNING

At the termination of the XenoROL ® line-

shaft driven conveyor(s), the open end of

the line-shaft guard must be covered with

the end cover kit provided in the loose

parts. This kit includes instructions,

mounting hardware and 1" bore set collar.

The set collar replaces the unused coupler

sprocket. This end cover must be used at

all exposed ends including XenoROL ter-

minations abutting other types of conveyor

or machinery.

WARNING

Remove any coupler sprocket which is not

coupled to an adjacent sprocket. These

sprockets must be removed BEFORE the

bed is installed. The white line-shaft safety

caps must be installed in place of the

sprockets to cover the end of the keyway.

14

90480006rev101210

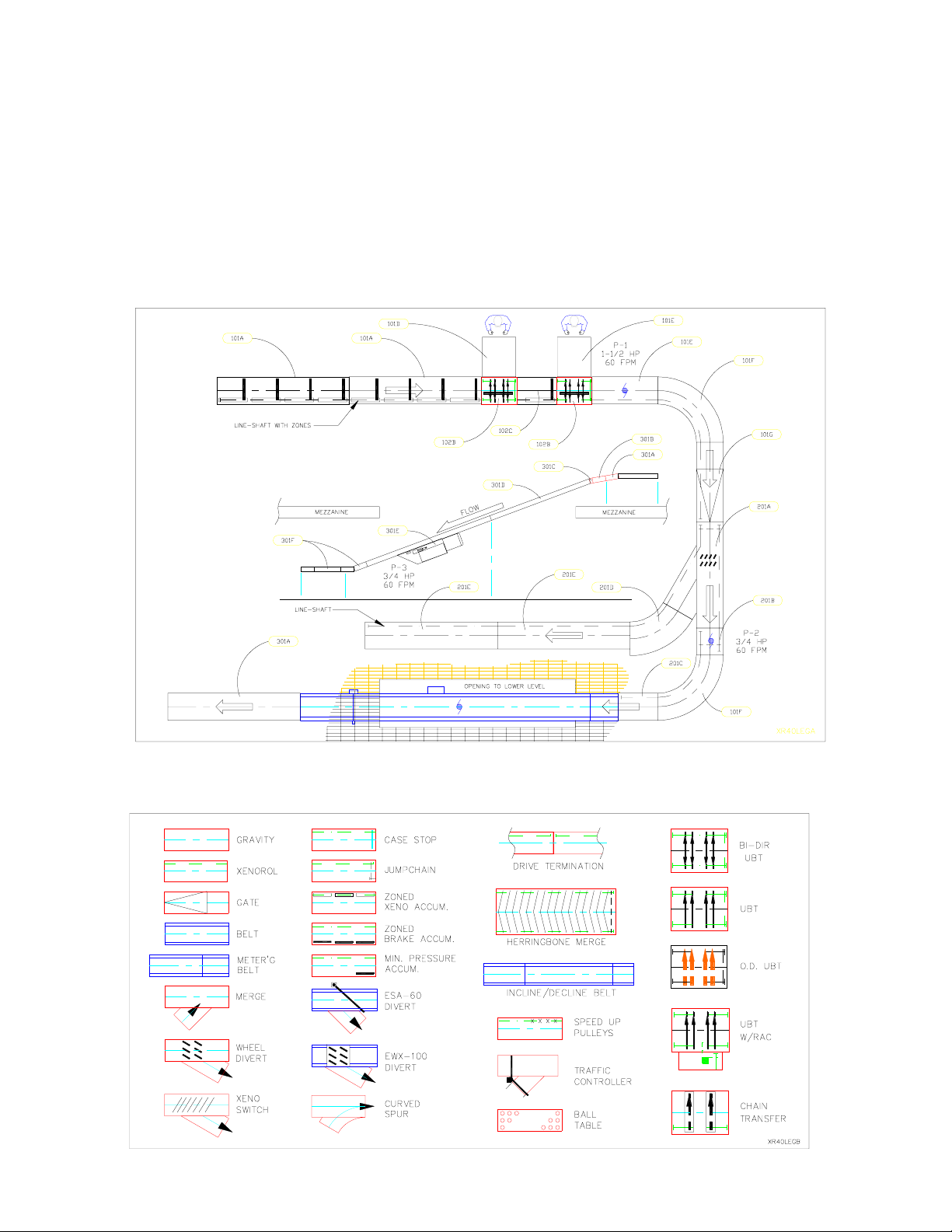

FLOOR SUPPORTS

Install bolts used to attach the standhead to the frame

so the nut is on the bottom. Standhead bolts should

be left finger tight while the conveyor is being as-

sembled and aligned.

There are various frame rail depths depending on options

and accessories. Floor supports are ordered by nominal

height range, which is the dimension from the floor to top of

the support. Conveyor elevations are shown on the layout

by top-of-roller elevations. This difference must be recog-

nized when setting the support elevations. XenoROL

® con-

veyor is 4-7/8" from top-of-support to top-of-rollers with a

4-1/2" deep frame channel.

It is important that conveyor frames be installed level.

Floor supports will accommodate normal irregularities

in the floor surface. Adjustment for elevation in floor

supports is accomplished with metal-on-metal bolt

clamping force. To achieve the support's st ated load

rating, it is necessary to tighten the elevation adjust-

ment bolts (3/8" diameter) to 23 ft.lbs. of torque.

Supports should always be installed in the vertical position,

and any variations due to conveyor pitch or floor slope will be

compensated for in the pivoting standhead of the support.

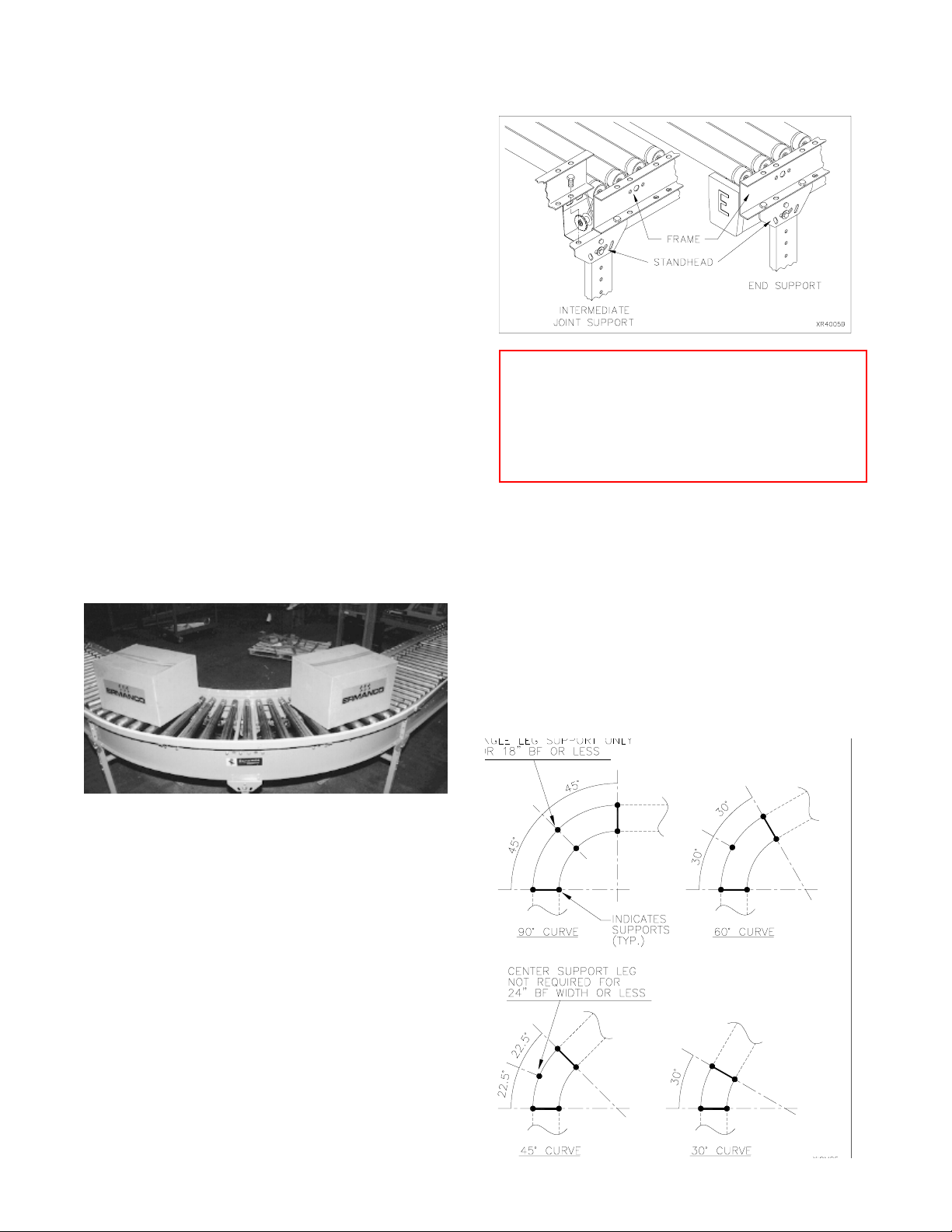

90° curve with true taper rollers. A single support leg is

located on the center of the outside channel. Over 18" width

should have full support.

ANCHORING

Anchoring in concrete floors is accomplished by drilling into

the floor and inserting the suitable anchor bolt. The hole

diameter and depth must be in accordance with the anchor

bolt manufacturer's instructions.

Anchor intermediate floor supports with two anchor bolts,

one through each support foot plate using minimum 3/8" di-

ameter anchor bolts. For floor supports over 5' high or when

supporting drives, use 1/2" diameter anchor bolts.

Stagger anchors from front hole on one side to rear hole on

opposite side. Anchor bolts for equipment subject to impact

loads should be a minimum of 1/2" diameter.

SUPPORTING ARRANGEMENTS

WARNING

Place a bolt through the frame and support

immediately with finger tight nut. This will

prevent the frame from falling off the sup-

port, if bumped, and causing injury.

CURVE SUPPORT POINTS - The curve illustration be-

low indicates proper support locations for curves of vari-

ous degrees and widths. The dots illustrate the support

connecting point to the conveyor. The dark line between

dots indicates a full support with welded crossmember or

ceiling hanger cross tube. A single dot on the outside

center of the curve indicates only the outer curve rail is

supported with either a ceiling hanger drop at that point

or a single leg floor support. If a full width support with

welded crossmember is supplied where only a dot is indicated,

use the full support. The illustration below is minimum

supporting arrangement.

15

90480006rev101210

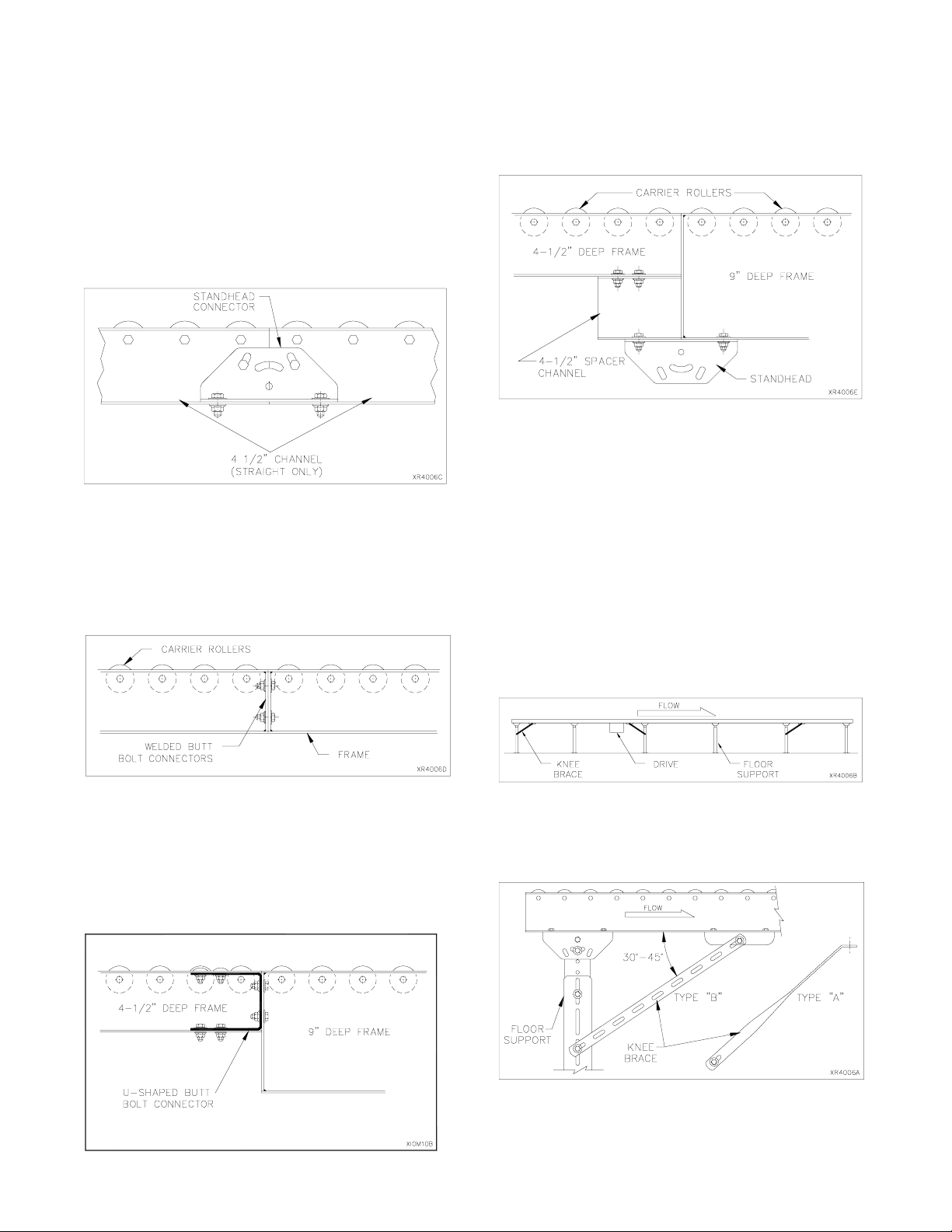

CONNECTORS

Adjoining beds may be connected using optional stand-

head connector plates (one on each side). Connectors

are normally used with ceiling hangers when the hanger

is not centered on the frame joint. The hanger should

be within 1' of the joint while maintaining 10' maximum

centers. The beds should be temporarily supported

while the support and connectors are installed.

Each standhead connector uses two bolts through the

flange of the frame plus two bolts through the vertical

leg and conveyor channel web.

Beds should be checked for squareness before

final tightening of bolts.

Welded butt bolt connectors may be used to join two straight

frames, straight to curve, straight spur or 4-1/2" to 9" deep

frame (urethane belt transfers). Welded butt bolt connectors

must be ordered on designated bed frames.

The spacer channel connector kit consists of two formed

channels 4-1/2" deep with mounting hardware. This

connector is a standard component of ceiling hangers

but is also used to allow a support on the frame joint

between 4-1/2" and 9" deep channel frames. This is

another choice to join a 4-1/2" channel to a UBT frame.

Welded butt bolt connector available for 4-1/2" deep

frames. They are standard with 9" deep frames.

U-shaped butt bolt connectors are commonly used to con-

nect a 4-1/2" channel frame to a urethane belt transfer which

uses a 9" deep frame. The UBT has pre-welded butt bolt

plates in each end.

A 4-1/2" deep spacer channel bolts to bottom flange of

4-1/2" deep bed and standhead of the floor support or a

ceiling hanger.

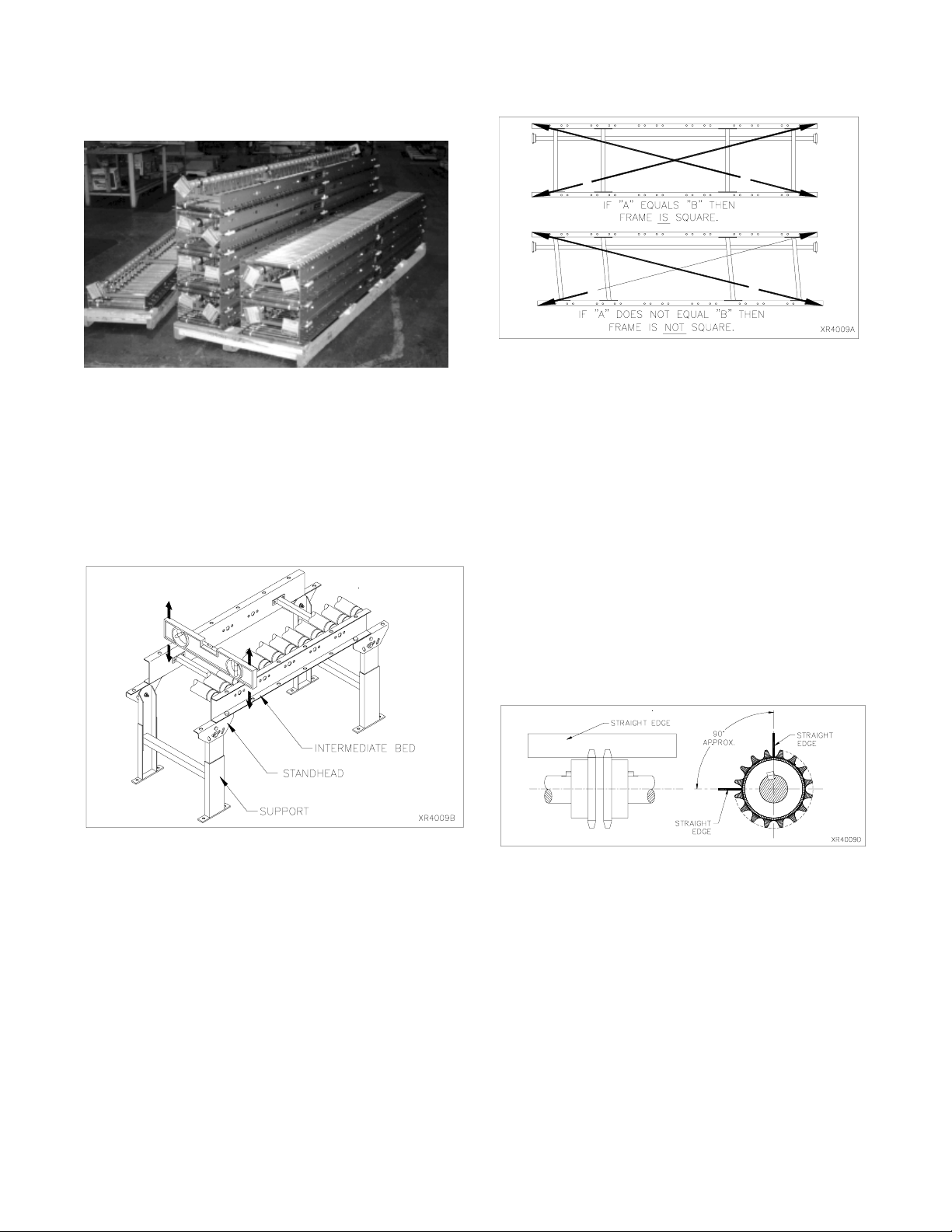

KNEE BRACES

Stability along the conveyor length is achieved with knee

braces. Braces resist stresses caused by direction of prod-

uct flow, drives, stop s and st arts. Every support does not

require bracing. Braces are used at the ends of straight runs

and approximately every 30' in between. Braces should be

located toward the discharge end (DOWNSTREAM) side

putting them in tension. Starting the conveyor puts oppo-

site stresses on the supports, which is resisted by in-

stalling a brace near the drive toward the receiving end

(UPSTREAM).

For best results the angle between the knee brace and

frame should not exceed 45 degrees, or be less than 30

degrees. On short supports where a small angle results,

the knee brace may need to be shortened.

Type "C" braces (not shown) use two type "B" braces

overlapped and bolted together for extended length

when conveyor height is 48" or more.

16

90480006rev101210

After hanger uprights are installed and the heavy ex-

tension nuts welded to angle hangers, thread the drop

rods into the extension nuts. Thread the jam nuts and

stop nuts on the drop rods far enough up the rods to

allow installation and adjustment of the cross pipe.

While still on the floor, loosely attach cross pipe, V-brack-

ets, flat strap connectors and bed connector to one end

of a bed section. Hoist the bed section between the

drop rods guiding the rods through the mounting holes

in the cross pipe. Thread the weld nuts on the drop

rods to support the bed. Weld the weld nuts to the drop

rods to prevent loosening. Hoist the next bed section

into place and connect it using the flat strap connectors

and V-brackets. Level the bed lengthwise and side to

side by threading the drop rods up or down by using a

wrench on the weld nuts. Tighten the jam nuts against

the extension nuts and the stop nuts against the cross

pipe. Continue for the length of the conveyor.

Drop rods and nuts are optional. The extension nut is

welded into the angle hanger upright during installation.

WARNING

Consult the building architect or a struc-

tural engineer regarding ceiling loading or

structural limitations of the building for siz-

ing header steel.

Cross pipes, V-brackets and flat strap connectors are

provided with ceiling hangers. Threaded 3/4" rod and

attaching nuts are available as an option. Bed connec-

tors are recommended with all ceiling hanger applica-

tions.

If hanger uprights are field fabricated, they should be a

minimum of 1-1/2" x 1-1/2" x 3/16" angle.

WARNING

Consult your distributor or a structural engi-

neer to determine what size hangers should

be used to support your maximum antici-

pated load.

CEILING HANGERS

17

90480006rev101210

SWAY BRACING (CEILING HANGER)

1. Sway bracing should be a minimum of 1-1/2" x

1-1/2" x 3/16" angle.

2. Sway bracing is secured to the hanger upright near

the conveyor support and extended upward at an

angle of approximately 30 degrees from the hanger

upright. The sway brace angle should not be over

45 degrees to the upright. When hangers are in-

stalled adjacent to building columns, a horizontal

brace may be installed securely to the column.

3. Hanger uprights over 12'-0" in length must have

horizontal bridging angles connected between the

upright and the sway brace at approximately the

half way point.

4. Sway bracing should be installed on every third

hanger (maximum of 30'-0" centers).

5. If sway bracing cannot be placed on the outside of

the uprights, alternate X-bracing between every

other pair of uprights.

6. Additional bracing should be used:

• Before and after curves

• At drives

• At product diverting points

DIAGONAL SWAY BRACE (FLOOR SUPPORT)

Floor support sway bracing consists of one 1-1/2" x

1-1/2" structural angle and mounting hardware.

APPLICATION: Due to natural side to side movement

of line-shaft conveyor, a diagonal sway brace has been

designed to reduce side movement in the standard

floor support. Side movement is most prevalent in long

straight lines which are not side braced by adjoining

conveyors, curves, etc. or where they cannot be

braced to columns, machinery, or other conveyors.

This is more noticeable when the conveyor elevation

is greater than its width. One brace can be mounted to

every third or fourth support diagonally across the sup-

port with the low end on the opposite side of every

other brace (alternate orientation). The holes in the

support uprights need to be field drilled.

If excessive oscillation persists after bracing has been

added, it may be the result of harmonics. This can

occur when the conveyor operating speed generates

vibrations with a frequency at or near the conveyor's

natural frequency of its structure. This rare condition

normally occurs between 85 FPM and 120 FPM. It

may be minimized by adding more bracing or by either

increasing or decreasing conveyor speed.

Sometimes it is better not to add a brace at the drive

location. Some experimentation may be required.

CAUTION

Before adding X-braces between uprights,

check for adequate product clearance.

18

90480006rev101210

MULTI-LEVEL XENOROL® SUPPORT

To mount XenoROL to multiple level supports, bolt two

V-brackets and two spacer channels to each horizontal

crossmember. Measure from the floor to the top of the

spacer channels, set the crossmember to the desired

elevation minus the distance from the bottom of the

frame to the top of the rollers. Tighten the bolts only

enough to hold the crossmember in place.

Set up two multiple deck supports and, starting with the

lowest line, bolt the ends of a frame to the spacer chan-

nels. On the end beds, install one support completely

on the frame so that the center of the upright is 6" from

the end of the frame. All intermediate supports are in-

stalled and centered on the joint.

After three supports and beds are installed, make final

elevation adjustments and level the beds lengthwise

and side to side. Securely tighten the crossmember

bolts. Continue for the length of the conveyor.

Clamping of stringers or headers to building trusses will nor-

mally be done only at panel points. Specific customer per-

mission and load calculations by a qualified engineer are

necessary to safely clamp between panel points.

Headers when used for short spans, such as between roof

purlins, will be securely clamped to building steel. Stringers,

when used between headers, may be welded or bolted to

the headers directly or with suitable angle clips.

Concrete Ceilings

Accomplish anchoring by drilling into the concrete ceil-

ing and inserting suitable anchor bolts. The hole diam-

eter and depth must be in accordance with the lag bolt

manufacturer's instructions.

Anchor each hanger with four bolts (two per upright)

minimum size 1/2" diameter. Consult your distributor

or structural engineer to determine your needs.

WARNING

Do not use explosive type anchors.

For heavier concentrated loads like drives or points

where movement or vibration can occur , use 5/8" di-

ameter through bolts with backup plates. If this is not

permissible or possible, then header steel must be in-

stalled using several anchor bolts to spread the load.

Wood Joists/Beams

Hangers may be attached directly to the joists provid-

ing the load rating of the building will permit. Attach

hangers to the vertical side of the joist in two places,

one above the other, on each hanger upright. Anchor-

ing is accomplished by drilling through the joist in the

upper position and using a 1/2" diameter through bolt

with a backup plate or heavy washer. A 1/2" diameter

lag screw may be used in the lower position.

When a header is required to support the load, it must

bridge across two or more joists. This header will be

attached to each joist in the manner specified in para-

graph above. Hanger uprights should then be bolted or

welded securely to the headers. Consult a structural

engineer to determine which method should be

used for your load requirements.

Concrete/Masonry Walls

Equipment may be supported from concrete walls through

use of suitable bolts and anchors or by bolting through the

wall if the condition of the wall or load dictates it. A

1/2" diameter through bolt should be used with a backing

plate.

METHODS FOR ANCHORING CEILING HANGERS

Open Building Steel

The following references are from the American Insti-

tute for Steel Construction manual (AISC).

Welding of auxiliary steel (stringers or headers) to build-

ing steel is prohibited.

Drilling and bolting to building steel is not recommended

and will be done only with the customer's written per-

mission.

Note: Flat strap across joint is required when spacer

channel is not used.

19

90480006rev101210

BASICS OF XenoROL®INSTALLATION

GENERAL

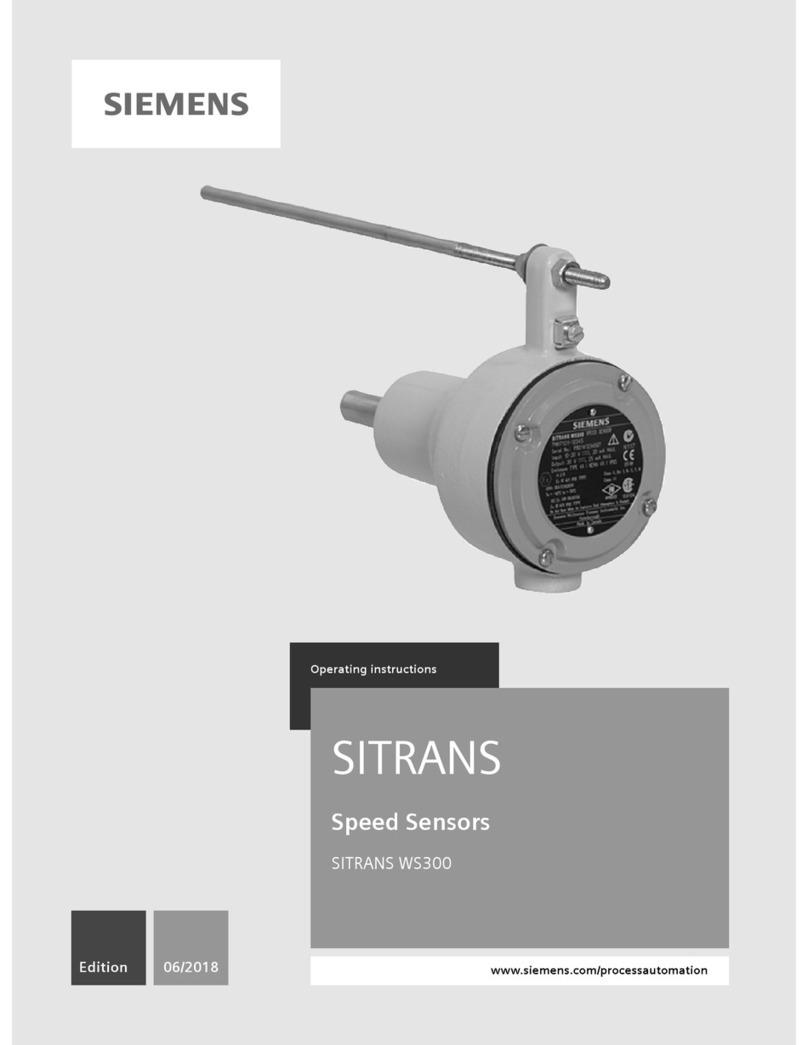

FRAME ALIGNMENT

Conveyor frames must always be installed in a straight

line from end to end as described in GENERAL PRO-

CEDURES. After a number of sections have been

installed to the chalk line and leveled, check the align-

ment of each line-shaft assembly. As the conveyor sec-

tions are bolted together, the coupler sprockets may

require adjusting. The edge of the 1" diameter line-

shaft must be 2" from the frame channel to start.

COUPLER ALIGNMENT

Check the alignment of each pair of coupler sprockets.

Parallel alignment can be checked with a straight edge

placed on the two sprockets at the root of the teeth.

Alignment should be checked in at least two places, at

90 degree intervals. The straight edge must appear

level to the coupler hubs or line-shaft. This will put par-

allel alignment within the specified .005" limit.

If it becomes necessary to shorten a bed frame, cut the

end bed where a coupler is not needed, if possible. If

the drive must be continued, it is best to disassemble

the line-shaft assembly and re-keyway the line-shaft's

cut end. If only a small amount of conveyor is driven by

the cut bed, the coupler sprocket may be field welded

or pinned to the cut end of the shaft.

When joining bed frames it is important to align the roll-

ers and line-shaft. Care must be taken to make sure

the rollers are level (carrying surfaces) from bed to bed.

All bed frames should be checked for squareness. To

check, measure diagonally from corner to corner. Mea-

sure the opposite corners in the same manner. If the

bed is square, the two measurements will be the same

within 1/16".

If the coupler sprockets do not align vertically, adjust

either or both of the following:

1. Loosen the crossmember mounting bolts of two

crossmembers in each bed and adjust the height

of the crossmember within the limits of the mount-

ing holes.

2. Insert shims between the bearing housing and the

bearing hanger of the crossmember.

Tip: Loosen one coupler sprocket and slide it against

the other. Adjust the line-shaft for zero gap between

sprocket faces and exact mating of teeth. Then move

loose sprocket back 9/32" and tighten set screws to 13

ft.lbs.

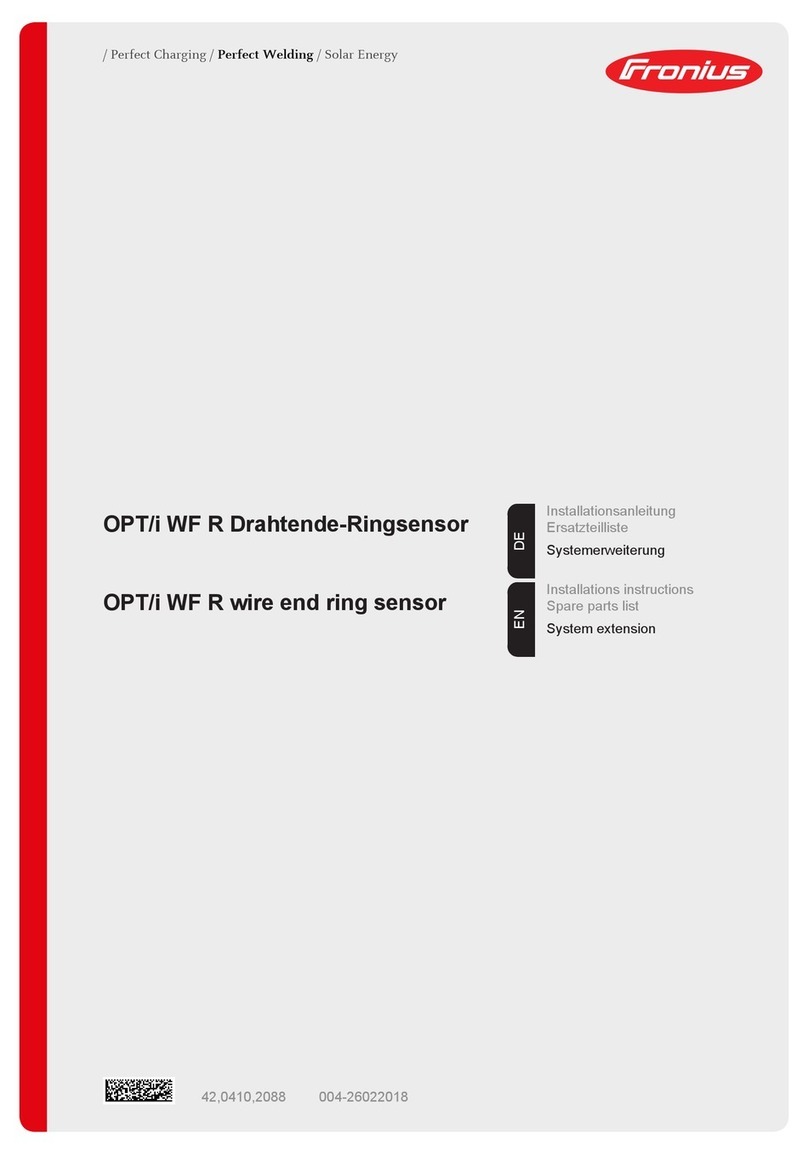

XenoROL®bed sections stacked on pallets for shipping

(7) intermediate beds per side.

Straight bed sections may be installed using any of the

support methods previously described (see SUPPORT-

ING ARRANGEMENTS). As each bed is installed in

the system, level it lengthwise and across the bed width

on a roller. The supports should also be checked for

vertical. A shorter level may be required to check the

upright without the level overlapping the lower boot.

B

A

AB

This manual suits for next models

1

Table of contents

Other TGW Accessories manuals

Popular Accessories manuals by other brands

FRONIUS

FRONIUS OPT/i WF R installation instructions

Siemens

Siemens SITRANS WS300 operating instructions

Byron

Byron SX-80 Installation and operation instruction

Pogo Bounce House

Pogo Bounce House Tropical Marble 35' Dual Lane Slip N Slide manual

Panasonic

Panasonic KX-HNS104FX installation guide

Interlogix

Interlogix SDX-135Z-433 user guide