TGW NBC User manual

NBC, TGW Nitta Belt Welding

Instructions

NBC Full Welding Instruction with

Nitta Blue Urethane Belt

P/N: 1207439

Date: 09/13/2019

TGW

P/N 1207439 Rev Date 09/13/2019 Page 2of 30

CONTENTS

INTRODUCTION............................................................................................................. 3

PURPOSE ..................................................................................................................... 3

SCOPE ......................................................................................................................... 3

TGW SAFETY INFORMATION....................................................................................... 4

WARNINGS AND SAFETY INSTRUCTIONS .......................................................................... 4

TGW SYSTEMS RECOMMENDED STANDARDS FOR CONVEYORS........................................ 5

TGW SAFETY RECOMMENDATION .................................................................................. 6

NBC CONVEYOR PREPARATION................................................................................. 7

FINGER PUNCH PROCESS ........................................................................................ 11

NBC WELD INSTRUCTIONS ....................................................................................... 15

TGW KITS & REPLACEMENT PARTS......................................................................... 22

TROUBLESHOOTING – NITTA CORPORATION ........................................................ 24

AIR BUBBLES .............................................................................................................. 24

IMPROPER BELT WELDING ........................................................................................... 27

WORKS CITED............................................................................................................. 29

TGW SYSTEMS INFORMATION.................................................................................. 30

History – Revision Changes

Revision Date Description

9/13/2019 Add caution note to use only TGW welder equipment

06/27/2019

Changed belt overlap length. NBC-150-AT from 36” to 18” and added 500-AT

to be 36”.

TGW

P/N 1207439 Rev Date 09/13/2019 Page 3of 30

INTRODUCTION

PURPOSE

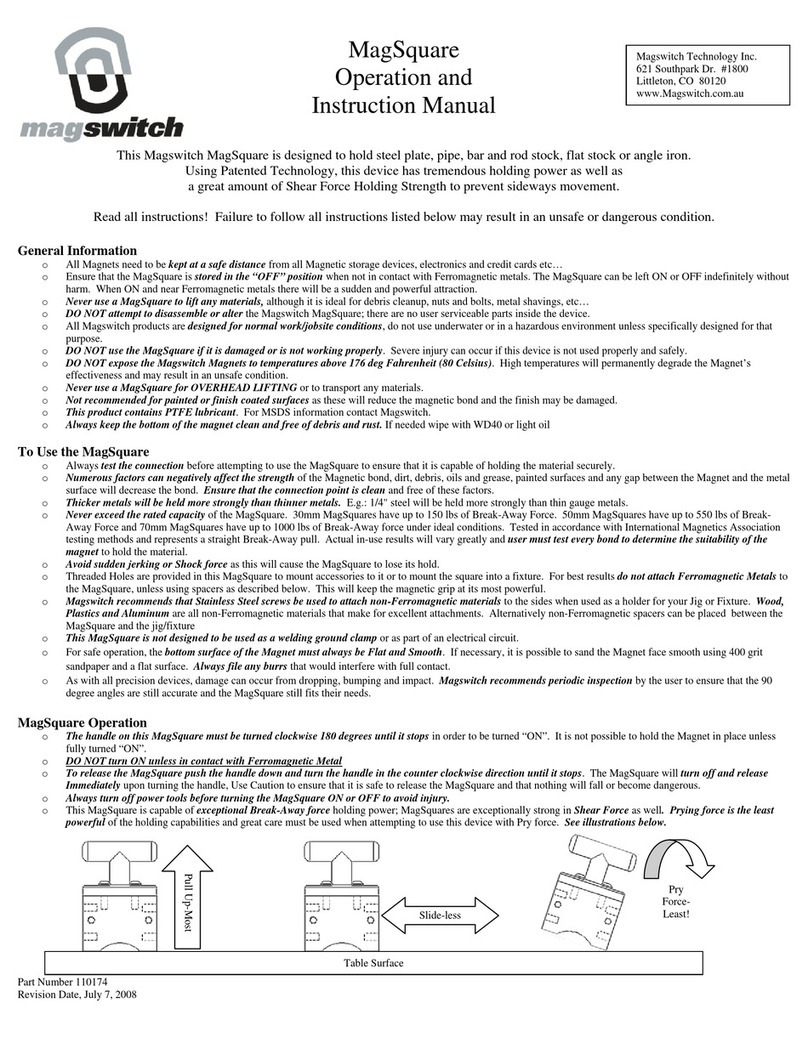

This manual contains the instructions to properly weld a Nitta belt for use with TGW

NBC flat belt conveyor. These instructions use the TGW Nitta belt Finger Punch and

Weld Press. TGW recommends watching the enclosed flash drive video instruction

along with all TGW or Nitta manuals before repairs.

SCOPE

The purpose is to obtain strong, consistent belt joints in a safe and efficient manner.

To accomplish this, these instructions must be followed closely.

For more TGW conveyor information:

Visit www.tgw-conveyor.com for more maintenance videos and TGW IOM manuals.

WARNING:

•Use Only TGW Nitta belt welder and punch equipment for TGW Nitta belt

splice/welding. Non-TGW Nitta belt welding or punch equipment is not

compatible with the TGW Nitta belt!

CAUTION

TGW

P/N 1207439 Rev Date 09/13/2019 Page 4of 30

TGW SAFETY INFORMATION

WARNINGS AND SAFETY INSTRUCTIONS

Failure to follow the instructions and

cautions throughout this manual and

warning labels on the conveyor may

result in injury to personnel or damage

to the equipment.

Your TGW Systems conveyor is

powered by a motor and can be

stopped only by turning off electrical

power to the motor. As with all

powered machinery, the drive-related

components – including sprockets,

chains, shafts, universal joints, and

pneumatic devices – can be

dangerous. We have installed or

provided guards to prevent accidental

contact with these parts, along with

warning labels to identify the hazards.

Special attention must be paid to the

following areas of this manual:

•Indicates a potentially

hazardous situation,

which, if not avoided,

could result in death or

serious injury.

•Indicates a situation, which, if not

avoided, could result in property

damage.

WARNING

CAUTION

TGW

P/N 1207439 Rev Date 09/13/2019 Page 5of 30

TGW SYSTEMS RECOMMENDED STANDARDS FOR

CONVEYORS

TGW Safety Recommendation

For additional safety information:

TGW agrees to the following safety instruction or

guidelines listed within this manual. This is not to

conflict with your state or legal requirements.

TGW Recommends for maintenance or repair

purposes, to incorporate a lock out or tag

procedure. To ensure all starting devices, prime

movers, or powered accessories are off before

attempting to maintenance or repair.

The procedures below are designed to protect

everyone involved with the conveyor against an

unexpected restart. To include understanding of

potential hazard of stored energy, which can exist

after the power source is locked out.

For additional information, refer to the latest issue

of ANSI Z244.1, American National Standard for

Personnel Protection −Lockout/Tagout of Energy

Sources− Minimum Safety Requirements.

http://www.ansi.org/

OSHA 29CRF Part 1910.147 “Control of

Hazardous Energy Sources (Lockout/Tagout)”,

which includes requirements for release of stored

energy and OSHA Safety and Health Regulations

for Construction 1926.555 Conveyors

https://www.osha.gov/

Conveyor Design and Safety Guidelines

A safety risk evaluation is required for all of our

standard equipment. The safety risk evaluation

considers every potential hazard on the

conveyor, weighs the probability and the severity

of the potential injury, and addresses methods of

mitigation to make the risk of injury either low or

negligible. We use the ANSI B11 TR3 standards

for all of our risk evaluation. In addition, all of our

equipment is designed to comply with the

following national and industry standards:

•ANSI Z535.1 – Safety Color Code

•ANSI Z244.1 – Lockout/Tagout of Energy

Sources

•ASME B15.1 – Safety standard for

Mechanical Power Transmission Apparatus

•ASME B20.1 – Safety standard for

Conveyors and Related Equipment

•CEMA – Safety Standards and Labels

•OSHA 1910.147 – The Control of Hazardous

Energy

•OSHA 1910.212 - General Requirements for

all Machines

•OSHA 1910.95 – Occupational Noise

Exposure

•Definitions:

•ANSI = American National Standard Institute

•ASME = American Society of Mechanical

Engineers

•CEMA = Conveyor Equipment Manufacturers

Association

•OSHA = Occupational Safety and Health

Administration

•Safety: Always lock out power source and follow recommended

safety procedures.

WARNING

TGW

P/N 1207439 Rev Date 09/13/2019 Page 6of 30

TGW SAFETY RECOMMENDATION

TGW agrees to the following safety instruction or guidelines listed within this manual.

This is not to conflict with your state legal requirements.

TGW Recommends for maintenance or repair purposes, to incorporate a lock out or

tag procedure. To ensure all starting devices, prime movers, or powered accessories

are off before attempting to maintenance or repair.

The procedures below are designed to protect everyone involved with the conveyor

against an unexpected restart. To include understanding of potential hazard of stored

energy, which can exist after the power source is locked out.

For additional information, refer to the latest issue of ANSI Z244.1, American

National Standard for Personnel Protection −Lockout/Tagout of Energy

Sources− Minimum Safety Requirements. http://www.ansi.org/

OSHA 29CRF Part 1910.147 “Control of Hazardous Energy Sources

(Lockout/Tagout)”, which includes requirements for release of stored energy and

OSHA Safety and Health Regulations for Construction 1926.555 Conveyors

https://www.osha.gov/

•Pay attention to the safety instructions!

•Prior to working at or in the immediate vicinity of the system

it is recommended that you make yourself familiar with the

safety instructions included in the present document!

•TGW recommends reading all manuals supplied by TGW

or Nitta Corporation. https://www.nitta.com/

•TGW recommends only trained and maintenance personal

for conveyor repairs.

•Do not use tools or equipment stated in this manual for

other application.

•Do not dismantle or remodel equipment or tools under any

circumstances.

WARNING

TGW

P/N 1207439 Rev Date 09/13/2019 Page 7of 30

NBC CONVEYOR PREPARATION

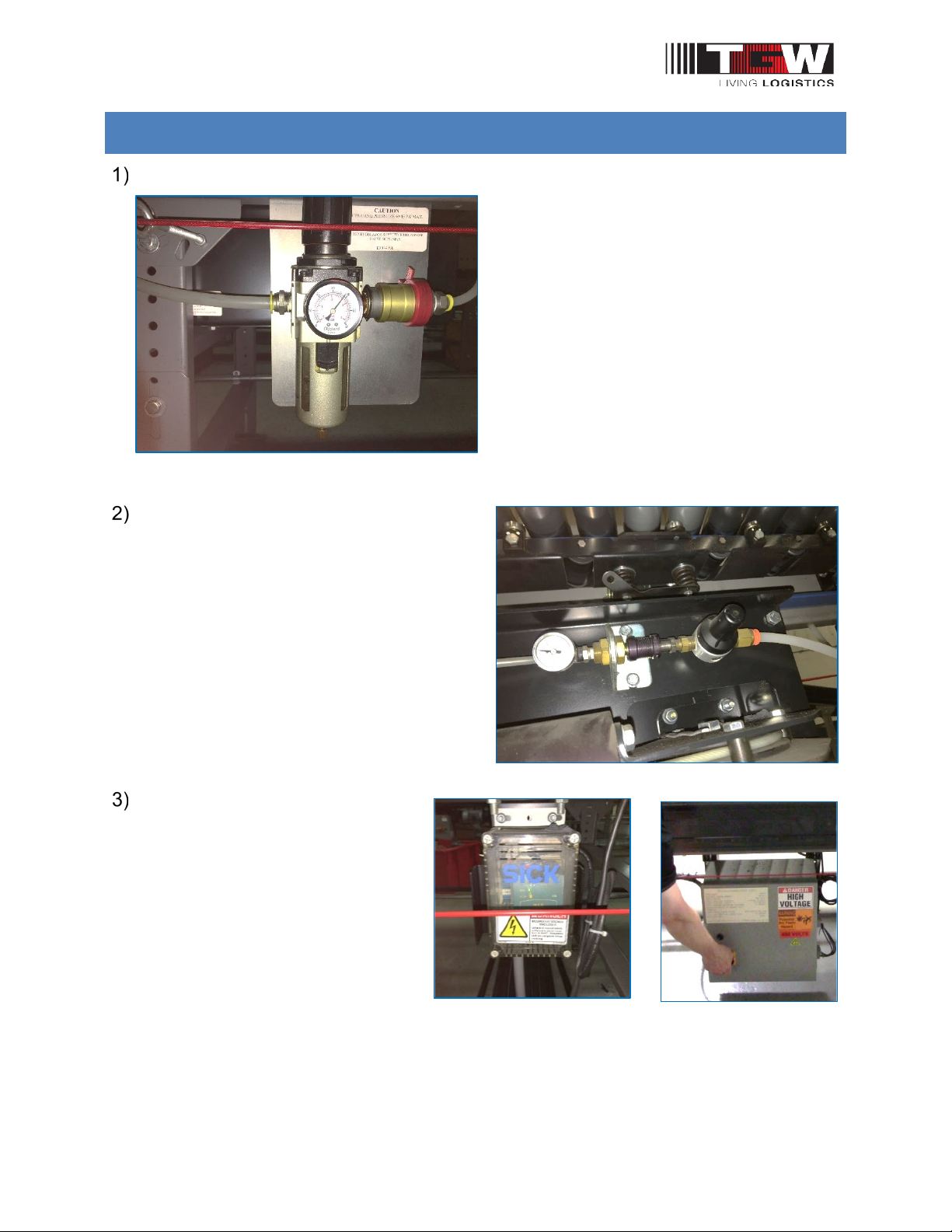

Make sure the main air regulator is at 40psi.

Before installing the belt, make sure the

air is OFF to the belt take-up. This

moves the take-up pulley to the

retracted position which allows you to

work with the maximum belt slack.

Turn off the power to the logic

modules.

Note: If you can’t find the power

supply, you can disconnect the

main power to the logic modules.

This will allow air to flow through

to the pressure pans and push the

pressure pans down.

TGW

P/N 1207439 Rev Date 09/13/2019 Page 8of 30

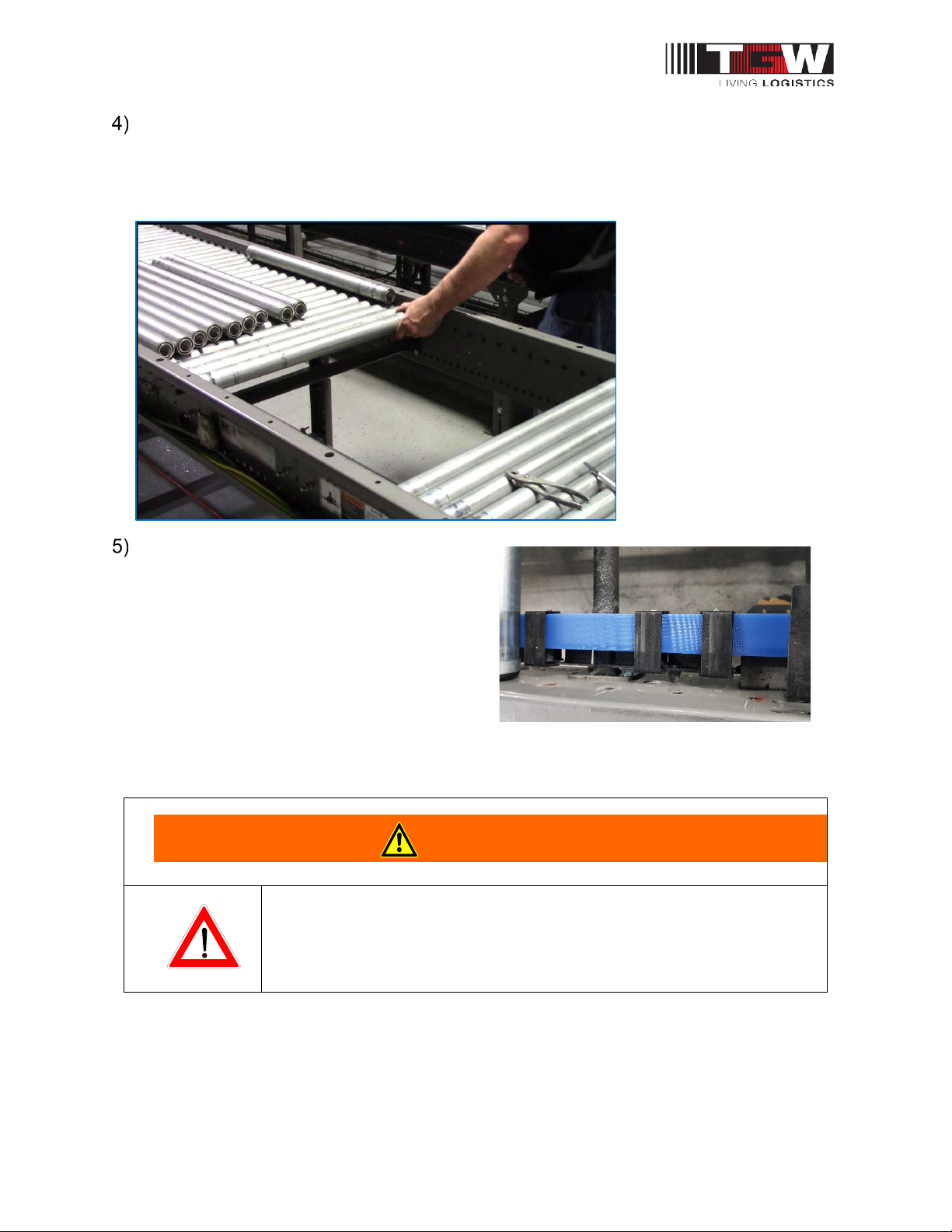

Remove rollers between two pressure pan supports in a 3' zone. Any zone can be

selected, but it is easier to select one near the charge or discharge end of the

conveyor.

Note:Pull the axles with pliers to protect the frame.

Remove any figure guards.

Depending on your work zone area, there

may be three (3) different finger guards.

Those between the pressure lift

assemblies simply snap-in or out. Those

over the pressure assemblies are

removed by rotating a quarter turn

clockwise and pulling out. If the belt

splicing work area includes in crossmember, a different shape finger guard is used,

which also snaps into place.

•Pay attention to the safety instructions!

•After maintenance, REPLACE guards immediately!

WARNING

TGW

P/N 1207439 Rev Date 09/13/2019 Page 9of 30

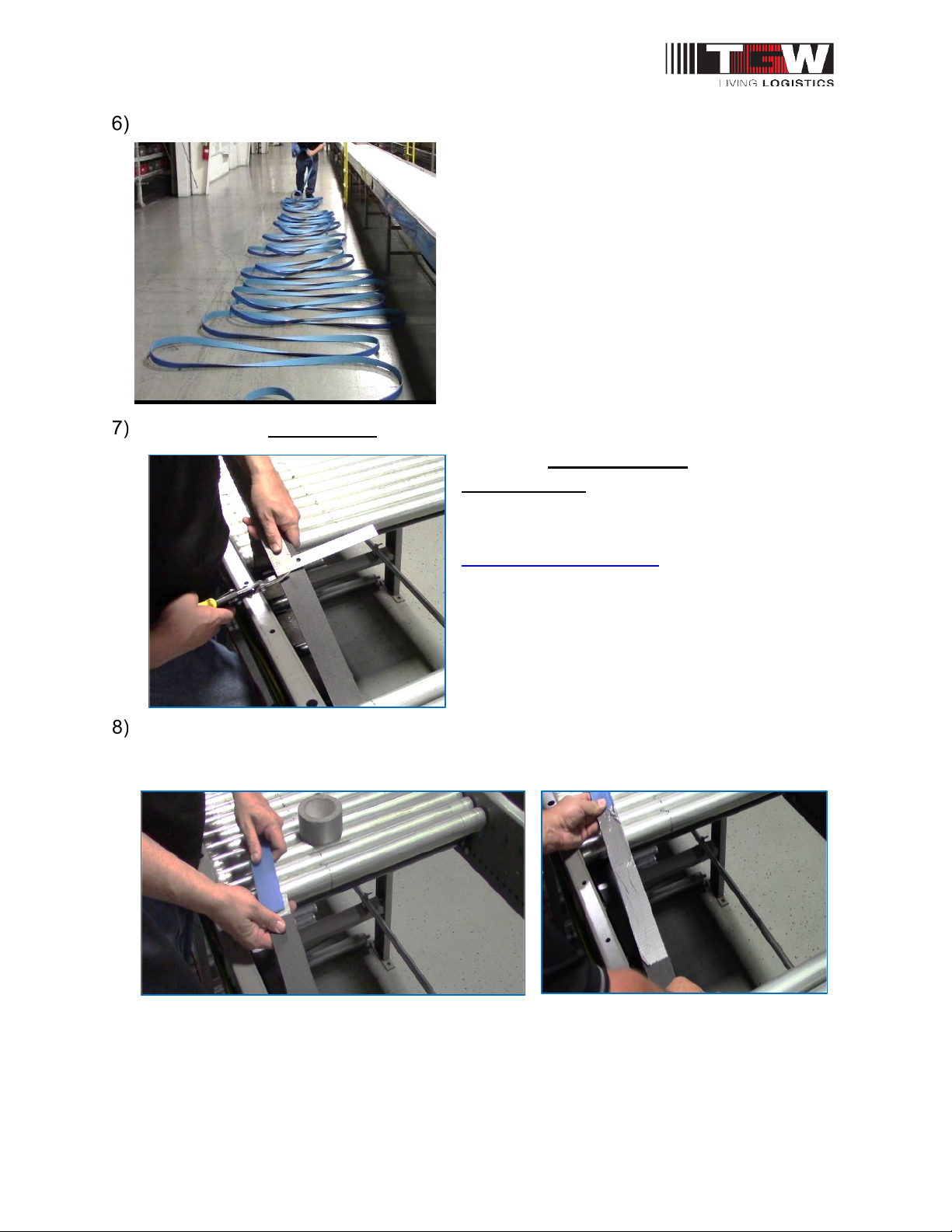

Un-coil the Nitta belt.

If replacing an existing belt, cut the previous belt straight.

Note: For new installation use the NBC

threading tool (located and attached under

each drive from factory). NBC threading

instructions are also in TGW IOM Manual at

www.tgw-conveyor.com.

Duct tape the top and bottom of the old belt end to the new Nitta belt end (thick

polyurethane side up) making sure to keep both belts are flat and straight, do not

overlap the belts.

TGW

P/N 1207439 Rev Date 09/13/2019 Page 10 of 30

Pull the new Nitta belt through the conveyor. Make sure the Nitta belt is routed

correctly over all the return pulleys underneath the conveyor. Remove the Duct

tape.

Before cutting the belt to length, make sure there is 18” overlap for NBC 150-AT

and for NBC 500-AT 36” overlap. The overlap is to compensate for belt loss in the

finger splice process. Both belt ends must be cut straight.

TGW

P/N 1207439 Rev Date 09/13/2019 Page 11 of 30

FINGER PUNCH PROCESS

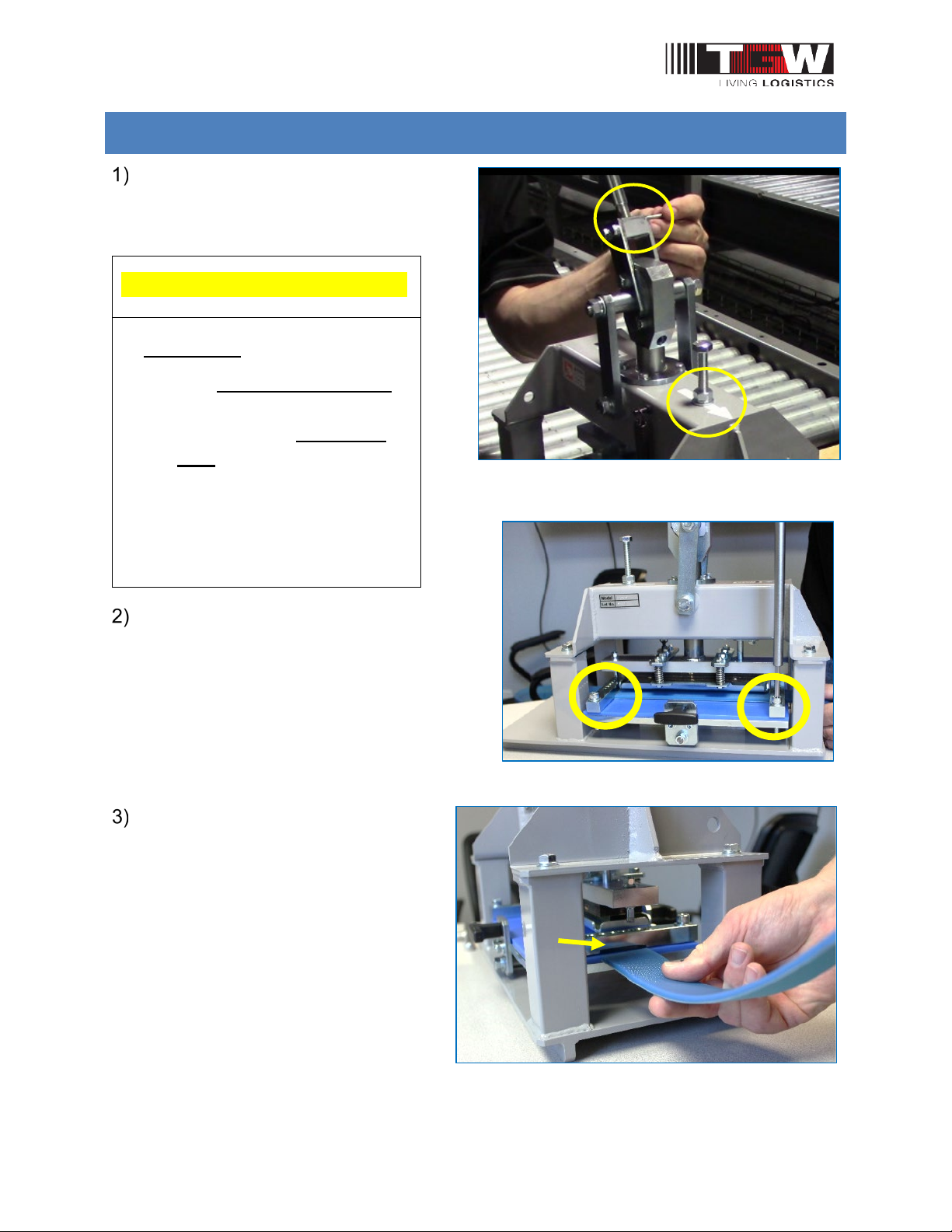

Using the Nitta Finger Punch Press

assemble the handle and place the

press with the arrow sticker pointing in

the belt flow direction.

Loosen the bolts to the hold-down plates.

Insert one end of the belt,

polyurethane side up, through the

notched guide on the hold-down

bar. Slide the belt all the way

through to the other end of the

press.

WARNING:

•Use Only TGW Nitta belt

welder and punch

equipment for TGW Nitta

belt splice/welding. Non-

TGW Nitta belt welding or

punch equipment is not

compatible with the TGW

Nitta belt!

CAUTION

TGW

P/N 1207439 Rev Date 09/13/2019 Page 12 of 30

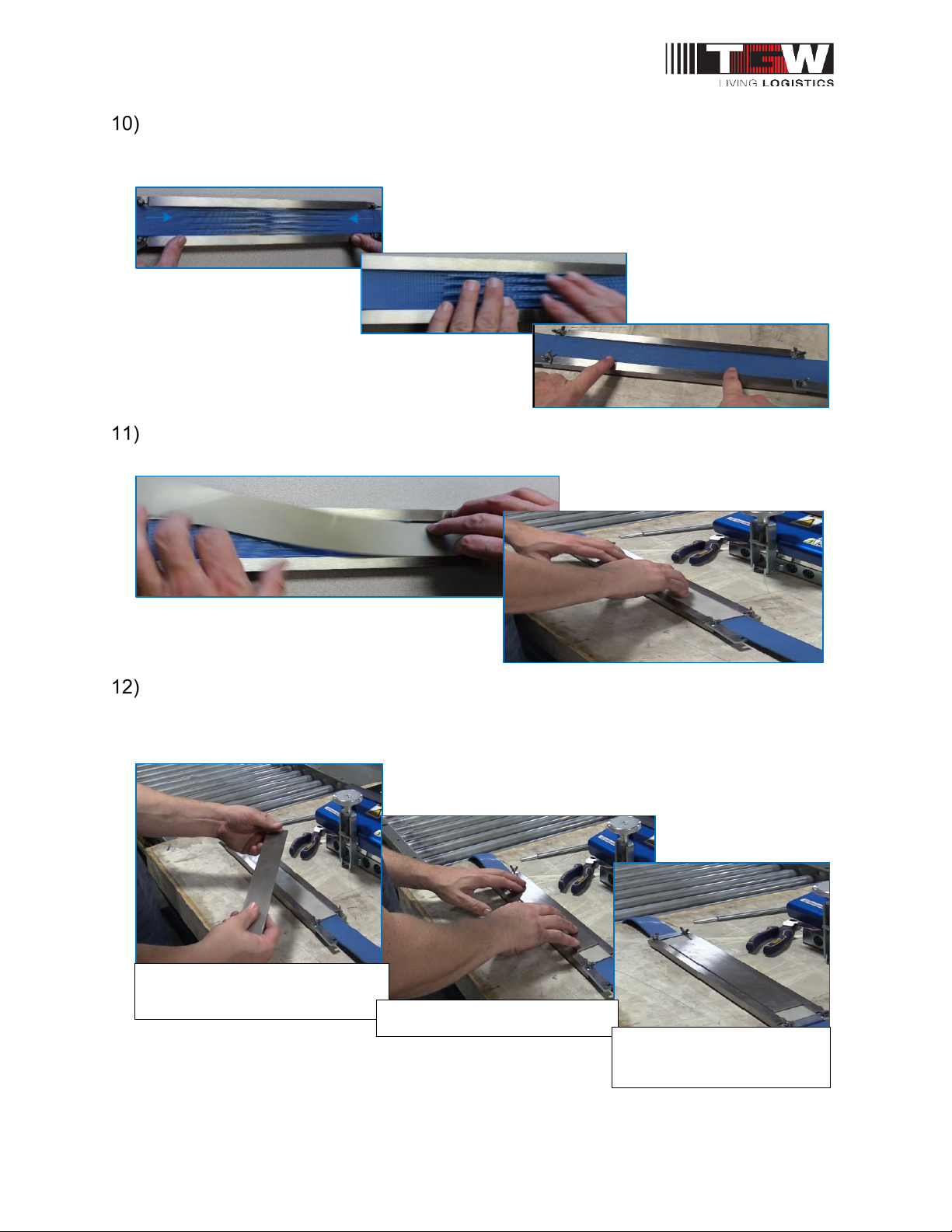

Hold the belt firmly while tightening the

hold-down bars bolts in an alternating

pattern.

Position the top index pin with the first

outside hole on the hold-down plate.

WARNING: Each hole must be punched in PROPER SEQUENCE and

in EVERY HOLE (6x). Failure to do so will cut off one of the fingers

making the belt unsliceable.

Starting at one end of the puncher,

make sure the top pin is aligned with

outside hole. Press the handle all the

way down. This is the 1st punch of 6

needed for each belt end.

Index pin

Hold-down holes (6X)

Move plate to align top index pin with the

first hole

TGW

P/N 1207439 Rev Date 09/13/2019 Page 13 of 30

Return the handle to original position. Move the support plate to the next hole and

repeat the process. When complete, loosen the hold-downs and remove the belt.

Repeat process for other belt end.

Thread the belt into the puncher from the

opposite direction.

WARNING: DO NOT ROTATE THE

FINGER PUNCH PRESS! The press

must stay in the same orientation for

the entire process.

Trim about 0.25”off each fingertip. This will

mate each finger in the pre-setter and to

ensure a good splice.

Handle to slide the support plate

Belt inserted from the left

Belt inserted from the right

TGW

P/N 1207439 Rev Date 09/13/2019 Page 14 of 30

Install one end of the belt in the Pre-setter mold, making sure the belt fingers are

centered in the pre-setter plate. Insert the other end of the belt and slide the fingers

together, mating them with no overlaps or large gaps.

Install the silicone sheet, with textured side facing down on the belt finger spliced

section.

Place the pre-setter top plate center over the finger spliced area. Once the top plate

is centered, tighten the keeper plate wing nuts to keep the belt flat and secure.

Place pre-setter top plate

Center top plate

Tighten the keeper plate

wing nuts

TGW

P/N 1207439 Rev Date 09/13/2019 Page 15 of 30

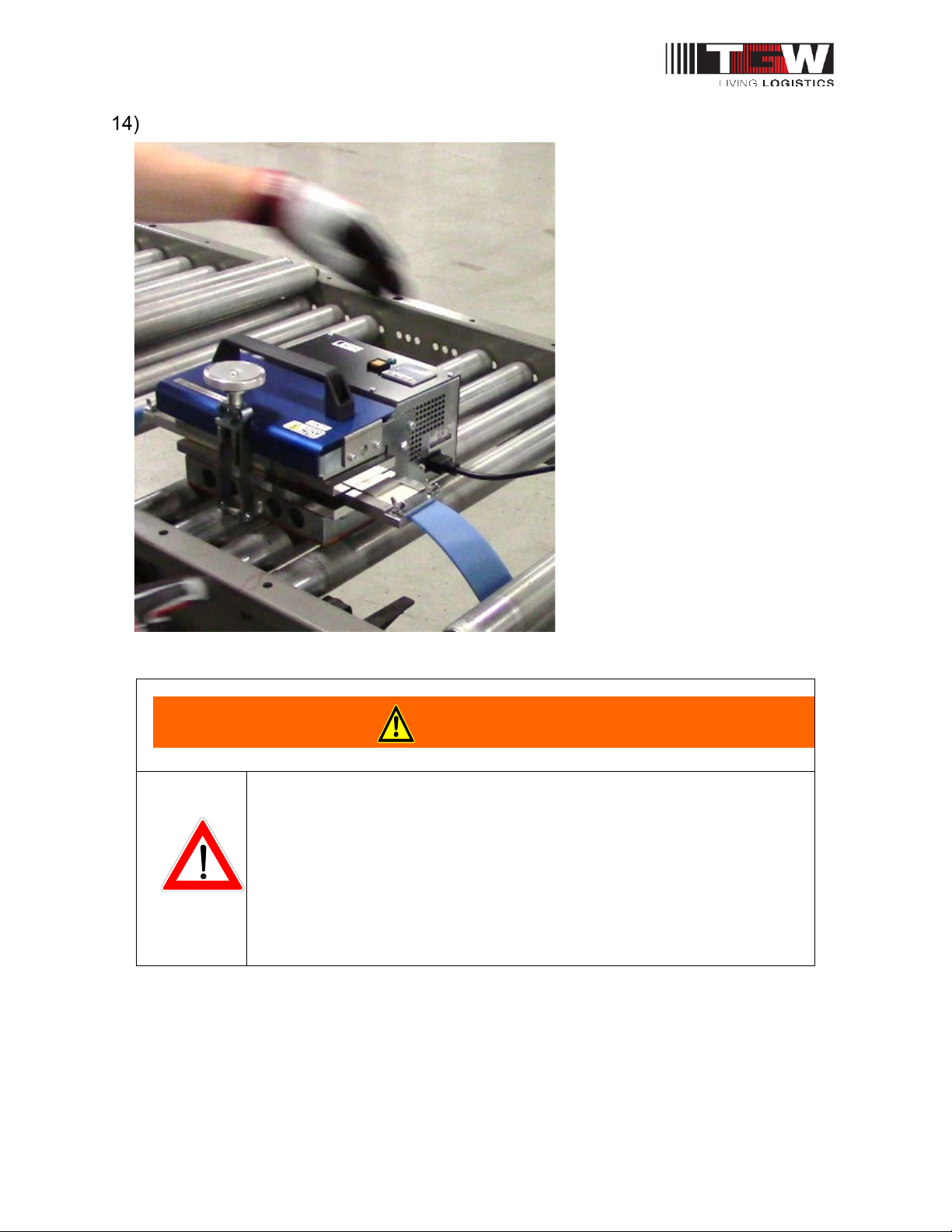

NBC WELD INSTRUCTIONS

Place the TGW welder press on the conveyor and set the pre-setter mold center in

the weld press. Clamp the press closed and turn the knob until it slips.

CAUTION: Be careful not to pull out the belt from the pre-setter as this may cause

the finger splice to gap or overlap.

WARNING:

•Use Only TGW Nitta belt welder and punch equipment for TGW Nitta

belt splice/welding. Non-TGW Nitta belt welding or punch equipment is

not compatible with the TGW Nitta belt!

CAUTION

TGW

P/N 1207439 Rev Date 09/13/2019 Page 16 of 30

Plug in the TGW welder cord then push the yellow button to start.

WARNING! WELD PRESS IS HOT! TGW recommends to wear

heat resistant gloves when operating the press.

WELD PRESS IS HOT! Do not leave press unattended while in

use. To prevent others people from touching the weld press.

Failure to do so may cause others to touch the press and get

burned.

WARNING

TGW

P/N 1207439 Rev Date 09/13/2019 Page 17 of 30

Note: The green light is the actual temperature reading. The amber light is the welder

press pre-programmed temperature and should be set at 185 Degrees Celsius

(185°C).

Note: When starting the TGW welder press it will automatically run a diagnostic test

for about 6 seconds then starts heating up to the preset temperature. After 10

minutes at full temperature, the press will automatically shut down the heaters and

start the cooling fans. (Total weld time is approximately 60 minutes).

Note: The weld cool down process is

done when the actual temperature

gage (green light) is 50°C or lower.

WARNING:Before opening the

weld press remove the power

cord to ensure the power is off.

WELDER IS HOT! TGW

recommends wearing heat

resistant gloves!

GREEN LIGHT IS THE

ACTUAL TEMPERATURE

AMBER LIGHT IS

PRE-SET TEMPERATURE

AT (185°C)

50°C or BELOW

REMOVE WELDER POWER CORD!

TGW

P/N 1207439 Rev Date 09/13/2019 Page 18 of 30

Only when the actual temperature (green light) is 50°C or lower and when the

welder press power cord is unplugged it’s safe to open the TGW welder press.

Loosen the knob and pull the clamp down to open the press.

•WARNING! WELD PRESS IS HOT! TGW recommends to

wearing heat resistant gloves when operating the press.

•WELD PRESS IS HOT! Do not leave press unattended while in

use. Failure to do so may cause others to touch the press and

get burned.

WARNING

TGW

P/N 1207439 Rev Date 09/13/2019 Page 19 of 30

Remove the pre-setting mold, pre-setter top plate, silicone sheet, and loosen the

keeper plate wing nuts to unlock the belt. Remove the belt from the pre-setter mold.

TGW

P/N 1207439 Rev Date 09/13/2019 Page 20 of 30

Inspect the top and bottom of the belt. Make sure the belt splice has smoothly

joined even fingers with no bubbles, gaps, or overlaps. (See troubling shooting

section for defect details.)

TOP OF BELT (WELDED)

BOTTOM OF BELT

(WELDED)

Other manuals for NBC

1

Table of contents

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric LN-7 Operator's manual

Lincoln Electric

Lincoln Electric AutoDrive 4R90 Brochure & specs

ThermOweld

ThermOweld CRE-1 instructions

AMERICAN WELDQUIP

AMERICAN WELDQUIP 550A manual

Scheppach

Scheppach AWH-500FL Translation of original instruction manual

ESAB

ESAB PSF 250 instruction manual

ewo

ewo 913 ASD operating instructions

Rohrman Schweißtechnik

Rohrman Schweißtechnik XA-5001 Pro instruction manual

Trafimet

Trafimet ADAPTIG G9 Operating and maintenance manual

EWM

EWM TIG 17 G operating instructions

GYS

GYS 038424 manual

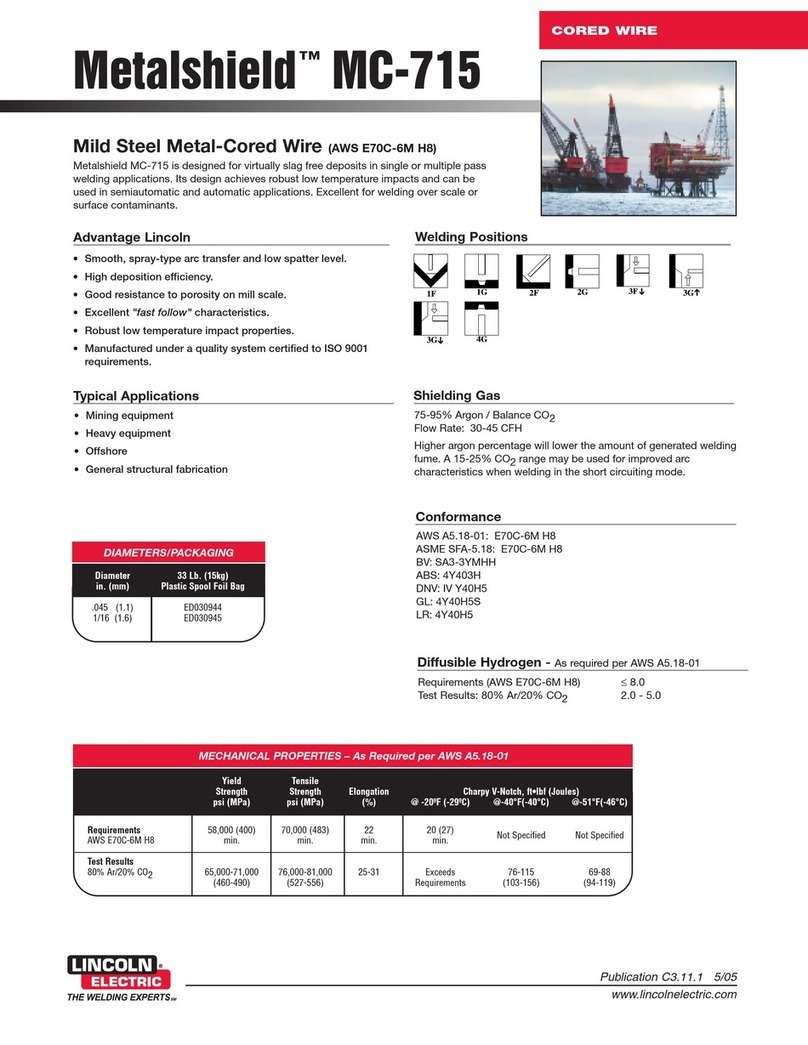

Lincoln Electric

Lincoln Electric Metalshield MC-715 Specification sheet