THE ELECTRON MACHINE CORPORATION MPR E-SCAN Service manual

OPERATING AND SERVICE MANUAL

MPR E-SCAN

Microprocessor Refractometer with Color Display

Designed and Manufactured by

THE ELECTRON MACHINE CORPORATION

15824 CR 450 West (352)-669-3101

Post Office Box 2349 FAX: (352)-669-1373

Umatilla, FL 32784-2349 E-Mail: sales@electronmachine.com

http://www.electronmachine.com

Rev. A

MPR E-SCAN INTRODUCTION

Introduction

The Electron Machine Corporation

MPR E-SCAN

The MPR E-Scan is a microprocessor driven critical angle refractometer. It is used to

measure the refractive index of process fluids which directly correlate with customer

request for dissolved solids, Brix or other meaningful measurement. The E-Scan may be

used as an error indicator or an integral part of a complete process control system.

The MPR E-Scan is equipped with a broad range of diagnostics to aid in fault isolation

without the use of special test equipment. The instrument is calibrated before leaving the

factory and should not need recalibration unless some modification is made to the sensing

head. Calibration procedures are available to change system parameters and allow the

refractometer to measure different process fluids.

Extensive literature is available for various industries listing the correlation between

refractive index, degrees Brix, or % solids and specific process parameters.

The E-Scan consists of:

• Sensing head

• Console

• Interconnecting cable

MPR E-Scan Overview

1

MPR E-SCAN INTRODUCTION

Important Manual Information

The Chapter title is at the top of each page for quick reference through the manual.

Important points, reminders, and warning messages are printed in bordered boxes as:

This is a general use manual. In the back of the manual are addendums and

configuration information specific to the individual unit.

NOTE: Box indicates important messages.

CAUTION

When removing the sensing head from an operating line, do not assume that

the line is empty or that the isolation or bypass means is working properly.

Only trained staff are to use an EMC Isolation Valve Adapter. Isolation Valve

Adapter must be properly maintained and reconditioned after 10 years of

service. No pressure should be felt on the head as the mounting nut is being

removed. See the EMC Isolation Valve Adapter manual for more information.

ANY PRESSURE FELT WHEN THE NUT IS LOOSENED MUST BE

INVESTIGATED BEFORE PROCEEDING. Prism cleaning systems

should be turned off before attempting to remove the sensing head.

Personal Protective Equipment must be used that is appropriate for a line

break activity (as determined by installed site’s health and safety personnel).

Contact Electron Machine for additional information and for current

documentation, training materials, and procedures.

2

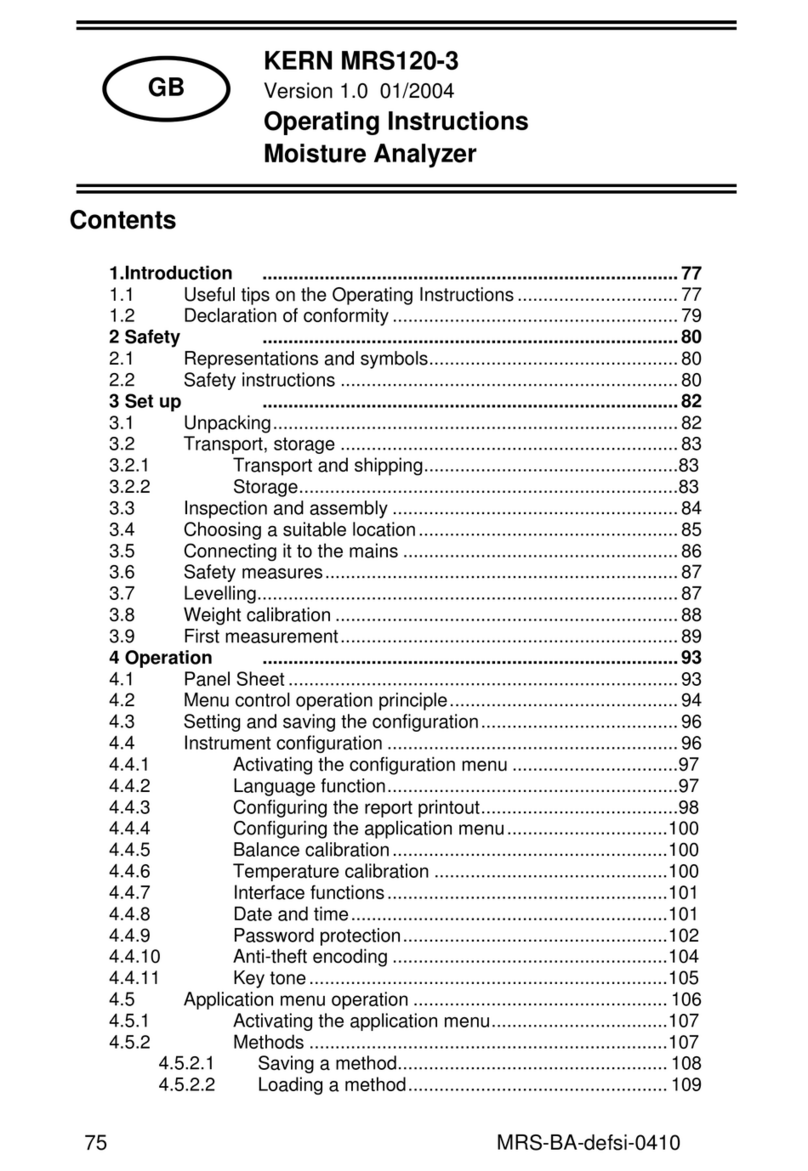

Table of Contents

1. Installation............................................................................................................... 1 - 1

1.1 Site Selection .............................................................................................. 1 - 1

1.2 Power Requirements ................................................................................... 1 - 1

1.3 Attaching the Sensing Head ....................................................................... 1 - 1

1.4 Steam Purge Attachment ............................................................................ 1 - 2

1.5 Interconnection ........................................................................................... 1 - 3

1.5.1 Analog Outputs ............................................................................... 1 - 3

1.5.2 Printer Output ................................................................................. 1 - 4

1.6 Prism Clean ................................................................................................ 1 - 4

1.6.1 Steam Pressure ............................................................................... 1 - 4

1.7 Start-Up ...................................................................................................... 1 - 4

2. Operation................................................................................................................. 2 - 1

2.1 The Operator's Panel .................................................................................. 2 - 1

2.1.1 Display ............................................................................................ 2 - 1

2.1.2 Button Touch Pad Function Chart .................................................. 2 - 2

2.1.3 Measurement Signal Graphing for the MPR E-Scan ..................... 2 - 3

2.2 Normal Mode ............................................................................................. 2 - 4

2.2.1 What Normal Mode Does ................................................................ 2 - 4

2.2.2 System Indicators ........................................................................... 2 - 4

2.2.3 The Menu Options in Normal Mode .............................................. 2 - 5

2.2.4 Overview of Menu Options ............................................................ 2 - 6

2.3 Product Selection ........................................................................................ 2 - 7

2.4 Calibration Selection ................................................................................ 2 - 10

2.5 Configuration Selection ............................................................................ 2 - 15

2.6 Print Selection .......................................................................................... 2 - 20

2.7 Diagnostic Selection ................................................................................. 2 - 21

2.8 Offset Selection ........................................................................................ 2 - 24

2.9 Purge Selection ......................................................................................... 2 - 25

2.10 Hold Selection .......................................................................................... 2 - 26

3. Problem Analysis .................................................................................................... 3 - 1

3.1 Procedures .................................................................................................. 3 - 1

3.2 Trouble Shooting Chart .............................................................................. 3 - 2

4. Service..................................................................................................................... 4 - 1

4.1 EMC Warranty ........................................................................................... 4 - 1

4.2 Return of Defective Parts ........................................................................... 4 - 1

4.3 Service in the Field ..................................................................................... 4 - 1

4.4 Spare Parts .................................................................................................. 4 - 2

4.4.1 How to Order Parts ........................................................................ 4 - 2

4.4.2 Available Spare Parts ....................................................................... 4 - 2

4.5 Preventive Maintenance ............................................................................. 4 - 3

4.6 Caution ....................................................................................................... 4 - 3

4.7 Maintenance Log Sheet .............................................................................. 4 - 4

5. System Information ................................................................................................. 5 - 1

5.1 Technical Description ................................................................................ 5 - 1

5.1.1 Sensing Head ................................................................................ 5 - 1

5.1.1.1 Optics ........................................................................... 5 - 1

5.1.1.2 CCD Linear Array.......................................................... 5 - 2

5.1.1.3 Signal ............................................................................. 5 - 2

5.1.2 Console .......................................................................................... 5 - 3

5.1.2.1 Display ........................................................................... 5 - 3

5.1.2.2 Switch Matrix................................................................. 5 - 3

5.1.2.3 Cable entry and mounting .............................................. 5 - 4

5.1.2.4 IB (interface board) for external connection ................. 5 - 4

5.1.2.5 Power supply .................................................................. 5 - 4

5.1.2.6 I/O card .......................................................................... 5 - 4

5.1.2.7 CPU Card ....................................................................... 5 - 5

5.1.2.8 Supplemental Card Information ..................................... 5 - 6

5.2 Refractometer Specifications ..................................................................... 5 - 7

5.3 Available Options ....................................................................................... 5 - 7

6. Drawings List .......................................................................................................... 6 - 1

MPR E-SCAN INSTALLATION

Care must be taken not to damage the thermistor probe

protruding from the sensing head on units so equipped.

1. Installation

1.1 Site Selection

The E-Scan console can be mounted in any area where ambient conditions allow personnel to

remain for extended periods. The cabinet is Nema 4X rated and should be kept closed.

MPR E-Scan Instrument 1.2 Power Requirements

The A.C. power should be supplied from a line which is not

subjected to power interruptions or heavy inductive loads. A.C.

power can be 120/220 VAC at 50 or 60 Hertz.

1.3 Attaching the Sensing Head

The sensing head as received may have a calibration cup

installed, if purchased.

The sensing head is attached to the process line by an adapter

which can be carbon steel, stainless steel (316) or a material

specified by the customer. This adapter must not be placed in an

area where vibration is severe or excessive.

Sensing Head to Adapter

Positioning.

If the sensing head is to be mounted on a horizontal pipe, the head

should be mounted in a horizontal plane (parallel with the ground)

on the side of the pipe (not the top or the bottom).

If the sensing head is to be mounted on a vertical pipe, the fluid

flow should be upward. The arrow on the adapter should point in

the direction of fluid flow. (See Head to Adapter Positioning.)

To facilitate fast thermal response the tip and walls of the probe

are very thin making it somewhat fragile.

1-1

MPR E-SCAN INSTALLATION

This o-ring must be in place prior to installing the head into the adapter to prevent the process

leaking out.

The nut should be tightened with a wrench (supplied by EMC) to a maximum 50 foot-pounds

of torque (68 Newton-Meter).

Alignment marks are provided for units utilizing a steam purge cleaning cycle to ensure that

the thermistor probe will not be in a direct line of the steam blast. (See drawing below.)

In applications where the product may solidify

at ambient temperature, a check valve must be

installed onto the steam port.

Steam purge time must be kept at a minimum typically from 1 to 10 seconds duration, to avoid

excessive prism deterioration, while at the same time keeping the intervals between these purge

times at maximum, which may vary from minutes to many hours.

The probe end of the sensing head has a groove for an interface o-ring.

The head is attached to the adapter by a 2-inch sanitary nut.

The sensing head houses optical components which are susceptible to the effects of moisture.

The cover is moisture proof and contains a desiccant to absorb any moisture remaining in the

head after assembly. The sight glass on the head allows inspection of the desiccant. Light

orange indicates that it remains effective. Clear indicates it is no longer effective and must be

changed. The desiccant can be renewed by heating to approximately 250° F (121° C) until it

recovers its orange color.

1.4 Steam Purge Attachment

Steam Purge Attachment- for liquids

which exhibit a tendency to "coat" The steam purge valve must be similarly

mounted to the adapter with a minimum of 6"

and a maximum of 18" from the steam port on

an adapter preferably with 1/4" tubing.

Steam pressure must be at least 50 psi (3.44 bar)

above process pressure with adequate

condensate drainage at the steam valve in order

to ensure hot steam for cleaning the prism. Trial

and error must, of necessity, be employed in

determining the minimum steam time necessary

for proper steam cleaning of the prism due to

variables from application to application.

Contact Electron Machine for more information.

1-2

MPR E-SCAN INSTALLATION

The cable should not be placed in a tray or conduit with wires attached to heavy inductive loads

or SCR drives. A separate conduit is recommended.

1.5 Interconnection

The E-Scan offers many options for external device connections.

1.5.1 Analog Outputs

In addition to voltage outputs, the E-

Scan also offers current outputs for the

measurement and also the temperature.

The measurement is a standard output

and temperature is an option. Output

for these readings is a 4 to 20 mA

signal that is referenced to ground

(non-isolated) so that any device that is

connected to these outputs must have a

floating (or isolated) input. Isolated

current output modules are available as

an option.

The output for the measurement

reading is found on TB 3 terminals 1

and 2. Terminal 1 is the positive output

for both the isolated output option and

the standard non isolated output

module. The output for the temperature

is located on TB 3 terminals 3 and 4, 3

being the positive output in this case.

The modules on the top of the interface

board represent the output modules.

The one on the left U1 is the output

module for the measurement. U2 is the output module for the temperature. The other modules

(U3 and U4) are for optional features and are explained in the optional addendums to this

manual. It is an easy process to change from a non-isolated module to an isolated output module.

You must first remove the power supply, then unplug the non-isolated module and replace it with

the isolated module. The isolated modules are blue potted modules while the non-isolated

modules are bare board modules. If a 0-10 voltage output is desired then TB 4 terminal 1 is the

measurement output and terminal 2 is the temperature output. Terminal 3 is the common for

both of these outputs.

1-3

MPR E-SCAN INSTALLATION

1.5.2 Printer Output

The E-Scan offers a printer output as an option via CPU card parallel port J17. The connector is

easily installed either in the field or at the time the instrument is manufactured. The standard

printer output is via the Com/LPT card. Please refer to interconnection drawing for the Com/LPT

Card for the proper connection of a printer to the E-Scan. The printer output should be used for

short runs only, less than 50 feet (15.2 meters). If a longer cable is desired then a printer buffer

should be used to extend the cable length.

1.6 Prism Clean

The following refers to steam, however, other mediums may be used as the prism cleaning agent:

The MPR E-Scan provides two normally open contacts for prism clean. These contacts are

intended to directly operate the steam (TB2-11,12) and condensate drain (TB2-9,10) valves.

Electrical interconnection for these devices is also shown in the interconnection drawing. These

contacts are dry contacts and power must be supplied from an external source as shown on the

drawing. Contact Electron Machine for specific application information.

1.6.1 Steam Pressure

The steam pressure must be no less than 50 psi (3.44 bar) and preferably no greater than 100 psi

(6.89 bar) above the process line pressure. Both the steam and condensate drain valves should be

located as close to the steam purge fitting as possible. The condensate drain valve is provided to

remove water from the steam line to allow free passage of steam to the head. See also Steam

Purge Attachment in Installation Section.

1.7 Start-Up

Turn power on. Allow sufficient time for the sensing head to stabilize at the process

temperature. It is recommended that no adjustments be made for at least 15 minutes after start-

up.

Compare the reading against a sample taken from the process line close to where the unit is

installed and at the process operating temperature. If the sample does not equal the displayed

reading, adjust the analog zero per Operation/Calibration section.

Important: Prior to shipment the sensing head is matched to the console and factory calibrated.

DO NOT ATTEMPT TO RE-CALIBRATE

1-4

MPR E-SCAN OPERATION

2. Operation

2.1 The Operator's Panel

The Operator’s Panel or Front Panel consists of a display and a 20-button touch pad which form

the interface between the operator and the instrument. The display consists of a 640 x 480 pixel

TFT LCD screen which provides the operator with various messages. The 20-button touch pad

allows the operator to make entries and instigate commands.

2.1.1 Display

The three basic types of messages displayed are:

Variable:

These information lines contain either

set points that may be altered by the

operator, or measurement variables

that are updated by the CPU.

Alternate Action:

Acts much like a two-position switch

and is used to select various menu

options. The operator is able to

alternate between two states, such as

ON and OFF.

Error Display:

Flashes continuously to attract

operator’s attention to an error

condition.

This equipment is designed for continuous operation and may be left on for extended periods of

time.

2-1

MPR E-SCAN OPERATION

2.1.2 Button Touch Pad Function Chart

Scrolls cursor horizontally to the left and also used to

initiate editing of calibration voltages in the calibration

table, and temperature values in the compensation table.

Scrolls cursor horizontally to the right and also used to

initiate editing of all system parameters excluding those

accessed by the LEFT ARROW.

Scrolls cursor vertically in the “Up” direction.

Scrolls cursor vertically in the “Down” direction.

ENTER Used to select all cursor items and to save edited data.

Esc Used to abort to previous operation without saving

edited data.

Menu Used to immediately display the normal mode of operation

without saving information or main menu selections if

already in normal mode.

PgUp Displays previous screen of information or mode of

operation when indicated on the screen. Used to exit graph

mode and return to normal mode.

PgDn Displays the next screen of information or mode of

operation when indicated on the screen. Used to enter

graph mode from normal mode.

+/- Allows data fields to be either positive or negative.

Toggles configuration and diagnostic options as well as

control modes, if configured for P.I.D. control. Also used to

record sample readings used for analog zero adjustment.

0-9 Numeric keys used to input data.

2-2

MPR E-SCAN OPERATION

2.1.3 Measurement Signal Graphing for the MPR E-Scan

Graph Mode Screen

The MPR E-Scan offers a

graphical mode display, which

can be accessed from the normal

mode of operation via the PgDn

button on the front panel switch

matrix. PgUp will then return to

the normal mode display. The

graphical mode display comes

equipped with all the essential

information including the

current product, error status, and

measurement reading, in

addition to the graph span and

time.

The graph span limits are derived

from the analog low and high

limits in calibration and are drawn on the display at the top and bottom of the graph area as

dotted lines.

The graph time can range from 5 minutes to 9999 minutes and can be accessed via the

button on the front panel switch matrix.

The calibration alarm limits are also displayed graphically within the graph area and are drawn

as red dashed lines to differentiate them from the graph span limits. The alarm limit lines are

drawn 20 pixels apart horizontally, which gives the added feature of breaking the graph time into

20 equal parts. Thus, if the graph time were 20 hours, each alarm limit segment would represent

1 hour.

Finally, the measurement signal itself is drawn in the graph area and can be recognized as a

single continuous stream of information that is 2 pixels thick. The measurement graph offers a

high-quality display with 574 pixels of horizontal and 295 pixels of vertical resolution.

2-3

MPR E-SCAN OPERATION

2.2 Normal Mode

2.2.1 What Normal Mode Does

In normal mode the system displays the following information:

• Name of the current product being measured along with an associated product number.

• Software version number.

• Current time and date.

• On-line measurement such as BRIX, SOLIDS....

• On-line temperature in Degrees Fahrenheit and Centigrade.

• Alarm points for measurement and temperature.

• Error status for system measurement, temperature and voltage levels.

• Graphics menu to allow access to other MPR E-Scan system features.

• Purge information when configured for purge operation.

Note: In normal mode set points cannot be changed or adjustments made.

2.2.2 System Indicators

C Isolation valve is closed. The MPR E-Scan will not initiate a prism clean.

T Below min purge temperature limit. No prism clean allowed.

H Measurement Hold. Current readings and analog outputs are maintained until complete.

Can be invoked by menu selection in normal mode or by external input if configured for

on demand hold. Measurement Hold can also indicate a cleaning cycle in progress which

is indicated by a purge message as well as a current measurement voltage display while

in normal mode.

P Purge failed. This means the previous purge cycle did not properly clean the prism. This

indicator is used only when smart prism cleaning is configured.

O Measurement over range. Current reading above last calibration point for MPR E-Scan

in the calibration table.

U Measurement under range. Current reading below first calibration point for MPR E-Scan

in the calibration table.

S Measurement sample reading has been recorded as the reference for analog zero

adjustment.

2-4

MPR E-SCAN OPERATION

Note: The screen names and setpoints below are just an example, they will vary from

application to application.

2.2.3 The Menu Options in Normal Mode

Normal mode is entered by default, upon power up. To gain access to other system features

select the MENU button on the Front Panel Touch Pad.

Normal Mode Screen with Menu Options

When the MENU button is

selected, the following menu

options are displayed on the

normal mode screen:

Normal Mode Screen with Purge and Hold Options

If “Purge” and “Hold” options

are configured, the following

menu options are displayed on

the normal mode screen:

2-5

MPR E-SCAN OPERATION

2.2.4 Overview of Menu Options

PRODUCT option allows the operator to select a product from a list of previously calibrated

products. When a new product is chosen, all operating parameters are automatically loaded so

that the E-Scan can immediately be ready to measure the “new” product selected. This menu

option also allows the operator to enter actual product names which are attached to associated

product numbers. In addition, this option enables the operator to create new products by storing

product information into unused product numbers.

CALIB option allows the operator to enter calibration set points. This consists of calibration

limits, measurement, temperature compensation, and analog zero adjustment. Since a complete

calibration is performed in advance by EMC, it would be a rare condition for the operator to

access calibration measurement and temperature compensation. However, system limits may be

changed more frequently if the operator chooses to change the alarm limits, analog output limits,

alarm delays, purge cycle information, or other limits. An analog zero adjustment is provided to

“zero in” the instrument to match lab samples or reach a target measurement if needed.

CONFIG option allows the operator to configure the E-Scan to perform various functions. Such

configurations would include: purge/hold interface, smart cleaning, measurement and

temperature alarms, 232 output and associated baud rates, measurement title, and displayed

reading decimal format. Other configuration options are selected in advance by EMC and would

not normally be changed by the operator. Thus, access to other system configurations is gained

only by entering a correct password.

PRINT option allows the operator to print all system calibration and configuration settings as

well as current measurement and temperature readings with a time and date stamp.

DIAG option provides the operator with data that can be used to test and troubleshoot system

problems. The operator can display all voltages from the sensing head, test relays on the

interface board, output min., mid., and max. analog data to test and calibrate chart recorder

output, and enter system time and date in cases of battery failure.

ANLG. 0 Same as “ANLG. 0” in calibration menu

OFFSET option allows the operator to add an adjustment to the current reading in order to reach

a target value.

PURGE option allows the operator to initiate a purge from normal mode in addition to the

automatic purge cycle timing setup in calibration limits. The purge function cleans the sensing

head prism and if configured for smart cleaning will automatically start another purge cycle if

the previous purge was unsuccessful. Purge can be aborted using the Front Panel ESC button.

HOLD option allows the operator to initiate a hold condition from normal mode, which will

freeze system information. This freezes both displayed readings as well as analog output. Hold

can be aborted using the Front Panel ESC button.

2-6

MPR E-SCAN OPERATION/PRODUCT SELECTION

2.3 Product Selection

The product menu displays the

current product selected, a list of all

available products, and three menu

options: “Get”, “Store”, and

“Name”. Using the Front Panel

buttons the operator can highlight

and then select specific menu

options.

The “Get” option allows the

operator to choose a specific

product, provided this product has

been previously calibrated and

configured for on demand use. In

this example, only two products

(“PRODUCT 1 NAME” and

“PRODUCT 2 NAME") are

available.

When the “Get” option is selected, the following is displayed:

The product menu options have

been replaced by the “Get Mode”

and “Enter Product #” messages.

Using the Front Panel buttons the

operator can enter a product number

and then “Get” that product.

NOTE: The operator can only

“Get” products that are available

which are identified by a product

name.

P Product Screen

Get Mode Screen

2-7

MPR E-SCAN OPERATION/PRODUCT SELECTION

The second menu option, “Store”, allows the operator to create a new product by selecting a

product number that will be the destination for the current product calibration and configuration

information.

When the “Store” option is selected, the following is displayed:

The product menu options have been

replaced by the “Store Mode” and

“Enter Product #:” messages.

Using the Front Panel buttons, the

operator can select a product number

that will be the destination of the

current calibration and configuration.

In this example, all of product 01

information will be copied to product

03 thus creating a new product.

The next step would be to assign a meaningful name to the newly created product which can be

accomplished by selecting the third product menu option, “Name”.

The product menu options have been

replaced by the “Name Mode” and

“Enter Product#:” messages.

In this example we will assign a

meaningful name to a newly created

product. Notice product 03 is

designated by the message “NEW

PRODUCT”, indicating that it has

been newly created by the “Store”

product menu option.

Store Mode Screen

Name Mode Screen

2-8

MPR E-SCAN OPERATION/PRODUCT SELECTION

Using the Front Panel buttons, product 03 can be selected which would result in the following

display:

This is the product name mode alphabet menu.

It displays the current product selected

in the upper left corner, the alphabetic

characters available for assigning a

product name in the center, and the

product name at the bottom which is

updated as characters are selected.

Using the Front Panel ARROWS and

the ENTER button a product name

can be selected and then saved. The

“PgDn” and “PgUp” messages at the

top right indicate the status of the

editing mode. Toggling between these

modes allows the operator to move

the edit cursor to a desired position

either in the alphabet or the product name. When the “-Save-” option is selected the product

name is saved.

Note: Up to 99 products are available. The operator can use the “PgDn” and “PgUp” buttons

to view a set of 20 products per page.

Name Mode Alphabet Screen

2-9

MPR E-SCAN OPERATION/CALIBRATION

2.4 Calibration Selection

The calibration menu contains four

menu options:

1. Limits - This option contains

the system limits for alarms, purge

cycle, analog output, filter weight,

measurement scale and offset.

2. Meas. - This option allows entry

to the calibration measurement

routine. This is used to calibrate

the process measurement so that a

linear interpolation can be made to

get the Refractive Index based on

the current measurement voltage.

3. Temp. - This option allows entry to the calibration temperature compensation routines. This

is used to compensate the process measurement changes that are caused by temperature changes.

4. Anlg. 0 (Analog Zero) - This option is used to adjust or “zero in” the instrument to match a

target value.

Using the Front Panel buttons, the

operator can highlight and then select

the specified calibration menu

options. Selecting the “Limits” menu

option would generate the following

display:

Using the Front Panel arrow buttons,

the operator can scroll through and

edit selected system limits. In this

example, Measurement Alarm Low

can now be changed using the

RIGHT ARROW button and the

numeric keys.

Measurement Alarm Low: If the measurement falls below this limit, a system alarm is

activated. An error message will appear in the status window in normal mode, and the low

measurement alarm relay will be turned on.

Calibration Limits Screen 1

Calibration Mode Screen

2-10

Table of contents

Other THE ELECTRON MACHINE CORPORATION Measuring Instrument manuals