2macnaught | instruction manual

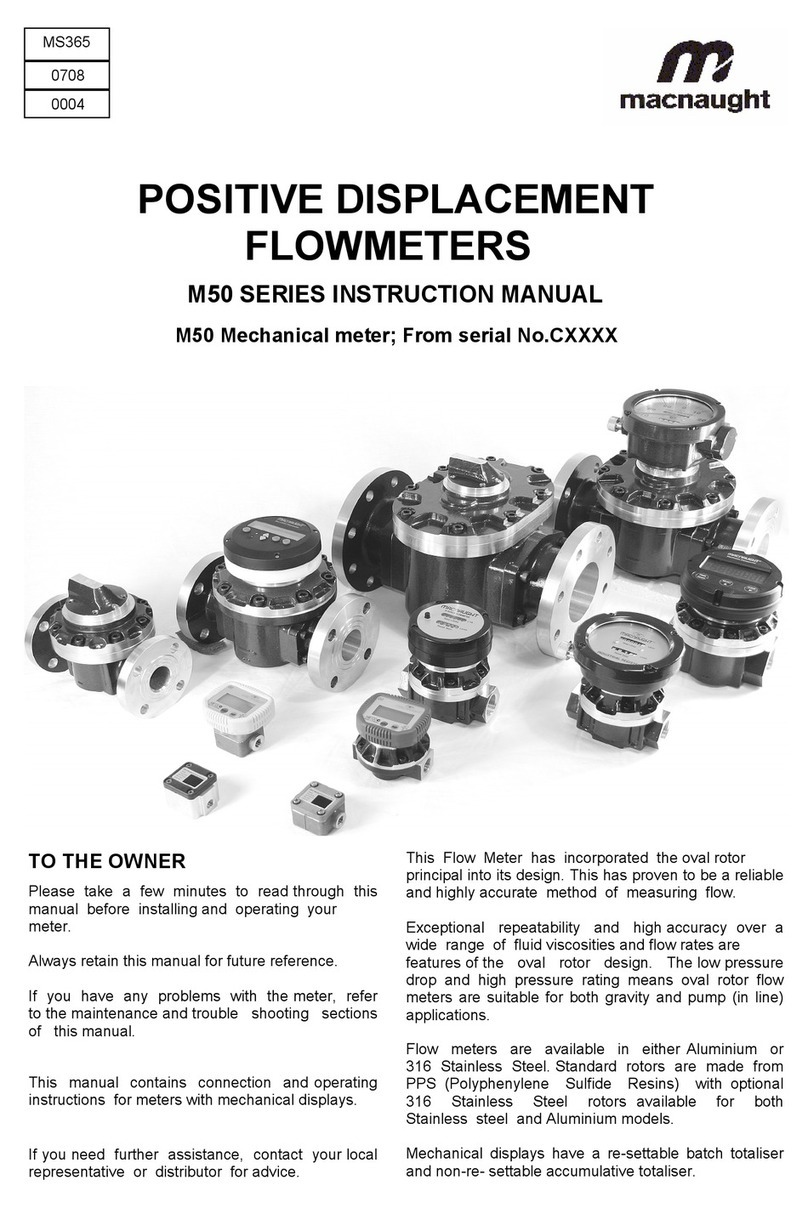

MECHANICAL DIESEL METER

AMFM

INSTRUCTION MANUAL

INTRODUCTION

Thank you for purchasing a Macnaught AMFM Mechanical

Diesel Meter.

The AMFM meter is a mechanical nutating disc meter

providing a reliable, accurate method of measuring diesel. The

meter has two totals available (resettable batch total and non-

resettable total).

Macnaught manufacture a full range of pumps, meters and

accessories to suit most of your fluid transfer needs. Please

consult your local Macnaught reseller for more information.

Please read and retain this instruction manual to assist you in

the operation and maintenance of this quality product.

This manual assists you in operating and maintaining your

new Mechanical Diesel Meter. The information contained will

help you ensure many years of dependable performance and

trouble free operation.

Your in-line nutating meter is designed to accurately measure

low viscosity fluids and water. This nutating disc meter is

ideal for use on low pressure in-line applications, mobile

installations and electric diesel pumps, generally fitted close

to the dispensing nozzle.

GENERAL INFORMATION

OPERATION

CAUTION

Observe precautions against fire or explosion when

dispensing flammable liquid. Do not operate the meter in the

presence of any source of ignition including running or hot

engines, lighted cigarettes or gas or electric heaters.

Ensure that you follow all the correct earthing and grounding

procedures before use.

Inspect seals and connections for leaks weekly

when using flammable liquids.

Do not use Teflon tape on any connections when using

flammable liquid.

Do not use this meter with gasoline or any fluid other than

the compatible fluid specified in this manual.

Do not use the meter above the maximum pressure of 3.5

bar.

Both the batch total and accumulative total will turn

simultaneously when fluid passes through the meter.

Turn the reset knob to reset the batch total to zero.

The meter has been manufactured for standard horizontal

fitting with a flow direction from left to right. The orientation

can be changed using the following procedure.

1. Remove the 4 screws that hold meter cover.

2. Remove the 2 screws that hold register.

3. Remove the 8 screws that hold meter aluminium top.

4. Turn the body to the desired location, ensure you do

not damage the sealing body o-ring.

5. Tighten the 8 screws that hold meter aluminium top, do

not exceeds max torque of 4,5 Nm.

6. Carefully fit the register to the meter body, ensure you

do not bend the pinion shaft.

7. Tighten the 2 screws that hold register, do not exceeds

max torque of 2 Nm.

8. Carefully place the meter cover.

9. Tighten the 4 screws that hold meter cover, do not

exceeds max torque of 2 Nm.

NOTE: When fitting meter, ensure direction of flow is the

same as the arrow cast to underside of the meter.

Macnaught recommends that a filter screen of at least 40

mesh is installed prior to the flow meter. Macnaught has a

HA1S (10 micron) fuel filter available if required.

DO NOT exceed a maximum pressure of 3.5 bar (50psi).

INSTALLATION