PH-II Simple Application Controllers

ENG-v

ENG

Table of Contents

Guidelines of Safety ...................................................................ENG-iii

1. Introduction......................................................................................ENG-1

1.1 Special Features of the PH-II Series System ................................................ ENG-2

1.2 Available Models ........................................................................................... ENG-3

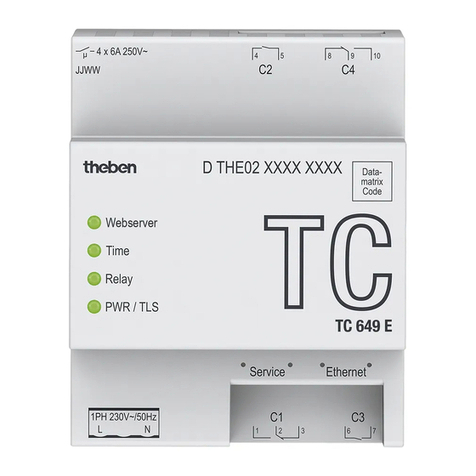

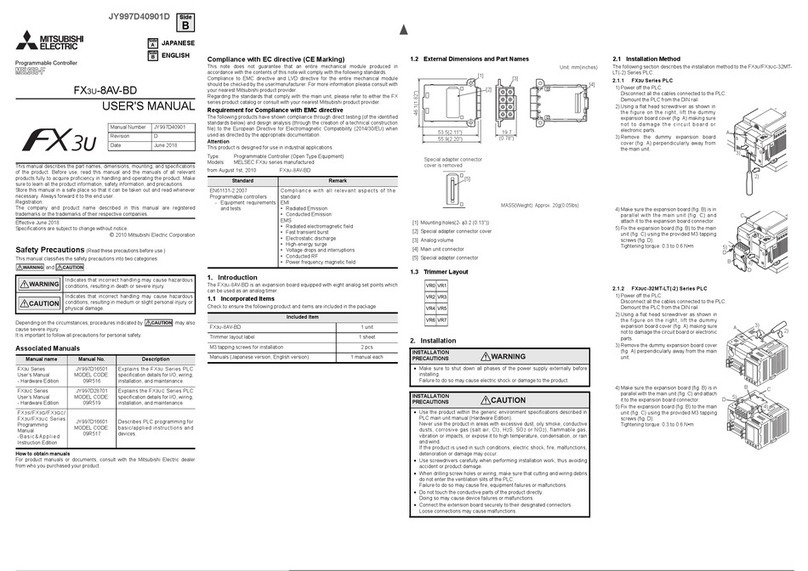

1.3 Dimensions and Each Part Name ................................................................. ENG-4

1.4 System Configuration .................................................................................... ENG-5

1.5 Applicable Programming Software ................................................................ ENG-5

2. Specifications ..................................................................................ENG-7

2.1 Power Supply Specification ........................................................................... ENG-7

2.2 Input Specification ........................................................................................ ENG-8

2.3 Output Specification .................................................................................... ENG-10

2.4 General Specification .................................................................................. ENG-11

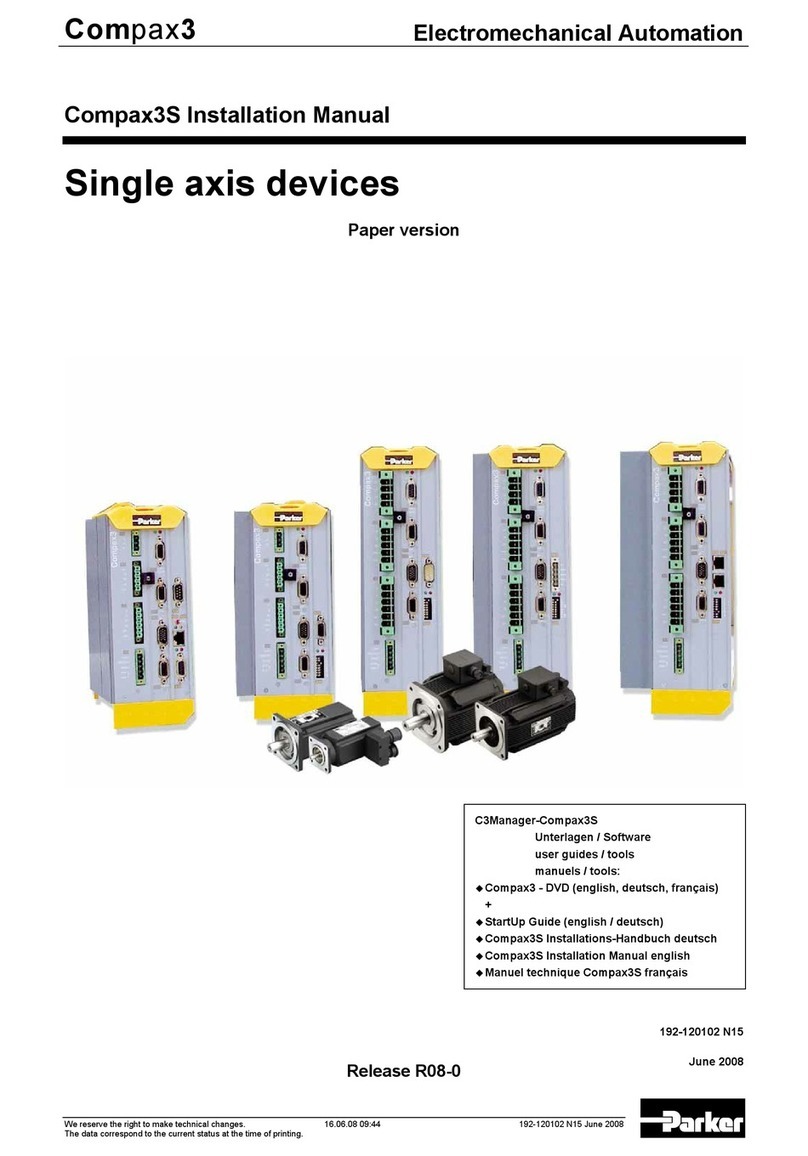

3. Installation .....................................................................................ENG-13

3.1 Installation Mounting Notes ......................................................................... ENG-13

3.2 DIN RAIL Mounting of Main Unit ................................................................. ENG-14

3.2.1 Installation ......................................................................................................... ENG-14

3.2.2 Remove ............................................................................................................. ENG-14

3.3 Direct Mounting of Main Unit ....................................................................... ENG-15

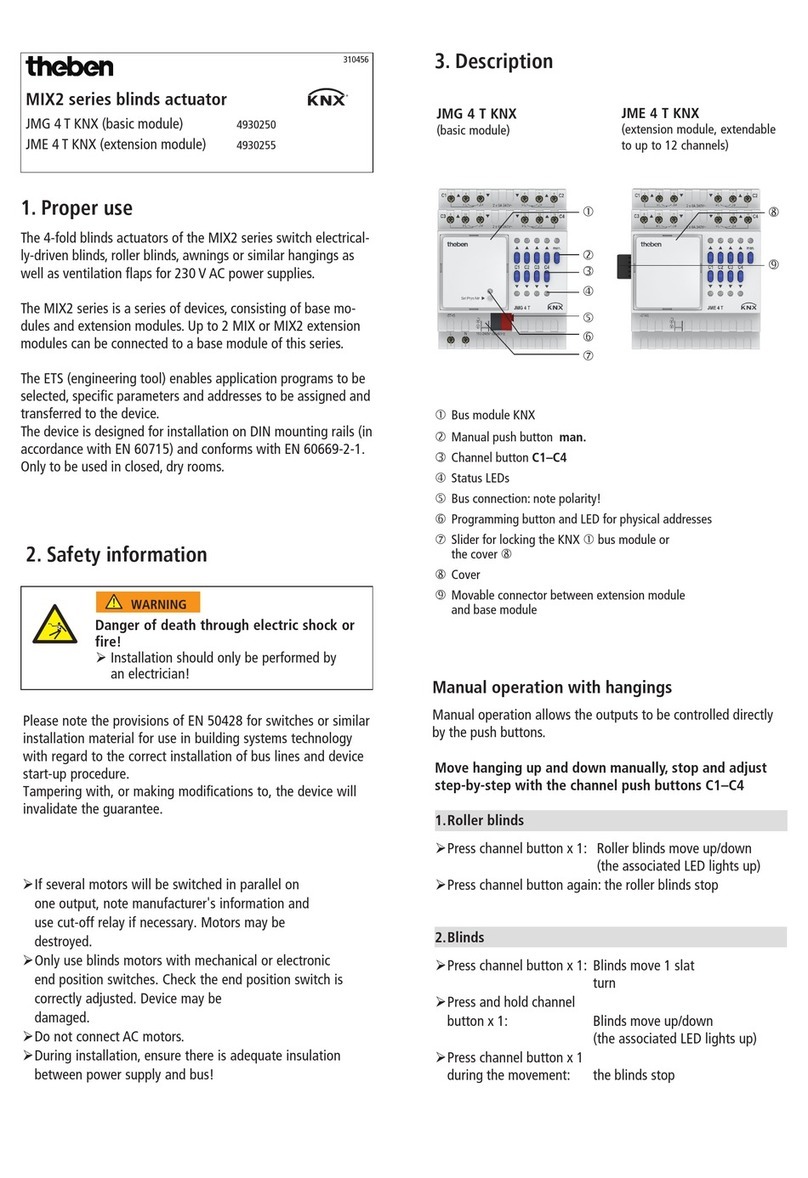

3.4 Install Extension Module.............................................................................. ENG-15

4. Wiring ............................................................................................ENG-17

4.1 Installation Wiring Notes.............................................................................. ENG-17

4.2 Wire Size ..................................................................................................... ENG-18

4.3 Power Supply .............................................................................................. ENG-19

4.4 AC Power Supply and Input Wiring ............................................................. ENG-20

4.4.1 AC Power Supply and Input Wiring ................................................................... ENG-20

4.4.2 PH-II 4ED Input Wiring ...................................................................................... ENG-20

4.5 DC Power Supply and Input Wiring ............................................................. ENG-21

4.5.1 DC Power Supply and Source (“+” Common) Input Wiring Diagram ................ ENG-21

4.5.2 PH-II 4EDA Source (“+” Common) Input Wiring Diagram ................................. ENG-21

4.5.3 DC Power Supply and Sink (“-” Common) Input Wiring Diagram...................... ENG-22

4.5.4 PH-II 4EDA Sink (“-” Common) Input Wiring Diagram....................................... ENG-22

4.6 Output Relay and Transistor Wiring ............................................................ ENG-23

4.6.1 Relay Output Wiring Diagram main unit (AC and/or DC) .................................. ENG-23

4.6.2 Relay Output Wiring Diagram PH-II 4AR (AC and/or DC)................................. ENG-24

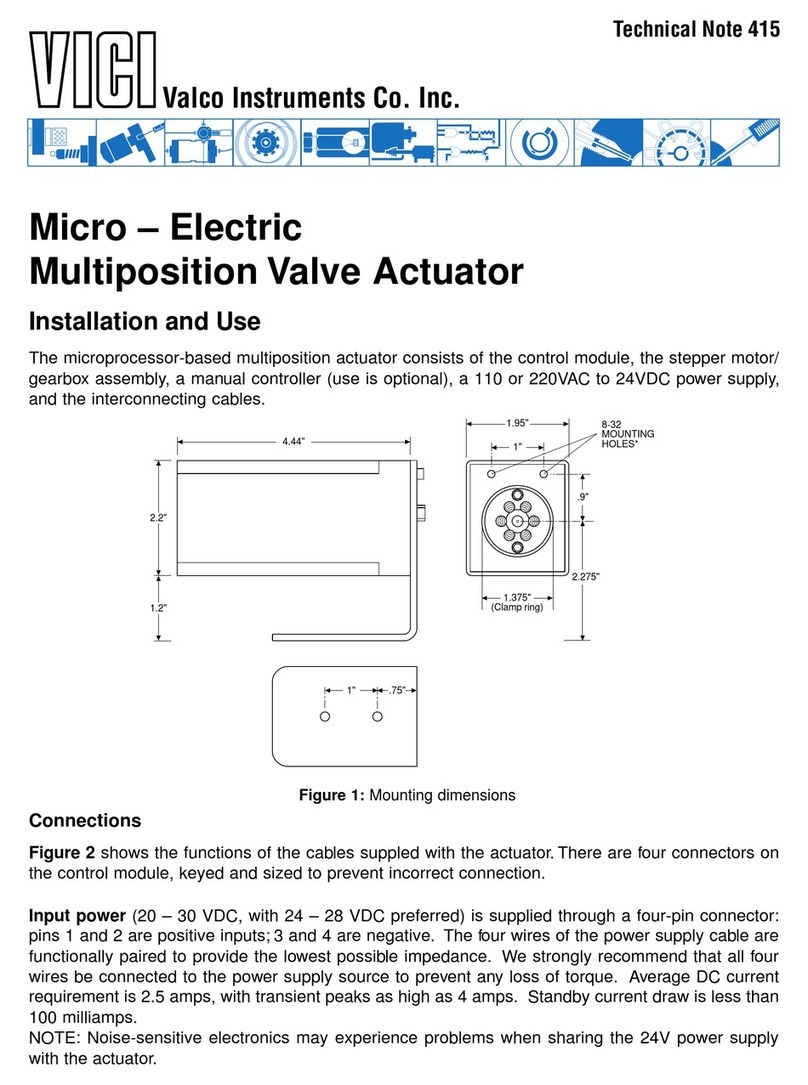

4.6.3 Transistor Output (Source or “+” Common Only) Wiring Diagram

PH-II 4AT........................................................................................................... ENG-25

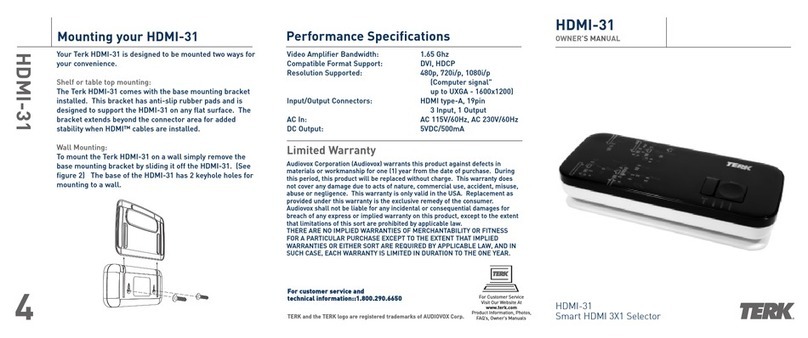

5. Terminal Layout............................................................................ENG-27

6. PH-II EEPROM..............................................................................ENG-29

6.1 Installation ................................................................................................... ENG-30