THERMA-KLEEN Ultra Propane 600 User manual

Ultra Propane - Ultra 600

January 15, 2019

1

THERMA-KLEEN®

Operators Manual

Ultra Propane – Model 600

Made in the USA

THERMA-KLEEN®

2415 E. Huron PO Box 805

Au Gres, MI 48703

Ph: 630-718-0212 Fax: 989-876-6640

E-mail: sales@therma-kleen.com

Web Site: www.therma-kleen.com

Ultra Propane - Ultra 600

January 15, 2019

2

OWNERS MANUAL

Do Not Use This System Without Reading This Manual First

You should be familiar with the information in this manual before you operate your

equipment. The manual is structured so that it can be used for your reference.

Page Description

3 SERVICE INFORMATION

4 MACHINE SPECIFICATIONS

6 SAFETY INFORMATION

9 GROUNDING

9 OPERATING INSTRUCTIONS – START-UP

10 OPERATING INSTRUCTIOND – SHUT DOWN

11 PREVENTIVE MAINTENANCE

12 DESCALING PROCEDRUE

12 MAINTENANCE OF PUMP

13 MAINTENANCE OF MOTOR

14 CHEMICAL INJECTION

14 TROUBLE SHOOTING

19 HOSE MAINTENANCE

20 PARTS

24 L.P. GAS PROPANE

25 WARRANTY

All information, illustrations and specifications contained within this manual are based on

the information available at the time of production.

THERMA-KLEEN®, reserves the right to make changes at any time.

Ultra Propane - Ultra 600

January 15, 2019

3

SERVICE INFORMATION:

Therma-Kleen® Model 600

Please take the time to fill out the form on this page. When completed, this reference

form will provide information essential to the proper servicing and ordering of parts for

your THERMA-KLEEM® ULTRA 600.

OWNER:

Name of Business: ___________________________________________________

Address: ___________________________________________________________

City, ______________________________ State: __________ Zip Code: _______

Telephone: ___________________ E-mail: ______________________________

Serial #: _____________ Date Shipped: ___________________________

Our sales and parts department will be glad to answer any questions or provide

troubleshooting help over the phone. All parts will be shipped via UPS unless otherwise

specified. The warranty card must be filled out on our Web Site to activate your

warranty.

www.THERMA-KLEEN.com

Therma-Kleen®

P.O. Box 805, 2415 E. Huron Rd. Au Gres, MI 48703

Telephone: 630-718-0212 Fax: 989-876-6640

E-Mail: sales@therma-kleen.com

Ultra Propane - Ultra 600

January 15, 2019

4

MACHINE SPECIFICATIONS:

SPECIFICATIONS Ultra 600

WATER PRESSURE:600 PSI

MAXIMUM WATER TEMP: 340˚F

WATERVOLUME: 1.5 GPM

SIZE: 18” W x 23” L x32” H

WEIGHT: 100 lbs.

FUEL: Vaporous LP gas on all models

BTU/hr.: 130,000

FUSE SIZE: 10 amp

STANDARD UNIT INCLUDE:

25 ft. Steam Hose X

50 ft. Steam Hose

Fan Nozzle X

Blast Nozzle X

Trigger Gun X

4 ft Wand Deluxe X

LP Gas Regulator X

Bungie Cord X

Internal Chemical Injection System

Fuel Pressure Gauge X

Temperature Gauge - Hi-Limit X

Electric Pilot Ignition X

Pressure Gauge X

Ultra Propane - Ultra 600

January 15, 2019

5

INSTRUCCIONES PARA OPERAR LA MAQUINA DE LIMIEZA

Conecte una manguera de agua a la rosca que se encuentra en la parte baja de la maquina

en el lado derecho. Conecte la manguera de vapor al desaguadero que se enchufa en el

lado izquierdo (ver instrucciones “quick connect coupling” pagina 14.)

Prenda el agua y deje que corra atraves de la maquina hasta que haya un flujo constante de

agua saliendo del tubo de acero (ver instrucciones “Wand” pagina 15.) Si le quita la

boquilla al tubo se le va hacer mas rapido el proceso. Un flujo constante de agua significa

que no hay aire en el serpentin y no hay restricciones en la boquilla. Cuando obtenga este

flujo constante la bomba va a funcionar major. Recuerde de poner la boquilla otra vez en

la punta del tubo de acero.

Conecte la maquina a una fuente de corriente de 115 voltios haciendo tierra. No prenda la

maquina sin hacer tierra. Prenda el boton de la bomba. Si la bomba se agita, es porque

esta usando una extencion de electricidad muy larga, la cual no puede conducir suficientes

voltios para la maquina. Use una extencion de 50 pies bastante grueza. Solamenta usa

AGUA FRIA; el agua caliente le danara los sellos de la bomba.

Conecte el gas propano a la pieze que gira sobre el eje (swivel fitting). Conecte el

regulador del gas propano al tanque de gas propano con el regulador puesto hacia arriba.

Ue solamente el gas propano que es vaporizado. Abra la valvula de gas completamente

(swivel fitting) que esta localizada sobre el tanque de gas. Para abrir todas las piezas y

valvulas, gire hacia la izquierda y para cerrar, hacia la derecha.

Prenda la maquina. Espere 60 sequndos para que encienda. Si la maquina se apaga,

espere a que se vuelva a encender automaticamente. Si la maquina se nueva, o no ha sido

usada en 12 horas o mas, variosminutos seran necisarios para que arranque. Esto es muy

normal ya que las lineas de gas tienen que sacar todo el aire y llenarse poco a poco.

Prenda y apague el arrancador varias veces.

Si usted quiere apagar el flujo de agua con el control del tubo de acero, mueva la valvula

90 grados para cerrar. No deie la valvula de control predida por mas de 2 minutos. Esto

puede danar y romper su maquina. Para volver abrir el flujo de agua, alinie la bolita de la

valvula paralelamente con el tubode acero. La unidad automaticamente se encendera en

60 segundos despues que se avra la valvula.

Como apagar la maquina:

….Apague el arrancador.

….Deje que la maquina continue corriendo hasta que toda el aqua caliente ha sido forzada

fuera del serpentin, y la valvula de la temperature margue 140 grados F.

….Apague la bomba, cierra la valvula del gas en el tanque de gas.

….Apague el agua y desconectela de la fuente de corriente.

Ultra Propane - Ultra 600

January 15, 2019

6

SAFETY TIPS:

While your THERMA-KLEEN®, portable, high pressure, steam cleaner is designed to be an

entirely safe cleaning tool, incorporating the latest and the most state of the art safety

features, the following safety tips are recommended by the manufacturer for the user to

implement:

1. ALWAYS - Check the machine, power & steam hose for damage

prior to start-up. If damage is detected, it must be repaired

prior to use.

2. ALWAYS - Check LP gas quick connect to make sure it has

snapped tight and there are no leaks.

3. DO NOT - Light the unit is there is any smell or indication of a Gas Leak.

4. ALWAYS - Use the heat deflector when operating the unit under low ceilings,

sprinkler systems, Heat/alarm systems, plastic light covers and any plastic

material, or flammable items.

5. DANGER – NEVER - Place hands, arms, neck, and loose clothing

Etc. over the top of the cylinder when and while ignition of the

burner takes place and during the actual operation of your high-

pressure steam cleaner. Beware of the flame in windy

conditions.

6. ALWAYS - use appropriate safety googles and gloves while operating your

cleaner.

7. ALWAYS - wear long sleeves, long pants, while operating your

cleaner.

8. DO NOT touch or grab the steam hose without gloves when

hose is being used or hot.

9. CAUTION - Before use check the electrical cord for damage, ware &

tare, cuts or abrasion.

a. DO NOT - use your machine with a damaged electrical cord.

10. ALWAYS - use the electrical plug that is on an approved

grounded circuit for this model.

a. CAUTION - If unsure if the circuit is properly grounded or has

the correct voltage\amperage for this machine, contact a

certified electrician.

Ultra Propane - Ultra 600

January 15, 2019

7

b. CAUTION - If the Power Outlet is damaged, have a certified

electrician repair the outlet.

c. NEVER - Touch the electrical plug or unplug the unit with

wet hands or while standing in a wet environment.

d. NEVER - Allow the electrical power cord to lie in water

while cleaning.

e. NEVER - Unplug from the receptacle by pulling on the cord,

always grasp the plug itself Make sure the unit is unplugged.

11. NEVER - Touch the system with wet hands or while standing in a

wet environment.

12. NEVER - Allow the machine to get wet as electrical shock may

occur.

13. CAUTION - Use extra caution when using the system around

water (Swimming Pools, Spas, Toilets, Etc.)

14. DO NOT - Allow the electrical power cord or Steam Hose to be run over,

stepped on or have something placed or dropped on it.

15. DO NOT - Allow the Electrical Power Cord or Steam Hose to be caught in a

closed door or pull over a sharp corner.

16. CAUTION - Turn off all controls prior to unplugging the unit.

17. ALWAYS -

18. CAUTION - Make sure all attachments are secured before activating the gun.

a. CAUTION - Only operate the unit when it is in a Horizontal position.

19. WARNING - To prevent scalding or burning, ALWAYS keep your hands and body

away from the nozzle tip during operation and wear

appropriate protective clothing.

a. DO NOT - Touch the steam nozzle while in use, or until

after it cools.

b. DO NOT - Grab the hot steam hose without appropriate

gloves.

20. NEVER - Point or direct the wand or steam at any person, animal or electrical

outlet or anything which could be damaged.

21. DO NOT - Move or lift the machine by pulling on the electrical cord.

22. DO NOT - Move or lift the machine by pulling on the steam hose

or gun.

23. DO NOT - Bend the steam hose past the 2” bend radius. This

will shorten the life of your hose.

Ultra Propane - Ultra 600

January 15, 2019

8

24. DO NOT - Operate your unit while the unit stands atop carpeted

floors, wood flooring or linoleum type tiled floor, as the heat

from the burner could damage these items.

25. DO NOT - Point or direct the wand and nozzle with high

pressure steam at any person/animal as this could result in

burning or harming another person/animal.

26. DO NOT - Point of direct the water spray from the wand towards an electrical

outlet or box.

27. DO NOT - Operate the machine without water as this may cause damage to the

unit.

28. DO NOT - Disconnect steam hose from the machine while the water

temperature exceeds 100˚F.

29. CAUTION - Only operate the machine while it is in an upright position.

30. DO NOT - Use in small confined areas.

31. DO NOT - Steam clean asphalt driveway material or floor grouting while using

the blast nozzle. To prevent pitting of such materials, we suggest that you only

use the fan nozzle.

32. DO NOT - leave the machine unsupervised while cleaning away from the

machine.

33. NEVER - Pull or tug on the machine with the power cord or steam hose.

34. CAUTION - Make sure all attachments are securely attached before activating

the gun.

35. NEVER - Allow children or un-trained persons to use or handle or operate the

machine.

36. CAUTION - Only operate the unit in an upright position.

37. Only - Use approved THERMA-KLEEN® components and parts in these units.

38. ALWAYS - Empty machine of all water when finished.

39. NEVER - Store machine outside.

40. NEVER - Store machine with water in it.

41. NEVER - Allow the unit to be exposed to freezing temperatures as

severe damage will occur.

WARNING:

Your Therma-Kleen Vapor Steam Cleaner MUST BE PLUGGED INTO A GROUNDED

OUTLET, or electrical shock can occur. Check with a certified

electrician if there is any doubt that the outlet is grounded. Do not

modify the Power Cord/Plug provided with the Therma-Kleen Vapor

Ultra Propane - Ultra 600

January 15, 2019

9

System. If it will not fit the outlet, have a properly grounded outlet installed by a

certified electrician.

WHY THIS UNIT MUST BE GROUNDED:

If the unit should malfunction or break down, grounding provides a path of least

resistance for the electrical current to pass, reducing the risk of electrical shock.

All Therma-Kleen units are equipped with a power cord with an equipment

grounding conductor and plug. The plug must be inserted into an appropriate

outlet which is properly grounded in accordance with national & local electrical

codes and ordinances.

Therma-Kleen® units are designed for use with a normal

110/120 volt circuit and has a grounded cord and plug such as

what is illustrated in picture “A”. In no cases should a “2”

adaptor (which is illustrated in picture “B”) plug be used to

adapt “3” prong grounded plug to an ungrounded electrical

outlet.

NOTE:

If an electrical extension cord is used with this system, it must be at a minimum,

12-gauge, 3 wire, grounded, SJ Quality, 60 Degree C, less than 50 ft. long.

DO NOT remove the ground prong on the power cord. This will void the warranty

on your machine and can be dangerous because it does not protect the user.

OPERATING INSTRUCTIONS START-UP:

1.) Connect the machine to 115 volt, GROUNDED electrical service. A 12 gauge/3

prong extension cord is required for the Ultra 1000 or the Ultra 1300 model.

Using an improper extension cord could cause damage to the machine and cause

erratic operation. For 220 volt machines, use a 220 volt grounded outlet.

2.) Connect a garden hose from a cold water source to the inlet fitting on the lower

right hand side of the steam cleaner.

3.) Connect a steam hose to the water outlet quick connect or European threaded

fitting on the left hand side. If a quick connect system was used on your machine,

make sure it “snapped” tight.

4.) Connect the wand to the steam hose end using the same method as step #3.

DO NOT USE

B

A

Ultra Propane - Ultra 600

January 15, 2019

10

5.) Connect the LP gas regulator to the LP tank keeping the regulator upright. The

threads in the tank fitting are reversed. DO NOT OVERTIGHTEN the fitting. Make

sure the LP tank is in the proper upright position to supply ONLY VAPOROUS LP

gas to the machine. Keep the regulator positioned away from the machine.

NOTE: Natural gas option; this model needs to be vented.

6.) Connect the LP gas hose to the connection on the control panel. Make sure it is

completely connected before continuing.

7.) Open the main fuel valve completely located on top of the LP gas tank. If any

leaks are suspected, check for bubbles by covering the connection with soapy

water.

8.) Keep the gas pressure low on the fuel pressure gauge at this time. If the pressure

is too high, adjust the red regulator counter-clockwise (upward) to reduce the

pressure. You should start the machine with about 2-3 lbs. of fuel on the larger

models and 1-2 lbs. on the Ultra 250 and Ultra 600.

9.) Keep the gas pressure low on the fuel pressure gauge at this time. If the pressure

is too high, adjust the red regulator counter-clockwise (upward) to reduce the

pressure. You should start the machine with about 2-3 lbs. of fuel on the larger

models and 1-2 lbs. on the Ultra 250 and Ultra 600.

10.) Turn the cold water supply source on completely.

11.) Squeeze the trigger on the wand allowing the water to come through the gun.

12.) Turn the PUMP switch “ON” and let the machine run until the pump runs

smoothly and the water isn’t sputtering. To speed the process up you can close

the trigger gun for about 10 seconds and open again. This will help bring the air

to the front of the wand.

SHUT DOWN:

1.) Turn off the ignition switch.

2.) Let the pump continue to run until the water cools down and the temperature

gauge reads

3.) About 100° F

4.) Turn off the pump, close the LP gas valve on the tank.

5.) Turn off the water and disconnect the electricity.

6.) Store the unit where it will not be subject to freezing temperatures as this will

destroy the pump, coils and/or the flow switch.

a.) If this cannot be done:

Ultra Propane - Ultra 600

January 15, 2019

11

WINTERIZE THE UNIT:

1.) The Ultra 250 and Ultra 600 require: 1 gallon of windshield wiper fluid or anti-

freeze.

2.) The Ultra 1000 and Ultra 1300 require: 2 gallons of windshield wiper fluid or

anti-freeze.

3.) Windshield wiper fluid is good to about -20˚F and the anti-freeze goes even

further.

4.) See Preventative Maintenance Section

CONTROL PANEL DIAGRAM

1.) Nozzle Holder

2.) Fuel Pressure Gauge

3.) Combistat. This is a

temperature gauge and an

adjustable high limit switch

all in one.

4.) Ignition Switch

5.) Fuse Holder

6.) Pump Switch

7.) Soap Injector (on Ultra 1300

only)

Location may vary per machine.

PREVENTIVE MAINTENANCE:

1.) Periodically inspect and clean water inlet screen located at the inlet of the unit (at

the hose attachment on the Ultra 600/1300 models-Ultra 250 filter is part of the

pump).

2.) Periodically inspect nozzle to make sure it is clean. Restricted water flow, shut

down or interrupted spray pattern is an indication of obstruction in the nozzle.

3.) DESCALING: hardness or mineral content in water along with steam temperatures

will eventually create a coating or build-up of scale in the heating coils. Excessive

scale will shorten coil life and interfere with temperature controls. Scale appears

periodically. Check for scale build-up on inside of steam connections. When scale

has built-up to such a degree that the machine senses accurate low water flow

internally, the unit will not light, or will light and shut-off. A test for scale build-up

Ultra Propane - Ultra 600

January 15, 2019

12

is to remove the nozzle and see if the machine lights, and if it does, then you may

need to descale the unit. Other low water issues maybe the cause, such as a bad

pump, etc. See DESCALING Section.

4.) DO NOT FREEZE the machine. This can ruin the coils, pumps and flow switch.

Winterize the machine when necessary. This can be done by running anti-freeze or

windshield wiper fluid through the garden hose, as you do when you descale a

machine. See DESCALING Section. The Ultra 250, 600 and 1300 models require 1

to 2 gallons of fluid to completely fill the coils and water system. When you are

ready to resume using the machine, flush thoroughly and dispose of the anti-freeze

carefully before heating the system.

DESCALING PROCEDURE:

1.) Obtain THERMA-KLEEN® descaling compound from your salesman or use

equivalent product. Only use THERMA-KLEEN® recommended product safe for

aluminum coils.

2.) Place in a bucket in concentrated form, or mix according to manufacturer’s

instructions. (½ gallon of descalant is needed).

3.) Remove nozzle from the wand.

4.) Turn water supply and pump “ON” as if you were going to start the machine. After

the pump is primed, quickly turn “OFF” the pump and water supply and disconnect

the hose from the water connection and place the garden hose into the bucket

along with the wand end.

5.) Quickly turn “ON” the pump and let the solution circulate through the machine for

about five (5) minutes. Flush the unit with clear water before starting the machine.

6.) If you are winterizing the unit, 1 gallon is needed for the Ultra 250 & 600 and 2

gallons of liquid is needed for the Ultra 1300. Watch for the solution to exit the

wand. Quickly shut- off the pump.

MAINTENANCE OF PUMPS:

ULTRA 600:

The pumps used on these models are factory sealed. When replacing a pump or motor it

is necessary to re-lubricate the plunger and bearings. Use synthetic grease with PTFE.

We recommend this brand: Super Lube. Check for sufficient lubrication as a

maintenance procedure to extend the life of your pump and motor. Repair a pump as

needed to prevent damage to the motor and/or bearing. Check the pump pressure on a

regular basis.

Ultra Propane - Ultra 600

January 15, 2019

13

All pumps:

The warranty will be void if you do the following:

1.) If you don’t flush the unit with fresh water after each day’s use.

2.) If you attempt to mix dry powder chemical in solution feed.

3.) If you fail to properly install kit components, or modify kit.

4.) If you use chemicals greater than 9 PH OR LESS THAN 6 PH.

5.) If you re-wire the motor incorrect and the motor runs backwards.

6.) If you use water that is hotter than 140˚F.

7.) Run the pump dry, causing cavitation.

MAINTENANCE OF MOTORS:

ULTRA 600:

The bearings are pre-lubricated. Periodic maintenance to assure enough

lubrication is recommended.

The motor is equipped with and AUTOMATIC thermal protector to guard against

overheating and will trip if it gets too hot.

Push the red button on the side of the cooled motor to reset the motor on the

Ultra 1300 only

FULL LOAD AMPS:

Ultra 250: 3.4 on 220 volts/ 6.8 on 115 volts

Ultra 600: 3.4 on 220 volts/ 6.8 on 115 volts

Ultra 1000: 7.5 on 220 volts/ 15.0 on 115 volts

Ultra 1300: 7.5 on 220 volts/ 15.0 on 115 volts

INTERNAL CHEMICAL INJECTION SYSTEM (Ultra 1300):

1.) Open knob on control panel all the way counter- clockwise.

2.) Drop chemical feed line into chemical.

3.) DO NOT USE HARSH CHEMICALS THROUGH THIS SYSTEM, IT CAN DAMAGE

YOUR PUMP AND ALUMINUM COILS. If you need a harsh chemical, apply it on the

item you wish to clean before you start cleaning…wait…and steam clean the item

after 10 - 15 minutes, or use the optional external chemical injection system.

4.) To end using the chemical injection, turn the knob on the machine all the way

closed. The soap will now stop drawing. Please make sure this knob is closed

when you are not using this system so the pump does not draw unnecessary air.

5.) Blocked internal chemical injection can affect the water flow to the pump and

cause damage.

Ultra Propane - Ultra 600

January 15, 2019

14

MAXIMUM WATER INJECTED PER MINUTE:

Ultra 1000: at 1000 PSI at 20 PSI pump inlet conditions… you yield 8 ounces per minute.

MAINTENANCE:

If the opening around the needle valve stem becomes clogged, clean valve stem and

passage way with warm soapy water. Rotate the control knob assembly counter

clockwise (which includes the control knob and needle valve stem) until it can be lifted

out of the body. Inspect valve stem O-ring and replace if necessary. Install control knob

assembly by pushing down firmly on knob and turning clockwise until it is in the closed

position. Set injector to desired setting.

SOAP SYSTEM NOT DRAWING:

1.) Make sure all of the soap lines are connected to barbs inside the machine.

2.) Make sure soap injection is now open on top of machine.

3.) Air may have been drawn into line and caused an air lock. Fill soap line with water

forcing air through system.

4.) Water regulator is set at factory, but may be adjusted to create suction though the

soap line. Adjust by setting T-bar in or out slightly.

TROUBLE SHOOTING GUIDE:

WHEN YOU GET THE “CLICK” BUT THE UNIT DOES NOT IGNITE:

1.) Make sure water is flowing through nozzle end of wand. The unit will not light if

the

gun valve is in the closed position. Unit will light faster if nozzle is removed before

lighting, this speeds up any air locks.

2.) Check to verify that propane tank is not empty and that the propane tank valve is

open.

3.) Check water supply to ensure adequate flow to unit. Your unit requires at least 20-

30 lbs. of water line pressure, or the machine will not operate, a safety feature of

your unit.

4.) Check to make sure nozzle is totally clear of obstructions.

5.) Check to see that your gas reading is NOT MORE than three or four pounds of

pressure.

Too much pressure will also prohibit lighting.

6.) Check for spark at pilot burner:

b.) Is spark electrode hooked up? (This is the red nipple attached to the control

module.)

Ultra Propane - Ultra 600

January 15, 2019

15

c.) Is the burner grounded on the coil? If it is then re-position coil away from

the burner.

d.) Is the spark ceramic cracked or chipped or cable damaged? If so, replace the

pilot assembly.

e.) Check gap to see if it is 0.1”. The spark gas is part of the pilot assembly

housing.

f.) If there is still no spark, replace the control module.

7.) Make sure your burner system in unit is not wet.

8.) Check to see if pilot is lit.

CAUTION: NEVER LOOK DOWN THE CYLINDER TO CHECK FOR THE PILOT

a. To check this, put a mirror under the body of the machine to view the burner

area. If there is a pilot, go to step 10.

b. Check for a clogged pilot orifice.

a. Remove the thin coupler line and unscrew the pilot

orifice from the pilot assembly. Two very little holes

should be clear upon inspection up to a good light source. If not, then

replace.

9a.) Check for supply of gas, if there isn’t any then get propane tank filled or check for

obstructions in gas lines or regulator. Fuel pressure gauge should never be run

higher than 6 lbs. of fuel pressure, the burner can become flooded and not allow

ignition.

9b.) Check to see if pilot solenoid is opening by connecting the wires to an alternate 24

volt

source. (For example, lines three through six on the terminal strip. Touch one wire

to this source and the other wire to a ground.) You should hear the “click” or the

pilot solenoid opening. If you don’t, then replace the solenoid.

10.) If there is a pilot:

a.) Check to see if the flame sensor is red hot, if not, clean or replace the pilot

orifice.

b.) Check if the flame sensor wire is not damaged and hooked up properly. Replace

or go on to “c”.

c.) Check for cracked flame sensor. Removing the flame sensor will give you an

accurate view of any chips or cracks to the flame sensor. If you find these, then

replace the sensor. Tighten just slightly past hand tight.

Ultra Propane - Ultra 600

January 15, 2019

16

WHEN YOU DO NOT GET THE “CLICK”

PROCESS TO CHECK IGNITION SYSTEM BY A TESTER OR METER:

1.) Turn the pump and ignition switch to the “ON” position with the unit plugged in.

The gas tank should NOT be hooked up to the machine at this time.

2.) Make sure the wand control is open and water is flowing through the machine.

3.) Check for 24 volts at the transformer. (Left side of the transformer as you face it.)

If there is no voltage reading, change the transformer.

4.) To check for 24 volts on the terminal strip, start on line 4. Touch one wire of the

volt meter to the wire on the terminal strip at position four and the other wire on a

ground or neutral wire. If you get a reading then go on to line five and continue

until the power is interrupted. Every switch has 2 wires, one accepting the power,

and the other feeding back from the switch after it has been energized. Once the

faulty switch is determined, then replace.

TEMPERATURE RISES TOO QUICKLY

1.) The air has not been purged from the system. Shut down and allow air to escape.

To speed up this process, take the nozzle off and turn the pump “ON” and “OFF” a

few times. Once there is a steady stream of water and there is no sputtering, then

the pump should run smoothly also. Replace nozzle, turn on pump and machine

should be ready to light. IF YOU LIGHT THE MACHINE AND HEAT AN AIR POCKET,

YOU COULD BLOW A COIL. CAUTION IS ADVISED.

FUSES KEEP BLOWING

1.) If your circuit trips then move to a different outlet. You may be overloading that

circuit.

2.) If the fuse on the machine is blowing again and again, you most likely have a

problem with either your pump or motor, or you may be using too long of an

extension cord. Try not to exceed 50 ft. of heavy-duty extension cord. Or you may

be using the wrong size fuse. Check the machine specification table for correct

fuse size.

PILOT BURNER DOESN’T SHUT OFF

1. The pilot solenoid may have debris in the valve not allowing it to close all the way.

To repair: Remove any debris that may be lodged in the brass section of the valve.

EXCESS CARBON FORMS ON COILS

1.) Check position of coils to insure clear area around top of burner.

Ultra Propane - Ultra 600

January 15, 2019

17

2.) Mushroom section on the top of the burner may be loose and therefore shifted.

Replace burner if this piece can be moved by hand.

3.) Inspect burner for debris in opening. If nothing is found, replace burner.

GAS FLAME GOES OUT OR IS IRREGULAR

NOTE: Various safety features will turn gas off automatically.

1.) If there is inadequate or fluctuating water pressure supply to the machine.

2.) If the unit overheats or rises on temperature to the red line on the temperature

gauge.

3.) If internal gas pressure is too high.

4.) If you have a weak pilot or a cracked flame sensor rod.

WAIT 30 seconds for automatic re-ignition. If re-ignition does not occur, or if

machine shuts repeatedly, check the following:

a.) Reduce LP gas pressure to reduce temperature by turning knob on the gas

regulator counter-clockwise.

b.) Check nozzle for restrictions and clean.

c.) Check water supply for adequate flow, check for leaks at fitting and incoming

water pressure.

d.) Remove pilot orifice and clean dirt out.

e.) Inspect and/or replace flame sensor rod, if cracked.

f.) Make sure the propane tank was not overfilled.

UNIT DOES NOT BURN HOT ENOUGH

1.) Check for max. setting on the temperature gauge. The knob may be adjusted

downward. Keep red line @ 340˚.

2.) Adjust LP gas regulator upward to a higher temperature by turning knob clockwise.

3.) Check fuel supply. The fuel pressure may be dropping due to the tank freezing.

Change to a second tank.

4.) Check and make sure mushroom top on burner is secure and will not turn freely. If

it does, replace.

5.) Burner may be blacked partially and not allowing enough gas supply to burn

evenly. Check flame color around mushroom. Inspect the flame with a mirror

under the machine to view burner area. If only a partial flame is visible, then

replace the burner.

Ultra Propane - Ultra 600

January 15, 2019

18

ULTRA 600:

For electrical trouble shooting information, please refer to the web pages that assist with

this information. Go to www. THERMA-KLEEN.com and go to the manuals. “Click on” the

section that shows the terminal strip in the troubleshooting section of the propane

manual. Follow the directions to help determine which component that maybe breaking

the current.

HOSE MAINTENANCE:

ULTRA 600 PUMP EXPLODED VIEW:

Rebuilt Kits are available.

Kit A: Plunger with “O” rings, washers and lubricant

Kit B: Valve kit with “O” rings and washers

Kit C: Bearing (use with lubricant)

Lubricant: Synthetic grease with PTFE Brand: Super Lube.

Failure to maintain pumps can cause damage to bearings and motors.

ULTRA 600 PUMP:

Ultra Propane - Ultra 600

January 15, 2019

19

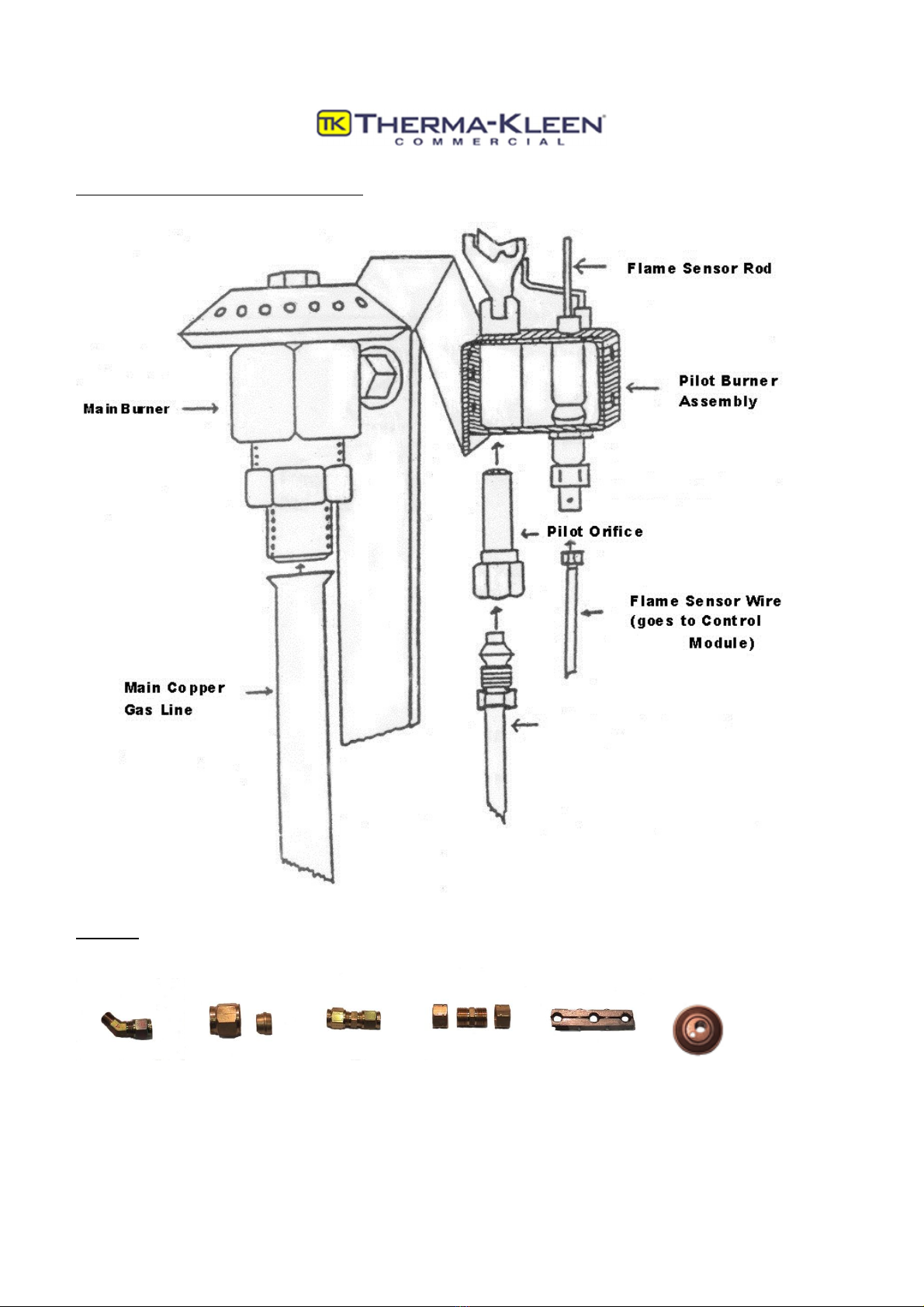

BURNER WITH PILOT ASSEMBLY:

PARTS:

Coil Compression fittings

45˚Fitting Cap and Ferrule Complete Compression Spacer Bearing

Ultra 1300 for Ultra 1300 Compression Fittings for Coil #3632 #6012

#3973 #3768/3767 Fitting 1300 33971 Ultra 250/600 #3174

Ultra Propane - Ultra 600

January 15, 2019

20

Elbow Compression Ultra 1300 Compression Ultra 250 Pump Ultra 600 Pump Ultra 1300 Pump

Fitting for Ultra 1300 Fitting Breakdown #3738 #6021 #3903

#3972

25-50-100 ft. European European Swivel Fittings Main Regulator with 2.5 ft. Wand Snub Nose

Steam Hose Hose Plug Female Male LP Gas Hose Fittings #3905 Wand #3668

#3805/3673/3160 #3675 #3674 #3671 Quick Connect #3527 (Optional Accessories)

Flame Pilot Assembly Pilot Orifice Solenoid Trigger Gun 4 ft. Wand

Sensor w/Spark Wire #3384 #3723 #3359 #3661

Rod #3383

#3345

Control Module Fuel Pressure Gauge Transformer Combistat

#3241-A #3348 #3359 #3240

Front Wheel for Wheel Socket 10 inch Wheel Front Wheel for

Ultra 600 #3880 250/600 #3870 #3871 Ultra 1300 #3878

Ultra 250/600 Coils Vertical Coil Blast Nozzle Fan Nozzle

Ultra 250/ 600

Table of contents

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual