THERMA Big Dipper IS Series Installation instructions

Copyright ©2005 Big Dipper® Thermaco, Inc. • P.O.Box 2548 • Asheboro, NC 27204

Toll Free: (800) 633-4204 • V: (336) 629-4651 • F: (336) 626-5739

E-mail: [email protected] • Online: www.big-dipper.com

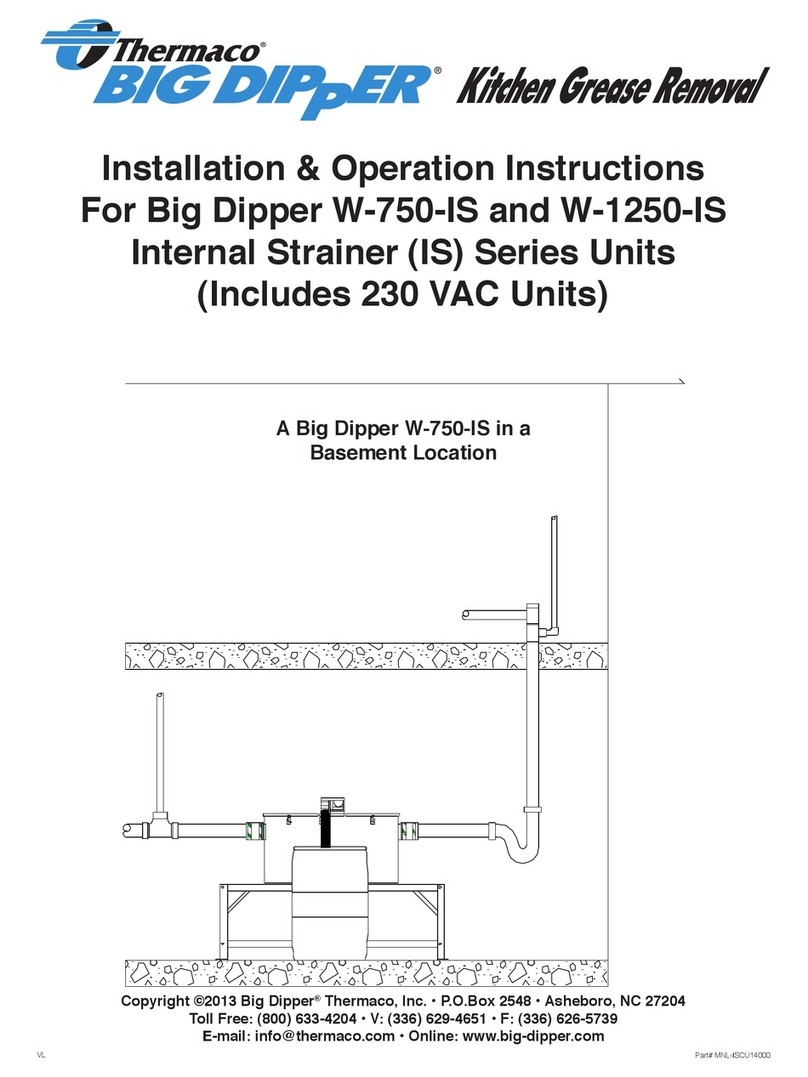

Installation & Operation Instructions

For Big Dipper Internal Strainer

(IS) Series Units

Big Dipper W-200-IS Servicing

A Pre-Rinse Sink

Big Dipper W-200-IS Servicing

A 3-Compartment Sink

®

Part# MNL-IS6000

* Please consult Thermaco, Inc. for specific models tested,

certified and/or listed by these organizations.

TC

**

*

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 2

®

Table of Contents

Table of Contents

IS System Overview 3

IS System Maintenance 4

IS Timer Operation 5

IS System Troubleshooting 6

How To Reverse IS System Operation 9

Plumbing Installation 10

Electrical Installation 12

IS System Wiring Diagram 13

IS Component Identification 14

IS Replacement Parts 15

Limited Warranty 16

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 3

®

Big Dipper® Internal Strainer (IS)

System Overview

Big Dipper® Internal Strainer (IS) System Overview

The Thermaco, Inc. Big Dipper® Automatic

Grease and Oils Removal System removes free-

floating grease & oils from kitchen drain water

flows. As most food service facility managers

already know, grease buildup within a buildingʼs

plumbing drainage system is a major cause of

problems due to drain line blockages. These

problems jeopardize normal operations as well

as create health and safety hazards within the

facility itself.

The proper installation of a Big Dipper System

can reduce or eliminate grease problems. Use

of the Big Dipper assures minimization and/or

elimination of costly sewer surcharges and fines

through efficient separation and removal of free-

floating grease & oils. In addition, the Big Dipper also helps reduce and/or eliminate pumping and

disposal costs associated with conventional grease traps or interceptors. The recovered grease

& oils are virtually water-free so local rendering companies or recyclers can collect it.

The Big Dipper system is an automatic, self-cleaning device. As greasy kitchen effluent drains

from kitchen fixtures, the unit traps the grease & oils. These separate from the effluent and rise

to the surface of the stainless steel tank. The unit automatically skims the trapped grease & oils

at least once per day and transfers the grease & oils to a collection container. A timer controls

the self cleaning operation, activating the skimming wheel at the proper time. Only the “cleaned”

water exits the unit and flows into the facility drain lines. The Big Dipper IS automatic systems

operate most efficiently when servicing single fixtures such as a 1 to 3-compartment sink or a

pre-rinse station.

The Big Dipper systemʼs stainless steel construction and compact footprint allows installation

directly at the source, where grease problems originate. The system design also allows easy

maintenance and operation by non-skilled personnel and requires only a minimal amount of daily

and weekly maintenance to maintain peak operating performance.

The Big Dipper system design allows for maximum installation flexibility. Reversing the system

operation is a simple as rotating the cover assembly of the unit.

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 4

®

Big Dipper® Internal Strainer (IS)

System Maintenance

*CAUTION! DISCONNECT POWER TO UNIT BEFORE CLEANING

to prevent damage to the unit and personal injury

*NOTE: Before energizing unit after cleaning, fill tank with water

to protect wipers and heater from damage

Big Dipper® Internal Strainer (IS) System Maintenance

Daily Maintenance:

(A) Empty the clear plastic grease/oils collection container (located beside the unit) once each

day (or more frequently, if necessary). The Big Dipper recovers grease and oil virtually water-free

so that they can be recycled. The collector container should be washed periodically.

(B) The internal strainer basket should be emptied into a garbage container by shaking briskly.

Wash the inside and outside surfaces of the strainer after emptying.

Weekly Maintenance:

(A) Check the collection trough and the wiper blades for any solids build-up. Wipe off any accu-

mulated deposits and assure that the wiper blades are clipped in place properly.

(B) Check the Timer to be sure it is set and operating correctly.

(C) Check the thickness of the grease layer at the top of the unit. There should be no appreciable

amount of grease or oil left in the tank immediately after the daily automatic skimming cycle. If

there is more than a 1/2” (13 mm) thick layer of grease after the skimming cycle, this indicates

a need to increase the skimming time. Increase the timer settings accordingly until a clean unit

appearance is obtained after the automatic skimming cycle (A simple guide is to increase the “on”

time by 30 minutes for each 1” (25 mm) of grease layer observed after the skimming cycle).

(D) The internal strainer basket in the unit is designed to remove coarse solids from the wastewater.

Over a period of time, sediment consisting of very fine particles may begin to accumulate on the

bottom of the unit. If this build-up is allowed to continue, it may eventually block the outlet baffle.

To prevent this from occurring, remove the lid and stir the bottom of the unit with a long handled

spatula while water is flowing to flush out the sediment. It may also be necessary to occasionally

drain and clean the unit thoroughly. A wet vac works well for this purpose.

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 5

®

TO SET TIMER:

1. Push on/off tabs on the outer

ring of timer inward into dial at

desired “ON” times. 1 Tab = 15

minutes. Minimum of one (1) tab

(15 minutes) recommended.

2. Turn dial CLOCKWISE

one or more complete revolutions

until the present time is aligned

with the time-of-day indicator

point.

3. Fill the unit with water by turning

on the sink water taps, then plug

the Big Dipper unit into grounded

electrical outlet.

Big Dipper® IS System Suggested Settings/Timer Operation

NOTE: IN CASE OF POWER FAILURE, RESET TIMER. (See Step 2 above).

After the plumbing installation is complete, the Big Dipper unit needs to be set for the proper

automatic self-cleaning operation for the facility. All Big Dipper IS models are equipped with a 24

Hour/96 Event time controller. This time controller is located under the lid of the motor housings

mounted on top of the Big Dipper lid (See Pages labeled “Electrical Connection Detail” sketches

of this location).

Depending upon the amount of accumulated grease and oils, the system may need to be reset

to operate more or less time to skim all separated grease and oils. This can be determined by

removing the top cover and observing the depth of the separated grease layer shortly after a

cleaning cycle is completed. This layer should not be more than 1/2” (13 mm) thick. If this layer

is consistently thicker, increase the operating times of the Big Dipper IS System by 30 minutes for

each additional 1” (25 mm) of grease not to exceed 2 hours in a complete run cycle. If required,

additional run cycles can be added throughout the day.

3

2

1

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

Time-of-day

indicator point Tabs punched in

indicate “ON”setting

Tabs NOT

punched

in indicate

“OFF”setting

Big Dipper® IS System

Suggested Settings/Timer Operation

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 6

®

Big Dipper® IS System Series

Troubleshooting

Big Dipper ®

unit overflows

If installation is

new

Make sure no

P-Traps are

installed on outlet

Make sure outlet

piping is not

reduced in size

Have as few 90˙

on outlet piping

as possible

Vent outlet pipe

Make sure flow rate

does not exceed

maximum flow rate as

listed on unit

Make sure internal

strainer basket is in

place and emptied

regularly

Check bottom for excessive

silt & solids buildup;

periodically disconnect

power, drain unit, and clean

out bottom

If installed into

existing facility

Check downstream for

proper rooting and/or

blockages

Make sure flow

control is in place. If

it is, install smaller

flow control orifice

assembly

All 90˚ bends

should be

sweeps

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 7

®

Big Dipper® IS System Series

Troubleshooting

No grease

collected in

container

Make sure power

in on and timer is

set correctly

"On" time should

be no less than 15

minutes per day

Timer should be

set to activate

during periods of

no or low flow

Open Wheel

Cover

Clean wiper blades

& collection trough

Make sure wiper

blades are properly

attached

Replace wiper

blades when

worn

Set timer to "On"

position

Make sure

skimmer wheel

turns

Check heater

assembly

The heater is on at all

times. If the water in the

tank is not warm, the

heater should be

replaced

If skimmer motor

does not

activate:

Check motor

coupling for

tightness

If coupling tightness is

assured, motor needs

to be replaced

If skimmer motor

activates:

Check tightness of safety

switch & assure switch is fully

depressed when lid is

fastened to unit

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 8

®

Big Dipper® IS System Series

Troubleshooting

Objectionable

odor

Make sure fats, oils

and grease are being

properly skimmed

from the unit

Check for excessive

silt/solids buildup in

bottom of unit

Empty internal strainer

basket and/or grease

collector more frequently

Check timer

settings

Increase in

operation period

or frequency

Wash down after

emptying

Make sure timer is set

to operate unit during

period of low or no

wastewater flow

Excessive water

observed in

grease collector

Make sure waste water

flow to unit does not

exceed rated flow

Check timer for

excessive "On" time

Check for blockages

downstream of unit

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 9

®

How To Reverse Big Dipper®

IS System Unit Operation

1) Unlatch the Unit lid. Pull the

side wings outward.

2) Lift the center module up off of

the unit, ensuring clearance for the

heater.

3) Rotate the center module

180º.

4) Lower the center module back

down on top of the unit. Move the

two side wings back into place & fas-

ten all six latches.

1) 2)

4)3)

Grease

Outlet

Heater

Power

Cord

How To Reverse Big Dipper® IS System Unit Operation

Clearance Required

To Remove Lid

*ALWAYS UNPLUG UNIT BEFORE REMOVING LID

*SYSTEM WILL NOT OPERATE UNLESS CENTER LID LATCHES ARE FASTENED

14.000”

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 10

®

Big Dipper® IS System

Plumbing Installation

Locating the Unit

To minimize grease build-up in piping, a Big Dip-

per system should be located as close as possible

to the fixture it is serving. The system should

be visible and easily accessible for maintenance

and inspection. Make sure that adequate room

is provided around the system to allow easy

removal of the grease collection container and

to access the electrical assembly. Make sure

the height above the Big Dipper access cover

is enough to properly service the system.

Inlet/Outlet Piping

The inlet and outlet piping connections require

flexible sleeve pipe couplings. Keep outlet pip-

ing as straight as possible. Use only “sweep”

connections. Do not reduce the pipe sizing

on the outlet piping. Do not install “P” trap on

outlet connection of system. (Note: The system

already has a internal gas trap)

Flow Controls

Big Dipper systems are equipped with an internal

flow control located inside the inlet end of the

system. Verify its location and placement prior

to connecting the inlet piping.

Fill Unit With Water Before Applying

Power

Big Dipper systems, equipped with an electric

heating element, MUST be filled with water before

energizing the power to the system. Failure to

do so may damage the electric heating element.

These elements will NOT be replaced under

Thermacoʼs Limited Warranty.

Venting the Outlet

An outlet vent or approved vacuum breaker of

at least 1/2 the diameter of the systemʼs outlet

connection must be present as close as pos-

sible to the Big Dipper outlet to prevent possible

siphonage problems. Failure to provide a vent

for the system voids Thermacoʼs Limited War-

ranty for the system.

For High Head Height Applications

Over Six (6) Feet (1.95 m)

For installations where there is head height of

greater than 6 feet (1.95 meters), Thermaco, Inc.

recommends installation of the optional VFCA

Vented Flow Control. Thermaco, Inc. recom-

mends an inlet vent on the piping connection

as close a possible to the inlet of the Big Dipper

and tied in to the facility vent. Please see the

following page for installation instructions.

Do Not Use With Food Grinders, Potato

Peelers or Waste Disposal Units

Installations where the internal solids strainer

basket is not used or where the system is

connected to a Waste Disposal Unit, Garbage

Grinder or potato peeler will void Thermacoʼs

Limited Warranty for the system.

Note: This equipment must be

installed to comply with all

applicable national, state, and local

plumbing codes for your area.

Installation should only be

performed by a qualified plumber.

Big Dipper® IS System Plumbing Installation

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 11

®

Big Dipper® IS System Plumbing Installation

(For Installations With Head Height Greater Than 6 feet (1.95m))

For installations where there is a significant amount of head height (More than 6

ft./1.95 m), Thermaco, Inc. recommends installation of the optional VFCA Vented

Flow Control module.

Big Dipper® Unit

Connect To Facility Vent

VFCA-20 Vented Flow Control for W-200-IS

VFCA-25 Vented Flow Control for W-250-IS

VFCA-35 Vented Flow Control for W-350-IS

VFCA-50 Vented Flow Control for W-500-IS

Connect To Facility Vent

Installations where head height is

greater than 6 feet (1.95 m)

Note: This equipment must be installed to comply with all

applicable national, state, and local plumbing codes for your area.

Installation should only be performed by a qualified plumber.

* Installation in high head height locations requires

removal of the Internal Flow Control (small rubber

cap under no-hub coupling over the Inlet).

Big Dipper® IS System

Plumbing Installation

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 12

®

Big Dipper® IS System

Electrical Installation

Big Dipper® IS System Electrical Installation

NOTE:

Time Clock is supplied with system.

This equipment must be installed to comply with all national, state

and local electrical codes for your area. Installation should only

be performed by a qualified electrician.

Electrical Panel

(NOT SUPPLIED)

115 VAC Circuit,

From Ground Fault

Circuit Breaker

(NOT SUPPLIED)

Socket Outlet

(NOT SUPPLIED)

Big Dipper Internal Strainer (IS) Models

Big Dipper Internal Strainer Series Models utilize one 24 hour time control-

ler. The timer is located under the hinged lid of the motor enclosure on top

of the lid of Big Dipper (See Timer Operation Instructions). The Big Dipper

should only be plugged into a properly grounded 3-prong 120 VAC outlet.

If possible, the power supply outlet for the Big Dipper should be connected

to an electrical circuit controlled by a ground fault circuit breaker.

This Big Dipper unit is shipped from the Factory wired for Simultaneous

Operation. This means the Heater and Motor operate at the same time

under timer control. Continuous Heater Operation is where the Heater is

active at all times. To switch to Continuous Heater Operation, switch the

RED WIRE on the THERMOSTAT with the BLACK WIRE. (Instructions are

on the wiring Diagram in the electrical enclosure.

Note: The Big Dipper unit will not operate when the lid is removed.

Timer

(Under Hinged Lid)

Big Dipper Electrical Requirements

4.5 Amps @ 120 VAC 60Hz (520 Watts)

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 13

®

Big Dipper® IS System

Wiring Diagram

NOTE:

220-240V Units (International Units) have the

following wire color changes:

On the POWER SUPPLY CORD:

The Black Wire becomes Brown

The White Wire becomes Blue

The Green Wire becomes Yellow/Green

Wiring Diagram For Big Dipper Models

W-150-IS Through W-500-IS

POWER SUPPLY CORD

MOTOR

INTERLOCK�

SWITCH

HEATER

THERMOSTAT

GREEN

BLACK

WHITE

BLACK

WHITE

WHITE

BLACK

RING TERMINAL TO�

GROUND STUD

BLACK

FULLY INSULATED�

QUICK CONNECT

FULLY INSULATED�

QUICK CONNECT

PIGGY-BACK�

CONNECTOR

FULLY INSULATED�

FEMALE CONNECTOR

BLACK

RED

WHITE

WHITE

WHITE

BLACK

BLACK

BLACK

TIMER

RED

1 2 3 4 5

UNIT IS SHIPPED FROM

THE FACTORY WIRED�

FOR SIMULTANEOUS

OPERATION. THIS MEANS

THE HEATER AND MOTOR

OPERATE AT THE SAME

TIME UNDER TIMER

CONTROL. CONTINUOUS

HEATER OPERATION IS

WHERE THE HEATER IS

ACTIVE AT ALL TIMES. TO

SWITCH TO CONTINUOUS

HEATER OPERATION,

SWITCH THE RED WIRE

ON THE THERMOSTAT

WITH THE BLACK WIRE.

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 14

®

Big Dipper® IS System

Component Identification

Hinged Skimming Wheel

Cover Motor/Electrical

Cover

Timer

Cover

Grease

Collector

Strainer Basket

Cover

Big Dipper Internal Strainer (IS) Lid Components (With Covers In Place)

Inlet Outlet

Wheel Wiper Assembly

Part #WWA-2

Skimming Wheel Assembly

Part #PDA-3

Wheel Drive Sprocket

Part #WDS-3

Big Dipper Internal Strainer (IS) Lid Components (With Wheel Cover Removed)

Wiper Blades (2)

Part #PB-3

Inlet Outlet

Flow Control

(Covering Inlet)

Safety Switch (Under Motor Cover)

Part #MSS-5

Big Dipper® IS System Component Identification

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 15

®

Big Dipper® IS System Replacement Parts

NOT SHOWN:

INTERNAL FLOW CONTROL (1 per unit)

PART# MFC-15 FOR W-150-IS

PART# MFC-20 FOR W-200-IS

PART# MFC-25 FOR W-250-IS

PART# MFC-35 FOR W-350-IS

PART# MFC-50 FOR W-500-IS

LID GASKET

PART# RG-7

WIPER BLADES (2 per unit)

PART# PB-3

WHEEL WIPER ASSEMBLY (1 per unit)

PART# WWA-2

WHEEL DRIVE SPROCKET (1 per unit)

PART# WDS-3

SKIMMING WHEEL ASSEMBLY (1 per unit)

PART# PDA-3

SOLIDS STRAINER BASKET

FOR MODEL# USE PART#

W-150-IS THROUGH W-250-IS ST-17

W-350-IS & W-500-IS ST-57

GREASE/OILS COLLECTION CONTAINER

FOR MODEL W-150-IS USE PART# GC-4

FOR W-200-IS THROUGH W-500-IS USE PART# GC-6

TIMER (Under Cover)

FOR ALL MODELS USE PART# ETC-1

Big Dipper® IS System Replacement Parts

©2005 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 MNL-IS6000 16

®

Big Dipper® Limited Warranty & Remedy

Thermaco, Inc. warrants, to the original user, that those products supplied by it and used in the

service and in the manner for which they are intended shall be free from defects in materials

and workmanship for a period of one year after installation, but not longer than 15 months from

date of shipment from the factory. All replacement parts have a 30 day replacement warranty.

Clean defective parts shall be returned, within the warranty period, with proof of purchase to

Thermacoʼs factory, 646 Greensboro Street, Asheboro, NC 27203, transportation charges pre-

paid, for warranty evaluation. At Thermacoʼs option, based on the determination of the warranty

evaluation, Thermaco may repair or supply a replacement part from its factory. Any and all items

which may be returned shall include the serial number from which the item was removed, and a

return goods authorization number issued by Thermaco. This warranty is void if the product has

been damaged by its customer prior to acceptance or as a result of unreasonable use, neglect,

flooding, alteration, damage incurred by/during facility construction, improper installation, improper

service, maintenance neglect, improper electrical service, installation and/or operation without timer

controls, or other causes not arising out of defects in material or workmanship. Equipment must

be installed according to manufacturerʼs guidelines. This warranty is void if equipment is used

in excess of rated flow. Thermacoʼs products are intended to remove only free floating animal

fats, vegetable oils and cooking grease. Thermacoʼs products do not remove emulsified fats

and oils. Thermaco shall not be responsible for damage to equipment which results from vault

flooding, sewer line backup, pumping or lift station failure, ambient water flow or other sources

of water damage. This warranty is void if the serial number on the product has been altered

or defaced. Thermaco will not replace timers which have been installed in underground vaults.

This warranty is void should use, installation and application be contrary to a written agreement

between Thermaco and the user. Thermaco does not make any other representations or war-

ranties, express or implied, including, but not limited to, any implied warranty of Merchantability

and any implied warranty of fitness or performance for a particular purpose.

The sole and exclusive remedy with respect to the above limited warranty or with respect to any

other claim relating to defects or any other condition or use of the product supplied by Ther-

maco, however caused, and whether such claim is based upon warranty, contract, negligence,

strict liability or any other theory, is LIMITED to the repair or replacement of the part or product,

excluding labor or any other cost to remove or install said part or product or, at Thermacoʼs op-

tion, to repayment of the purchase price. Notice of any such claim must be given in writing to

Thermaco, Inc., PO Box 2548, 646 Greensboro Street, Asheboro, NC, USA 27204-2548 within 15

months after the first installation or use of the products. In no event shall Thermaco be liable for

special, direct, indirect, incidental, personal, property or consequential damages, including, but not

limited to, loss of use or profits or to interruption of business activity. Thermaco neither assumes

nor authorizes any representative or any other person to assume any liability in connection with

the sale of its products. Thermaco makes no warranties, express or implied, with respect to

parts, accessories, components or other goods not manufactured by Thermaco. Alteration and/or

substitution of Thermaco parts, assemblies, accessories including electrical and/or mechanical

components voids Thermacoʼs warranty.

Thermaco® Big Dipper® Automatic Grease/Oils Removal Units and system parts may be sold lo-

cally by Thermaco Sales Affiliates.

Other manuals for Big Dipper IS Series

1

This manual suits for next models

1

Table of contents

Other THERMA Industrial Equipment manuals

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Internal Strainer Series Installation instructions

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Big Dipper 40000 Series User manual

THERMA

THERMA Trapzilla TZ-1826 Installation and operating instructions