THERMA Big Dipper 51000 Series User manual

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

Replacing the Printed Circuit Board PCB-3.

1

Tools required to replace PCB-3 Printed

Circuit Board: Phillips head screwdriver,

mini small at-head screwdriver and needle

nose pliers.

1. Unplug the center module and remove the

center module from the Big Dipper tank.

2. ere will be (4) bolts on the front and (1) in

the rear.

3. Using a Phillips head screwdriver, turn

counter-clockwise and remove (5) bolts. Set

the bolts aside.

4. Li the cover over the skimming wheel to

pry open the EECA cover. Pull upwards until

EECA is completely removed from the

center module.

Please scan QR code to watch a video tutorial.

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

Replacing the Printed Circuit Board PCB-3.

2

5. Your wiring may dier. Please take a

reference photo to replace wiring to original

conguration.

6. Unplug the ribbon cable.

7. Unplug the motor wire by pressing the tab

inward and pulling out.

8. Using needle nose pliers, unplug the 3

wires – for the heater, safety switch and

jumper – from the board.

9. Using a mini at head screwdriver, turn

counter-clockwise to loosen and remove the

thermistor wires.

10. Remove the printed circuit board.

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

Replacing the Printed Circuit Board PCB-3.

3

11. Place the new replacement board on the

board groove.

12. Connect the push button ribbon.

13. Connect the motor wire. 14. Connect the 3 wires back on their original

position. Connect the black heater wire on

top, black safety switch on the side and white

jumper wire on the side. (per September 2019

updated wiring.)

15. Insert the thermistor wires inside

the terminals and, using a mini at head

screwdriver, turn clockwise to tighten the

terminals.

16. Apply the provided sealant provided along

the groove of the EECA cover and center

module as illustrated above.

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

Replacing the Printed Circuit Board PCB-3.

4

22. Set the center module on the Big Dipper

tank and latch the lids on each end. Place the

grease collector on the front end.

20. EECA cover should be ush with the

center module.

21. Flip the center module and secure the 5

bolts used to remove the cover – (4) in the

front and (1) on the rear side.

17. Before re-assembling the EECA, be sure

the main board and electrical plate are

aligned to their holding groove.

18. Connect the push button to the EECA push

button adapter.

19. With the skimming wheel cover open.

Place the EECA on the center module.

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

51000 Series

1. Scan this QR code to watch a video tutorial.

2. You will need a Phillips head screwdriver

driver and a replacement EEC (Electrical

Enclosure Cover).

4. There will be (4) bolts on the front and (1)

in the rear.

3. Unplug the center module and remove

from Big Dipper tank.

6. Lift the skimming wheel cover and start

prying open the EEC cover. Pull upwards

until EEC is completely removed from

center module.

5. Use a Phillips head screwdriver and turn

counterclockwise to remove (5) bolts. Set

bolts aside.

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651

Replacing the Printed Circuit Board PCB-3.

5

23. Plug the unit to a power source. Select the

appropriate skimming cycle for your business.

If you continue to experience issues please contact ermaco Technical Support Team at

For additional troubleshooting guides go to www.dipperhelp.com

Other THERMA Industrial Equipment manuals

THERMA

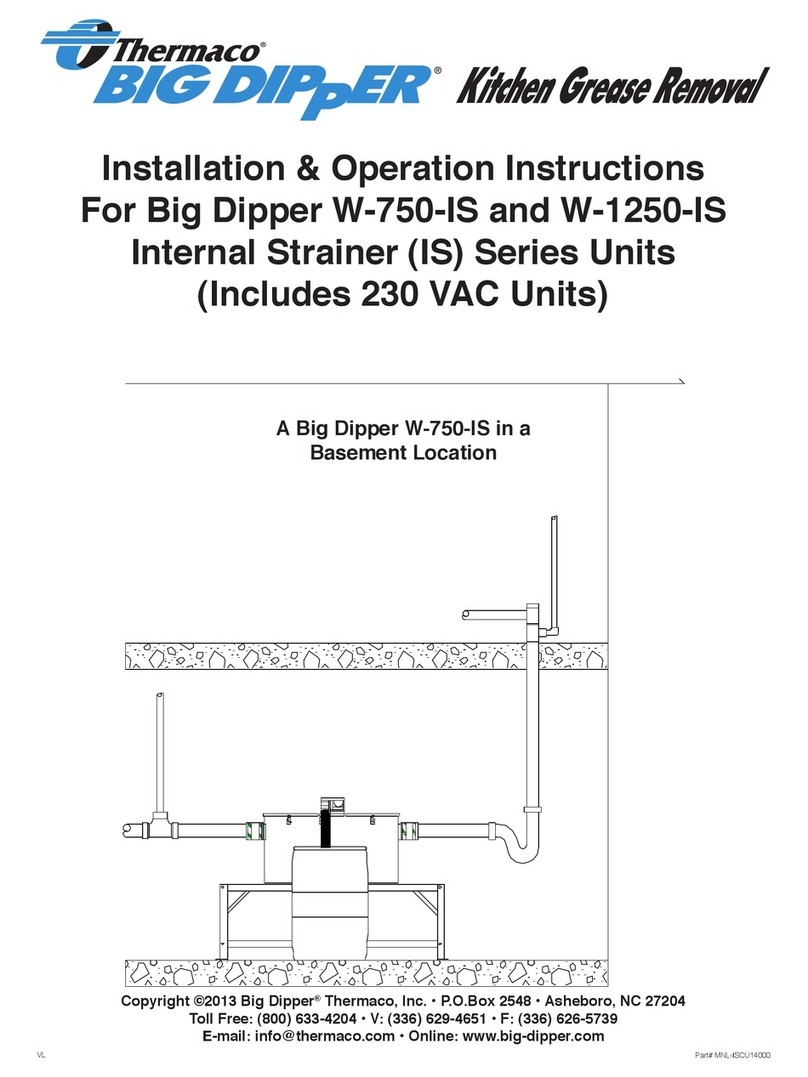

THERMA Big Dipper IS Series Installation instructions

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Trapzilla TZ-1826 Installation and operating instructions

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Big Dipper 40000 Series User manual

THERMA

THERMA Internal Strainer Series Installation instructions