Thermo Scientific ALPHA COND 560 User manual

Other Thermo Scientific Controllers manuals

Thermo Scientific

Thermo Scientific ALPHA PH 2000 User manual

Thermo Scientific

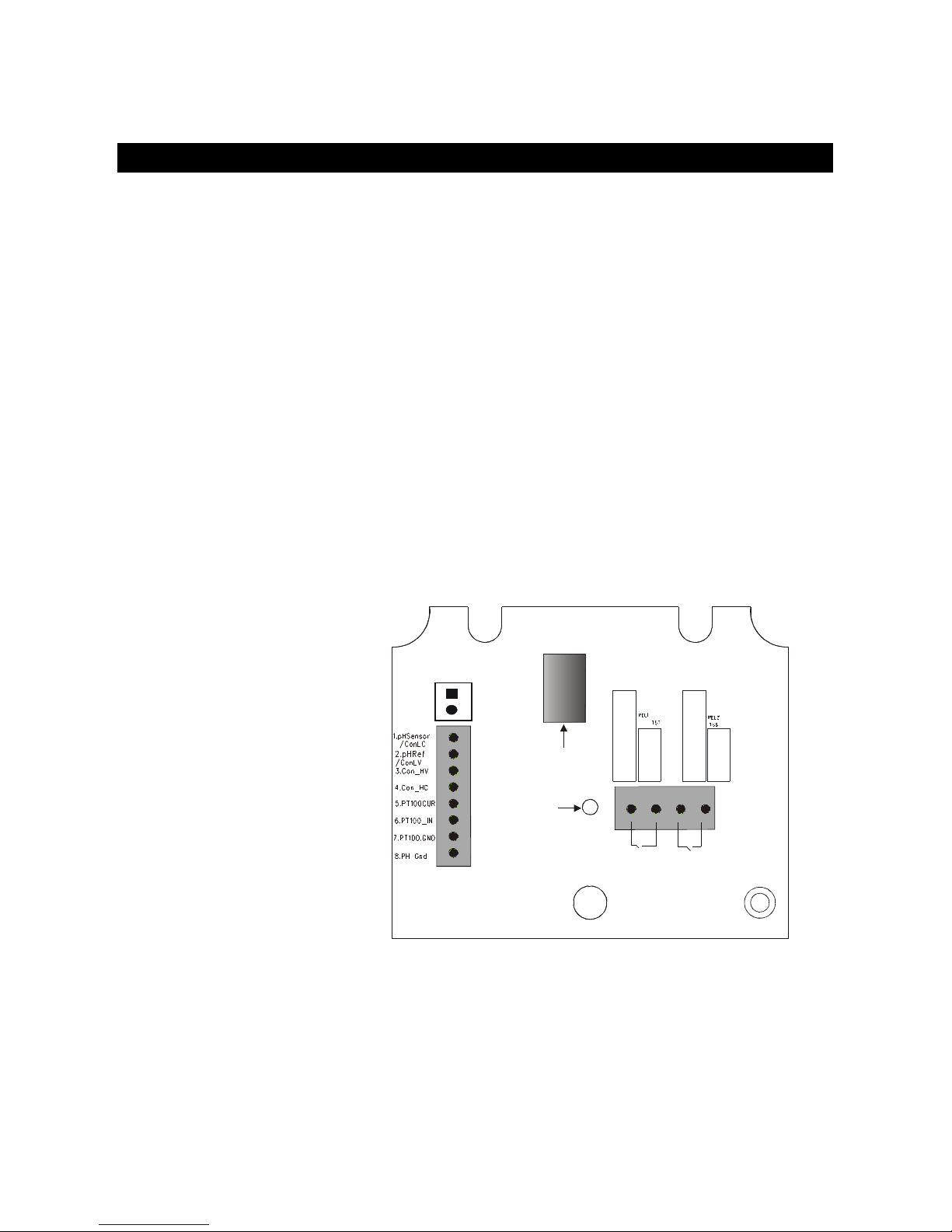

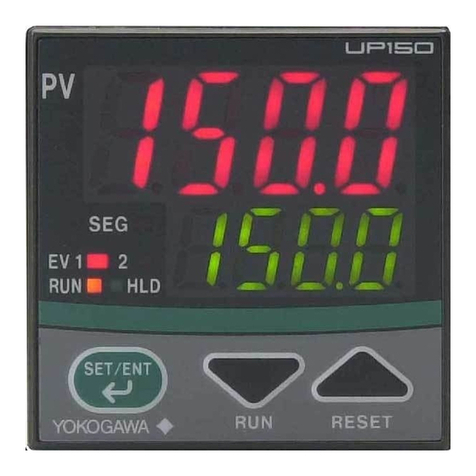

Thermo Scientific Uniry Lab Services UP150 Instruction Manual

Thermo Scientific

Thermo Scientific 3060 Operating instructions

Thermo Scientific

Thermo Scientific Alpha pH 560 User manual

Thermo Scientific

Thermo Scientific ALPHA PH 560 User manual

Thermo Scientific

Thermo Scientific ALPHA PH 560 User manual

Thermo Scientific

Thermo Scientific Dionex RFC User manual

Thermo Scientific

Thermo Scientific TSB140R Manual

Thermo Scientific

Thermo Scientific PRO902C User manual

Thermo Scientific

Thermo Scientific ALPHA COND 1000 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions