3

BACK TO INDEX For more informaon about our products and how to contact us, please visit thermopatch.com

Contents

Copyrights ..........................................................................................................................................2

Introducon........................................................................................................................................2

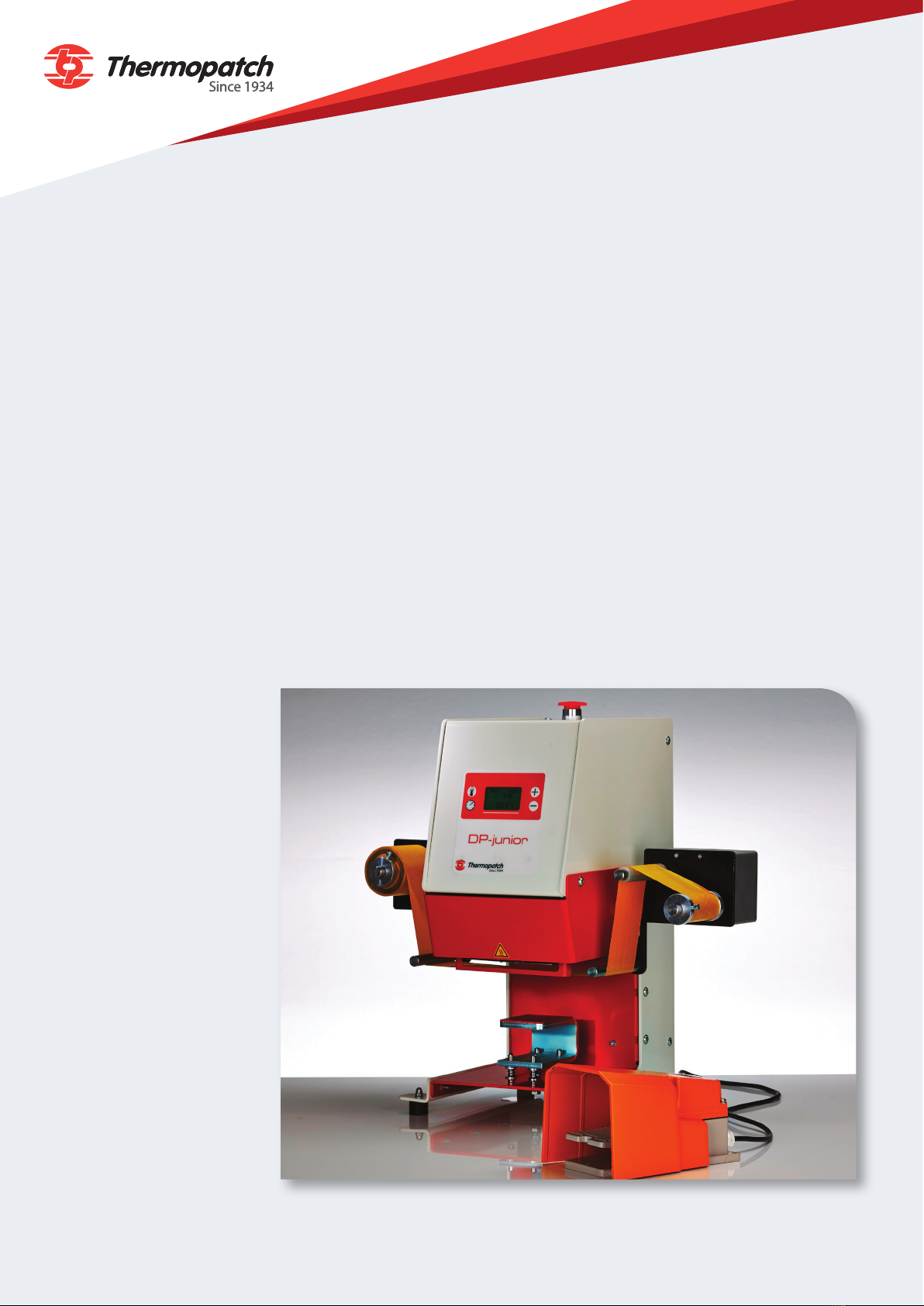

1. General descripon ..............................................................................................................5

1.1 Delivery ........................................................................................................................................ 5

1.2 Condions of warranty ............................................................................................................... 5

2. Intended use .........................................................................................................................6

3. Technical specicaons.........................................................................................................7

3.1 Specicaons of the DP-junior..................................................................................................... 7

4. Overview of safety measures and warnings..........................................................................8

4.1 Safety............................................................................................................................................ 8

The safety frame .......................................................................................................................... 8

The emergency stop buon......................................................................................................... 8

5. Transport and storage .........................................................................................................10

5.1 Transport .................................................................................................................................... 10

5.2 Storage ....................................................................................................................................... 10

6. Operang instrucon..........................................................................................................11

6.1 Operang the DP-junior............................................................................................................. 11

6.2 Safety frame ............................................................................................................................... 11

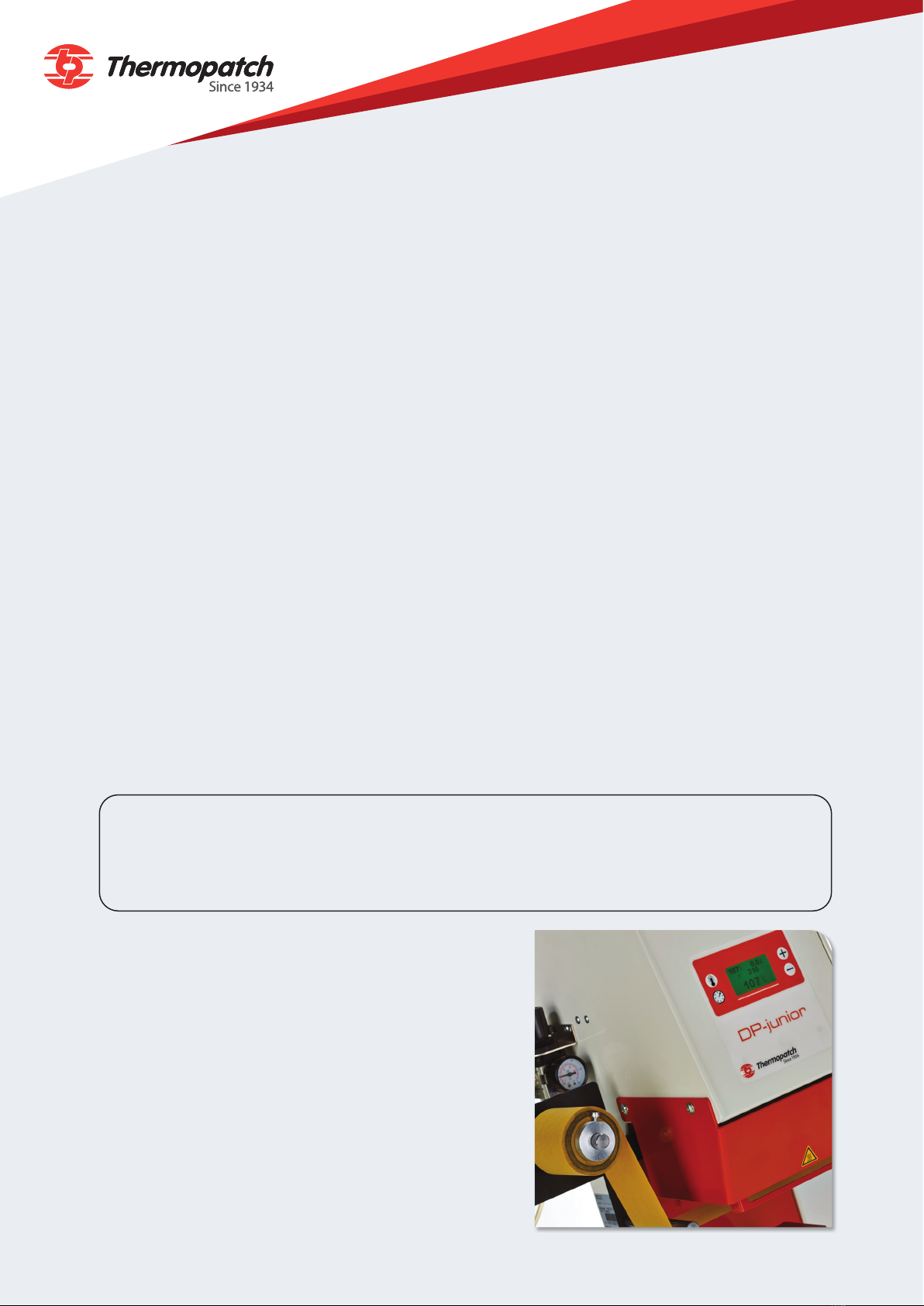

6.3 The control panel ....................................................................................................................... 11

6.4 Sengs....................................................................................................................................... 12

6.4.1 Temperature sengs ................................................................................................................. 12

Change temperature sengs .................................................................................................... 12

6.4.2 Time sengs .............................................................................................................................. 13

Change sealing me................................................................................................................... 13

Change the C-tape transport me............................................................................................ 14

6.4.3 Interrupng the operaon ot the DP-junior ............................................................................. 14

6.4.4 Counter....................................................................................................................................... 15

6.4.5 Error codes ................................................................................................................................ 16

6.5 Inserng C-tape.......................................................................................................................... 17

6.6 Inserng the cliché..................................................................................................................... 18

7. Assembly and installaon ...................................................................................................19

7.1 Assembly .................................................................................................................................... 19

7.2 Installaon.................................................................................................................................. 19