12V Marine Air Conditioning

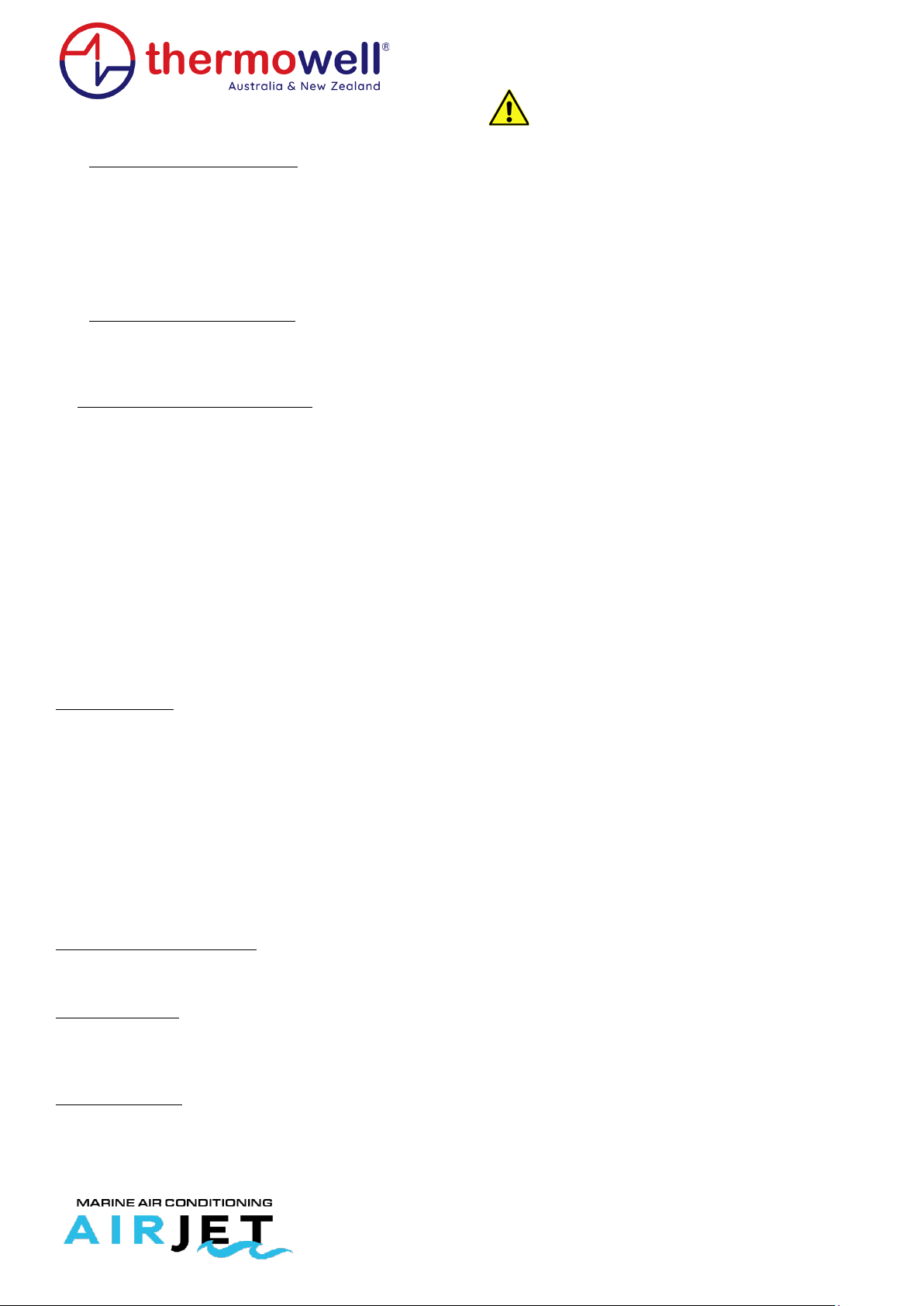

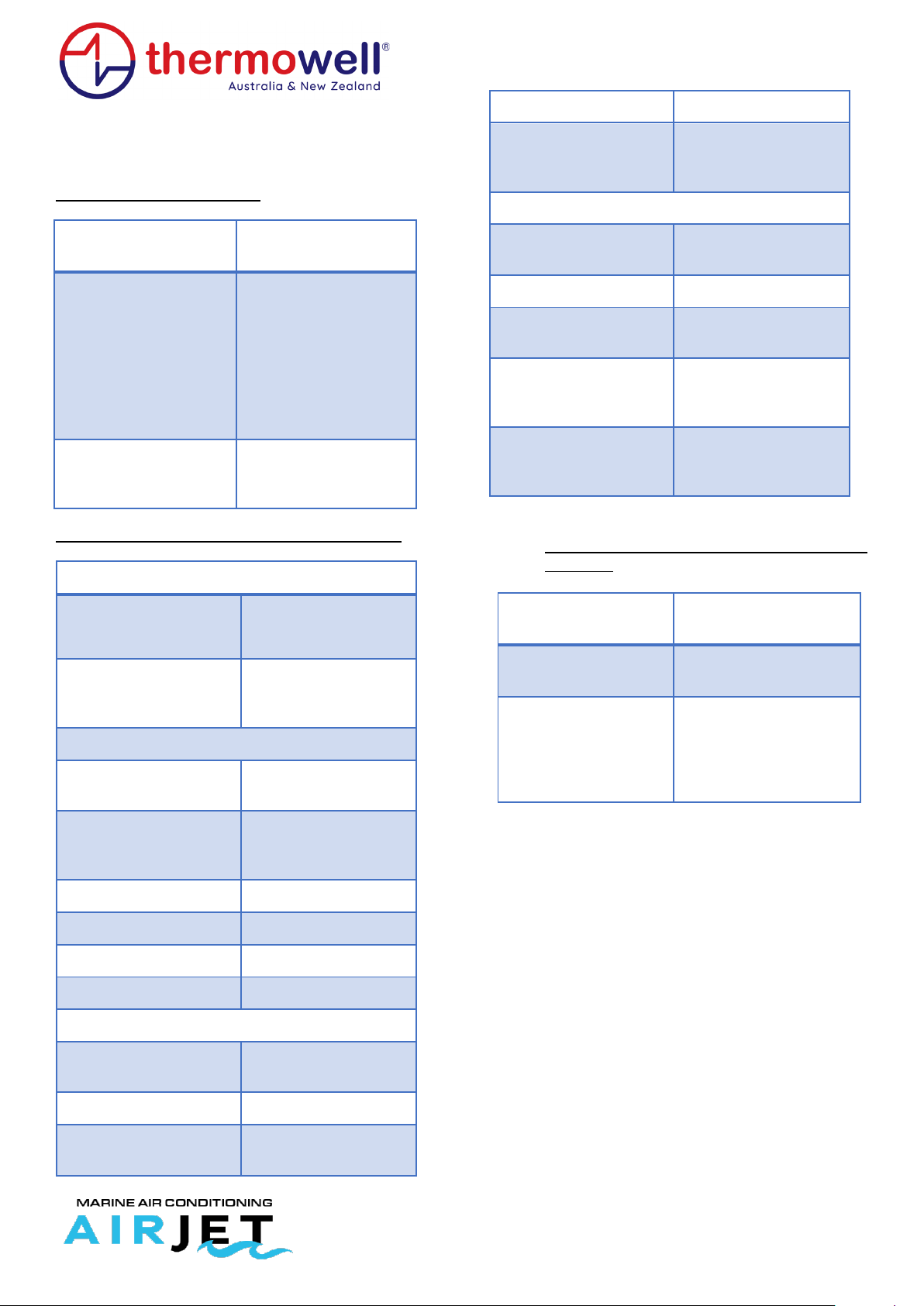

10. Electrical Installation

10.1. Cables

Main’s power must be supplied by means of a fuse or a switch with

a corresponding rating. To make the following connections, use PVC

insulated three-core, four-core or multi-core cables with copper

conductors laid in accordance with the established conditions. The

dimensions of the cables should be selected for 100% of the rated

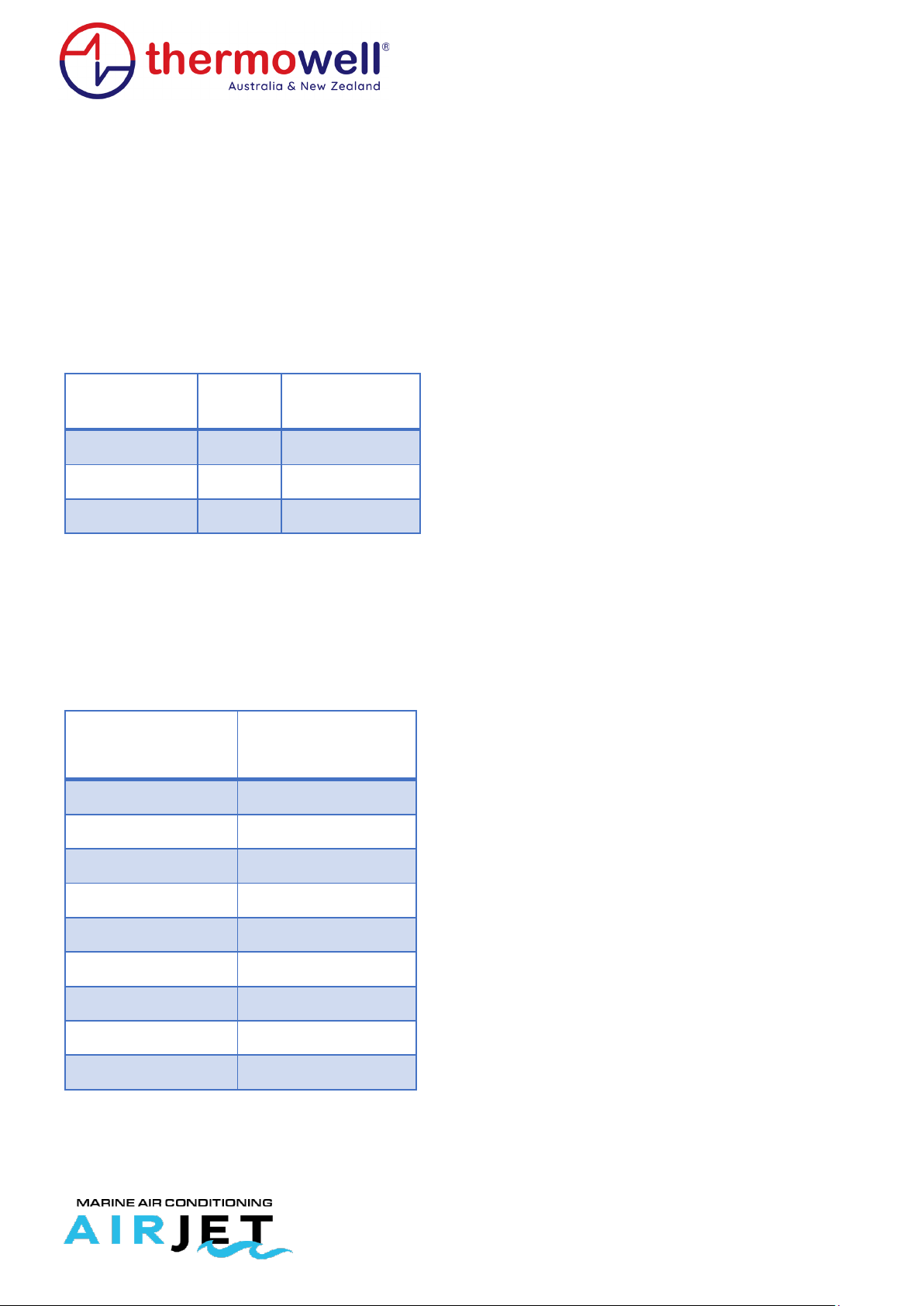

currents of the consumers. This table is a simple reference for

correct cable sizing.

CURRENT

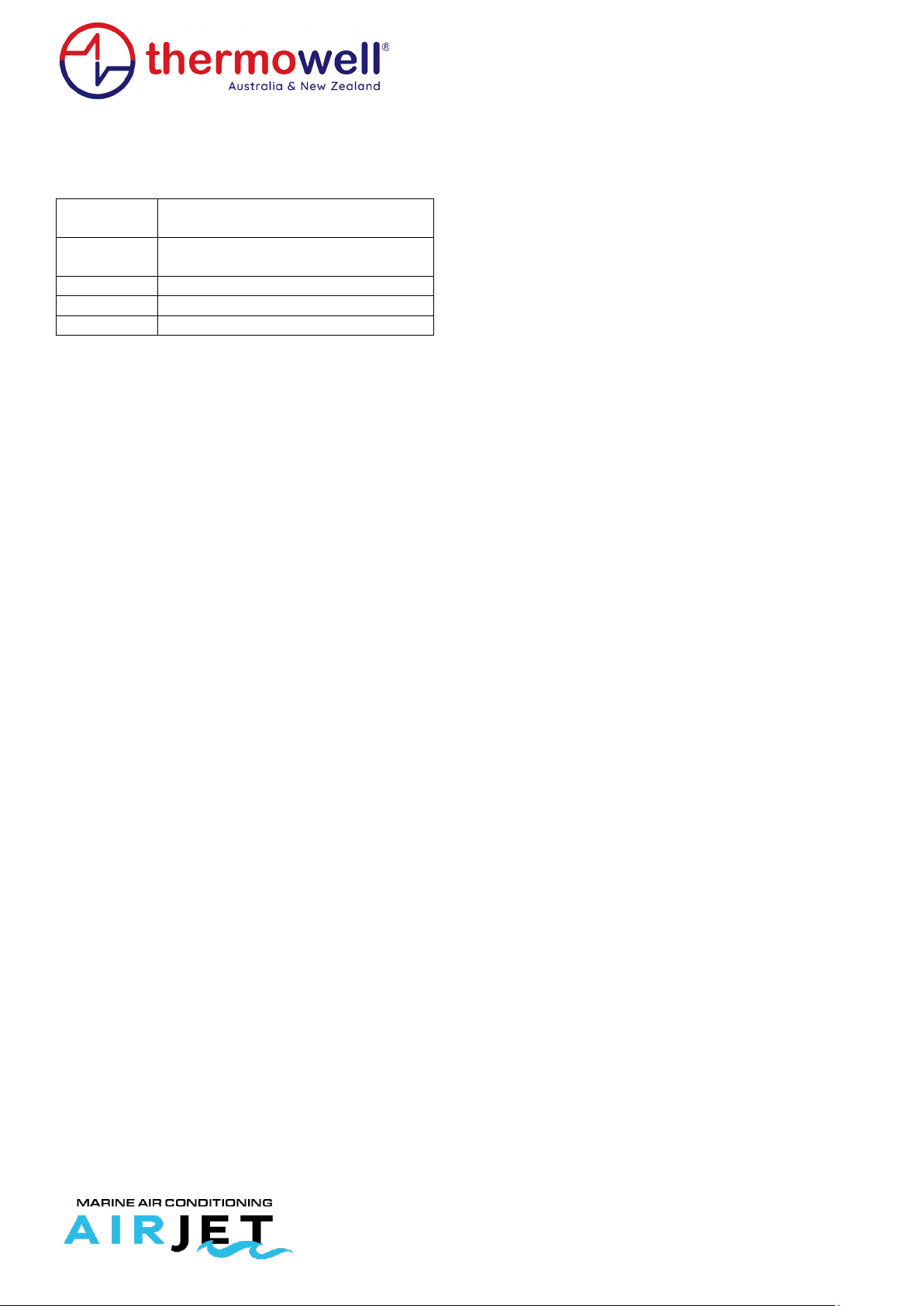

The flow rates shown in the above table have been defined at a

conventional ambient temperature of 30°C (it is assumed that the

temperature may occasionally reach 35°C). If the ambient

temperature is lower than the conventional temperature, the flow

rate increases, but if the temperature increases, the flow rate

decreases. The following table shows these room temperature

correction coefficients.

for flow rate

,

11. Regulatory references

The main reference standards are listed below:

UNI EN 14511-1:2018 Air conditioners, liquid chillers, and heat

pumps with electrically driven compressors for space heating and

cooling, and process cycle chillers with electrically driven

compressors - Part 1: Terms and definitions

UNI EN 14511-2:2018 Air conditioners, liquid chillers, and heat

pumps with electrically driven compressors for space heating and

cooling, and process cycle chillers with electrically driven

compressors - Part 2: Test conditions

UNI EN 14511-3:2018 Air conditioners, liquid chillers, and heat

pumps with electrically driven compressors for space heating and

cooling, and process cycle chillers with electrically driven

compressors - Part 3: Test methods

UNI EN 14511-4:2018 Air conditioners, liquid chillers, and heat

pumps with electrically driven compressors for space heating and

cooling, and process cycle chillers with electrically driven

compressors - Part 4: Requirements

UNI EN 378-1:2017 Refrigeration systems and heat pumps - Safety

and environmental requirements - Part 1: Basic requirements,

definitions, classification, and selection criteria

UNI EN 378-2:2017 Refrigerating systems and heat pumps - Safety

and environmental requirements - Part 2: Design, construction,

testing, marking and documentation

UNI EN 378-3:2017 Refrigerating systems and heat pumps - Safety

and environmental requirements - Part 3: Installation site and

personal protection

UNI EN 378-4:2017 refrigerating systems and heat pumps - Safety

and environmental requirements - Part 4: Operation, maintenance,

repair, and recovery

UNI EN 1736:2009 Refrigeration plants and heat pumps - Flexible

piping elements, vibration isolators, expansion joints and non-

metallic pipes - Requirements, design, and installation

UNI EN 1861:2000 Refrigeration systems and heat pumps - System

flow diagrams and diagrams of piping and instrumentation - Layout

and symbols

UNI EN 12178:2017 Refrigerating systems and heat pumps - Liquid

level indicators - Requirements, testing and marking

UNI EN 12263:2000 Refrigerating systems and heat pumps - Safety

switching devices for pressure limitation - Requirements and tests

UNI EN 12284:2004 Refrigerating systems and heat pumps - Valves

- Requirements, testing and marking

UNI EN 12828:2014 Heating systems in buildings - Design of water

heating systems

UNI EN 12831-1:2018 Energy performance of buildings - Method for

calculating design heat load - Part 1: Heat load for space heating,

Module M3-3

UNI EN 13136:2019 Refrigeration plants and heat pumps - Pressure

relief devices and associated piping - Calculation methods