Thiele Streamfeeder Value Series User manual

Manual

Value Series V-710DM

Part Number: 00900394

© 2010 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent of

Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

315 27th Avenue NE

Minneapolis, MN 55418 USA

Tel:(763) 502-0000

Fax:(763) 502-0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

i

Value SerieS V-710DM Manual

Contents

Safety Information ........................................................ii

Specications ..............................................................iv

Section 1: About the Machine .......................................................1

Section2: InstallingtheMachine ..................................................4

Section3: PreparingforOperation .............................................18

Section4: HowtoOperate ...........................................................29

Section5: OperationalTroubleshooting ....................................32

Section6: InspectionandCare ...................................................34

Section7: MechanicalComponents ...........................................40

Section8: ElectricalComponents...............................................54

Section9: TechnicalTroubleshooting ........................................58

ii Value SerieS V-710DM Manual

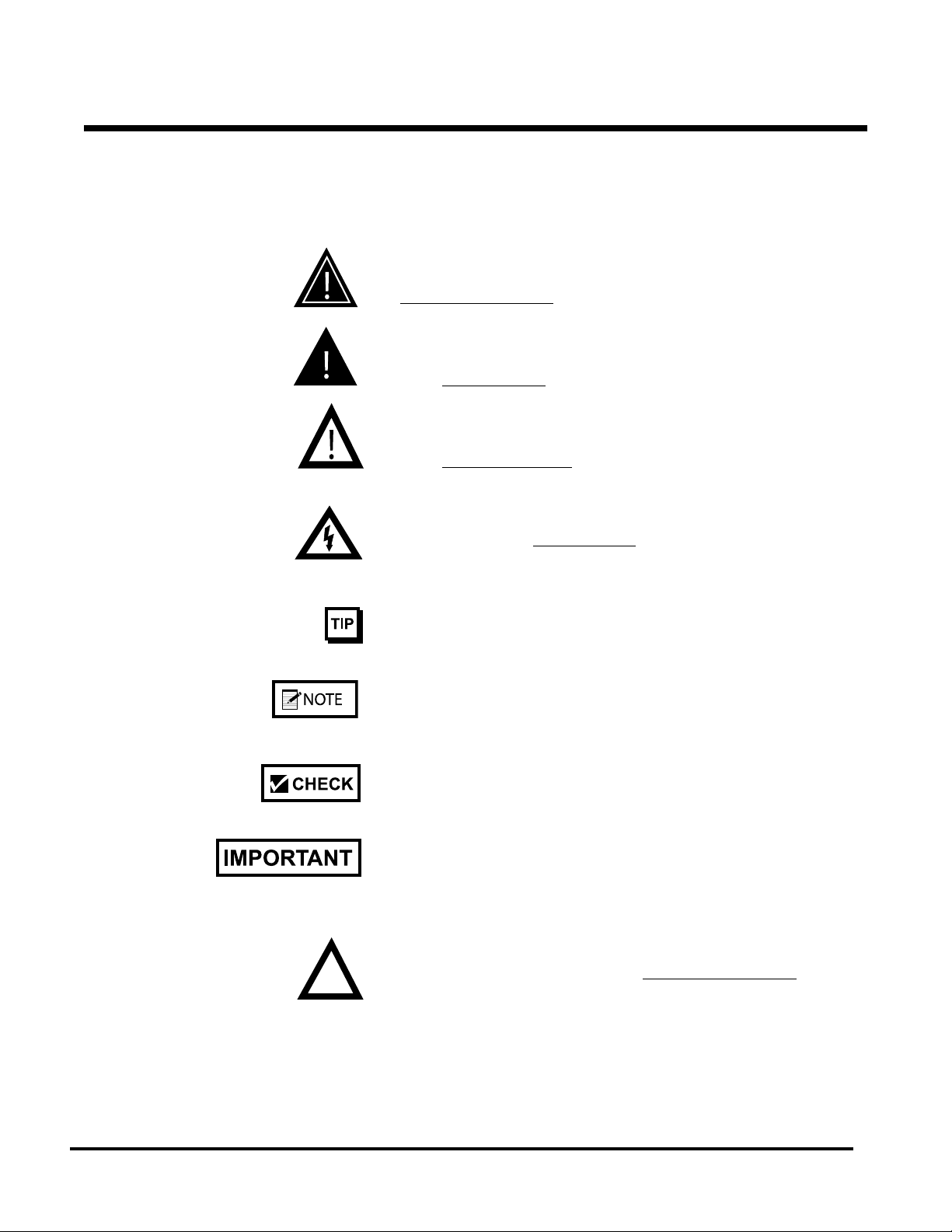

Message

Conventions

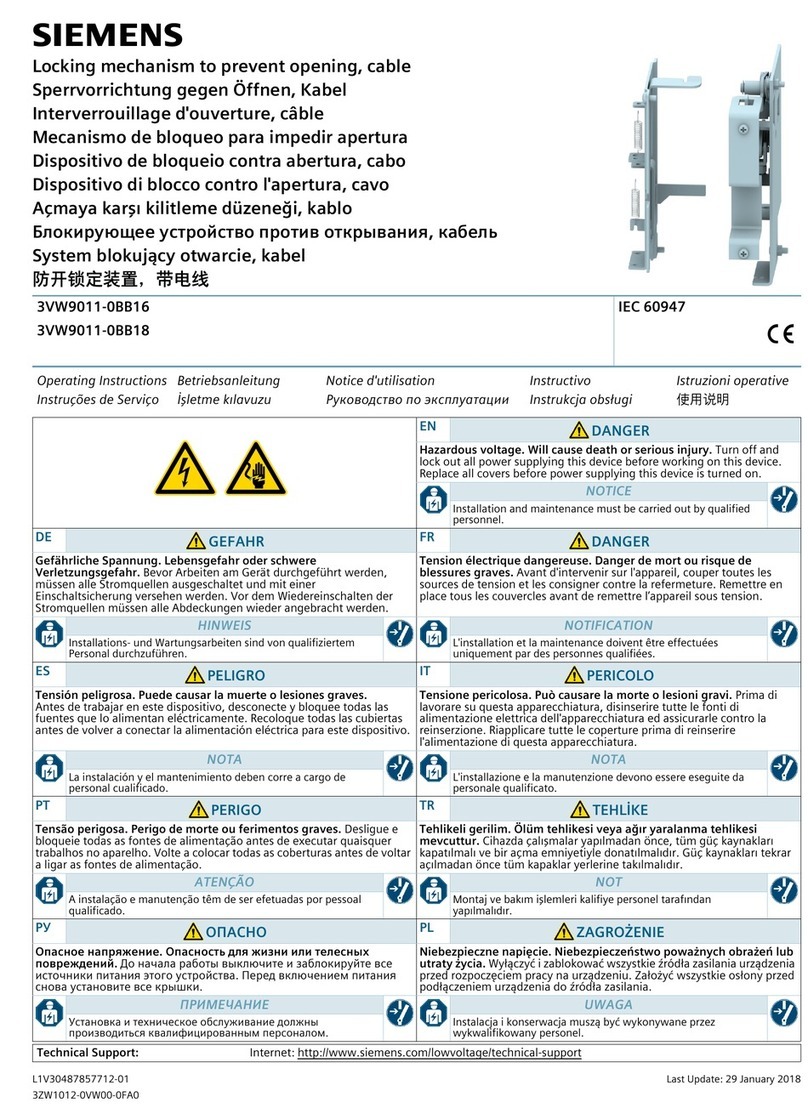

DANGER signies an action or specic equipment area that can result

in serious injury or death if proper precautions are not taken.

WARNING signies an action or specic equipment area that can

result in personal injury if proper precautions are not taken.

CAUTION signies an action or specic equipment area that can

result in equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signies an action or specic equipment

area that can result in personal injury or death from an electrical haz-

ard if proper precautions are not taken.

TIP signies information that is provided to help minimize problems

in the installation or operation of the feeder.

NOTE provides useful additional information that the installer or

operator should be aware of to perform a certain task.

CHECK signies an action that should be reviewed by the operator

before proceeding.

IMPORTANT alerts the installer or operator to actions that can poten-

tially lead to problems or equipment damage if instructions are not

followed properly.

WARNING LABELS afxed to this product signify an action or spe-

cic equipment area that can result in serious injury or death if proper

precautions are not taken.

Before You Begin

iii

Value SerieS V-710DM Manual

Message

Conventions

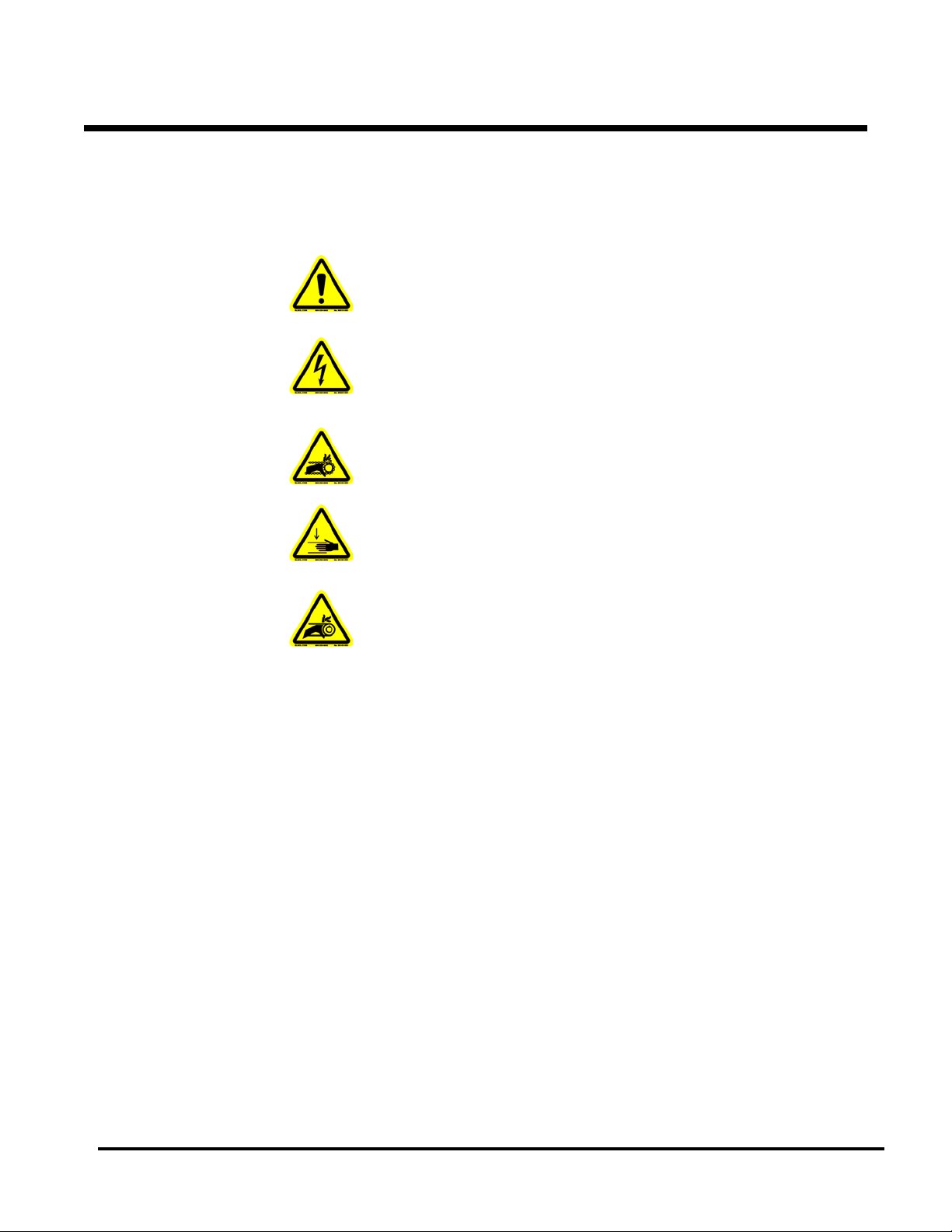

Before You Begin

Avoid injury. Do not reach around guards.

Hazardous voltage. Contact will cause electric shock or burn. Turn off

and lock out power before servicing.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

Pinch point. Keep hands and ngers clear.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

iv Value SerieS V-710DM Manual

Maximum Product Size: ......................... 12 W x 12 L in (305 x 305 mm)*

Minimum Product Size: ........................ 3.75 W x 3.75 L in (95 x 95 mm)

Optional: ...................................................... 2.5 W x 2.5 L in (63 x 63 mm)

Min/Max Product Thickness: ........................ .003-.75 in (.076-19.1 mm)

Belt Speed: ................................................ 4000 in/min (101,600 mm/min)

Electrical Requirements: ................................... 115/230vac, 50/60Hz, 3A

Weight: ............................................................................... 41 lbs. (18.6kg)

*Optional product size available

speCifiCations

v

Value SerieS V-710DM Manual

1Value SerieS V-710DM Manual

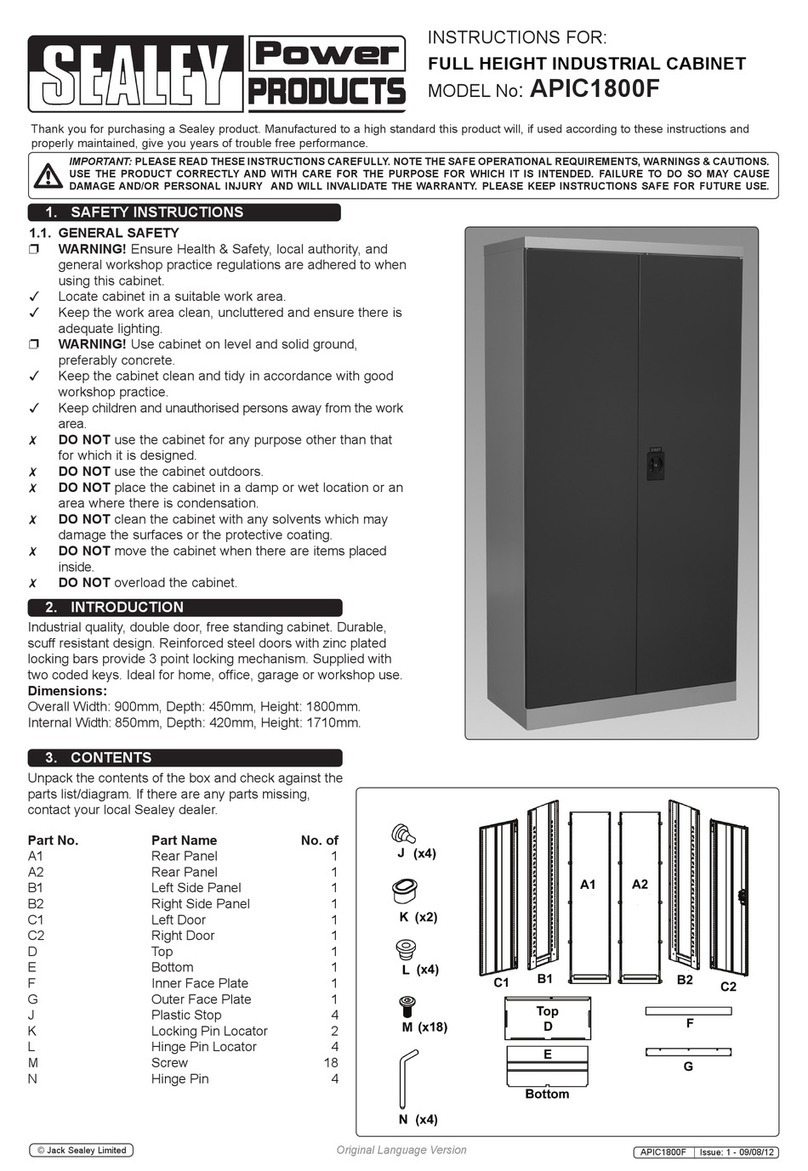

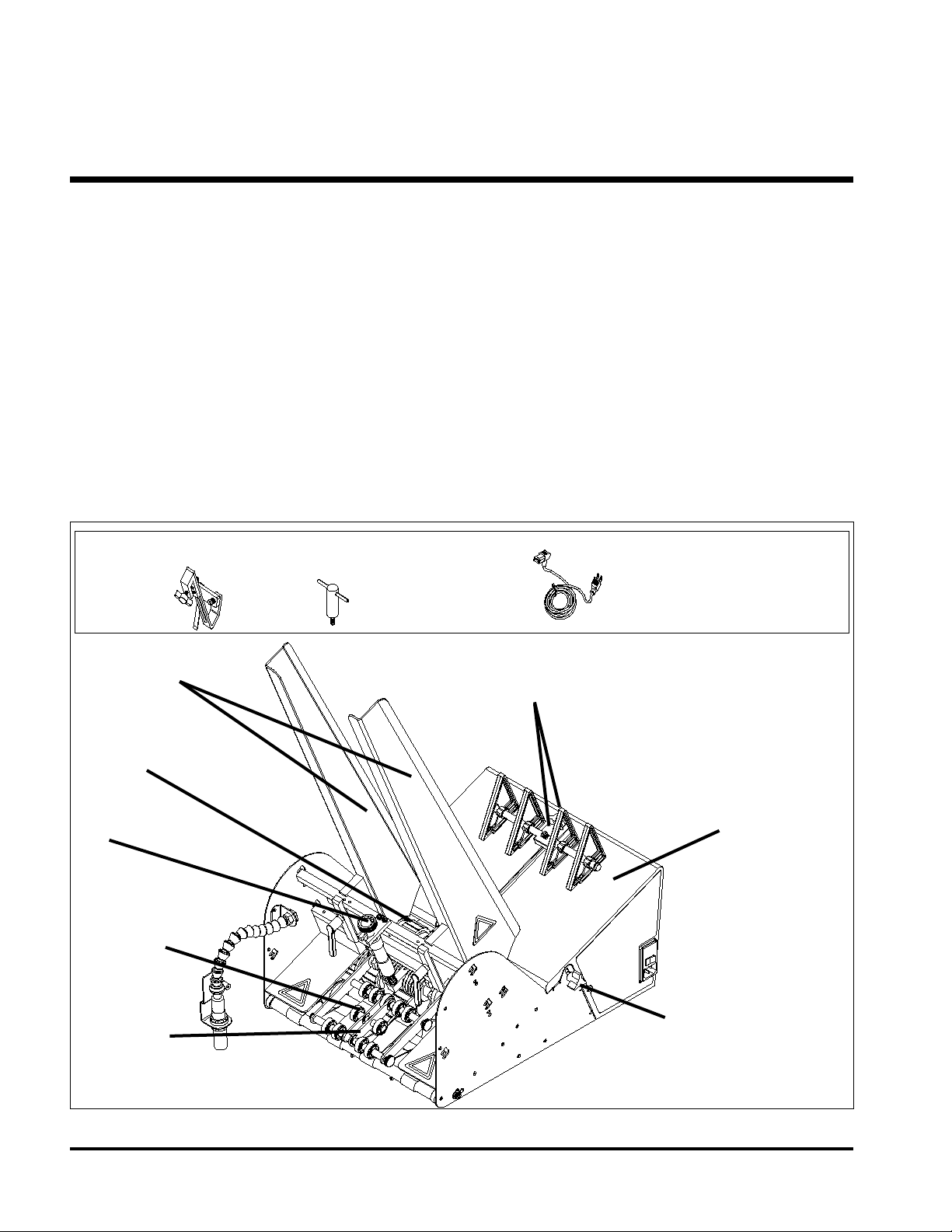

Back Wedge and Adjustments

Standard O-Ring

Gate

Table Top

Feed Belts

Hold-Down

Assembly

Discharge

Belts Raised Feed Belts

Adjustment

Side Guides

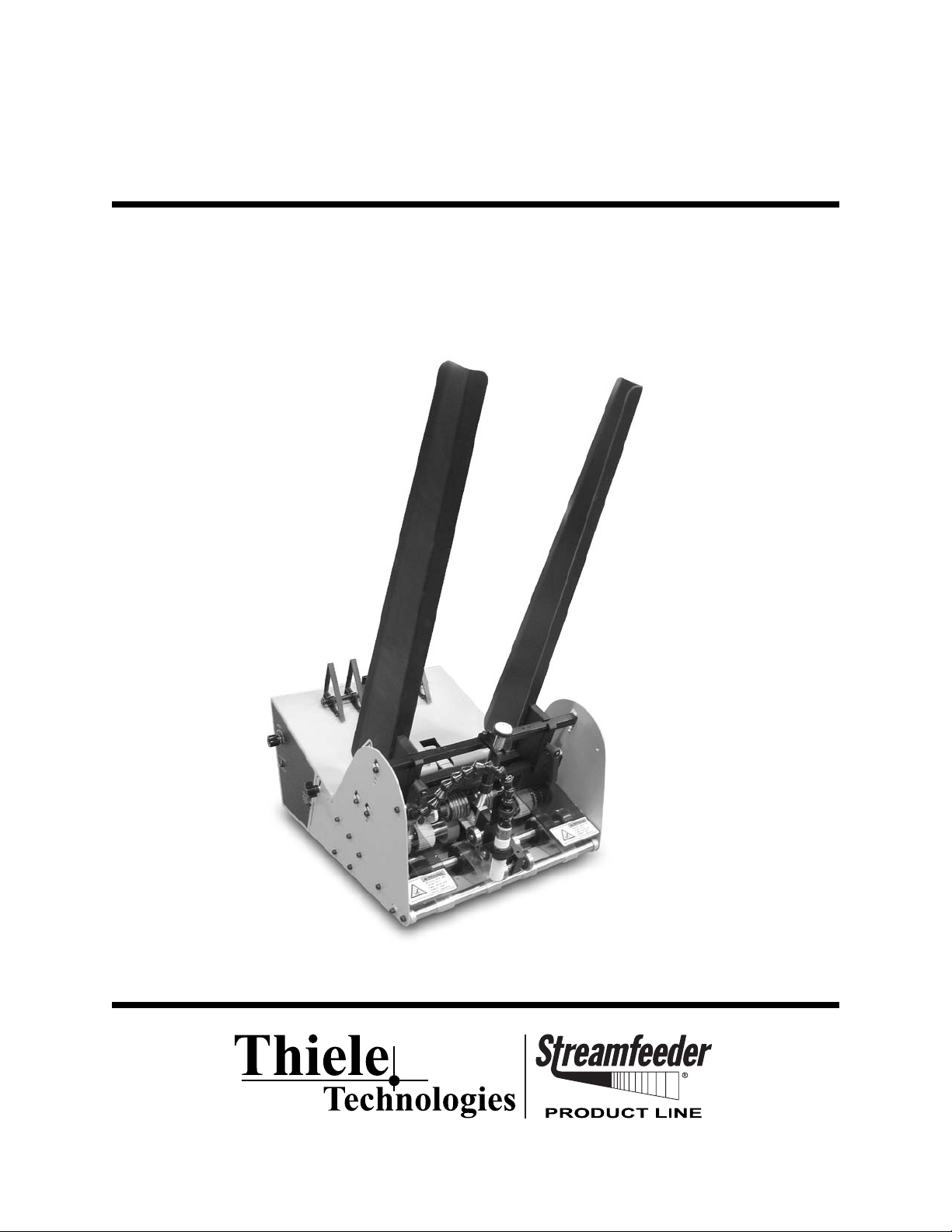

1About the Machine

The V-710DM Universal Friction Feeder is designed for reliability,

exibility, and ease of use with a variety of host systems. Included are

such applications as vacuum and non-vacuum bases and gripper-arm

inserters. All parts required for setup, loading, feeding, sensing and

easy operator control are combined into one compact unit.

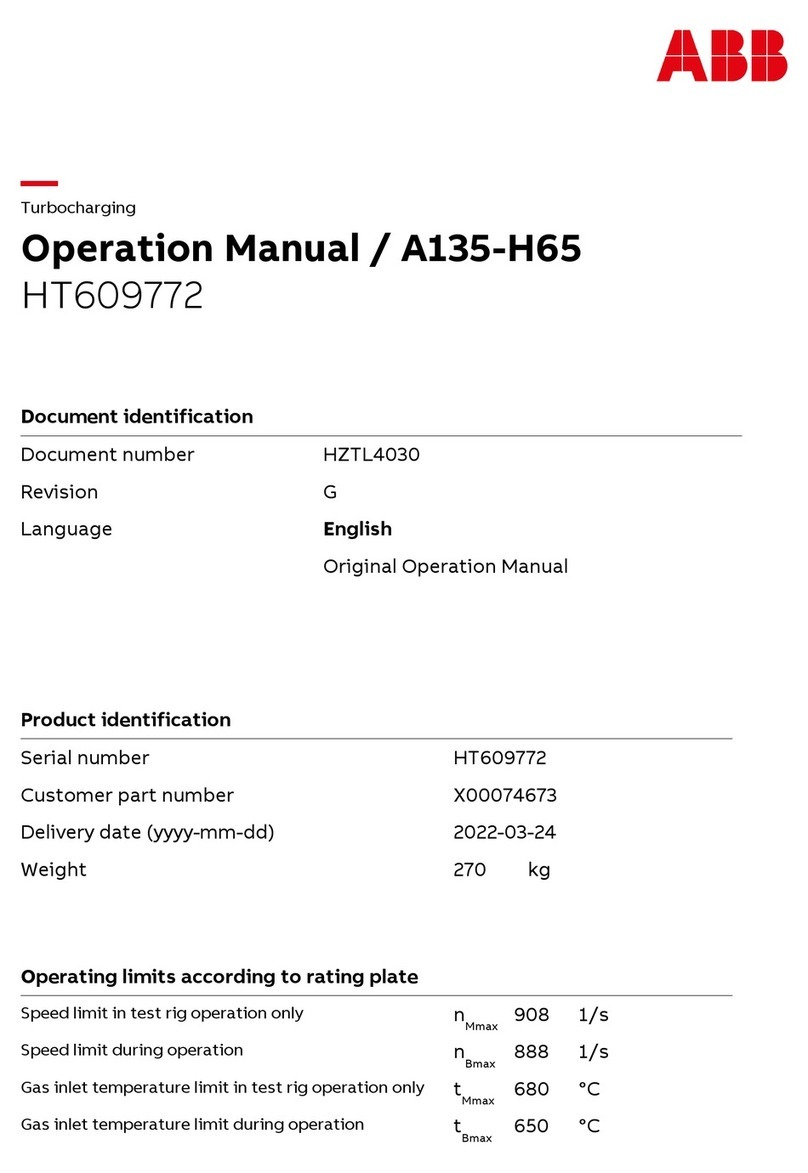

Review the main assemblies in Figure 1-1 to become familiar with

names and locations of feeder parts and adjustments. This will help to

prepare you for initial setup. Descriptions are found in Table 1-1.

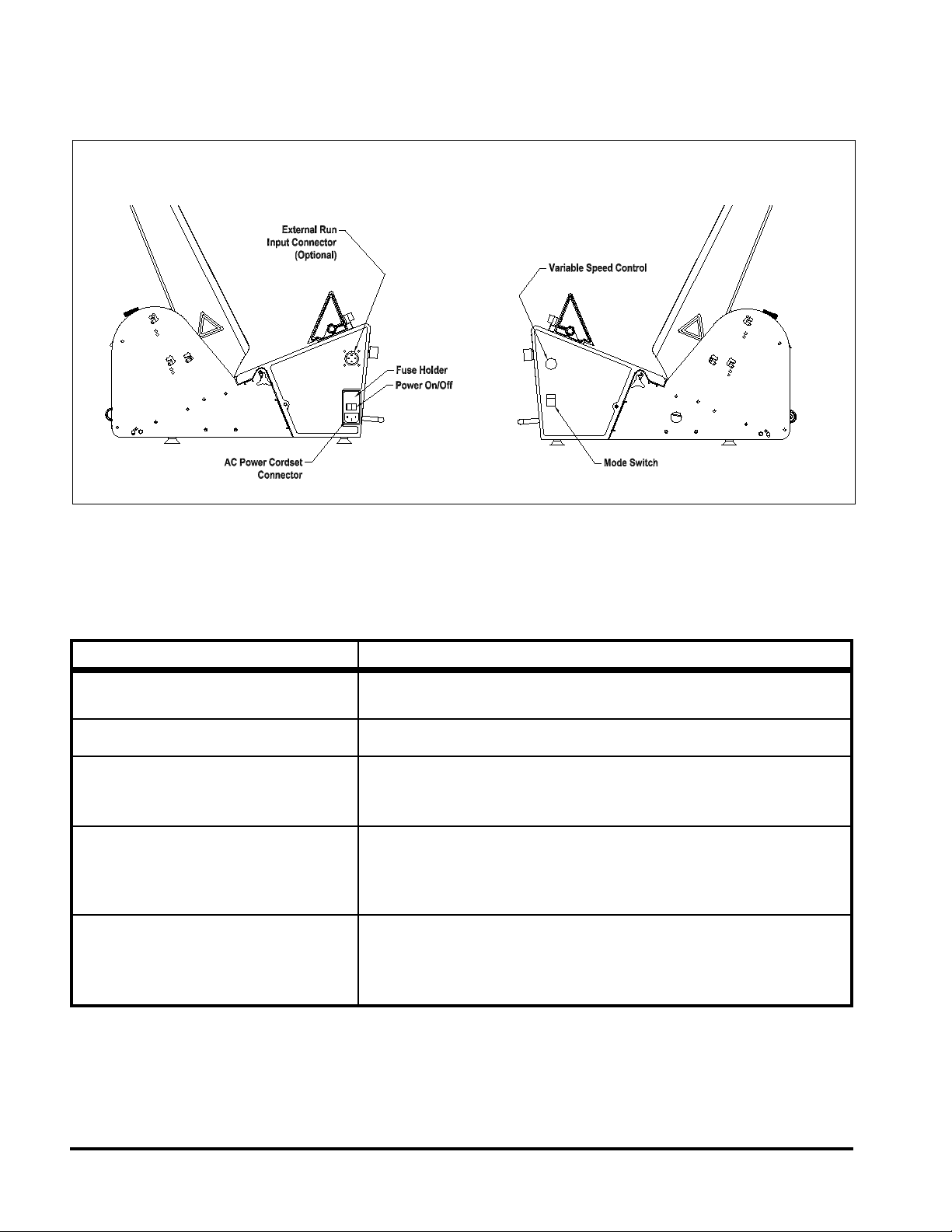

Review the control panel components in Figure 1-2 to become fa-

miliar with names and locations of specic connectors, switches, and

controls. This will help to prepare you for installation and operation.

Descriptions are found in Table 1-2.

AC Power

Cord

(2)

Hold-Down Spring

Assemblies

(2)

T-Handle Screws

with (4) #8 Flat

Washers

Features

Main Assemblies

Loose Parts Supplied Not Shown:

•SideGuides(2)

•SupportPedestal

Figure 1-1. Main Assemblies of the V-710DM Universal Friction Feeder

2

Value SerieS V-710DM Manual

Table 1-1. Main Assemblies Feature Descriptions

Feature Description

Gate assembly and adjustment Mounted on a gate bracket assembly above the feed belts, this device

provides a curvature to help preshingle stacked material. When properly

adjusted, a clearance is created to help singulate and feed material.

(Note: For multiple page material, a 1 to 1.5 maximum thickness is

typical.)

Table top Used to support the back wedge.

Raised feed belts adjustment Located on each side of the feeder, these adjustment knobs allow you to

raise the rear feed belts above the table top to achieve optimum contact

with material.

Side guides (adjustable) Holds a stack of material to be fed and helps keep it straight for proper

entry through the gate assembly area.

Back wedge and adjustments Lifts the material to keep it off the table top, reduces excessive contact

with the feed belts, and helps push the material against the curvature of

the gate assembly. To achieve proper lift, adjustment wing-nut allows you

to slide the wedge to various positions and angles.

Photosensorandexibleextension Also called a sheet-detect photo sensor, it "looks" for the leading edge of

the material to stop the feeder. For optimum setting, a exible extension

allows you to adjust for distance and perpendicular angle to material.

(Note: Sensor is used for gripper-arm inserter applications only.)

Feed belts and discharge belts Feed Belts: Provide the friction and motion necessary to pull individual

material from the bottom of the stack and through the gate assembly

area. Discharge Belts: Combined with the top roller hold-down assembly,

provides the friction and motion necessary to transport material away from

the gate assembly area.

Top roller hold-down assembly Provides the friction and motion necessary to pull materials away from the

gate assembly. Positioned above discharge belts.

AC power cord, 8 ft. (2.44 m) IEC320 removal three-prong. Shipped loose.

Discharge safety shields Provides a residual risk protection to operator when feeder is running.

Support pedestal Supports part of feeder that extends over the inserter's back deck plate.

Includes built-in height adjustment. (Note: Not used on vacuum base

applications.)

LOOSE PARTS

Hold-down spring assemblies (Note: For inserter applications.) As a piece of material exits the feeder

gate assembly area, these two hold-down spring assemblies help keep it

aligned and in proper position for the gripper jaw. Mounted on inserter.

T-handle screw assemblies (Note: For inserter applications only.) These two hand-tightening screws

secure the feeder to the inserter back deck plate. Fastened to underside

of feeder.

3Value SerieS V-710DM Manual

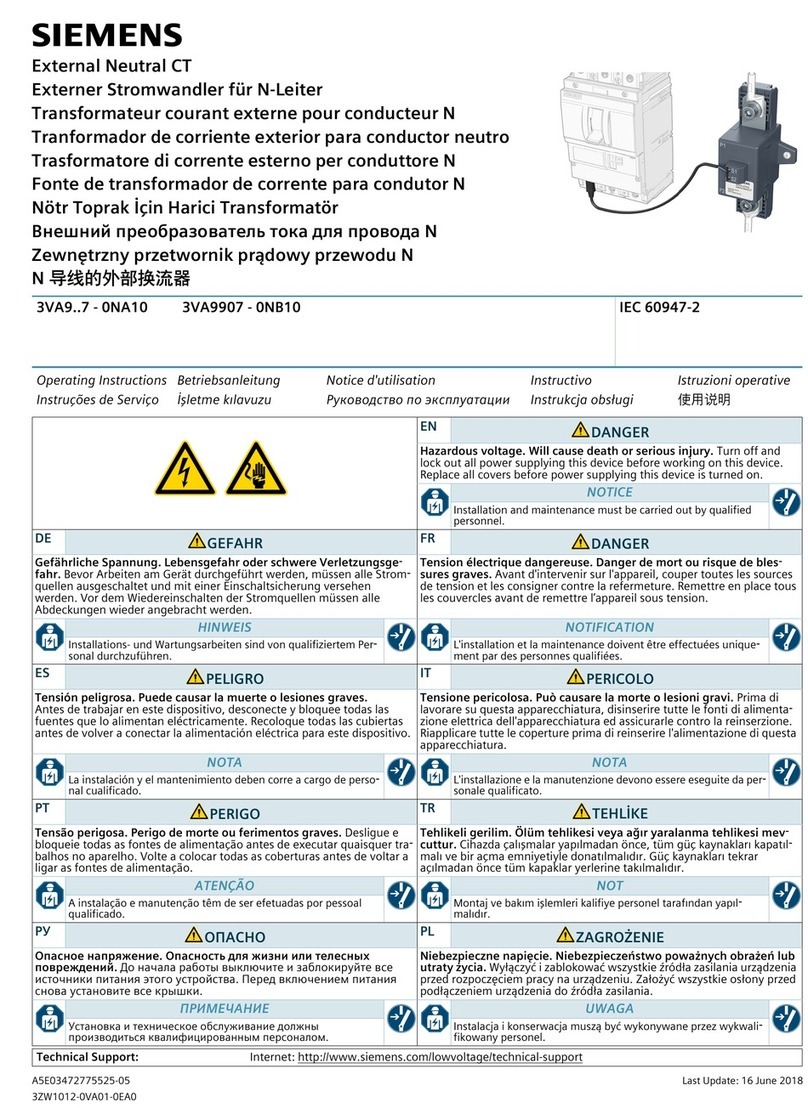

Feature Description

AC power cordset connector Cordset plugs into this IEC320 connector to provide feeder with power

from a grounded/fused outlet.

Power On/Off Toggles AC power On or Off.

Fuse holder Contains two replaceable GMD3, 3-Amp, 5-mm fuses. IMPORTANT:

Always make sure power module is replaced exactly as removed. Failure

to follow this caution will result in damaged electrical parts.

Variable speed control This dial switch (labeled Speed) allows the feeder speed to be

synchronized with an inserter, vacuum or non-vacuum base. Turning

counterclockwise decreases speed; clockwise increases speed. (Note:

Feeder motor stops if turned completely counterclockwise.)

Figure 1-2. Control Panel Components (Left and Right Side Views)

Control Panel Components

Table 1-2. Control Panel Feature Descriptions

Drycontactexternalruninput

connector and mode switch (optional)

This interface allows for the electrical integration into vacuum type bases for

integrated start/stop control.

Dry Contact

(Optional w/External Run)

4

Value SerieS V-710DM Manual

2Installing the Machine

When performing initial installation, always

make sure you turn Off the main power

switch and disconnect all equipment from the

electrical power source. Failure to do so can

expose you to a potential startup and moving

parts which can cause serious injury.

Do not attempt feeder installation while

the feeder and machine of application are

running. Failure to do so can expose you to

moving parts which can cause serious injury.

Do not wear loose clothing when operating the

feeder.

Avoid turning on the feeder or making initial

adjustments until all parts are secured. Failure

to do so can cause damage to equipment.

This section provides information on how to the install the V-710DM

Universal Friction Feeder in the following application environments:

• Vacuum base installation (2A)

• Inserter installation (2B)

Information for a particular application typically includes procedures

for basic parts removal, feeder mounting and alignment, and cable

connections for power and control interface. Information that relates

to specic adjustments you must make to feeder prior to startup and

operation is found in Section 3, Preparing for Operation.

2A:

Vacuum Base

Installation of the V-710DM Universal Friction Feeder onto various

types of vacuum and non-vacuum bases is a relatively simple proce-

dure. Several minor modications to the vacuum base are required

prior to mounting and aligning the feeder.

To install the feeder onto a vacuum base, perform the following steps:

1: Repositioning front side guides

2: Removing back jogging plate/back hopper guide

3: Raising hopping rollers

4: Disabling the shuttle

5: Initial positioning of feeder

6: Providing AC power to feeder

7: Checking material discharge from feeder

8: Miscellaneous feeder adjustments

5Value SerieS V-710DM Manual

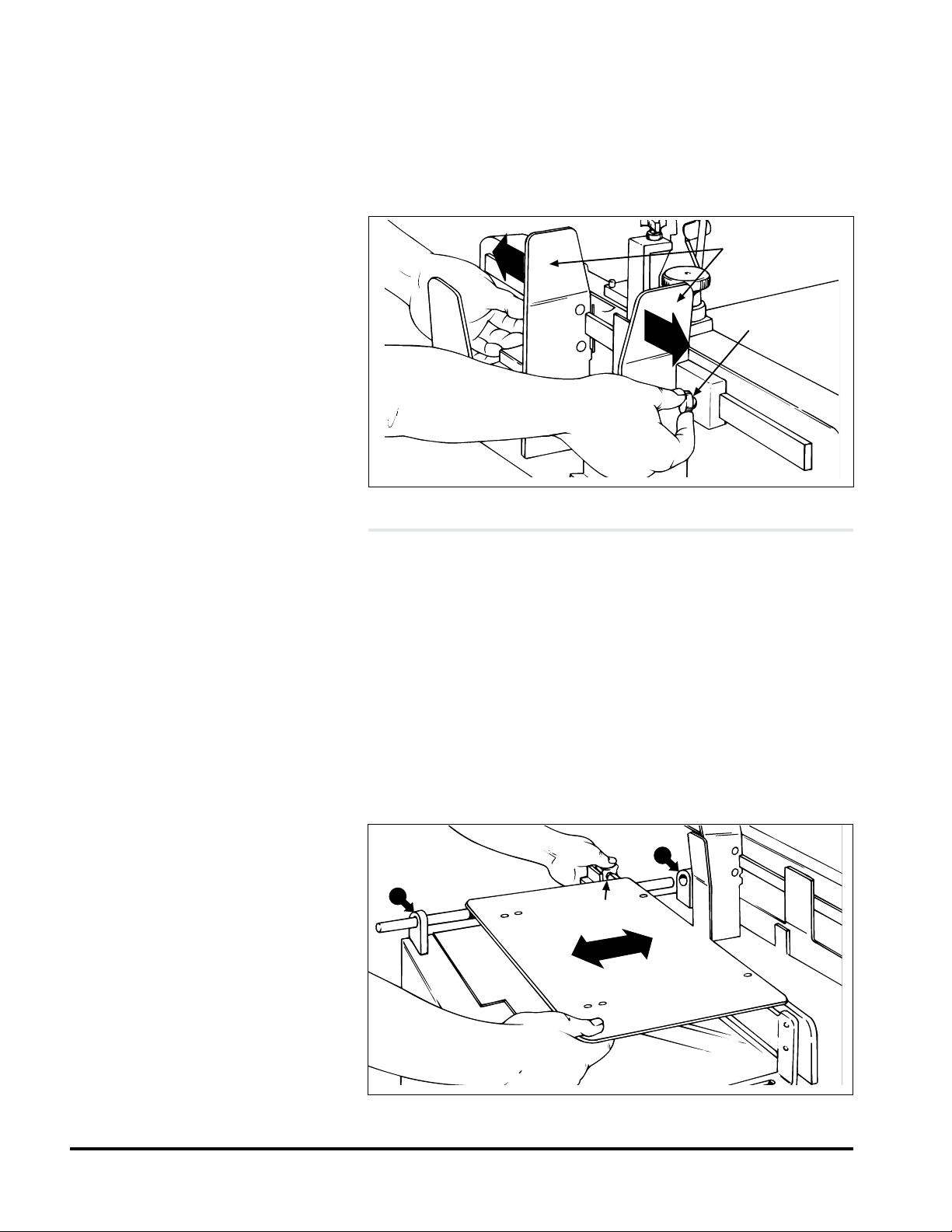

1. Loosen locking knobs at both side guides (Figure 2-1).

2. Slide each side guide to the outermost position. Do not lock in

place.

1. Loosen each of the setscrews at the two shaft housing assem-

blies A and B (Figure 2-2).

2. Slide shaft end closest to the vacuum base gate out of housing

A (with jogging plate/hopper guides still attached). Slide shaft

back far enough on housing B to allow removal of jogging

plate/hopper guides.

3. Loosen locking knob and slide jogging plate/back hopper

guide off of shaft and away from the surface of the vacuum

in-position, with no further disassembly.

4. Return shaft end to housing B. Lock setscrews in both housing

assemblies.

STEP 2:

Removing Back Jogging

Plate/Back Hopper Guide

STEP 1:

Repositioning Front

Side Guides

Figure 2-1. Front Side Guides Being Repositioned

Figure 2-2. Back Jogging Plate/Back Hopper Guide Removal

Front side

guides

Locking

knob

A

BLocking knob

6

Value SerieS V-710DM Manual

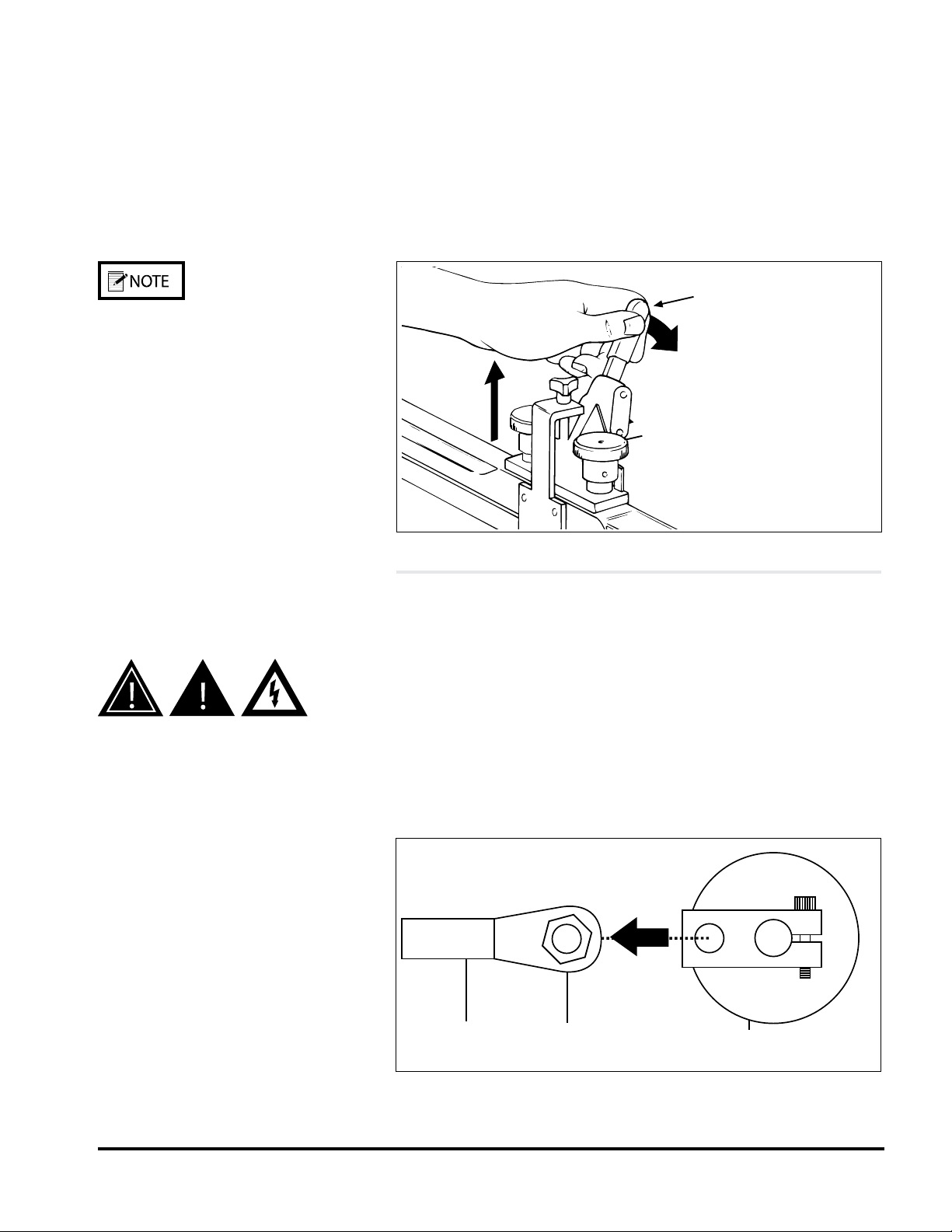

1. Locate the gate adjustment knobs (Figure 2-3) and turn com-

pletely in a clockwise direction to raise hopping rollers.

2. Then, locate the vertical adjustment lever on the hopping roll-

ers assembly and push down all the way. This will raise the

feed rollers to highest vertical position possible, thus making

for maximum clearance.

STEP 3:

Raising Hopping Rollers

If additional control of material is required

during feeding, you may choose to keep the base’s

hopping roller assembly in the down (or normal)

position.

1. Remove side access panel from vacuum base enclosure.

2. Locate the reciprocating arm and reciprocating block directly

beneath the underside of shuttle (Figure 2-4).

3. Using a box wrench, remove the hex-head rod end bearing

bolt holding the reciprocating arm to the reciprocating block.

4. Once the bearing bolt is removed, the reciprocating arm is ef-

fectively disconnected. As the shaft is connected to the shuttle

base plate on the other end, simply allow the shaft to hang

in-position, with no further disassembly.

5. Make sure the base plate of shuttle is all the way forward

(toward the vacuum base gate).

Figure 2-3. Using the Adjustments to Raise Hopping Rollers

STEP 4:

Disabling the Shuttle

To prevent any accidental startup of shuttle

motor and to eliminate the hazard of moving

parts, you can prevent accidental startup by

either disconnecting vacuum base from AC

power at the outlet, or you can remove the

internal AC power fuse (located behind the

access door of the vacuum base).

Figure 2-4. Disabling the Shuttle from Inside the Access

Panel

Vertical adjustment

lever

Gate adjustment

knob

Reciprocating

arm

Hex-head

rod end

bearing bolt

Reciprocating

block

7Value SerieS V-710DM Manual

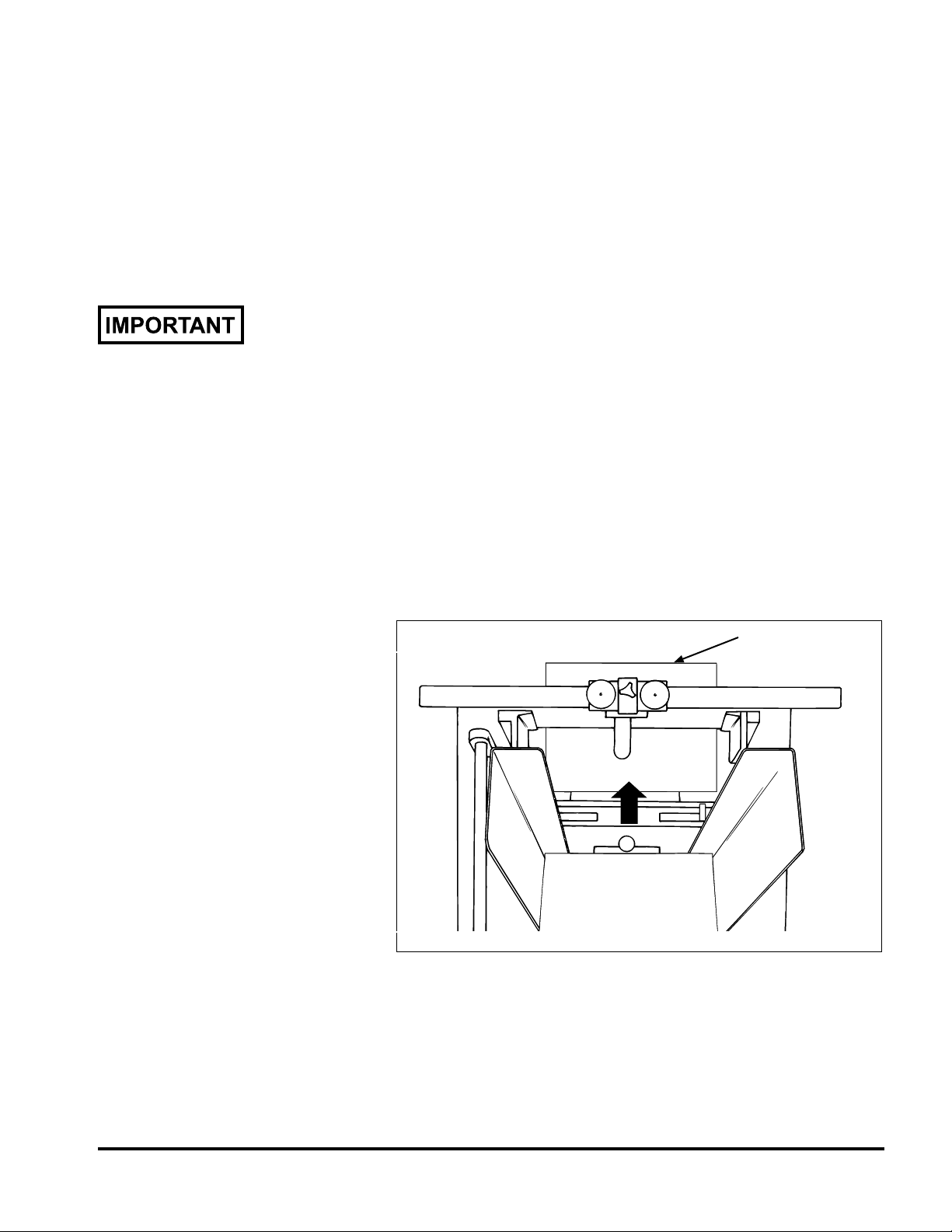

1. Position photo-eye pointing up and away from feeder and

vacuum base.

2. Lift the feeder onto the top plate of the vacuum base and slide

forward toward the vacuum base gate.

3. Center the feeder between the two side guides as you posi-

tion the feeder fully forward. To verify centering, sight down

the center of the feeder gate, making sure it is in-line with the

vacuum base gate (Figure 2-5).

4. Trap the feeder in-between the vacuum base side guides by

sliding each in toward the side plates of the feeder until they

gently touch. Tighten side guide knobs to secure in position.

1. Connect IEC320 end of power cord to the feeder (at the power

inlet module).

2. Connect three-prong end to nearest AC voltage power source.

STEP 5:

Initial Positioning

of Feeder

Figure 2-5. Positioning the Feeder on the Vacuum Base

STEP 6:

Providing AC Power

to Feeder

Please verify that the voltage shown at the power

inlet module matches the incoming voltage from

the power source.

Center

8

Value SerieS V-710DM Manual

STEP 7:

Checking Material

Discharge from Feeder

Make sure rollers on vacuum base are raised

in the highest vertical position so it does not

interfere with the material.

Figure 2-6. Checking for Proper Material Discharge from

Feeder to Vacuum Base

Leading edge

should be 2/3into

transfer section

As material leaves the feeder gate cylinder, the trailing edge must be

under the hold-down as the leading edge is entering the vacuum base

transfer section. There must be a good transfer of material from the

feeder hold-down to the vacuum base transfer section.

To verify:

1. Slide feeder back far enough to clear the vacuum base side

guides. If necessary, loosen the knobs on both side guides and

pull to the outside slightly to allow movement of the feeder.

2. Insert a piece of material under the hold-down bearings in

such a way that approximately 2/3 of the leading edge is ex-

tending out beyond the feeder (Figure 2-6).

3. Slide feeder back into position, making sure it is again cen-

tered between the side guides. As you do so, make sure the

leading edge of the material moves into the transfer section of

the vacuum base unobstructed.

4. Check to make sure the material is still under the hold-down

bearings and also resting on the vacuum base transfer section.

5. Trap the feeder in-between the side guides until they gently

touch. Tighten side guide knobs.

9Value SerieS V-710DM Manual

STEP 8:

Miscellaneous

Feeder Adjustments

Figure 2-7. Location of Variable Speed Control

Feeder motor stops if turned completely

counterclockwise.

1. Position photo-eye pointing up and away from all objects for

continuous operation.

2. Set the variable speed control (Figure 2-7) to the lowest speed

(counterclockwise). Gradually increase the speed to match the

speed of the vacuum base, thus bringing the gap of the mate-

rial closer together.

10

Value SerieS V-710DM Manual

Installation of the V-710DM Universal Friction Feeder onto the back

deck plate of an inserter is a relatively simple procedure. Several

minor modications to the selected insert station are required prior to

mounting, wiring, and aligning the feeder.

To install the feeder, perform the following steps:

1: Removing rear guide assembly

2: Removing T-plate

3: Repositioning separator foot

4: Removing suction cup and closing off vacuum hose

5: Repositioning insert guide tabs

6: Installing feeder hold-down spring assemblies

7: Aligning feeder with insert station

8: Securing feeder to inserter

9: Installing support pedestal

10: Providing AC power to feeder

11: Initial feeder photo sensor positioning

STEP 1:

Removing Rear

Guide Assembly

At the selected insert station, remove the fasteners that hold the

inserter rear guide assembly to the inserter back deck plate. Lift rear

guide assembly off of back deck plate (Figure 2-8).

Figure 2-8. Removing Guide Assembly Rear from Inserter

Rear guide

assembly

2B:

Inserter Installation

11 Value SerieS V-710DM Manual

STEP 2:

Removing T-Plate

With the rear guide assembly removed, you can now access the in-

serter T-plate. Simply lift off of back deck plate (Figure 2-9).

Figure 2-9. Removing T-Plate from Inserter

T-plate

STEP 3:

Repositioning

Separator Foot

1. Locate the separator foot at the front side of the inserter sta-

tion (attached to top rotating shaft).

2. With a screwdriver, loosen the inserter separator foot and tilt

away slightly from insert station assembly (opposite feeder)

so that foot does not interfere with material being fed (Figure

2-10).

3. Retighten to secure.

Figure 2-10. Repositioning Separator Foot at Front of Inserter

Separator foot

12

Value SerieS V-710DM Manual

STEP 4:

Removing Suction Cup

and Closing Off Vacuum

Hose

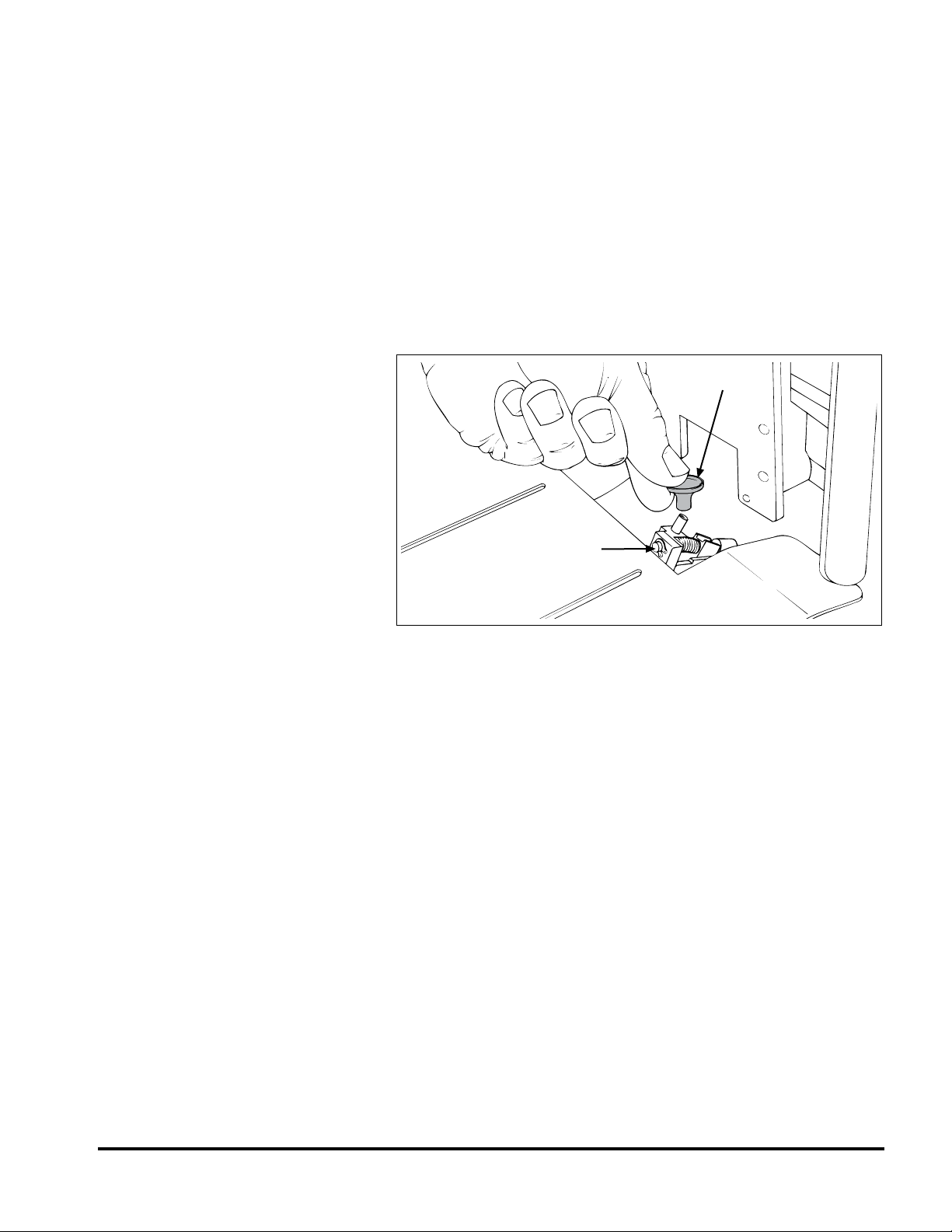

1. Locate the suction cup and hose from front side of insert sta-

tion.

2. Remove suction cup from vacuum assembly (Figure 2-11).

3. Lower and tilt the adjustable vacuum assembly forward (by

turning the built-in thumbscrew). The vacuum assembly may

be moved down and to one side if it interferes with the mate-

rial being fed.

4. Close off the vacuum hose opening; any convenient plugging

method will do.

Figure 2-11. Removing Suction Cup from Vacuum Assembly

Suction cup

Vacuum assembly

13 Value SerieS V-710DM Manual

STEP 5:

Repositioning

Insert Guide Tabs

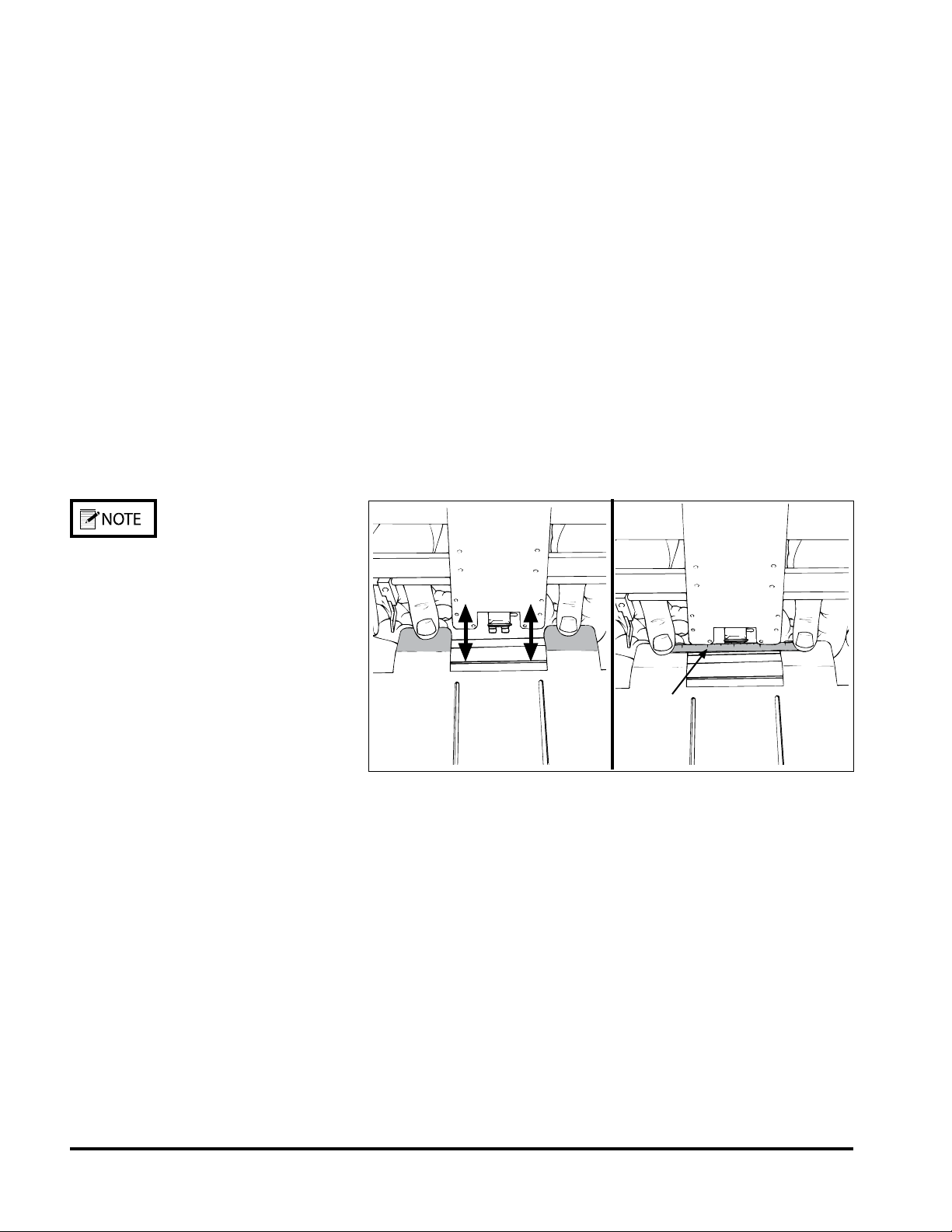

1. Cycle the inserter until the gripper arm jaw is approximately

.5 in. (12.7 mm) from the hopper plate (leading edge of mate-

rial exiting feeder stops here).

2. Locate the two insert guide tabs that protrude from under

the back deck plate. Bend these tabs as required (either up or

down) until their top surface is slightly above the bottom of

the gripper arm jaw (Figure 2-12A). The material to be run

will rest on these tabs. The bottom of the gripper arm jaw

must pass under the material without making contact with it.

3. As it is important that there be adequate clearance between the

guide tabs surface and the gripper jaw, use a at, thin rule (or

gauge) to test for clearance (Figure 2-12B). Ideally, the grip-

per jaw should be fully open when testing.

4. Center the gauge on the guide tabs and slide the gauge back

and forth on the tabs, making sure the gripper jaw does not

touch the bottom of the gauge (Figure 2-12B).

Figure 2-12. Repositioning Guide Tabs and Testing for

Clearance

Mailcrafters' inserters only:

Remove the two insert guide tabs that protrude

from the back deck plate. Make a bend in each

tab approximately 1.375 in. (34.9 mm) from the

tip by placing the tab approximately 1.375 in.

(34.9 mm) into the rear guide assembly. Bend

the tab slightly and repeat same for second tab.

Reinstall insert guide tabs to back deck plate.

Ruler or

gauge

A B

This manual suits for next models

1

Table of contents

Other Thiele Industrial Equipment manuals

Thiele

Thiele TWN 1340/1 User manual

Thiele

Thiele TWN 0796 User manual

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele TWN 0850/1 User manual

Thiele

Thiele TWN 1450 User manual

Thiele

Thiele TWN 0119 User manual