Thiele Streamfeeder Reliant 3700 User manual

Product Guide

Reliant 3700

Part Number: 00900383

© 2007 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent of

Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

103 Osborne Road

Minneapolis, MN 55432-3120 USA

Tel:763.502.0000

Fax:763.502.0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

Streamfeeder Reliant 3700

Universal Friction Feeder

i

Product Guide

Contents

Before You Begin .........................................................iv

Who Should Read This Manual ............................................................................... iv

How This Manual is Organized ............................................................................... iv

Message Conventions .............................................................................................. vi

Safety...........................................................................vii

Danger .................................................................................................................... vii

Warnings ................................................................................................................. vii

Cautions ................................................................................................................. viii

Labeling ................................................................................................................... ix

Electrical Noise........................................................................................................ ix

Safety Listings and Certifications............................................................................ ix

Specifications ........................................................................................................... x

Section 1: About the Machine........................................................1

Features..................................................................................................................... 1

Main Assemblies .............................................................................................. 1

Control Panel Components ............................................................................... 3

Section 2: Preparing for Operation ...............................................5

Step 1: Gate Assembly Adjustment .......................................................................... 5

Changing from Factory Set High-Tension to Low-Tension ............................. 8

Step 2: Side Guides Setting ...................................................................................... 9

Step 3: Back Wedge Adjustment ............................................................................ 11

Step 4: Top Roller Hold-Down Assembly Setting.................................................. 14

Step 5: Photo Sensor Adjustment ........................................................................... 15

Step 6: Manual Test to Verify ................................................................................. 17

Section 3: How to Operate ...........................................................19

Sequence of Operation............................................................................................ 19

Step 1 — Loading Material in the Hopper ..................................................... 19

Step 2 — Determining Stack Height .............................................................. 20

Step 3 — Powering On Feeder ....................................................................... 20

Step 4 — Setting/Adjusting Speed ................................................................. 21

Step 5 — Running Test Cycles ....................................................................... 21

Step 6 — Final Check..................................................................................... 21

Clearing a Jam ........................................................................................................ 22

Shutdown ................................................................................................................ 22

ii Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Contents

Section 4: Operational Troubleshooting .....................................23

No AC Power to Feeder .......................................................................................... 23

Feeding Doubles ..................................................................................................... 23

Continuous Feeding ................................................................................................ 23

Feed Belts Are Operating, But Material Not Feeding ............................................ 23

Feed Belt(s) Not Tracking on Rollers ..................................................................... 24

Jamming Occurs During Operation ........................................................................ 24

Material Skewing.................................................................................................... 24

Material Too Far from Gripper Jaw (Inserter Applications Only) .......................... 24

Material Too Deep in Gripper Jaw (Inserter Applications Only) ........................... 24

Section 5: Inspection and Care ...................................................25

Visual Inspection .................................................................................................... 25

Checking for Feed and Discharge Belt Wear.................................................. 25

Checking for Timing and Drive Belt Wear ..................................................... 25

Ensuring Proper Feed and Discharge Belt Tracking ...................................... 26

Ensuring Proper Timing and Drive Belt Tracking .......................................... 26

Checking for Gate Assembly Wear................................................................. 27

Advancing O-Ring Gate: Adjusting Worn Rings ........................................... 28

Standard O-Ring Gate: Adjusting Worn Rings ............................................... 28

Replacing Worn Angled Wedge ...................................................................... 28

Preventive Care....................................................................................................... 29

Cleaning Feed and Discharge Belts ................................................................ 29

Cleaning Gate Assembly ................................................................................ 30

Cleaning Photo Sensor ................................................................................... 31

Section 6: Additional Wedges .....................................................33

Load Compensating ................................................................................................ 33

Articulating Roller .................................................................................................. 34

Extended Narrow .................................................................................................... 34

Combination Triangle and Low-Profile .................................................................. 35

Separate Triangle and Low-Profile ......................................................................... 35

Separate Articulating Roller and Low-Profile ........................................................ 36

Streamfeeder Reliant 3700

Universal Friction Feeder

iii

Product Guide

Section 7: Mechanical Components ...........................................37

Low Profile Wedge ................................................................................................. 38

Single S Wedge ....................................................................................................... 40

1 Knob Gate Plate ................................................................................................. 42

Advancing O-Ring Gate with Horizon Adjust and Cover ...................................... 44

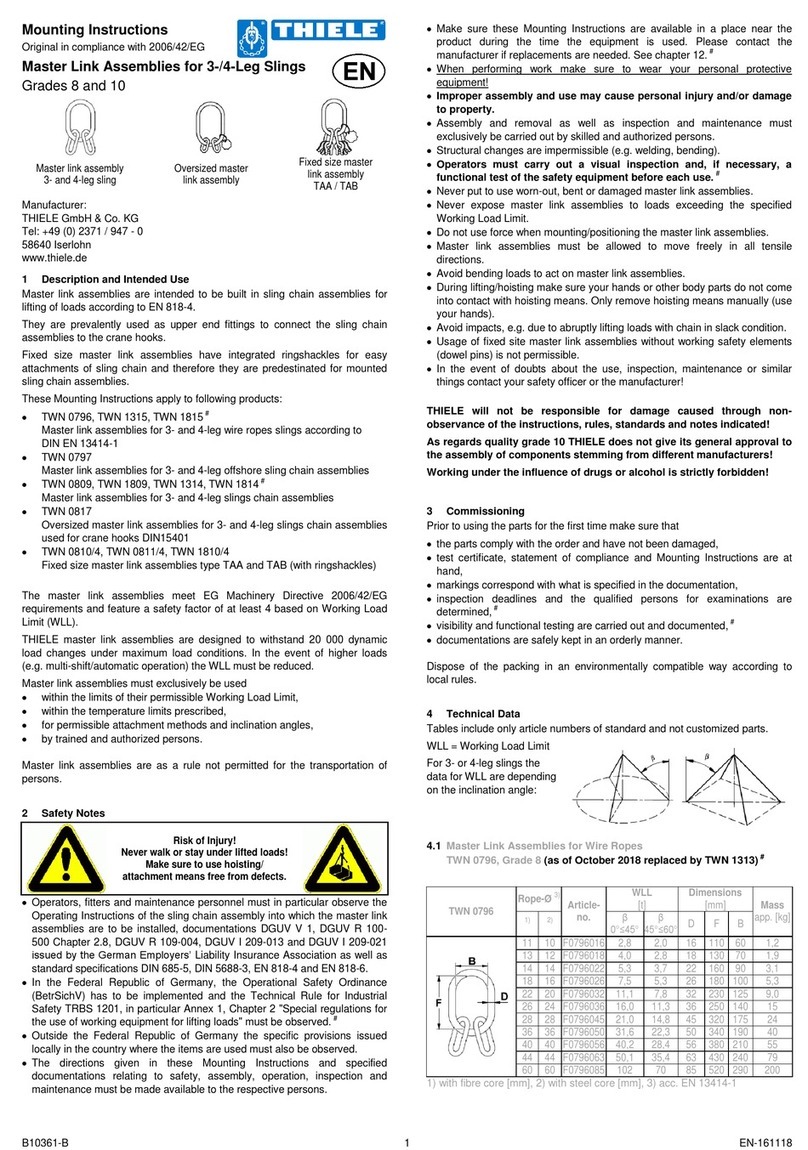

Grooved Gum Carriage .......................................................................................... 46

Hold Down ............................................................................................................. 48

Electrical Components ............................................................................................ 50

Base Features 1 ....................................................................................................... 54

Base Features 2 ....................................................................................................... 56

Section 8: Electrical Components ...............................................59

Electrical Wiring Diagram ...................................................................................... 59

Miss Detect Detail .................................................................................................. 60

Double Detect Option Detail .................................................................................. 61

E-Stop Option ......................................................................................................... 62

Power Entry Module............................................................................................... 63

DC Stepping Motor ................................................................................................ 64

Unipolar DC Stepping Motor Drive Board ............................................................ 65

CPU Board Detail ................................................................................................... 66

EPROM Replacement ............................................................................................ 67

Fault Output; How to Configure............................................................................. 68

Optional Burn-Thru Double Detection Calibration Procedure............................... 69

iv Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Section 9: Technical Troubleshooting ........................................71

General Troubleshooting Terms ............................................................................. 71

Gaining Access to the Electronics .......................................................................... 72

Wiring Diagrams .................................................................................................... 72

The Fault Lamp Reset Buttton ............................................................................... 72

Quick-Look Troubleshooting ................................................................................. 73

No Power to Feeder When Power Switch is Turned On .............................. 73

Fuses Blow on Power Up ............................................................................. 73

Decreased Power Experienced After Fuse is Replaced ................................ 74

Decreased Power Experienced After Drive Board is Replaced .................... 74

Motor Does Not Run, is Noisy, Makes a "Growling" Sound or

Runs in Reverse .................................................................................. 74

Drive Board Red LED Illuminated ............................................................... 75

Testing Stepper Motor Drive Board Output Pins ......................................... 75

Fan Does Not Operate/Testing DC Power Supply ....................................... 76

CPU Board "Heartbeat" Pulse Not Present .................................................. 76

On/Off Beeping Sound is Heard................................................................... 77

Steady Beep is Heard.................................................................................... 77

Feeder Will Not Cycle .................................................................................. 79

Testing the Fault Output Connector .............................................................. 80

Testing Motors .............................................................................................. 80

Testing the Transformer ................................................................................ 81

Warranty

Streamfeeder Reliant 3700

Universal Friction Feeder

v

Product Guide

Before You Begin

Who Should

Read This Manual

Welcome to Streamfeeder. This manual was included with your new

Streamfeeder Reliant 3700 Universal Friction Feeder. It provides all

the information you need to efficiently operate and maintain the

product.

This manual is primarily intended for operators who will be using the

Reliant 3700 Universal Friction Feeder in their day-to-day operations.

Please read it thoroughly before you operate the machine.

Qualified technicians should also be familiar with the information in

this manual.

This manual is divided into the following main areas:

•“Safety”: This section is at the front of this manual for good

reason. It covers all safety issues that you should be familiar with

before you go any further with adjustments, power-up, or operation.

• Section 1, “About the Machine”: Introduces you to the feeder. It

provides a complete description of all controls, connectors, and

sensors.

• Section 2, “Preparing for Operation”: Includes all adjustments

you should make before attempting to do a power-up and

successfully run material through the machine.

• Section 3, “How to Operate”: Walks you through the basic steps

needed to run the machine — from power-up to shutdown.

• Section 4, “Operational Troubleshooting”: Gives you the basic

diagnostic information you need to quickly and accurately solve

problems to minimize downtime.

• Section 5, “Inspection and Care”: Covers all the steps you can

take to keep your feeder running properly to minimize downtime

and increase longevity of parts.

• Section 6, “Additional Wedges”: Contains information about the

setup and use of parts which are optional on the Reliant 3700.

• Sections 7 and 8, “Mechanical Components” and "Electrical

Components": These sections contain extensive detailed

information for qualified technicians responsible for servicing and

maintaining the Reliant 3700.

• Section 9, “Technical Troubleshooting”: Gives you the basic

diagnostic information you need to quickly and accurately solve

problems to minimize downtime.

How This Manual

Is Organized

The information in Sections 4 and 9 is designed

to be a quick and easy method for the operator to

minimize downtime. Streamfeeder does not

recommend opening the feeder compartment, or

performing any part replacement based on the

information given in this manual. For more

detailed information, please consult with a

qualified technician.

NOTE

vi Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Before You Begin

Message

Conventions

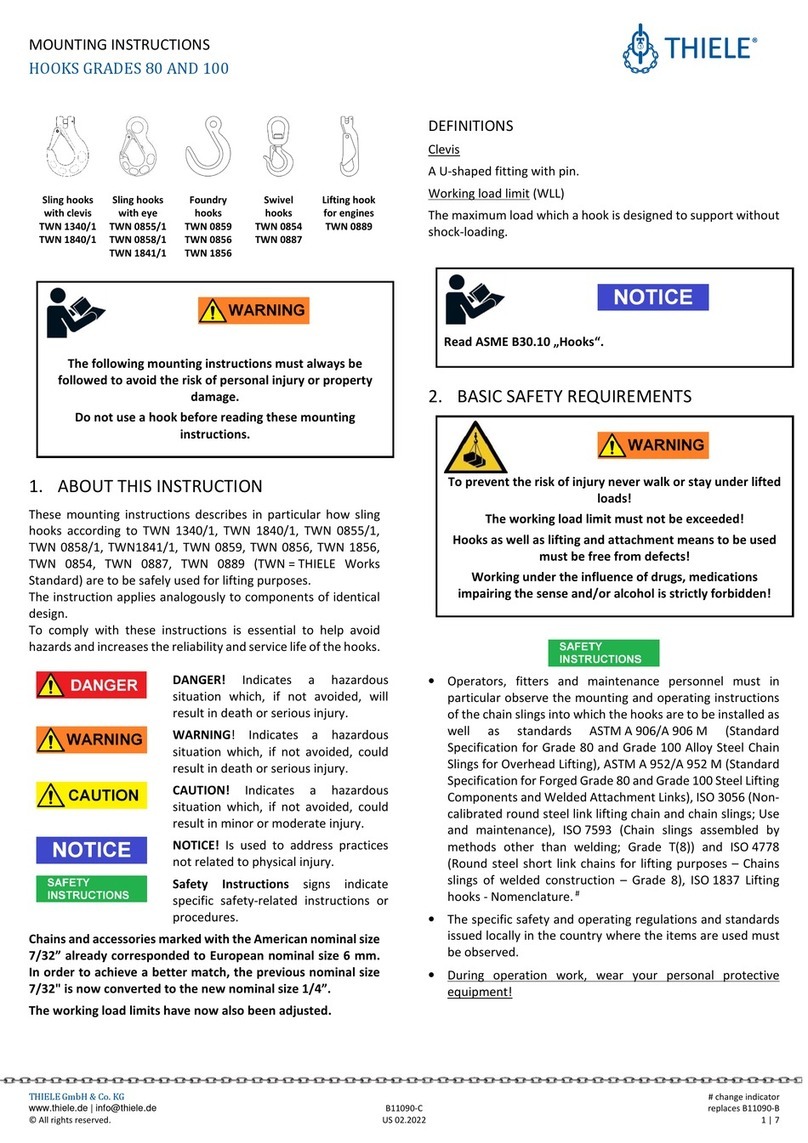

Here are eight types of messages that appear in this manual which

help emphasize information of particular interest:

DANGER signifies an operator action or specific equipment area that

can result in serious injury or death if proper precautions are not taken.

WARNING signifies an operator action or specific equipment area

that can result in personal injury if proper precautions are not taken.

CAUTION signifies an operator action or specific equipment area that

can result in equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signifies an operator action or specific

equipment area that can result in personal injury or death from an

electrical hazard if proper precautions are not taken.

TIP signifies information that is provided to help the operator mini-

mize problems in the operation of the machine.

NOTE provides useful additional information that the operator should

be aware of to perform a certain task.

CHECK signifies an action that should be reviewed by the operator

before proceeding.

IMPORTANT signifies alerting the operator to actions that can

potentially lead to operational problems or equipment damage if

instructions are not followed properly.

!

!

!

TIP

NOTE

CHECK

IMPORTANT

Streamfeeder Reliant 3700

Universal Friction Feeder

vii

Product Guide

Make sure you thoroughly read this Section until you become familiar

with all the safety issues relating to the safe operation of this machine.

Please read all of the Warnings that follow to avoid possible injury.

Although Streamfeeder has made every effort to incorporate safety

features in the design of this machine, there are residual risks that do

exist that an operator should be aware of to prevent personal injury.

Please read all of the Cautions that follow to prevent damage to the

machine. The Reliant 3700 Universal Friction Feeder is built with the

highest quality materials. However, damage can occur if the machine

is not operated and cared for within design guidelines as

recommended by Streamfeeder.

•Equipment interior contains incoming 120- or 240-VAC

electrical power. Bodily contact with these high voltages can

cause electrocution, which can result in serious injury or death.

•When operating the feeder, always make sure the discharge

safety shield is in the closed position (covering the discharge

belts and rollers). Failure to do so may expose your hands or

fingers to moving parts which can cause serious injury.

•When performing service or maintenance on the feeder, always

lift the discharge safety shield to disengage the safety interlock,

turn Off the main power switch, and disconnect the feeder from

the electrical power source. Failure to do so may expose you to

dangerous high voltage or moving parts which can cause serious

injury.

•When performing initial adjustments prior to operation, always

make sure you lift the discharge safety shield to disengage the

safety interlock, turn Off the main power switch, and

disconnect the feeder from the electrical power source. Failure

to do so may expose you to a potential start-up and moving parts

which can cause serious injury.

•Make sure you always plug the machine into a 3-prong,

properly grounded and fused electrical power source. Never

remove or disable the grounding lug at the outlet. Failure to follow

these warnings may expose you to dangerous high voltage which

can cause serious injury.

Safety

Danger

Warnings

!

!

viii Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

•Do not attempt to make any adjustments while the machine is

running. Failure to follow this warning may expose you to moving

parts which can cause serious injury.

•Never attempt to clear a jam from the machine until you turn

Off the main power switch and disconnect the machine from

the electrical power source. Failure to do so may expose you to a

potential start-up and moving parts which can cause serious injury.

•Do not attempt to gain access to the inside of the feeder. Refer

all questions or problems to a qualified technician.

•When the machine is not in use, avoid stacking or storing

materials on the carriage assembly to prevent damage to the

belts.

•When replacing fuses, always use the exact type supplied with

the machine as shipped from the factory. IMPORTANT: Always

make sure power module is replaced exactly as removed.

Failure to follow this caution can result in damaged electrical

parts.

•When performing routine cleaning of parts, only use those

methods and cleaning solvents (isopropyl alcohol) which are

specified by Streamfeeder. Failure to do so may cause

unpredictable results and can cause damage to machine parts. See

Section 5, Inspection and Care, for recommendations.

•Do not attempt to use the machine for any other purpose other

than what was recommended by Streamfeeder. Failure to follow

this caution may cause unpredictable performance, and/or can cause

damage to machine parts.

•Avoid leaving any loose cabling near any moving parts. Failure

to follow this caution may result in damage to machine parts.

•Avoid any type of direct impact to the sensor and extension

assembly. Failure to follow this caution will cause damage to the

photo sensor or extension.

•Do not apply lubricants to any part of the machine.

• Do not attempt to gain access to the inside of the feeder. Do not

attempt to remove and replace parts. Refer all questions or

problems to a qualified technician.

Warnings

(cont.)

!

Cautions

!

Streamfeeder Reliant 3700

Universal Friction Feeder

ix

Product Guide

Electrical Noise

Labeling

The air contains electromagnetic interference (EMI) fields and radio

frequency interference (RFI), also known as “electrical noise.”

Usually this noise is small enough in size (amplitude) to not be a

problem. If intense enough, however, it can cause problems for other

electrical equipment.

Streamfeeder has designed the feeder with noise immunity in mind.

Even the sensors provided with the machine have a certain amount of

noise immunity built-in. However, in extremely noisy environments,

these design considerations are not necessarily immune to electrical

noise and therefore, operational problems can occur. If you suspect

any such electrical noise problems, please report it to a qualified

technician.

Streamfeeder has affixed safety labels to those areas of the Reliant

3700 Universal Friction Feeder where potential operator hazards do

exist (such as moving belts or rollers). Shown below are label

examples, along with their respective locations.

Safety Listings and

Certifications

This symbol on the back panel means the product is in

compliance with the following standards under the

provisions of the Machinery Directive 89/392/EEC

and the amendments 91/368/EEC, 93/44/EEC and

93/68/EEC, and the EMC Directive 89/336/EEC.

Discharge

Safety Shield

Feed Belt

Guards

xStreamfeeder Reliant 3700 Universal Friction Feeder

Product Guide

Maximum Product Size: 11.75 in. W x 14 in. L(298.5 cm x 355.6 mm)

Minimum Product Size: 3.75 in. W x 3.75 in. L(95.3 cm x 95.3 mm)

Optional: 2 in. W x 2.5 in. L(50.8 cm x 63.5 mm)

Min/Max Product Thickness: .003 in. to 1 in. (.076 mm to 25.4 mm)

Speed: 5700 in/min (144,780 mm/min)

Batch Size: 1 to 99 pieces

Modes: One shot or batch count

Electrical Requirements: 115/230vac, 50/60 Hz, 3A

Weight: 75 lb. (34 kg)

Warranty: One-year limited

6SHFL¿FDWLRQV

Streamfeeder Reliant 3700

Universal Friction Feeder

1

Product Guide

1About Your Machine

The Reliant 3700 Universal Friction Feeder is designed for reliability,

flexibility, and ease of use with a variety of host systems. Included are

such applications as gripper arm envelope inserters and infeed

conveyors for various wrapping machines.

All parts required for setup, loading, feeding, sensing and easy

operator control are combined into one compact unit.

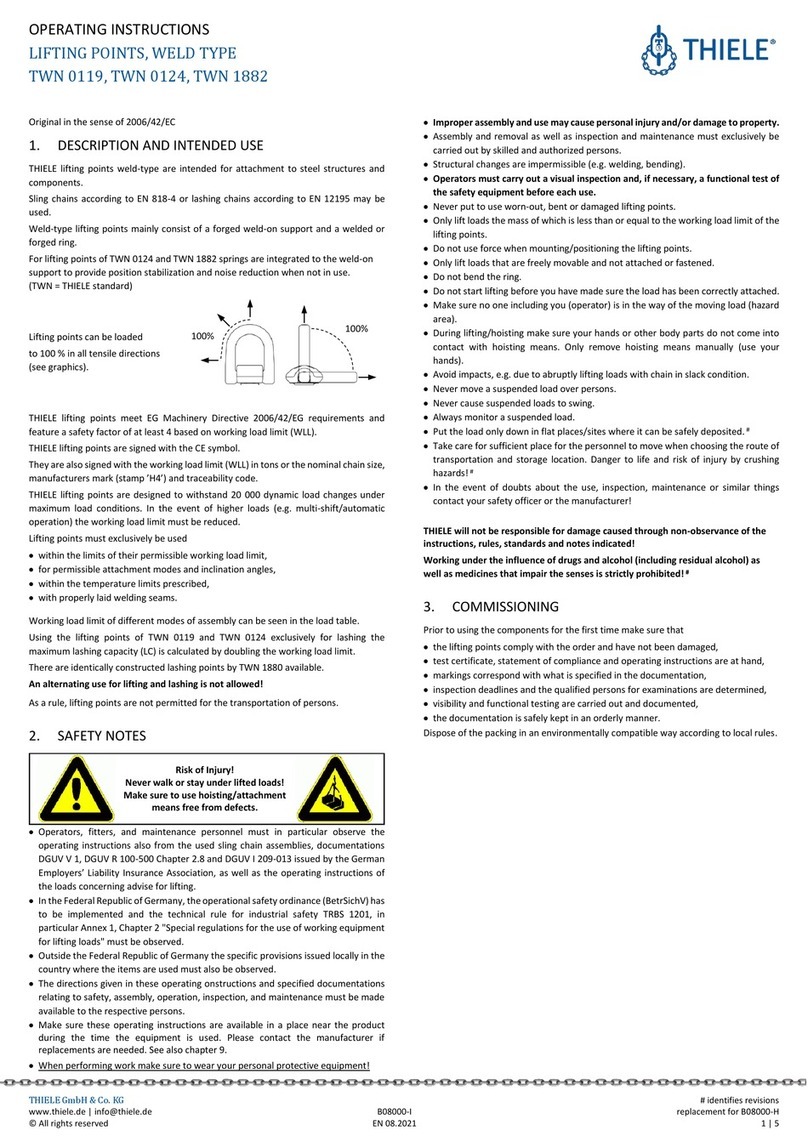

Review the main assemblies in Figure 1-1 to become familiar with

names and locations of feeder parts and adjustments. This will help to

prepare you for initial setup. Descriptions are found in Table 1-1.

Review the control panel components in Figure 1-2 to become

familiar with names and locations of specific connectors, switches,

and controls. This will help to prepare you for installation and

operation. Descriptions are found in Table 1-2.

AC Power

Cord

Figure 1-1. Main Assemblies of the Reliant 3700 Universal Friction Feeder

• Feeders can be configured two ways: one-shot

mode or batch count mode.

•One-shot mode feeders are capable of feeding

one piece of material when a flight signal is

received.

•Batch count mode feeders are capable of

feeding 1-99 pieces of material when a flight

signal is received.

• For purposes of illustration, a batch count

feeder is shown in all drawings of this manual.

NOTE

Features

Main Assemblies

Not Shown:

• Side Guides (2)

• Fault Output I/O Cable

• Low Profile Wedge

Flight-Detect

Sensor

Loose Parts Supplied When Shipped

Side Guides

(adjustable)

Control Panel

(this side)

Table Top

Photo Sensor and Flexible Extension

Discharge Belts

Discharge Safety

Shield

Top Roller

Hold-Down Assembly

(adjustable)

Gate Assembly

and Adjustment

Single S Wedge

and Adjustments

Feed Belts

2Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Gate assembly and adjustment Mounted on a gate bracket assembly above the feed belts, this device

provides a curvature to help preshingle stacked material. When properly

adjusted, a clearance is created to help singulate and feed material.

(Note:

For multiple page material, a 1 to 1.5 maximum thickness is typical.)

Table top Used to support the back wedge.

Side guides (adjustable) Holds a stack of material to be fed and helps keep it straight for proper

entry through the gate assembly area. Single adjustment knob allows you

to move side guides together or apart for different size material. Can be

positioned equally or offset.

(Note: Dual-knob design also available.)

Back wedge and adjustment Lifts the material to keep it off the table top, reduces excessive contact

with the feed belts, and helps push the material against the curvature of

the gate assembly. To achieve proper lift, adjustment wing-nuts and

locking levers allow you to slide the wedge to various positions and

angles.

Photo sensor and flexible extension Also called a

sheet-detect

photo sensor, it “looks” for the leading edge of

the material to stop the feeder. For optimum setting, a flexible extension

allows you to adjust for distance and perpendicular angle to material.

Feed belts and discharge belts

Feed belts:

Provides the friction and motion necessary to pull individual

material from the bottom of the stack and through the gate assembly area.

Discharge belts:

Combined with the top roller hold-down assembly,

provides the friction and motion necessary to pull material away from the

gate assembly area.

Top roller hold-down assy (adjustable) A block of small rollers mounted on a movable shaft. Used to gently force

the material down on the discharge belts so that it can be controlled after it

exits the gate assembly area. To achieve proper downward pressure,

T-nuts allow you to loosen the shaft to adjust block up or down.

Control panel All connectors and switches for sensor, interface, and AC power are

located here. For descriptions, see Figure 1-2 and Table 1-2.

Discharge safety shield Provides residual risk protection to operator when feeder is running.

Built-in interlock switch stops the feeder when opened.

LOOSE PARTS

AC power cord, 8 ft. (2.44 m) IEC320 removal three-prong. Shipped loose.

Flight-detect sensor Mounted at a remote location. It "looks" for a target on-line (such as a

hold-down ski or conveyor lug) to start the feeder.

Fault output I/O cable Provides the interface for host system integration.

Product Description Section 1

Table 1-1. Main Assemblies Feature Descriptions

Feature Description

Streamfeeder Reliant 3700

Universal Friction Feeder

3

Product Guide

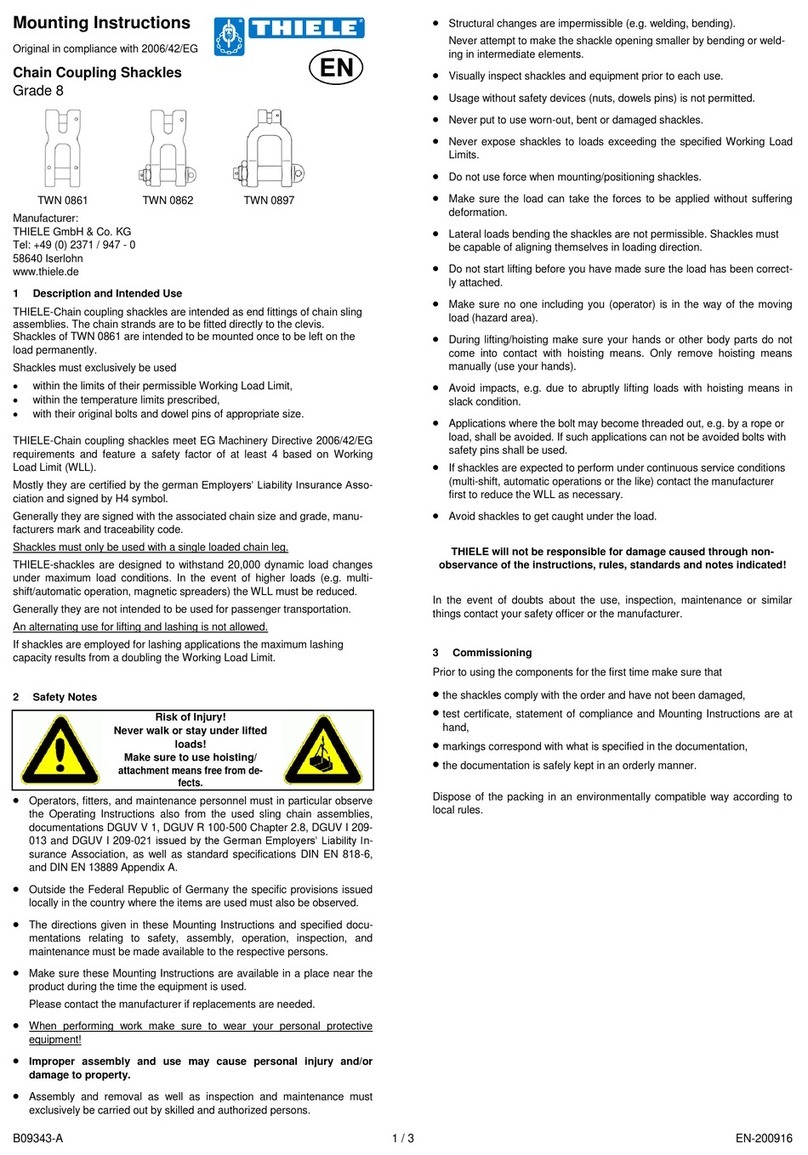

Figure 1-2. Control Panel Components

Control Panel Components

AC Power

Cordset

Connector

Power On/Off

Fuse Holder

Batch Count

Thumbwheels

(Optional)

Cycle

Button

Variable

Speed

Control

Feed/Flight

Trigger

Connector

Reset Button/

Fault Indicator

03

CYCLE

-+

SPEED

4Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Feature Description

AC power cordset connector Cordset plugs into this IEC320 connector to provide feeder with power

from a grounded/fused outlet. Switchable for either 115- or 230-VAC.

Feed/flight trigger connector The remote flight-detect sensor plugs into this 4-pin connector to provide

the “start” signal to begin a feed cycle.

Power On/Off Toggles AC power On or Off.

Fuse holder Contains two replaceable GMD3, 3-Amp, 5-mm fuses.

IMPORTANT:

Always make sure power module is replaced exactly as removed. Failure

to follow this caution can result in damaged electrical parts.

Reset button/fault indicator Labeled Reset, the primary purpose of this pushbutton switch/indicator is

to reset the feeder after: 1) a “time-out” occurs or, 2) the discharge safety

shield is opened or, 3) "miss-feed" occurs. Time-outs occur: 1) during a

misfeed or, 2) when the hopper runs out of material; or 3)

flashing

during

"miss" condition. Built-in indicator illuminates: 1)

steady

during a time-out

condition; 2)

flashing

during an “open” discharge safety shield.

Variable speed control This dial switch (labeled Speed) allows the feeder speed to be

synchronized with an inserter, or infeed conveyor. Turning counter-

clockwise decreases speed; clockwise increases speed.

Cycle button This pushbutton switch (labeled Cycle) is primarily used during

preparation and test, this is used to manually start (or run) a feeder cycle.

To “start” a cycle, push Cycle completely in and then release.

Batch count thumbwheels (optional)

Note: Batch count feeders only.

These two wheels allow you to select a

number from 1 to 99 to which the feeder will always count and then stop.

Fault ouput connector (not shown) The fault output I/O cable plugs into this connector to provide the host

system interface.

Fault configuration selector switch This switch allows the operator to select between stopping the feeder

(not shown) or sounding an alarm only when a fault is detected.

Table 1-2. Control Panel Feature Descriptions

Streamfeeder Reliant 3700

Universal Friction Feeder

5

Product Guide

2Preparing for Operation

!

!

!

When performing initial feeder adjustments

prior to operation, always make sure you turn

Off the main power switch and disconnect all

equipment from the electrical power source.

Failure to do so can expose you to a potential

startup and moving parts which can cause

serious injury.

Do not attempt to make any adjustments while

the feeder and machine of application are

running. Failure to do so can expose you to

moving parts which can cause serious injury.

Do not wear loose clothing when operating the

feeder.

Avoid making adjustments with loose or

unsecured parts. This can potentially damage

parts.

STEP 1:

Gate Assembly

Adjustment

Review

The gate assembly provides the curvature to help preshingle material

and the proper gap to help the feed belts pull material through the gate

assembly area — one at a time. The downward pressure (or weight) of

the stack in the hopper will provide the force to help push the material

against the curvature of the gate assembly, and help it contact the feed

belts. This preshingling will allow the gate assembly to efficiently

separate (and singulate) material.

To achieve the optimum separation, you have to use the adjustment

knob to either increase (clockwise) or decrease (counterclockwise) the

gap between gate assembly and the feed belts. Depending on the

characteristics of the material you are using, you may have to change

the gate assembly from the factory-set high spring tension to a low

spring tension. See “Changing from Factory Set High-Tension to

Low-Tension” to follow (page 7).

Objective

Adjust the gate assembly for minimum gap, with minimum pressure

on the material. Your objective is to adjust the clearance so that a

single piece of material passes without resistance. The optimum

setting should be a gap adjustment of 1.5 thickness of material.

NOTE

NOTE

Keep in mind the gate assembly works with the

wedge to provide the proper lift, curvature of the

material, and proper belt/material contact to

separate and feed one piece at a time.

Hopper refers to the space where the material is

stacked (made up of the side guides).

IMPORTANT

Feeding problems will occur with either too much

material in the hopper, or too large a gap

between the gate assembly and the material.

Once the Streamfeeder Reliant 3700 Universal Friction Feeder is

installed on your host system, you are ready to prepare the machine

for operation. To do so, you must perform several adjustments with

the material you are going to be feeding. And, you must do a test run

with this material to verify it is set correctly before you begin cycling

the feeder with your particular application. You will have to perform

this procedure for material you plan to feed.

The adjustments you must make (in order) are as follows:

1: Gate assembly adjustment

2: Side guides setting

3: Back wedge adjustment

4: Top roller hold-down assembly setting

5: Photo sensor adjustment

6: Manual test to verify

6Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Preparation and Adjustments Section 2

Procedure

To adjust the gate assembly for proper gap, follow these steps:

1. Slide two pieces of sample material under the gate assembly.

You may have to pull up on the adjustment knob to allow the

material to be inserted (Figure 2-1).

2. Test the top piece for clearance. Grasp with two hands and

slide it front-to-back under the gate assembly (Figure 2-2). A

proper adjustment allows a “slight” amount of drag on the top

piece of material.

3. With the top piece removed, test the bottom piece of material

for clearance. It should move freely, without any resistance.

4. Adjust the knob on the gate assembly until the material has

the desired drag: clockwise to increase clearance,

counterclockwise to decrease clearance (Figure 2-3).

5. Remove the top piece and turn the adjustment knob

counterclockwise 1/4 turn to lower the gate assembly. This

should set the gap for the optimum 1.5 thickness of material.

6. Repeat drag tests and adjust as needed until the desired

clearance is achieved.

STEP 1:

Gate Assembly

Adjustment

(continued)

!

Excessive lowering of the gate assembly can

damage material or lead to premature wear of the

O-rings or feed belts.

Figure 2-1. Lifting Gate Assembly Upward to Insert Material

Figure 2-2. Using Two Pieces of Material to

Set Gap

Figure 2-3. Adjusting Gate Assembly for Correct

Gap

TIP

A wider gap between material and belt provides

the highest tolerance for curled and bent edges.

L

O

W

E

R

If bottom piece of material does not move freely,

then the gate assembly is too tight. This can lead

to premature wear of the O-rings or feed belts.

Pull knob up

Slip sheet of

product under

gate assembly

Move

product

front to back

test for

slight drag

Turn knob

counter-

clockwise to

lower (or

decrease

gap)

Streamfeeder Reliant 3700

Universal Friction Feeder

7

Product Guide

STEP 1:

Gate Assembly

Adjustment

(continued)

NOTE

When feeding product with varying thickness

throughout, it may be necessary to turn both

adjustment rollers 1-2 full turns

counterclockwise to compensate for the

differential thickness. This procedure allows the

gate horizon to “float.”

IMPORTANT

The adjustment knob set screws are pre-set at the

factory to lock the knob to the threaded rod. DO

NOT OVER-TIGHTEN! Over-tightening the set

screws may damage the components.

To adjust the gate for effective material skew control, follow these

steps:

1. Repeat drag test.

2. Test the piece for uneven side-to-side drag. Grasp with two

hands and slide it front-to-back under the gate assembly. A

proper adjustment allows for equal drag on the left and right

sides of the piece of material.

3. To compensate for greater drag on one side of the material,

turn the opposite adjustment roller counterclockwise 1/8 turn.

Next, turn the other adjustment roller clockwise 1/8 turn.

4. Repeat drag tests and adjust as needed until equal drag is

achieved. You may need to repeat this procedure after

observing the feeder cycling (refer to Section 3, How to

Operate).

Figure 2-4. Horizon Adjustment (shown on Advancing O-Ring

Gate)

8Streamfeeder Reliant 3700

Universal Friction Feeder

Product Guide

Review

The Reliant 3700 is shipped to you with a high-tension spring in the

gate assembly. This works well for most materials, allows for tall

stack height, and helps provide the best performance in preventing

doubles. However, certain types of material may demand that you

change the gate assembly from a high-tension setting to a low-

tension setting (for example, irregular shaped material).

If you are feeding a material of irregular thickness, you should

change to low-tension. This provides the following benefits:

1) allows the gate assembly to adjust to the irregular thicknesses.

2) prevents marking on the material by the gate assembly.

3) prevents peeling back the top sheet of a multi-page item.

Procedure

To change the spring from a high to a low tension, follow these

steps:

1. Remove the gate assembly from gate bracket assembly. To

do so, pull cylinder down with one hand, lift up on knob

with other, and tip at slight angle to remove.

2. Remove the adjustment knob by turning counterclockwise

(Figure 2-5A). Then lift the cylinder off of top of spring

(Figure 2-5B).

3. Turn the cylinder around so the cylinder collar faces up

(Figure 2-5C). Then place the cylinder on top of the spring.

4. Replace the adjustment knob (make about 8 revolutions of

the knob before reinstalling gate assembly on gate plate).

Changing From

Factory Set

High-Tension to

Low-Tension

IMPORTANT

When changing from a low-tension to high-

tension setting, you may have to adjust the

stack height downward to prevent feeding

problems.

!

Excessive lowering of the gate assembly can

damage material and/or lead to premature

wear of the O-rings or feed belts.

NOTE

Certain types of single-sheet material may

require even more tension than the high-

tension setting can provide. To increase

tension even further, place a washer between

the cylinder and spring.

Washer

C

AB

Figure 2-5. Adjusting Gate Assembly for Low-Tension

Other manuals for Streamfeeder Reliant 3700

1

Table of contents

Other Thiele Industrial Equipment manuals

Thiele

Thiele TWN 0835/1 User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 0119 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele Streamfeeder Value Series User manual

Thiele

Thiele TWN 1450 User manual

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele TWN 0850/1 User manual

Thiele

Thiele TWN 0796 User manual