Thiele TWN 0119 User manual

OPERATING INSTRUCTIONS

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08000-I replacement for B08000-H

© All rights reserved EN 08.2021 1 | 5

100%

100%

Original in the sense of 2006/42/EC

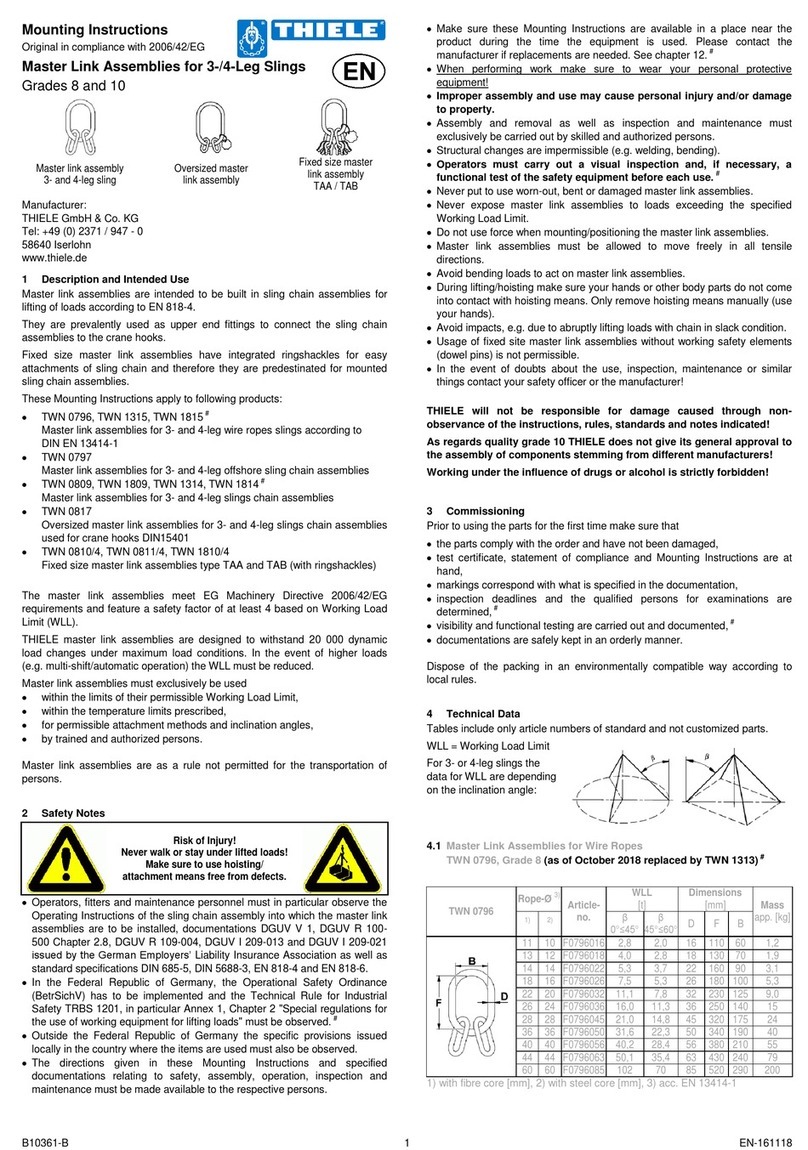

1. DESCRIPTION AND INTENDED USE

THIELE lifting points weld-type are intended for attachment to steel structures and

components.

Sling chains according to EN 818-4 or lashing chains according to EN 12195 may be

used.

Weld-type lifting points mainly consist of a forged weld-on support and a welded or

forged ring.

For lifting points of TWN 0124 and TWN 1882 springs are integrated to the weld-on

support to provide position stabilization and noise reduction when not in use.

(TWN = THIELE standard)

Lifting points can be loaded

to 100 % in all tensile directions

(see graphics).

THIELE lifting points meet EG Machinery Directive 2006/42/EG requirements and

feature a safety factor of at least 4 based on working load limit (WLL).

THIELE lifting points are signed with the CE symbol.

They are also signed with the working load limit (WLL) in tons or the nominal chain size,

manufacturers mark (stamp ’H4’) and traceability code.

THIELE lifting points are designed to withstand 20 000 dynamic load changes under

maximum load conditions. In the event of higher loads (e.g. multi-shift/automatic

operation) the working load limit must be reduced.

Lifting points must exclusively be used

•within the limits of their permissible working load limit,

•for permissible attachment modes and inclination angles,

•within the temperature limits prescribed,

•with properly laid welding seams.

Working load limit of different modes of assembly can be seen in the load table.

Using the lifting points of TWN 0119 and TWN 0124 exclusively for lashing the

maximum lashing capacity (LC) is calculated by doubling the working load limit.

There are identically constructed lashing points by TWN 1880 available.

An alternating use for lifting and lashing is not allowed!

As a rule, lifting points are not permitted for the transportation of persons.

2. SAFETY NOTES

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/attachment

means free from defects.

•Operators, fitters, and maintenance personnel must in particular observe the

operating instructions also from the used sling chain assemblies, documentations

DGUV V 1, DGUV R 100-500 Chapter 2.8 and DGUV I 209-013 issued by the German

Employers’ Liability Insurance Association, as well as the operating instructions of

the loads concerning advise for lifting.

•In the Federal Republic of Germany, the operational safety ordinance (BetrSichV) has

to be implemented and the technical rule for industrial safety TRBS 1201, in

particular Annex 1, Chapter 2 "Special regulations for the use of working equipment

for lifting loads" must be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally in the

country where the items are used must also be observed.

•The directions given in these operating onstructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be made

available to the respective persons.

•Make sure these operating instructions are available in a place near the product

during the time the equipment is used. Please contact the manufacturer if

replacements are needed. See also chapter 9.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if necessary, a functional test of

the safety equipment before each use.

•Never put to use worn-out, bent or damaged lifting points.

•Only lift loads the mass of which is less than or equal to the working load limit of the

lifting points.

•Do not use force when mounting/positioning the lifting points.

•Only lift loads that are freely movable and not attached or fastened.

•Do not bend the ring.

•Do not start lifting before you have made sure the load has been correctly attached.

•Make sure no one including you (operator) is in the way of the moving load (hazard

area).

•During lifting/hoisting make sure your hands or other body parts do not come into

contact with hoisting means. Only remove hoisting means manually (use your

hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be safely deposited. #

•Take care for sufficient place for the personnel to move when choosing the route of

transportation and storage location. Danger to life and risk of injury by crushing

hazards! #

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through non-observance of the

instructions, rules, standards and notes indicated!

Working under the influence of drugs and alcohol (including residual alcohol) as

well as medicines that impair the senses is strictly prohibited!#

3. COMMISSIONING

Prior to using the components for the first time make sure that

•the lifting points comply with the order and have not been damaged,

•test certificate, statement of compliance and operating instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are determined,

•visibility and functional testing are carried out and documented,

•the documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local rules.

OPERATING INSTRUCTIONS

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08000-I replacement for B08000-H

© All rights reserved EN 08.2021 2 | 5

4. TECHNICAL DATA#

4.1 TWN 0119

Nominal

size

WLL

Marking

Dimensions [mm]

Mass

[t]

E1)

F1)

C

L

H

D

B

[kg]

6-8

1,12

1

59

31

32

32

28

12

36

0,24

8-8

2,0

2

69

37

38

38

33

14

42

0,46

10-8

3,15

3

84

46

45

44

38

18

48

0,63

13-8

5,3

5

120

69

60

60

51

24

66

1,9

16-8

8,0

8

127

66

68

65

61

28

72

2,7

22-8

15

15

178

98

96

109

80

39

120

8,1

32-8

31,5

32

292

174

145

165

118

56

180

27,3

40-8

50

50

371

228

186

210

145

72

230

60

1) for vertical orientation

4.2 TWN 0124

Nominal

size

WLL

Marking

Dimensions [mm]

Mass

[t]

E2)

F2)

C

L

H

D

B

[kg]

6-8

1,12

1

56

0,24

32

32

28

12

36

0,25

8-8

2,0

2

67

0,46

38

38

33

14

42

0,43

10-8

3,15

3

81

0,63

45

44

38

18

48

0,72

13-8

5,3

5

117

1,9

60

60

54

24

66

1,9

16-8

8,0

8

122

2,7

68

65

61

28

72

2,8

2) for vertical orientation

4.3 TWN 1882

Nominal

size

WLL/

Marking

[t]

Dimensions [mm]

Mass

A

B

C

D

E3)

F3)

H

L

[kg]

6-10

1,5 t

65

38

50

13

68

42

26

35

0,4

8-10

2,5 t

76

45

50

15

73

46

27

42

0,57

10-10

4,0 t

85

50

56

17

87

56

31

46

0,84

13-10

6,7 t

116

68

78

23

122

78

44

63

2,2

16-10

10 t

130

69

92

27

126

72

54

63

3,4

3) for vertical orientation

4.4 Article numbers #

Type

Nominal

size

Article no. 4)

Article no.4,5)

TWN 0119

6-8

F35103

F35103A

8-8

F35113

F35113A

10-8

F35123

F35123A

13-8

F35133

F35133A

16-8

F35143

F35143A

22-8

F35163

-

32-8

F35183

-

40-8

F35193

-

TWN 0124

6-8

F35107

-

8-8

F35110

-

10-8

F35124

-

13-8

F35139

-

16-8

F35144

-

TWN 1882

6-10

F352041

F352041A

8-10

F352051

F352051A

10-10

F352061

F352061A

13-10

F352071

F352071A

16-10

F352081

F352081A

4) Standard article numbers, no customized editions

5) Edition for USA

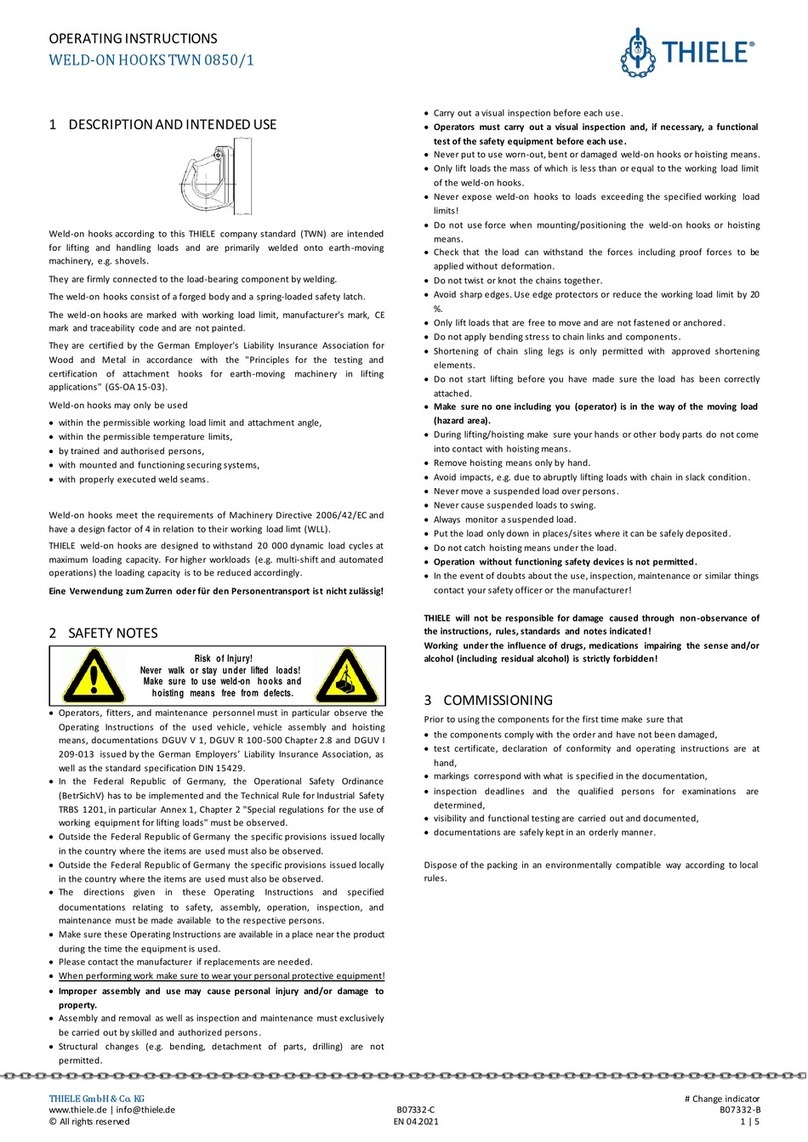

4.5 Working load limits depending on the application #

Attachment

mode

Inclination angle

Number

of legs

for TWN 0119 + TWN 0124 [t]

(marking)

for TWN 1882 [t]

(marking)

1

2

3

5

8

15

32

50

1,5 t

2,5 t

4,0 t

6,7 t

10 t

0°

1

1,12

2

3,15

5,3

8

15

31,5

50

1,5

2,5

4

6,7

10

0°

2

2,24

4

6,3

10,6

16

30

63

100

3

5

8

13,4

20

90°

1

1,12

2

3,15

5,3

8

15

31,5

50

1,5

2,5

4

6,7

10

90°

2

2,24

4

6,3

10,6

16

30

63

100

3

5

8

13,4

20

0° - 45°

2

1,6

2,8

4,25

7,5

11,2

21,2

45

71

2,1

3,5

5,6

9,4

14

45° - 60°

2

1,12

2

3,15

5,3

8

15

31,5

50

1,5

2,5

4

6,7

10

asymmetrical

2

1,12

2

3,15

5,3

8

15

31,5

50

1,5

2,5

4

6,7

10

0° - 45°

3 / 4

2,36

4,25

6,7

11,2

17

31,5

67

106

3,15

5,25

8,4

14,1

21

45° - 60°

3 / 4

1,7

3

4,75

8

11,8

22,4

47,5

75

2,25

3,75

6

10,1

15

asymmetrical

3 / 4

1,12

2

3,15

5,3

8

15

31,5

50

1,5

2,5

4

6,7

10

Spring

OPERATING INSTRUCTIONS

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08000-I replacement for B08000-H

© All rights reserved EN 08.2021 3 | 5

5. ASSEMBLY/ WELDING INSTRUCTIONS #

5.1 Preparations

The mounting location for each lifting point has to ensure that

•the load can take theforces including test loads safely to beapplied without suffering

deformation,

•no areas of danger are created (crushing point, shearing point),

•transportation is not restrained by overhang,

•lifting accessories will not be bypassed,

•incorrect use is avoided,

•the suspension gear cannot be damaged, for example by sharp edges,

•the lifting point can be used easily.

Make sure the welding surfaces are grinded down, flat, dry, free of impurity, flawless

and weldable (material see ISO/TR 15608 table 1, group 1). Make sure the weld area at

the component is able to absorb the input force without safety reducing deformation.

Make sure the weld seam area at the component is large enough for the lifting points

to be safely attached by welding.

5.2 Welding instructions #

Welding instructions relating to weld-onsupports (S355NL or similar) to be attached to

C22, S235, S355 or similar components.

The following general welding instructions must be observed:

•EN ISO 2560 Welding consumables –Covered electrodes for manual arc

Welding of non-alloy and fine grain steel

•EN ISO 14341 Welding consumables –Wire electrodes and weld

deposits for gas shield metal arc welding of non-alloy

and fine grain steel

•ISO 3834-2 Quality requirements for fusion welding of metallic

materials

•EN 1011-1, 2 Welding –recommendations for welding of metallic

materials

•EN ISO 9606-1 Qualification testing of welders –fusion welding

•DVS 0702-1 / 0711 Factsheet - Requirements for operation and personnel

Do not weld on the movable rings!

Take care not to widen the gap for the root run during tack-welding.

Take care for an accurate cleaning of the root run.

Take care to avoid end crater.

Continue the welding within one heat.

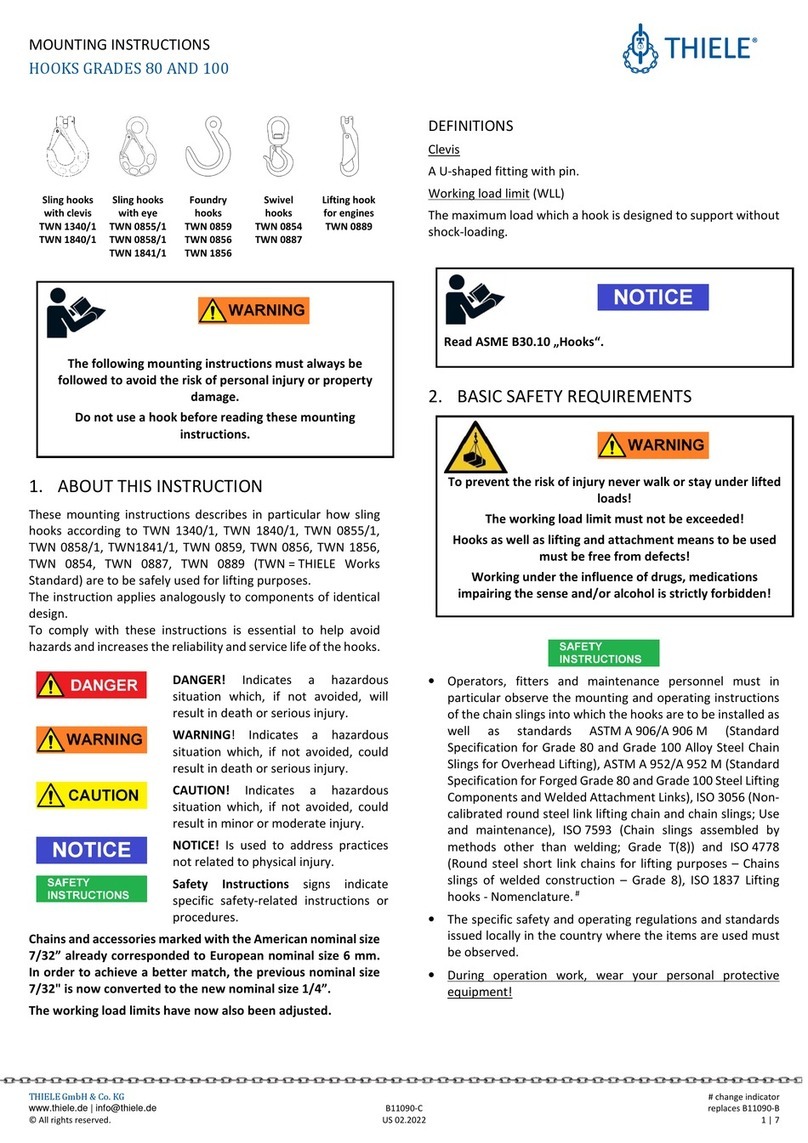

Sketch:

Miscellaneous:

1. Minimum notched-bar impact strength values of ISO-V specimens KV=27J at -40 °C

(e.g. S355J4G3 or S355NL, EN10025)

2. When selecting material grades other than those listed above please contact the

base material and filler metal manufacturers for information.

3. The responsible welding supervisor on site must make sure the welding current is

correctly adjusted to suit the given welding position. #

4. A procedure check is recommended to confirm the selected settings.#

5.3 Welding process MAG #

Welding process

Metal active gas welding (MAG) EN ISO 9606-1; No. 135

Welding groove

See sketch, taking into account EN ISO 9692-1#

Quality grade

For all layers according to EN ISO 5817 - C #

Wire electrode

EN ISO 14341-A:2011: ISO 14341-A-G 46 4 M21 3Si1

Possible alternatives must be selected and checked by the welding supervisor on site. #

Welding position

EN ISO 9606-1: PA, PB, PC, PF#

Preheating of parent metal

Thickness ≥20 mm: 150 °C#

Interpass temperature

≤ 400 °C

Postweld heat treatment

Thickness ≥40 mm: Tempering at 400 °C or apply quenching and tempering layer technology #

Pass

Root run

Intermediate run/ #

Final run

Temper pass

Wire electrode diameter

1 mm

1,2 mm

1 or 1,2 mm

Welding current (=)

130 –200 A

135 –290 A

See root run or stringer pass.

Note: The quench and temper

layer must only be applied to the

weld metal. Contact with the base

metal must be avoided. #

Electrode polarity

(= +)

(= +)

Voltage

19 –25 V

19 –32 V

Shield gas ISO 14175; M21

10 –12 l/min

12 –14 l/min

Kind of pass

Stringer pass

Stringer pass

Weld seam area

(HV weld + fillet weld)

Temper pass

Weld-on support

HV

OPERATING INSTRUCTIONS

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08000-I replacement for B08000-H

© All rights reserved EN 08.2021 4 | 5

5.4 Manual welding process MMA #

Welding process

Manual metal arc welding (MMA) EN ISO 9606-1; No. 111

Welding groove

See sketch, taking into account EN ISO 9692-1#

Quality grade

For all layers according to EN ISO 5817 - C #

Wire electrode

EN ISO 2560 A:2010: min. ISO 2560-A-E 38 4 B 42 H5 1) #

Possible alternatives must be selected and checked by the welding supervisor on site. #

Welding position

EN ISO 9606-1: PA, PB, PC, PF #

Preheating of parent metal

Thickness ≥20 mm: 150 °C#

Interpass temperature

≤ 400 °C

Postweld heat treatment

Thickness ≥40 mm: Tempering at 400 °C or apply quenching and tempering layer technology #

Pass

Root run

Intermediate run/ #

Final run

Alternative final run

Temper pass

Wire electrode diameter

2,5 mm

3,2 mm

4,0 mm

2,5 or 3,2 or 4,0 mm #

Welding current (=)

80 –110 A

100 –140 A

130 –180 A

See root run or stringer pass.

Note: The quench and temper layer

must only be applied to the weld

metal. Contact with the base metal

must be avoided. #

Electrode polarity

(= +)

(= +)

(= +)

Voltage

-

-

-

Shield gas ISO 14175; M21

-

-

-

Kind of pass

Stringer pass

Stringer pass

Stringer pass

1) Re-drying according to manufacturer's instructions

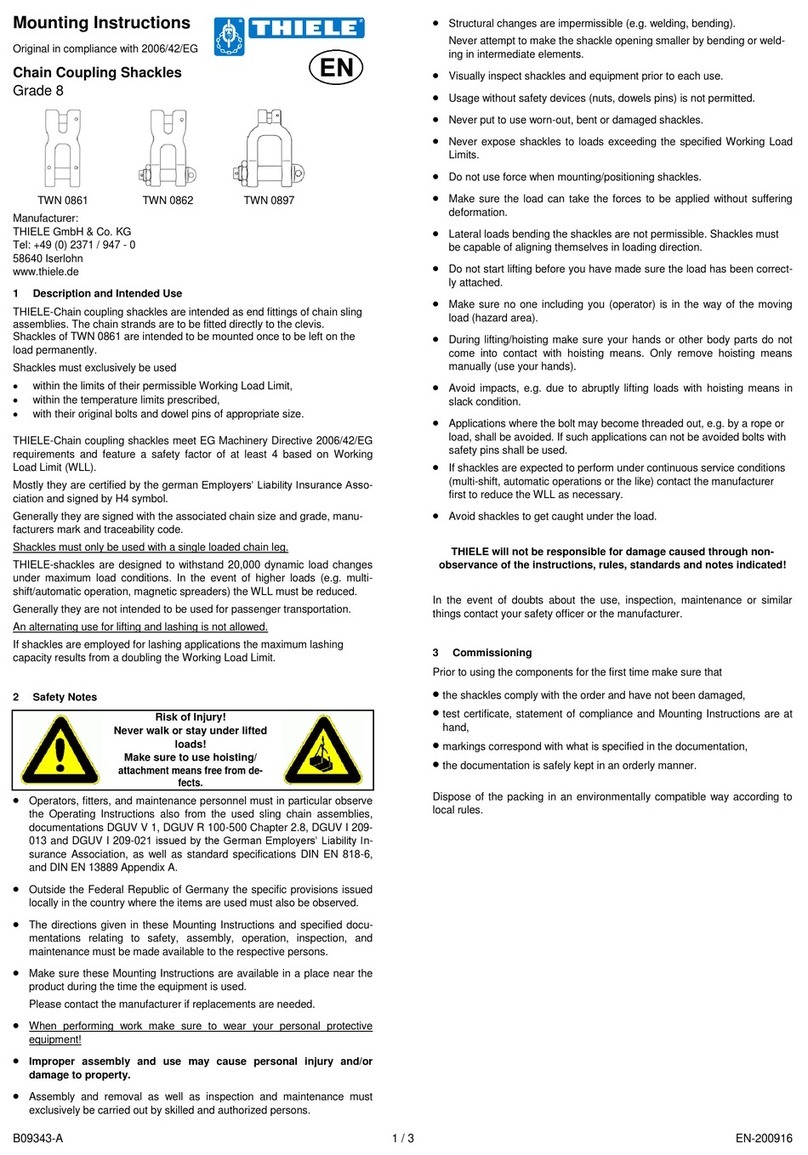

5.5 Geometry data weld seams #

Type

Nominal

size

Minimum

length 1)

HV-

weld

Fillet

weld

amin ⌳

Volume

appr.

[mm]

[mm]

[mm]

[cm3]

TWN 0119

6-8

2 x 32

9

3

2,0

8-8

2 x 38

9

3

2,3

10-8

2 x 44

10,5

3

3,0

13-8

2 x 60

15

4

7,3

16-8

2 x 65

17

4

8,5

22-8

2 x 109

24

6

25,8

32-8

2 x 165

36

16

131

40-8

2 x 210

36

22

260

TWN 0124

6-8

2 x 32

9

3

2,0

8-8

2 x 38

9

3

2,3

10-8

2 x 44

10,5

3

3,0

13-8

2 x 60

15

4

7,3

16-8

2 x 65

17

4

8,5

TWN 1882

6-10

2 x 35

7,5

3

2,5

8-10

2 x 42

7,5

3

3,0

10-10

2 x 46

9

3

3,8

13-10

2 x 63

12

4

8,1

16-10

2 x 63

15

4

9,8

1) corresponds to length L for both sides of the weld-on support

6. CONDITIONS OF USE

6.1 Normal use

The ring of the lifting point must always be freely movable.

It must not rest on or be supported by other structural parts.

Using 4-leg chain link assemblies may cause higher risk because only 2 opposite legs

carrying the load. Check the working load limit of lifting points and chain link assembly

carefully and chose if necessary bigger sizes.

6.2 Influence of temperature

The permissible working load limit of the lifting points reduces at elevated

temperatures.

The reduced working load Limit shown in the following tables shall only apply for short-

term use at the temperatures indicated.

If the lifting points have been exposed totemperatures exceeding the maximum values

specified, they must no longer be used.

Type

Temperature range

Remaining WLL

TWN 0119

TWN 0124

-40 °C ≤ t ≤ 200 °C

100 %

200 °C < t ≤ 300 °C

90 %

300 °C < t ≤ 400 °C

75 %

TWN 1882

-30 °C ≤ t ≤ 200 °C

100 %

200 °C < t ≤ 300 °C

90 %

300 °C < t ≤ 380 °C

60 %

6.3 Environmental influence

Lifting points must not be used in environments where acids, aggressive or corrosive

chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as well.

7. INSPECTIONS, MAINTENANCE, DISPOSAL

7.1 General

Inspections and maintenance must be arranged for by the Owner!

Inspection deadlines shall be determined by the Owner!

Inspections must be carried out and documented by competent persons regularly but

at least once a year, or more frequently if the lifting points are in heavy-duty service.

After three years at the latest they must additionally be examined for cracks. A load

test shall never be considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 209-062 or DGUV

I 209-063) to be prepared at first use. The register will show characteristic data as well

as identity details.

Immediately stop using lifting points that show the following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•heating beyond permissible limits,

•restricted hingeability of the ring,

•severe corrosion,

•wear exceeding 10 %, for example in the ring diameter area,

•weld failures.

OPERATING INSTRUCTIONS

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08000-I replacement for B08000-H

© All rights reserved EN 08.2021 5 | 5

7.2 Inspection service

THIELE offers inspection, maintenance and repair services by trained and competent

personnel.

7.3 Maintenance

Maintenance and repair work must only be performed by competent persons.

Minor notches and cracks at the rings may be eliminated by careful grinding observing

the maximum cross section reduction requirement of 10 % and avoid making more

severe cuts or scores.

All maintenance and repair activities are to be documented.

7.4 Disposal

All components and accessories of steel taken out of service are to be scrapped in line

with local regulations and provisions.

8. STORAGE

Lifting points are stored in dry locations at temperatures ranging between 0 and +40 °C.

9. THIELE OPERATING AND MOUNTING INSTRUCTIONS

Current operating and installation instructions are available as a PDF download on the

homepage.

10. IMPRINT

THIELE GmbH & Co. KG

Werkstrasse 3

58640 Iserlohn, Germany

Tel.: +49(0)2371/947-0

EC DECLARATION OF CONFORMITY

acc. to Machinery Directive 2006/42/EG, Annex II A for a machine

THIELE GmbH & Co. KG herewith declares as manufacturer that

LIFTING POINTS, WELD TYPE

TWN 0119, TWN 0124, TWN 1882

are placed on the market in the form of a complete machine by THIELE together with

the relevant test certificate and are in compliance with the applicable provisions of

the EU Machinery Directive 2006/42/EG.

The following harmonized standards have been observed:

•EN ISO 12100

•EN 1677-1

•EN 1677-4

The following testing principles of the Employer's Liability Insurance Association were

applied:

•GS-OA 15-04 Principles for testing and certification of anchor points

This declaration/statement is not meant to warrant any product properties.

Safety notes and instructions pertinent to the products must be observed.

Responsible for the documentation Iserlohn, 20th August 2021

Rene Völz Dr. Michael Hartmann

(Head of QA and EP) (Managing director)

Tel.: +49(0)2371/947-541

This manual suits for next models

2

Table of contents

Other Thiele Industrial Equipment manuals

Thiele

Thiele TWN 1450 User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 0796 User manual

Thiele

Thiele TWN 0850/1 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele TWN 1340/1 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele Streamfeeder Value Series User manual