Thiele TWN 1450 User manual

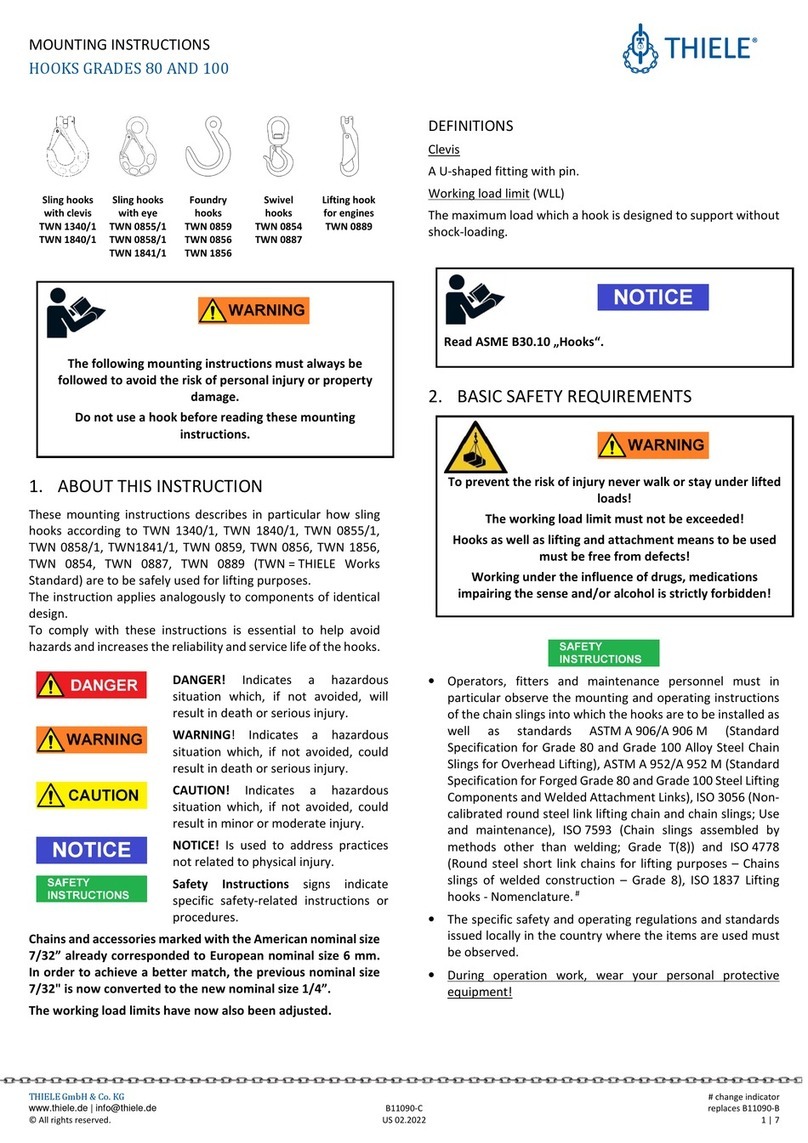

MOUNTING INSTRUCTIONS

CHAIN TENSIONERS

GRADES 8 AND 10

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B09099-B replaces B09099-A

© All rights reserved EN 01.2023 1 | 3

Original in compliance with machinery directive 2006/42/EC

1DESCRIPTIONAND INDENTED USE

THIELE-chain tensioners are exclusively intended for the use in chain slings according

to EN 818-4 for lifting loads or in lashing chains according to EN 12195-3.

These mounting instructions describe the safe use of chain tensioners according to

TWN 1450, TWN 1451 and TWN 1452 for grade 8 and TWN 1454 and TWN 1455 for

grade 10. (TWN = THIELE factory standard)

THIELE chain tensioners are used to adjust the length of individual chain legs, e.g. as

height adjustment for even loading of multi-leg chain slings or for length adjustment

or applying of pre-tensioning forces in lashing chains.

The chain tensioners are marked with the nominal chain size, grade, manufacturer's

mark and traceability code.

Parts of the chain leg to be adjusted are fastened by a clevis system on both sides.

The length is adjusted by turning the central sleeve by means of a lever or ratchet in

relation to the clevis systems at both ends.

The internal trapezoidal threads, which are protected by tube sections, are equipped

with anti-unscrewing devices. The chain tensioners are galvanised to protect them

against corrosion. They are manufactured in the following types:

•with lever,

•with ratchet system.

THIELE chain tensioners comply with the EC Machinery Directive 2006/42/EC and have

a safety factor of min. 4 related to the working load limit (WLL).

The chain tensioners are designed to withstand 20 000 dynamic load changes under

maximum load conditions. In the event of higher loads (e.g. multi-shift/automatic

operation) the working load limit must be reduced.

They are certified by the German Social Accident Insurance (DGUV) for use in chain

slings and are marked with the H4 stamp.

The chain tensioners must exclusively be used

•within the limits of their permissible working load limits or lashing capacities,

•within the permissible slinging or lashing methods,

•within the temperature limits prescribed,

•with suitable sling or lashing chains,

•by trained and authorised persons.

An alternating use for lifting and lashing is not allowed!

Chain tensioners are not intended for the transport of persons!

2SAFETY NOTES

Risk of injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/lashing means

free from defects.

•Operators, fitters and maintenance personnel must in particular observe the

operating instructions of the chain slings in which the chain tensioners are installed,

the documentation of the employers' liability insurance association DGUV V 1,

DGUV R 109-017, DGUV I 209-013 and DGUV I 209-021 as well as the standards

DIN 685-5 and EN 818 6 or EN 12195-3.

•In the Federal Republic of Germany, the Operational Safety Ordinance (BetrSichV)

has to be implemented and the Technical Rule for Industrial Safety TRBS 1201, in

particular annex 1, chapter 2 "Special regulations for the use of working equipment

for lifting loads" must be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally in the

country where the items are used must also be observed.

•The directions given in these operating instructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be made

available to the respective persons.

•Make sure these operating instructions are available in a place near the product

during the time the equipment is used. Please contact the manufacturer if

replacements are needed. See also chapter 9.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if necessary, a functional test of

the safety equipment before each use.

•Never use worn-out, bent or damaged chain tensioners.

•Never expose chain tensioners to loads higher than the specified working load limit.

•Only chain legs and chain tensioners of the same nominal size and grade may be

connected.

•Safety elements must not be excessively stressed or strained operationally.

•Do not twist or knot the chains together.

•In case of multi-leg chain slings never allow for inclination angles of less than 15 °

and in excess of 60 °.

•Avoid bending loads to act on chain tensioners.

•During lifting/hoisting make sure your hands or other body parts do not come into

contact with hoisting means.

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Operation without properly functioning safety devices (cotter pins, wedges, pins) is

not permitted.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through non-observance of the

instructions, rules, standards and notes indicated!

As regards grade 10 THIELE does not give its general approval to the assembly of

components stemming from different manufacturers!

Working under the influence of drugs, medications impairing the sense and/or

alcohol is strictly forbidden!

3COMMISSIONING

Prior to using the lifting points for the first time make sure that

•the lifting points comply with the order and have not been damaged,

•test certificate, statement of compliance, and operating instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are determined,

•visibility and functional testing are carried out and documented,

•documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local rules.

MOUNTING INSTRUCTIONS

CHAIN TENSIONERS

GRADES 8 AND 10

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B09099-B replaces B09099-A

© All rights reserved EN 01.2023 2 | 3

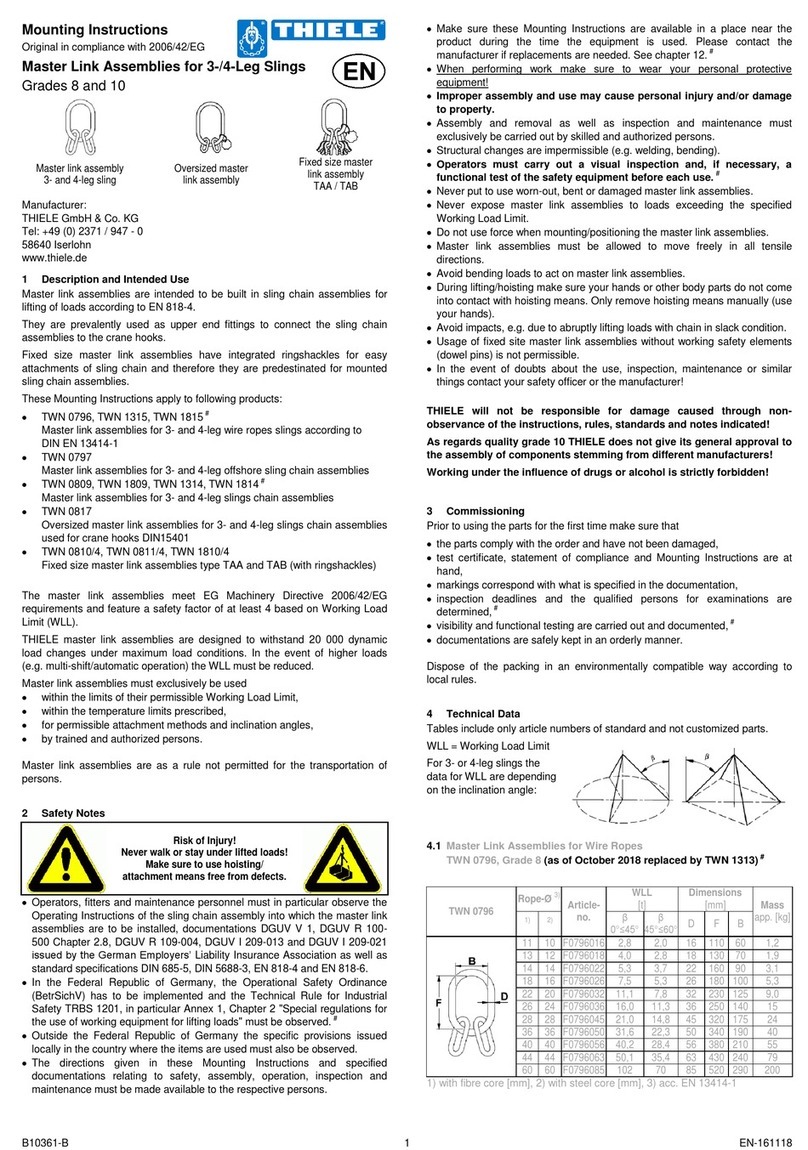

4TECHNICAL DATA

4.1 General

When used in lashing chains, the maximum permissible lashing capacity (LC) is obtained

by doubling the working load limit (WLL).

Use is only permitted in sling chains OR in lashing chains.

Tables include only article numbers of standard and not customized parts.

4.2 Chain tensioners TWN 1450 with lever

Nominal

size

Working

load limit

WLL

Lashing

capacity

LC

Stroke

Max.

Article

no.

Mass

[t]

[kN]

[mm]

[kg]

8-8

2,0

40

75

F34179

2,1

10-8

3,15

63

100

F34199

2,7

13-8

5,3

100

120

F34189

4,0

4.3 Chain tensioners TWN 1451 with ratchet

Nominal

size

Working

load limit

WLL

Lashing

capacity

LC

Stroke

Max.

Article

no.

Mass

[t]

[kN]

[mm]

[kg]

8-8

2,0

40

75

F34175

2,5

10-8

3,15

63

100

F34195

3,5

13-8

5,3

100

120

F34185

5,0

4.4 Chain tensioners TWN 1452 with lever

Nominal

size

Working

load limit

WLL

Lashing

capacity

LC

Stroke

Max.

Article

no.

Mass

[t]

[kN]

[mm]

[kg]

13-8

5,3

100

230

F341871

7,2

16-8

8,0

160

280

F34197

11,8

4.5 Chain tensioners TWN 1454 with lever

Nominal

size

Working

load limit

WLL

Lashing

capacity

LC

Stroke

Max.

Article

no.

Mass

[t]

[kN]

[mm]

[kg]

13-10

6,7

130

230

F341877

7,2

16-10

10

200

280

F341977

11,8

4.6 Chain tensioners TWN 1454 with ratchet

Nominal

size

Working

load limit

WLL

Lashing

capacity

LC

Stroke

Max.

Article

no.

Mass

[t]

[kN]

[mm]

[kg]

13-10

6,7

130

230

F341878

8,4

16-10

10

200

280

F341978

13,5

5ASSEMBLY AND REMOVAL

5.1 General

Always assemble and disassemble in an unloaded condition only.!

To dissassemble, remove the components in reverse order.

Only chain and component of same nominal size and grade belong together!

Only connect pins and attachment components of identical grade! (starting with

Ø 13 mm the pins are marked on the front end).

5.2 Assembly of clevis-type fastening system

If necessary, remove dowel pin and pin.

•(A) Place end of chain leg between the lateral clevis

elements.

•(B) Push pin from the side fully into the clevis and

through the last chain link of the leg.

•(C) Drive dowel pin fully in (must not project) to

secure the pin.

The slot must face away from the pin.

•Check the chain runs smoothly!

The dowel pins must only be installed once.

5.3 Disassembly of clevis-type fastening system

•Slacken the respective chain leg.

•(A) Drive dowel pin out using hammer and drift

punch.

•(B) Push pin out.

•(C) Remove the chain.

Suitable drift punches are available by article no. Z03303.

6OPERATION

6.1 Normal use

The force must be applied in the longitudinal direction. The chain tensioner must

remain freely suspended in the chain leg and must not come into contact with other

components.

The chain tensioner is to be operated exclusively by hand movements on the lever or

on the ratchet system.

By rotating the central sleeve, the clevis systems at both ends change their distances.

Make sure that the length is adjusted symmetrically starting from the inner or outer

end position, as this is the only way to ensure that the entire stroke range is available.

Make sure that the chain legs on both sides are not twisted. Vibration can otherwise

cause a significant reduction in the pre-tensioning force, especially when lashing.

When lashing, therefore, secure the chain tensioner directly after tensioning with an

additional safety chain (article no. F341711), which prevents the chain tensioner from

untwisting on its own.

Never use lever extensions (e.g. by means of an attached tube), as this causes an

impermissible pre-tensioning of the chain tensioner and chain, which can lead to an

overloading and even breakage if a load or lashing force is additionally applied!

The lengths of the levers are designed to ensure that the permissible forces are not

exceeded.

The operating direction of the ratchet system is set by switching the small lever to one

of the end positions. In the middle position, the ratchet system is inoperative and the

lever can move freely according to gravity or centrifugal force and may strike

unintentionally.

MOUNTING INSTRUCTIONS

CHAIN TENSIONERS

GRADES 8 AND 10

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B09099-B replaces B09099-A

© All rights reserved EN 01.2023 3 | 3

6.2 Influence of temperature

The permissible working load limit of the lifting points reduces at elevated

temperatures.

Grade

Temperature range

Remaining WLL

8

-40 °C ≤ t ≤ 200 °C

100 %

200 °C < t ≤ 300 °C

90 %

300 °C < t ≤ 400 °C

75 %

10

-30 °C ≤ t ≤ 200 °C

100 %

200 °C < t ≤ 300 °C

90 %

300 °C < t ≤ 380 °C

60 %

If a tensioner has been exposed to temperatures exceeding the maximum values

specified, it must no longer be used.

6.3 Environmental influence

Chain tensioners must not be used in environments where acids, aggressive or

corrosive chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as well.

Chain tensioners are not suitable for abrasive use in blasting plants.

7SPARE PARTS

Only use original spare parts.

7.1 Spare part sets for clevis fastening system

A set consists of pin and dowel pin.

Nominal size

Article no.

Nominal size

Article no.

8-8

F48352

10-8

F48355

10-10

F48688

13-8

F48358

13-10

F48689

16-8

F48361

16-10

F48690

8INSPECTIONS, MAINTENANCE, DISPOSAL

8.1 General

Inspections and maintenance must be arranged for by the owner!

Inspection intervals shall be determined by the owner!

Inspections must be carried out and documented by competent persons regularly but

at least once a year, or more frequently in case of heavy-duty service. After three years

at the latest they must additionally be examined for cracks. A load test shall never be

considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 209-062 or

DGUV I 209-063) to be prepared when the chain sling is first used. The register will

show characteristic data of the chains and components as well as identity details.

Immediately stop using chain tensioners that show the following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•heating beyond permissible limits,

•severe corrosion,

•ratchet system not functioning properly,

•wear by more than 10 %, e.g. bolt diameters,

•missing or defective pin locking device.

8.2 Maintenance

Maintenance and repair work must only be performed by competent persons.

Chain tensioners have only minimum maintenance needs. They should be cleaned if

they are dirty.

Make sure their screw threads can be easily turned. Threads are lubricated in the

factory.

For the rare case of relubrication, first dismantle the unscrewing locks in the form of

dowel pins and then unscrew the outer end pieces from the central sleeve.

Commercially available grease can be used as a lubricant. During assembly, make sure

that the two anti-rotation devices are installed and use new dowel pins. Please contact

the manufacturer for details. Recommendation: Have this work carried out by the

manufacturer.

For the ratchet mechanism a lube nipple has been arranged.

Minor notches and cracks at the rings may be eliminated by careful grinding observing

the maximum cross section reduction requirement of 10 % and avoid making more

severe cuts or scores.

All maintenance and repair activities are to be documented.

8.3 Inspection service

THIELE offers inspection, maintenance and repair services by trained and competent

personnel.

8.4 Disposal

All components and accessories of steel taken out of service are to be scrapped in line

with local regulations and provisions.

8.5 Storage

Tensioners are stored in dry locations at temperatures ranging between 0 and +40 °C.

9THIELE OPERATING AND MOUNTING INSTRUCTIONS

Current operating and installation instructions are available as a PDF download on the

homepage.

10 IMPRINT

THIELE GmbH & Co. KG

Werkstrasse 3

58640 Iserlohn, Germany

Tel.: +49(0)2371/947-0

This manual suits for next models

12

Other Thiele Industrial Equipment manuals

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele Streamfeeder Value Series User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 0119 User manual

Thiele

Thiele TWN 0835/1 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele TWN 0850/1 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 0796 User manual