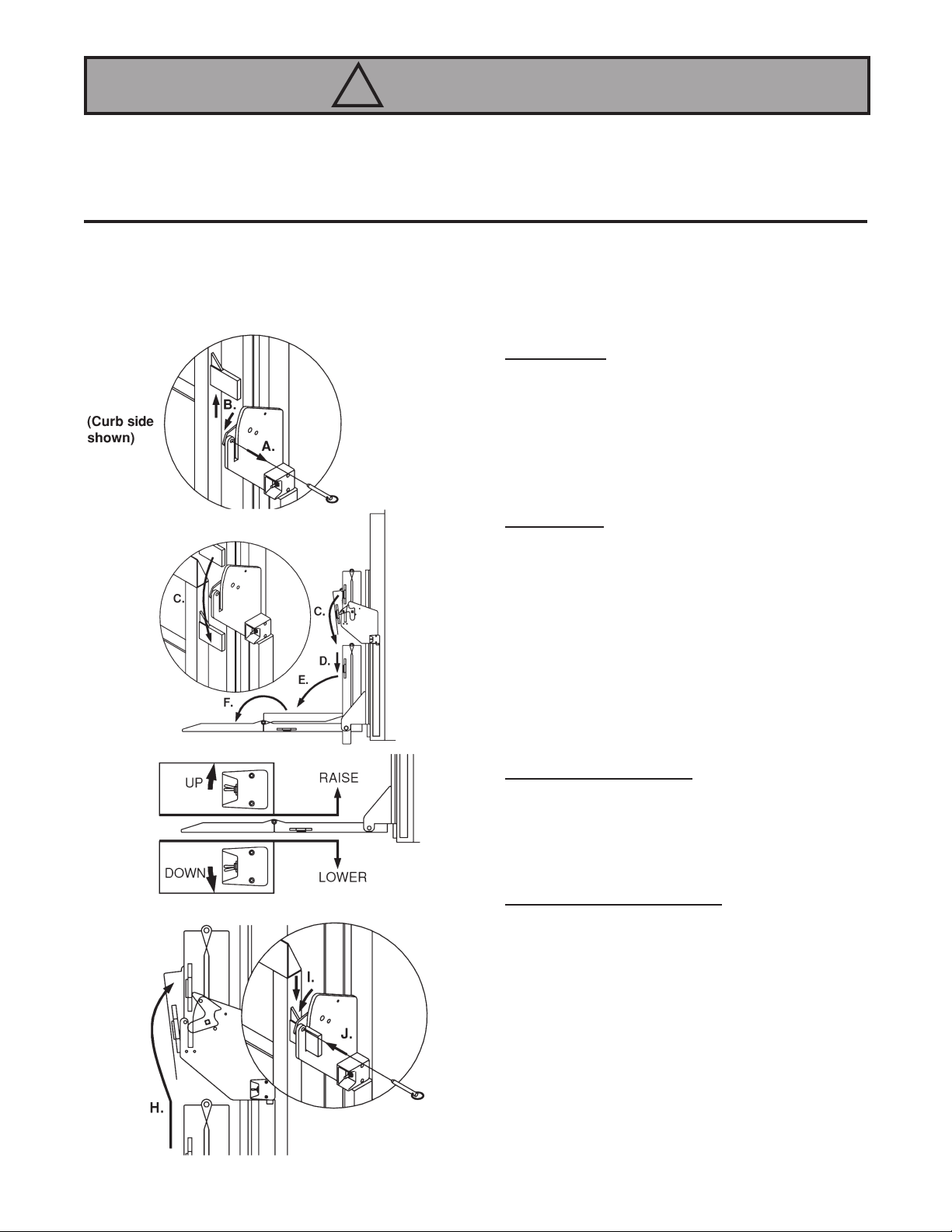

4.

WARNINGS!

1. DO NOT operate this Thieman liftgate without the Owner’s Manual for this model present on

the vehicle and without all decals present and legible, as guides for proper liftgate operation

and maintenance (see the “Decal Maintenance - Inspection and Location of Decals” section

of this manual). For replacement Owner’s Manuals, decals, etc. call Thieman at 419-586-

7727. For the latest manuals and warnings for each liftgate, visit our website at www.

thiemantailgates.com. Note: manuals and warnings update regularly.

2. The vehicle must be securely and properly braked on level ground before using the liftgate.

3. All protective covers and guards must be in place before operating the liftgate.

4. Before using liftgate, check for signs of improper maintenance or damage (unusual noises,

vibrations, fails to operate freely, missing hardware, cracked welds…etc. See the sections

in this manual with “Maintenance” in the title – refer to “Table of Contents” on Page 2).

DONOTusetheliftiftheseareevident.OnlyanauthorizedThiemandistributorisqualied

to do repairs on the liftgate. DO NOT attempt to do your own repairs or modify this liftgate.

Altering this product will void all warranties and may damage the liftgate or even cause

serious injury. If any repairs, adjustments, or maintenance not covered in this manual are

required, contact your nearest Thieman distributor or call Thieman at 419-586-7727.

5. THIS IS NOT A PERSONNEL LIFT. Because of the pinch point between the platform and

the truck, fall hazards, unstable loads, etc., riding the lift may cause severe personal injury

or death. ALWAYS stay clear of the liftgate when in operation. Do NOT ride the liftgate.

6. Make certain the areas, in which the platform will open or close, are clear before opening

or closing the platform.

7. Use this liftgate ONLY for its intended purpose of loading/unloading cargo between truck

bedandground.ItisNOTtobeusedforanythingotherthanthis.Thegroundisdenedas

the surface the truck is parked on.

(Warnings continued on following pages)

IMPROPER OPERATION OF THIS LIFTGATE MAY RESULT IN SERIOUS PERSONAL INJURY

AND/OR DEATH. DO NOT operate this liftgate unless you have been properly instructed and

have read and understood the Owner’s Manual and all of its warnings, operating instructions

and all decals.

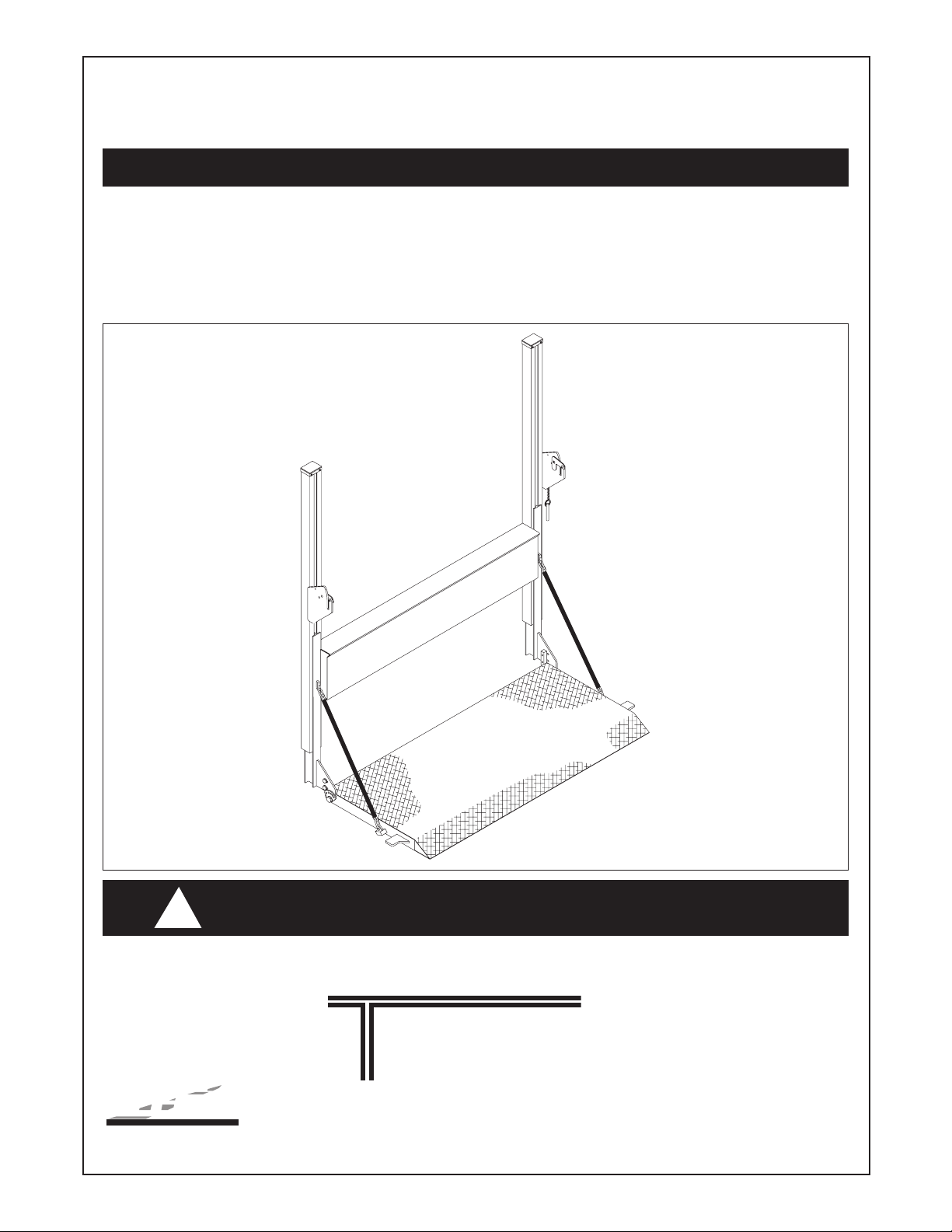

The following list of warnings is to be read and understood before operating the TVLR

series liftgate. The numbered list begins below and continues on the following pages.

!WARNING