Third Dimension GapGun Pro Manual

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

2© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Copyright © 2016 Third Dimension

All rights reserved.

You must not reproduce or distribute any part of this

publication in any form or by any means, electronic or

mechanical, without prior permission in writing from

Third Dimension. This includes photocopying, recording

or any other information storage or retrieval system.

This version produced on 16 September 2016

For support with your GapGun Pro please contact Third

Dimension:

Brabazon Office Park, Bristol, BS34 7PZ, UK

T: +44 (0)3333 44 3000

F: +44 (0)3333 44 0041

www.third.com

The laser complies with IEC60825-1 AM2:2001.

Because your blink reflex provides enough protection, it

is called eye safe

•Do not shine in eyes

•Do not view with optical instruments

•Do not shine in open space

•Take care around reflective surfaces

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 3

Page

Operator Guide 3

The GapGun Pro 4

Measuring with the GapGun 8

Checking Sensor Calibration 14

Administrator Guide 15

Creating a Checkplan 17

Measuring a Works Order 20

Setting nominals and tolerances 21

Glossary 23

4© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

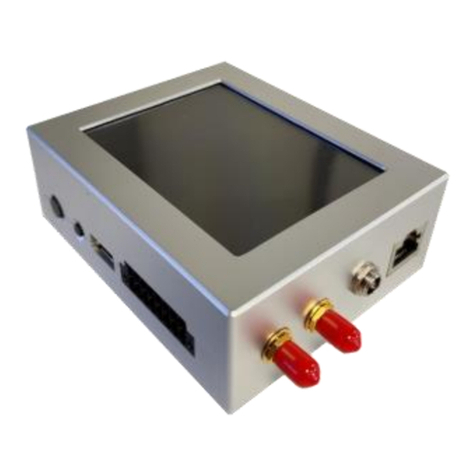

A. Laser source

B. Camera

C. Green indicator LEDs

D. Vchange collar release

E. Trigger

F. On / Off switch

G. USB slot

H. Touch screen display

I. Head power indicator

J. Red laser activity indicator

K. Drop Protection jacket

L. V-Standoff

M. Wrist strap

H

I J

K

L

M

A

B

C E

F

D

G

M

A. Desktop battery charger

B. GapGun Pro with VChange sensor

C. Calibration gauge block

D. Hex tool training artifact

E. Docking station

F. Docking Station Cabling

G. Calibration pin gauge

H. Gauge block cleaning brush

I. Clip-on rechargeable battery pack

J. Spare rechargeable battery

K. GapGun software memory stick

L. Space for Shock protection sensor jacket

M. Extra VChange Sensors

N. Standoffs

O. Desktop charger power supply

E

B

O

E

G

D

J

A

C

K

F

H

L M

N

NI M

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 5

The clip on battery pack attaches onto the base

of the handle and provides power for additional

4-6 hours.

The Desktop charger will recharge the battery in

about 1.5 hours.

The VChange sensor system allows sensor heads

to be quickly and easily changed without using

any tools. The Vchange system can be retrofitted

to existing MX+ handles and sensors. Sensor

heads can be freely interchanged between

different handles.

To swap the sensor head squeeze the orange

release tabs on the Vchange collar and pull the

sensor off the handle. Push the new sensor into

place until the collar lock clicks. The sensor can

be swapped without turning off the GapGun.

The GapGun Pro has an internal battery which can

power the GapGun for 4 to 5 hours of normal use.

The battery can be recharged using the docking

station or via the clip-on battery which can be used to

extend the period of use by a further 4-6 hours.

6© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Some heads have a three position mask in front of the laser. Turning the laser cap changes the mask:

Position I places a mask line in the centre of the laser line. This artificially divides the laser line into a left and

right side. It can be used to measure features where it is difficult to identify the left and right sides

of a feature.

Position II is the default position which allows the full width of the laser line to be used.

Position III masks the laser on the right and left ends of the line presenting a shorter laser line on the feature.

The Docking Station connects the GapGun to the PC

though an Ethernet connection.

It also powers the GapGun, recharges the internal

battery and is a safe place to store the GapGun.

Standoffs are used in applications where the

parts being measured can’t possibly move. The

standoffs help stabilise the GapGun and position

it correctly.

The black V standoffs are for measuring gaps and

the grey H standoffs are for sealant beads.

I

II

III

III

II

I

I

II

III

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 7

Protect the GapGun by always using the Head

Jacket (above) and wrist loop.

Before each use: check lenses are clean, check

for any damage and verify calibration.

If the GapGun is dropped, check it for damage

and verify calibration.

The GapGun lenses need to be clean: Inspect the

highlighted areas for dust, grease or fingerprints;

clean them with the kit provided if required.

The GapGun Pro is designed for indoor use; keep

the system and its accessories dry and clean. Do

not use solvents on any surface.

Always verify calibration before use by measuring the Gauge Block or Pin Gauge supplied with your system. See

the Checking Head Calibration section in this manual for more details on running the Head Check checkplan.

FOV15/40/80 To perform a calibration check successfully, place the gauge block on a flat, stable surface.

Using the V-standoff, locate the tip in the gap to position the sensor at the correct distance

from the block.

FOV7 To perform a calibration check successfully. Using the V-standoff, locate the pin into the V

from the top of the standoff, taking care not to apply undue pressure to the pin.

NOTE: Failure to follow these steps may cause false calibration failures.

FOV 15 / 40 / 80 FOV 7

8© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

A

B

C D

The SPC3D PC application is used to open Checkplans,

load Works Orders onto the GapGun and store the

measurements that are made.

A. Context-sensitive command ribbon.

B. Checkplan tree view.

C. Tabbed Properties, Results and GapGuns windows.

D. Tabbed Workspace, Checkplan and Live display.

1

This guide shows how use a Checkplan to verify

accuracy of the GapGun by measuring a calibration

block gauge or pin gauge.

It uses the pre-defined Calibration Checkplan. Open

this in SPC3D by selecting Open from the ribbon menu.

Place the GapGun onto the Docking Station.

The display will show the GapGun locating the SPC3D

host.

If Wi-Fi has been configured the GapGun will already be

connected.

2

When using the GapGun, it will have been

preconfigured to guide you through a sequence of

locations to scan (Features), each one has a picture, a

type of measurement (e.g. gap and flush) and a set of

tolerances.

This configuration is called a Checkplan, and an

instruction to measure a specific object with the

Checkplan is called a Works Order.

CHECKPLAN: Hex

SN: ####

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0001

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0002

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0003

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 9

3 4

To navigate on the GapGun tap on an item to select that action or pull the trigger if the item is already selected.

To download a Works Order based on the Calibration Checkplan:

3. Tap on the “Download…” item. Note: If the “Download…” item is not shown then there is a problem

connecting the GapGun to SPC3D.

4. Tap on the SPD3D server that is to supply the checkplan.

5. Tap on the name of the Checkplan to be downloaded. The GapGun can now be undocked and clipped into the

Clip-on battery pack.

6. Tap the name of the Checkplan to start measuring.

5

7 8

By default, a Works Order gives a list of five Jobs to perform. This allows you to make measurements on five separate

parts (or five times on the same part.) For each Job just pulling the trigger will take you through the menus in the

right sequence.

7. Pull the trigger to enter the selected Job.

8. Enter the serial number of the part to be measured in this Job.

9. This menu shows Groups of Features for each type of GapGun head. Click on the one that matches your

GapGun head type.

10. Pull the trigger to measure each Feature using the following steps.

9 10

6

10 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

11. Start with the GapGun 10cm/4” away from the feature, then pull the trigger. If standoffs are being used then

locate them on the object and this will place the GapGun in the correct range immediately.

12. Aim the laser line at right angles across the feature. Move the GapGun closer keeping it perpendicular to the

feature. The arrows on the display show whether to move the GapGun towards or away from the feature.

13. When the GapGun is at the best position the green LEDs will appear. When the count reaches eight the

measurement is made. The measurement can be delayed by keeping the trigger pulled.

13

12

11

14. The GapGun should to be moved closer to the feature.

15. The GapGun should be moved away from the feature.

16. The green LEDS will be lit and the counters will start to turn green. “Trigger Lock” is displayed when

measurement has been delayed by pulling the trigger.

17. When the counters all turn green the GapGun will beep and the measurement will be made.

If “Measurement Failed” is shown try again, however this may mean that the wrong virtual tool is being used.

14 15 16 17

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 11

+15

°

-15°

The GapGun must be held within ±15° of a perpendicular

line from the feature to be measured. The most accurate

measurements are made closest to the perpendicular.

Standoffs can be used to guarantee alignment.

Because the camera is set on a different axis from the

laser, edges can obscure parts of the feature.

Switching the GapGun round will solve this problem.

The laser stripe should be placed at right angles to the feature. Use standoffs to guarantee alignment.

For best performance with surface finish or colour differences always use U series measurement heads—these have

industry leading performance on challenging surfaces.

Always use M series measurement heads for measuring reflective finishes. When using U series light from the laser

can be reflected indirectly off the object back to the camera and return false readings.

12 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

18. The measured results will be green if successful and in tolerance. If the measurement failed or the results were

out of tolerance they will be shown in red. Pulling the trigger will move on to measure the next Feature.

19. If the measurement failed then Review screen is displayed. Tapping on a measured Feature will also show this

screen. Use <Remeasure> to try again, <Delete> to delete an incorrectly taken measurement, <Save> to store

it, <View> to display. <Error code> allows the operator to enter a code for a non-measurable Feature.

20. When the Group is complete, pull the trigger or tap the top line to return to the Group screen.

If everything is green then the calibration of the GapGun has been verified.

19

18 20

21. Each Group shows the percentage of Features that have been measured. Tap or Trigger moves to the next

Group. When all Groups are complete Trigger or Back arrow will return to the Jobs screen.

22. Tap or Trigger moves to the next Checkplan. Trigger or Back arrow will move to the Works Orders screen when

all Checkplans are complete.

23. “Lock & exit” prepares the results to return them to SPC3D. “Save & exit” saves results if more measurements

are to be made. “Lock & upload” will upload the results to SPC3D immediately.

24. The WorksOrders shows that the Calibration checkplan is locked ready for uploading. Place the GapGun onto

the Docking Station and tap on the name “Calibration” to begin the upload.

21 22 23 24

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 13

The results from the measurements are displayed in the

Results Tab. Click on the Checkplan, Group or Feature

to see results for that selection.

Measurements that are outside the tolerances are

flagged in red for easy identification.

25. Tap “Upload” to begin uploading. Unlock will allow more results to be added to a locked Checkplan.

26. Select the SPC3D server which supplied the checkplan.

27. When the data has been sent back to SPC3D the Checkplan can be removed from the Works Orders list. Use

Download... to download the next set of Jobs.

28

25 26 27

14 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

The calibration of the head can be checked by selecting the

Head Check

item at any time during measurement.

1. The Operator should then select the Group relevant to the head installed on the Gapgun.

2. Each of the features on the gauges should be tested using the up and down arrows.

3. Each measurement must be taken at least three times and the Cg and Cgk calculated. The check can be

restarted at any time by tapping Restart. Once enough successful measurements have been captured the result

is shown, in green if the calibration is okay and in red if it is out of calibration. The Operator should seek advice

on how to proceed from a Supervisor.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 15

16 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

This guide demonstrates how to configure a GapGun

Checkplan to measure three Gap/Flush features on the

Hex Tool training artifact supplied with the GapGun.

The Square cut gap has square cut edges as found in

many industrial or aerospace applications, such as

panels on aircraft.

This feature has embossed lettering which shows how

the GapGun can ignore surface imperfections around

the feature when measuring.

The Hex Tool training artifact provides a wealth of

features to practice on. This guide uses three common

features.

The Rounded Gap consists of a gap and flush (step) that

have rounded edges as found on many consumer items

such as cars and white goods.

The Rounded, square gap has one side is rounded and

the other square, as found for example in automotive

ring gauges.

One side of this feature is set at an angle, to show how

the GapGun can cope with geometries that are

challenging to measure manually.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 17

A

B

C

D

The SPC3D PC application is used to configure

Checkplans, collect measurements and configure

Features.

A. Context-sensitive command ribbon.

B. Checkplan tree view.

C. Tabbed Properties, Results and GapGuns windows.

D. Tabbed Workspace, Checkplan and Live display.

The GapGun uses a Checkplan to describe what

Features are to be measured and in what order.

Features can be put into Groups so that related

measurements can kept together.

The first step is to create a new Checkplan and give it a

descriptive name ‘Hex’.

A Checkplan can have one or more Groups, for example

grouping Features on one part of the object. A Group

can be copied to create repeating sets of Features or

mirrored to create a Group for the opposite side of the

object.

Add a Group to the Checkplan and give it a descriptive

name ‘Gaps’.

1 2

SPC3D is used to define the checkplan and configure the

features that are to be measured. These are combined

into a Works Order which is downloaded to the GapGun

to tell the operator what to measure and where to

measure each feature.

The measured results are then returned to SPC3D to be

stored and formatted for further processing.

Checkplan

Feature 1

Feature 2

Feature 3

Group 1

Group 2

18 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Feature describes the measurement of a feature on a

part. This can have multiple measurement values, for

example Gap and Flush.

Add three Features:

Rounded - set the link to \Tools\GapFlush\PanelRad

Square - set the link to \Tools\GapFlush\PanelGF

RndSq - set the link to \Tools\GapFlush\CRV_SQR

Markers can be added to indicate which way to aim the

GapGun. The triangle indicates the left side and the

circle indicates the right, these symbols are also etched

onto the sides of the GapGun head.

The Plus, Cross and Done buttons can be used to

manage user-defined markers.

A picture of the feature can be added so that the

operator knows the precise location of the feature and

how to orientate the GapGun.

Right-click the Feature name and click on “Define

Instruction graphic…”

Select a graphic from the left hand panel or click on

the Green Plus button to import a new picture. Delete

graphics using the Cross Button or click the ‘None’

button to remove the graphic from the Feature.

4

5 6

3

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5 19

7

It is recommended that the Checkplan is saved before

downloading to the GapGun this will make reviewing

measurements easier later on.

Select the Checkplan tab in the workspace then click the

Save icon on the ribbon or right-click the Checkplan

name and select Save.

8

Place the GapGun onto the Docking Station.

The GapGun will show the GapGun locating the SPC3D

host.

If Wi-Fi has been configured the GapGun will already be

connected.

To download a Checkplan to the GapGun it must first

be opened in SPC3D.

Select Open from the ribbon and select the required

Checkplan file. These files can be freely copied, emailed

or renamed.

On the GapGun the checkplan becomes a Works Order

which tells the operator what to measure.

The Operator Guide describes how to download the

Checkplan onto the GapGun and return the results.

10

9

20 © Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

By default, a Works Order gives a list of five Jobs to perform. This allows you to make measurements on five

separate parts (or five times on the same part.) For each Job just pulling the trigger will take you through the

menus in the right sequence.

Pull the trigger to enter the selected Job.

Enter the serial number of the part to be measured in this Job.

There is only one group in our checkplan so select this Group.

Pull the trigger to measure each Feature using the following steps.

The measurements must always be made in the same orientation so that the sign of the flush is the same.

When measuring as shown the flush will be negative, but when measured the other way round it will be

positive.

Take the measurement as described in the operator manual.

The GapGun will display the dimensions of the gap and flush measured. If the GapGun reports ERR11 then

the wrong tool is being used, ERR13 indicates that the GapGun is no being held stably enough to get good

images.

11

12

Other manuals for GapGun Pro

1

Table of contents

Other Third Dimension Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Orion

Orion 24759 user manual

TSI Instruments

TSI Instruments 3321 Operation and service manual

Johnson

Johnson 40-6064 instruction manual

Blancett

Blancett B1750 user manual

Bosch

Bosch GPL100-30G Operating/safety instructions

JEAN MÜLLER

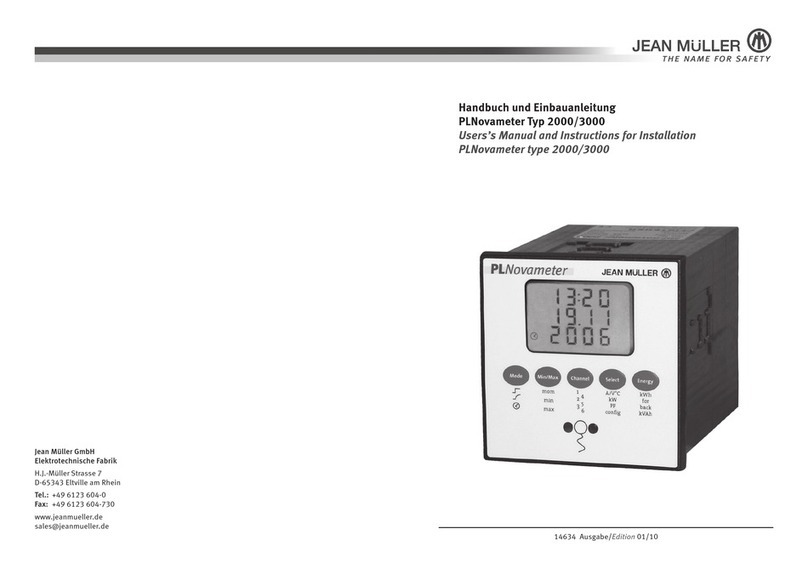

JEAN MÜLLER PLNovameter 2000 Users’s Manual and Instructions for Installation