Third Dimension GapGun Pro User manual

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

2© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

Copyright © 2016 Third Dimension

All rights reserved.

You must not reproduce or distribute any part of this

publication in any form or by any means, electronic or

mechanical, without prior permission in writing from

Third Dimension. This includes photocopying, recording

or any other information storage or retrieval system.

This version produced on 16 September 2016

For support with your GapGun Pro please contact

Third Dimension:

Brabazon Office Park, Bristol, BS34 7PZ, UK

T: +44 (0)3333 44 3000

F: +44 (0)3333 44 0041

www.third.com

The laser complies with IEC60825-1 AM2:2001.

Because your blink reflex provides enough protection, it

is called eye safe

•Do not shine in eyes

•Do not view with optical instruments

•Do not shine in open space

•Take care around reflective surfaces

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

GapGuns running 7.2 software and later by default use the fixed address 10.10.10.1

PCs running SPC3D 7.2 and later should be configured to use the fixed address 10.10.10.255

Network Mask 255.0.0.0

SPC3D 7 and the GapGun 7 software use the TCP/IP communication ports

Firewalls must be set to permit connections on these ports.

NOTE: The GapGun software will not work if these ports are not opened.

TCP/21030

UDP/21030

Inbound and Outbound

GapGun Pro CERDISP and CERHOSTGG5 use TCP/IP communication port UDP/987

GapGun MX+ CERDISP and CERHOSTGG4 use TCP/IP communication port TCP/987

Prior to V7.2 the GapGun and SPC3D used these default fixed addresses:

These should be replaced with the new 10.10.10.x addresses where possible.

100.0.0.1

100.0.0.255

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 3

USER GUIDE Page

TABLE OF OPERATIONS 4

GAPGUN OVERVIEW 6

MENU NAVIGATION 10

WORKS ORDER MENUS 11

ADMINISTRATOR MODE 16

INSTALLING SOFTWARE UPDATE 19

INSTALLING CALIBRATION FILES 19

CREATING STATISTICAL CHECKPLANS 20

INSTALL CONTEXT MENU CHECKPLANS 21

GLOSSARY 23

4© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

GapGun TCP/IP Network Configuration Information 2

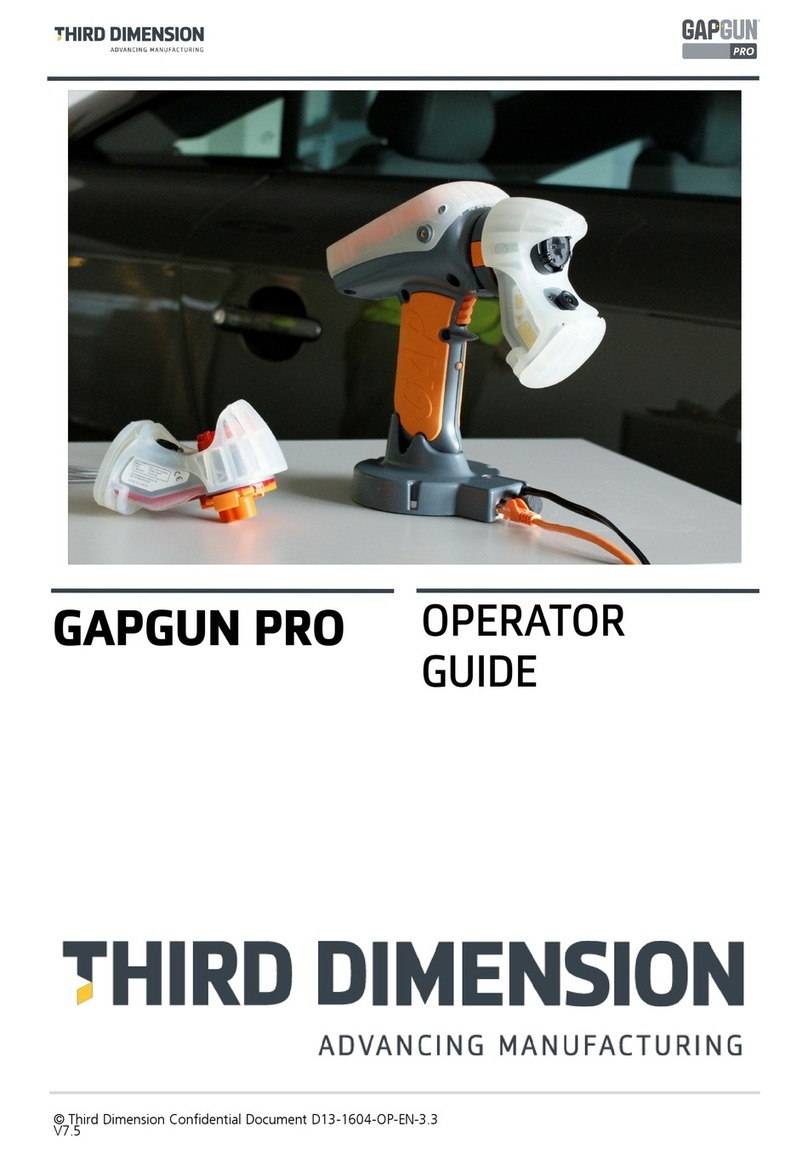

GapGun Pro Case Contents 6

GapGun Pro Overview 6

Power Management

Internal Battery 7

Clip-in Battery 7

Vchange Sensor heads 7

Docking Station 8

Standoffs 8

Image Mask 8

Usage

Daily Care, Cleaning and Calibration 9

Works order Menu 10

Works order Context Menu 10

Measurement Screen 11

OnScreen Keyboard 12

Results Menu 12

Works Orders

Downloading Checkplans 13

Running a Works Order 13

Feature display formats 13

Returning results 14

Deleting Works Orders 15

Feature Context menu

Filtering results 15

Deleting results 15

Deleting Works orders 15

Select List Feature details 16

Checking Head calibration 16

Power Management —Switching On and Off 17

Vchange Sensor Exchange 17

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 5

Administrator mode

Entering Administrator mode 18

Setting GapGun name 18

Setting Language 18

Setting Date and time 18

Configuring Coprocessor mode 19

CERDISP Remote Display mode 20

Calibrating the touchscreen 21

Networking

Configuring LAN communications 21

Wireless Wi-Fi Configurations 22

Personal Wi-FI Configuration

Configuring Wi-Fi IP Addressing 23

Personal Wi-Fi security overview 23

Configuring Personal Wi-Fi security 24

Creating and Configuring an Ad-Hoc Wi-Fi network 25

Enterprise Wi-Fi Configuration 26

Installing Root CA Certificates manually 26

Installing Root CA Certificates auto enrolment 27

Installing Personal Certificates for EAP-TLS 27

Installing Software Updates 29

Installing Calibration files 29

Installing Software Licences 30

Updating Licences and Calibrations via the Intenet 30

Disk Cleanup 21

Support Mode 31

Status Report 31

Installing checkplans on the context menu 32

Creating statistical checkplans 32

Head Check and Repeatability Theory 33

Updating the GapGun Operating System 34

Measurement Error Reporting 36

Glossary 37

6© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

A. Laser source

B. Camera

C. Green indicator LEDs

D. Vchange collar release

E. Trigger

F. On / Off switch

G. USB slot

H. Touch screen display

I. Head power indicator

J. Red laser activity indicator

K. Drop Protection jacket

L. V-Standoff

M. Wrist strap

H

I J

K

L

M

A

B

C E

F

D

G

M

A. Desktop battery charger

B. GapGun Pro with VChange sensor

C. Calibration gauge block

D. Hex tool training artifact

E. Docking station

F. Docking Station Cabling

G. Calibration pin gauge

H. Gauge block cleaning brush

I. Clip-on rechargeable battery pack

J. Spare rechargeable battery

K. GapGun software memory stick

L. Space for Shock protection sensor jacket

M. Extra VChange Sensors

N. Standoffs

O. Desktop charger power supply

E

B

O

E

G

D

J

A

C

K

F

H

L M

N

NI M

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 7

The clip on battery pack attaches onto the base

of the handle and provides power for additional

4-6 hours.

The Desktop charger will recharge the battery in

about 1.5 hours.

The VChange sensor system allows sensor heads

to be quickly and easily changed without using

any tools. The Vchange system can be retrofitted

to existing MX+ handles and sensors. Sensor

heads can be freely interchanged between

different handles.

To swap the sensor head squeeze the orange

release tabs on the Vchange collar and pull the

sensor off the handle. Push the new sensor into

place until the collar lock clicks. The sensor can

be swapped without turning off the GapGun.

The GapGun Pro has an internal battery which can

power the GapGun for 4 to 5 hours of normal use.

The battery can be recharged using the docking

station or via the clip-on battery which can be used to

extend the period of use by a further 4-6 hours.

8© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

Some heads have a three position mask in front of the laser. Turning the laser cap changes the mask:

Position I places a mask line in the centre of the laser line. This artificially divides the laser line into a left and

right side. It can be used to measure features where it is difficult to identify the left and right sides

of a feature.

Position II is the default position which allows the full width of the laser line to be used.

Position III masks the laser on the right and left ends of the line presenting a shorter laser line on the feature.

I

II

III

III

II

I

I

II

III

The Docking Station connects the GapGun to the PC

though an Ethernet connection.

It also powers the GapGun, recharges the internal

battery and is a safe place to store the GapGun.

Standoffs are used in applications where the

parts being measured can’t possibly move. The

standoffs help stabilise the GapGun and position

it correctly.

The black V standoffs are for measuring gaps and

the grey H standoffs are for sealant beads.

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 9

Protect the GapGun by always using the Head

Jacket (above) and wrist loop.

Before each use: check lenses are clean, check

for any damage and verify calibration.

If the GapGun is dropped, check it for damage

and verify calibration.

The GapGun lenses need to be clean: Inspect the

highlighted areas for dust, grease or fingerprints;

clean them with the kit provided if required.

The GapGun Pro is designed for indoor use; keep

the system and its accessories dry and clean. Do

not use solvents on any surface.

Always verify calibration before use by measuring the Gauge Block or Pin Gauge supplied with your system. See

the Checking Head Calibration section in this manual for more details on running the Head Check checkplan.

FOV15/40/80 To perform a calibration check successfully, place the gauge block on a flat, stable surface.

Using the V-standoff, locate the tip in the gap to position the sensor at the correct distance

from the block.

FOV7 To perform a calibration check successfully. Using the V-standoff, locate the pin into the V

from the top of the standoff, taking care not to apply undue pressure to the pin.

NOTE: Failure to follow these steps may cause false calibration failures.

FOV 15 / 40 / 80 FOV 7

10 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

Context Menu

Pressing the context menu button brings up a set of

additional items related to the current menu allowing

access to other functions or to system wide functions.

The example is the Works Order Context menu.

Power off

This allows the GapGun to be turned off.

Administrator

Provides access to the Administrator Menu, which is

password protected, it allows various features of the

GapGun to be configured such as GapGun Name,

Comms, Language, Font Size, Date/Time, Touch Screen

Calibration. In Administrator mode a green figure

appears in the top right hand corner.

Operator

Returns the user level to Operator restricting access to

configuration options.

Status report

The Status report provides information about the

current state of the GapGun. The report has three

sections; Handle, Head and Network.

Volume

Volume allows the operator to adjust the loudness of

the GapGun informational and warning sounds.

GapGun

Name

Set to the serial number of the GapGun

changed from the Admin Menu

Tools

Checkplan

Tools checkplan to make instant measure-

ments. In Metric and Inches.

Battery shows remaining charge, the flash indi-

cates that the battery is charging.

Wi-Fi connected, dark bars indicate signal

strength.

Download shows the GapGun is talking to a

host PC.

Co-processor Shown when the GapGun is

connected to a co-processor.

New Works Order.

Open Works Order not yet completed.

Locked Works Order ready to be uploaded.

Scroll up or down between menu items.

Scroll left or right between different views.

Context Menu Access to extra functions de-

pendent on which screen is in use.

Return to the previous menu

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 11

Manual Lock —The Manual Lock button has

been tapped. The GapGun will not complete the

measurement until the Manual Lock button is

tapped again or the trigger is pulled.

Trigger Lock —The trigger has been pulled. The

GapGun will not complete the measurement until

trigger is released.

Waiting… — The GapGun is waiting for the

sensor or the co-processor to respond. Check that

the sensor is plugged in correctly or that the

network link is still working.

Bad Range—The GapGun is not at the right

distance from the object. This can occur at the start

of measurement in which case point the GapGun

away from the object then re-aim it at the target.

Adjusting Laser—The GapGun is trying to find

the correct power for the laser to obtain the best

image. This may occur on difficult surfaces such as

very dark, very light or irregular surfaces.

A. The unique ID number of the current measurement.

B. The Serial Number (VIN) of the current job.

C. Instantaneous frame rate, capture time and current zoom setting.

D. Current Feature path

E. Frame record, green for frames which can be processed, red for frames which have failed. The

measurement continues until enough good frames have been gathered.

F. The calculated results from this measurement.

G. Angle indicator, the red line shows the angle of the GapGun relative to the average surface of the artefact,

the white sections show the acceptable angle limits for this Feature. The red line must be in the white

section.

H. Facsimile of the current measurement . The red line is the artefact surface, the grey blocks are the line fits

of the Feature to the data.

I. Minimum range of the measurement (maximum marker is obscured), the red data line must be between

the maximum and minimum range markers

Manual lock, when locked the measurement will not complete until the lock is removed,. The

manual lock can be removed by pulling the trigger.

J.

Zoom, the image data can be zoomed in and out so that the image can be examined more closely.K.

Process control, the GapGun Pro processes frames to calculate results which are instantly displayed

however measurements which fail are not recorded. To aid in debugging processing can be disa-

bled and the failing image data and the failure code returned to SPC3D for analysis.

L

A B C

D

E

F G

H

I

J K L

12 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

After a measurement has been made, tapping on the measurement again will display the Results Menu. The

GapGun will also show this screen if the measurement results in an error. The options available are to

Remeasure the Feature again, the previous result is overwritten.

View the measurement, which shows the processed image . The grey blocks show any line fits made to the

date and the white circles show the measurement points used to define the characteristics. The up and

down arrows moves through each frame allowing the user to examine why some frames did not succeed.

Enter an Error Code instead of a measurement. These codes can be customised for each Feature.

Delete this measurement entirely.

The onscreen keyboard is used at all times when the

user is prompted for information.

The selection of keys shown on the screen can be

changed by clicking the appropriate selector.

The \Tools\Special\Value feature allows the initial

setting to be preset.

Tapping the Bar button enables the barcode reader

which can read Code128, Code39 Interleaved 2/5.

The entry is completed by tapping the OK button.

Tapping the X key cancels the entry.

The DEL button deletes the previous character.

The +/-1 keys will increment the rightmost number

in the entry field wherever it is.

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 13

1. Tapping on the name of the Work Order displays five copies of the same checkplan, this number can be

changed in the Checkplan properties or globally in

System options...

under

WorksOrderDefaultNumJobs

.

2. The GapGun then prompts for a serial number which can be typed in, read by a barcode. The previous serial

number can be incremented or decremented using the +1 and –1 keys.

3. The

Groups

in the checkplan are then displayed showing how much of each Group has been measured.

4. Tapping on a Group displays the list of Features to be measured in that Group. Groups and Features can be

run in any order. However, the GapGun is configured to run through in the given order by pulling the trigger.

Note: Pressing and holding the up and down arrow keys automatically scrolls through the Groups and Features

lists.

The GapGun regularly searches for PCs running SPC3D when it is connected to a network. When it finds PCs

running SPC3D the

Download…

item appears.

1. Clicking

Download…

displays a list of the PCs running SPC3D.

2. To download a checkplan to the GapGun it must first be opened in SPC3D on the PC. Selecting a PC

displays a list of the checkplans that are open on that PC.

3. Selecting the checkplan downloads it to the GapGun where it becomes a Works Order.

4. The new Works Order is displayed on the

Works Orders

menu with the starred icon.

14 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

Once all Features in all Groups have been measured the GapGun returns to the Groups menu. The percentage

shows how many Features were measured and the green and red bands quickly show how many were in and out

of tolerance.

The Summary describes these results in more detail. Returning from the

Groups

menu prompts the Operator to:

Save & exit the Works order which saves the results so far but allows further Features to be measured.

Lock & exit which locks the Works order in preparation to be returned to SPC3D.

Lock & upload which locks the Works order and then prompts the Operator for a PC running SPC3D.

Once the upload is complete, the Works order can be deleted from the GapGun.

The features can be displayed in three formats, tapping the right and left arrows changes between the formats.

List format shows Features in a text-only list. By default, the Actual measurement and Deviation from nominal

is shown, displayed in green if they are in tolerance and red if out of tolerance. Other details can be displayed

using the context menu (see below).

Small Icon format shows Features with a small graphic to demonstrate how the measurement should be taken.

Large Icon format shows a large graphic to demonstrate how the measurement should be made.

The large Icon formats also show a text instruction to guide the operator. This text is set using the “Instructions” item

on the card view in the workspace window.

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 15

A Works Orders is normally deleted from the GapGun when it is completed and the results uploaded to SPC3D.

To delete it before this point requires Administrator Mode privileges, notice the Admin Icon in the top right

corner.

The new menu item

Delete works order

is tapped and the list of Works orders currently loaded on the

GapGun is shown.

Tapping the Works Order to be removed displays a prompt to confirm the action before deleting the

Works Order and any results associated with it.

Note: The

Tools

and

Head check

Works Orders should not normally be deleted.

Filters allows the Operator to only display subsets of Features such as all unmeasured features, all in-tolerance

features or all out-of-tolerance features.

Delete results allows the Operator to delete all the results measured so far in this Works order. If this is called

from the Groups or Features screens then the results from a single job only will be deleted. This allows wrongly

entered serial number to be corrected without losing all other results in this Works Order. If this is called from the

Jobs screen then ALL results associated with this Works Order will be deleted.

Delete works order allows the Administrator to delete the whole Works order from the GapGun.

Note: The

Tools

and the

Head Check

Works Orders should not normally be deleted.

16 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

The calibration of the head can be checked by selecting the

Head Check

item at any time during measurement.

1. The Operator should then select the Group relevant to the head installed on the Gapgun.

2. Each of the features on the gauges should be tested using the up and down arrows.

3. Each measurement must be taken at least three times and the Cg and Cgk calculated. The check can be

restarted at any time by tapping Restart. Once enough successful measurements have been captured the

result is shown, in green if the calibration is okay and in red if it is out of calibration. The Operator should

seek advice on how to proceed from a Supervisor.

Columns allows the details displayed in the List format to be customized. These settings are changed for all

Works orders measured on this GapGun once set.

Selecting more columns decreases the number of Features that can be displayed on one screen so there is a trade

-off between showing Features and showing details. All the details are displayed in the Large Icon Feature display

and can be accessed by using the left and right arrow keys at a time.

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 17

The GapGun can be turned on and off switch using the button below the trigger guard. The GapGun can also be

turned off by tapping the Power off option on the Context menu.

The battery icon indicates the charge remaining in the internal battery, an estimate of the remaining battery life is

displayed when the GapGun is running on its internal battery.

The battery will recharge from any external source such as a Docking station or a clip-on battery pack. It will

display a yellow flash to show that it is recharging.

The battery will not recharge if the internal temperature rises above 43°C, the temperature and a red cross are

displayed to shown when this condition occurs, charging recommences once the temperature drops below 43°C

again.

The Vchange sensors can be exchanged at any time in normal operation other than when in a measurement.

The GapGun registers that the sensor has been removed;

The GapGun registers that a new sensor has been mounted;

The GapGun tries to load the calibration data for the new sensor. If a no calibration file is found, the GapGun

will search a mounted USB stick for the required file. The calibration file must be loaded before it can be used

for measurement.

If the calibration file has expired, a warning message is given and the option to continue or search for a newer

calibration file is offered. The GapGun will probably continue to measure accurately which can be checked by

performing a Head Check but is technically out of calibration.

18 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

Many management and configuration options can only be performed by an Administrator.

To access these functions the GapGun must first be put into Administrator Mode. Click on the context

menu icon and tap on the Administrator item.

The password must be entered into the input screen. By default the password is set to 4321

The Administrator Menu lists various management and configuration options to configure the GapGun as

required. Because the list is longer than one screen the up and down arrow keys can be used to scroll up

and down the screen.

Note: When the GapGun is in Administrator Mode a small green figure is shown in the top right corner.

GapGun Name Before V7.6 this is set to the serial number of the GapGun but can be changed as required. From

V7.6 onwards it is used as the network name of the GapGun. The handle operating system adheres to RFC-952

which means this name cannot start with a number so “3DSW-xxx” is illegal. It now defaults to “GapGun”.

Language The GapGun interface language can be set to any of the languages on this menu.

Note: Checkplans will be displayed in the language of the SPC3D used to create them.

Font Size The size of the text on the GapGun screen can be changed between Huge and Tiny.

Date/Time The Date and Time on the GapGun can be altered. However, the date and time are normally

synchronised with SPC3D whenever the GapGun connects to the PC. The time zone should be set to match that

set on the PC.

© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6 19

The GapGun can operate in two modes; Roaming mode where GapGun does all its own processing and

Coprocessor mode where a PC running SPC3D does the calculations so that the GapGun can process the data

more quickly.

When using the GapGun MX+ and for some measurement Features such as the BSE family or complex multi-

curve fits when using the GapGun Pro, Coprocessor mode should be used to achieve acceptable speeds of

measurement.

To configure this mode:

Select a particular SPC3D server from the list or

Select Any so that any SPC3D server on the network may be used as coprocessor or

Select None to disable coprocessor mode.

The selection of co-processor configuration has been moved

from the GapGun to each individual Checkplan. This means

that which ever GapGun the Checkplan is run, it will try to use

the same co-processor.

However, this means that Checkplans produced by SPC3D V7.5

or earlier are not compatible with GapGuns running V7.6 or

later.

The co-processor is configured in SPC3D on the Works order

Tab of the Checkplan Properties.

The IP address or hostname of the PC running the co-processor

is specified, the port on which the co-processor will

communicate is set, this is normally

port 21030. Ticking the Coprocessor

box will make the GapGun contact

the co-procerssor on the specified

port when it runs the Works order.

This dialog is also used to define

where add-ins such as Inline View

are being run.

Note: V7.6 and later versions of

Inline View can also operate as co-

processors removing the need to run

a separate copy of SPC3D.

20 © Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

To control the GapGun MX+ via CERDISP uses a slightly different method the the GapGun Pro.

On the PC the program to run is: C:\Program Files (x86)\Third Dimension\SPC3d7\Utils\CERHOSTGG4.EXE

On the GapGunMX+, CERDISP requests the IP address of the PC on which CERHOSTGG4 is being run.

The utility can then be hidden by tapping the

Hide

button. Tapping CERDISP again will display the dialog

to allow the utility to be closed down.

On the PC a live image of the GapGun screen is displayed and this can be used to control the GapGun

interactively using the mouse and keyboard.

The GapGun can be accessed remotely from a Windows PC. Tap CERDISP on the Administrators Menu on the

GapGun.

To control a GapGun Pro, on the PC run: C:\Program Files (x86)\Third Dimension\SPC3d7\Utils\CERHOSTGG5.EXE

1. Run CERDISP from the Administrator Menu to advertise the GapGun on the network.

2. Run CERHOSTGG5, select

File->Connect

, select the target GapGun and click OK.

3. CERHOSTGG5 displays a live image of the GapGun screen. The GapGun can be used to controlled

interactively using the mouse and keyboard through this program.

Other manuals for GapGun Pro

1

Table of contents

Other Third Dimension Measuring Instrument manuals