Stahls Hotronix Fusion XF User manual

Other Stahls Hotronix Power Tools manuals

Stahls Hotronix

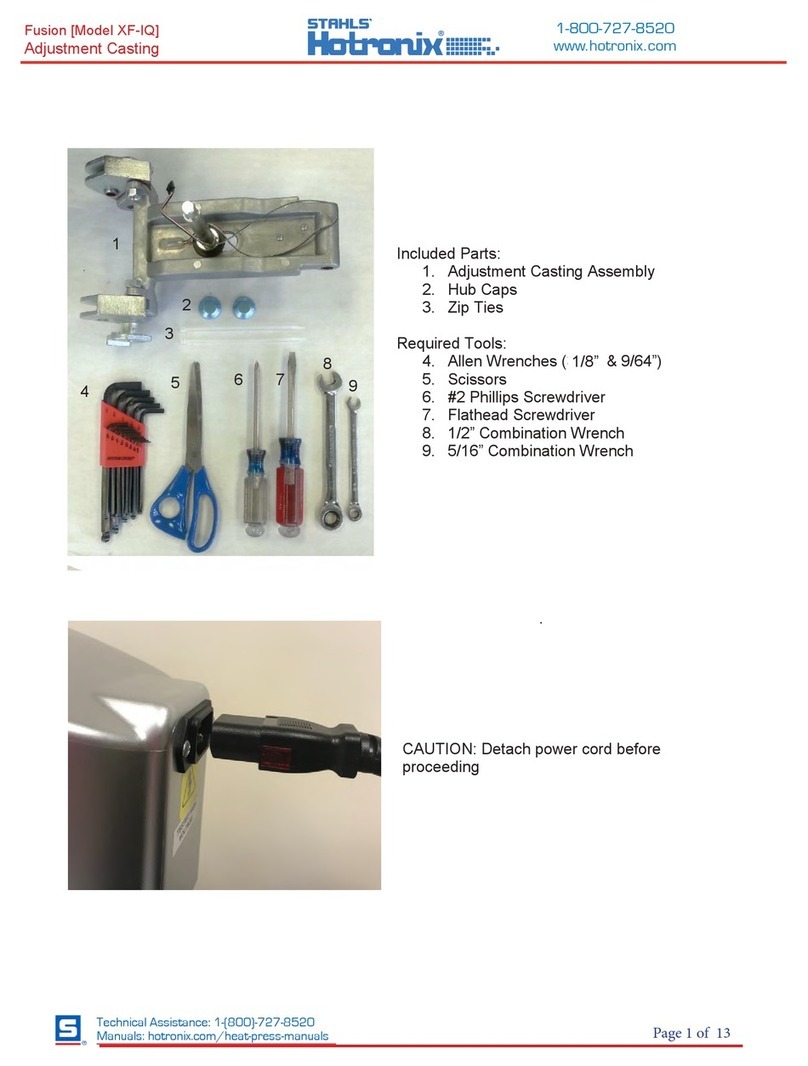

Stahls Hotronix Fusion XF-IQ User manual

Stahls Hotronix

Stahls Hotronix STX Series Use and care manual

Stahls Hotronix

Stahls Hotronix The MAXX Press User manual

Stahls Hotronix

Stahls Hotronix Fusion XF Operating and safety instructions

Stahls Hotronix

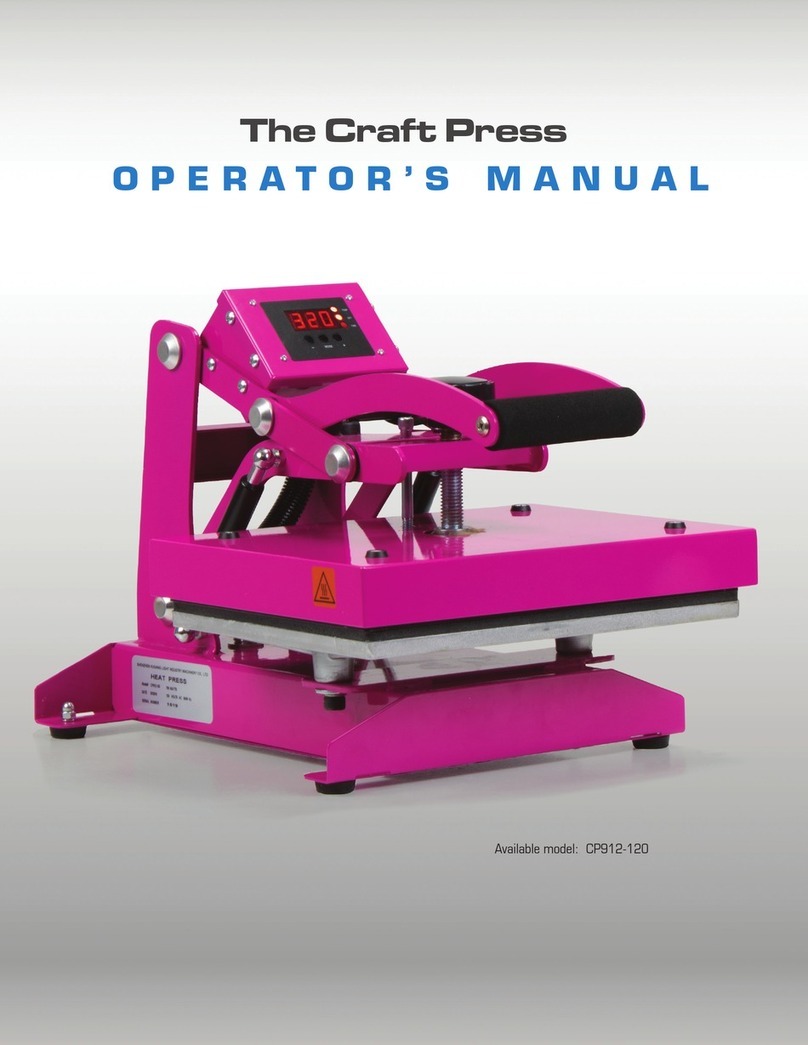

Stahls Hotronix CP912-120 User manual

Stahls Hotronix

Stahls Hotronix FUSION IQ User manual

Stahls Hotronix

Stahls Hotronix Air Fusion XRF Operating and safety instructions

Stahls Hotronix

Stahls Hotronix MAXX CLAM User manual

Stahls Hotronix

Stahls Hotronix FUSION 360 IQ User manual