i

i15

i

i

To help you make informed decisions about safety, you

will nd important safety information in a variety of forms,

including:

• Safety Labels on the post driver

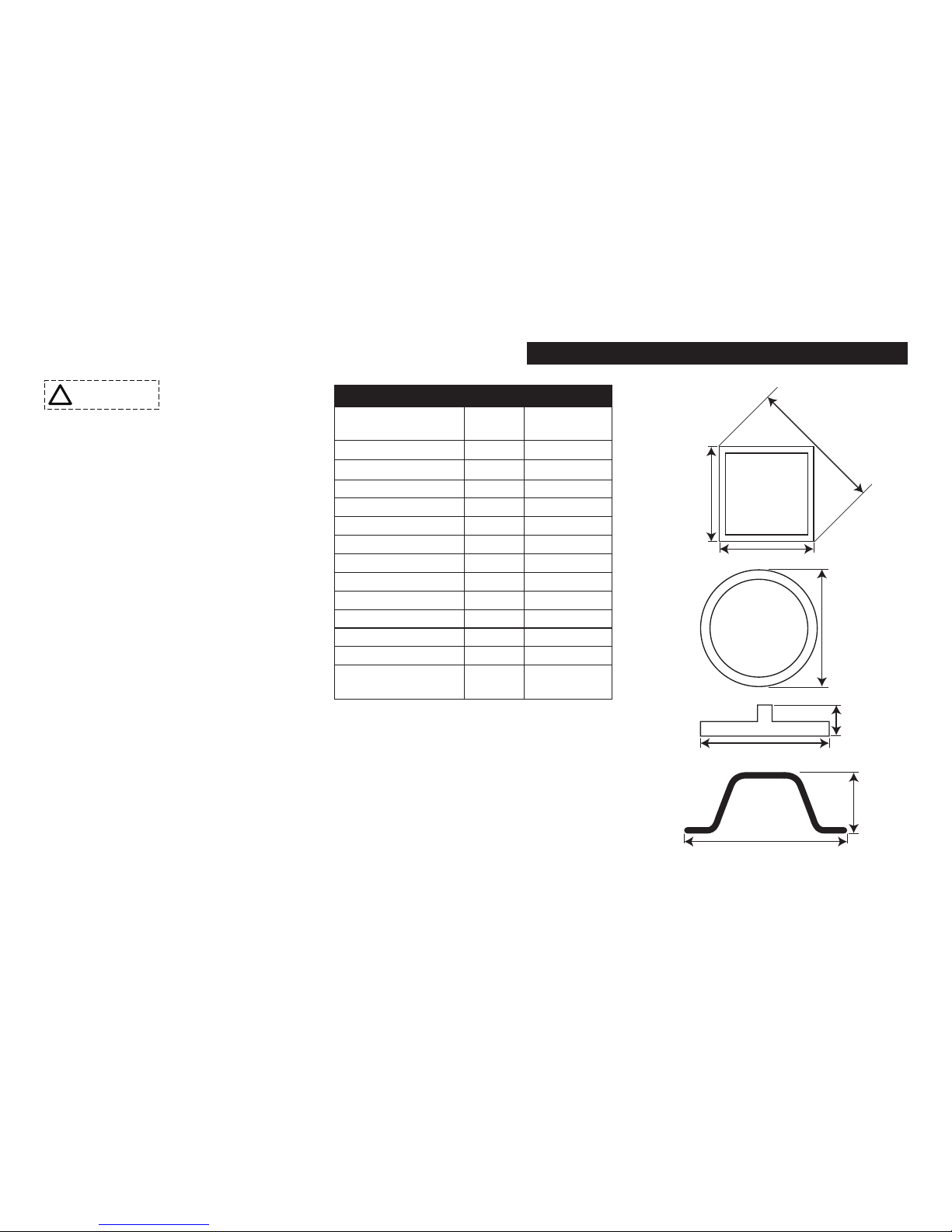

• Safety Messages Preceded by a safety alert

symbol and one of three signal words, DANGER,

WARNING, or CAUTION. These signal words mean:

Immediate hazards that will result in

severe personal injury or death.

Hazards or unsafe practices that could

result in personal injury.

Hazards or unsafe practices that could

result in injury, product or property

damage.

• Safety Headings such as IMPORTANT SAFETY

INFORMATION.

• Safety Section such as POST DRIVER SAFETY.

• Instructions how to use this post driver correctly

and safely.

TAKE SAFETY SERIOUSLY TROUBLE SHOOTING

15

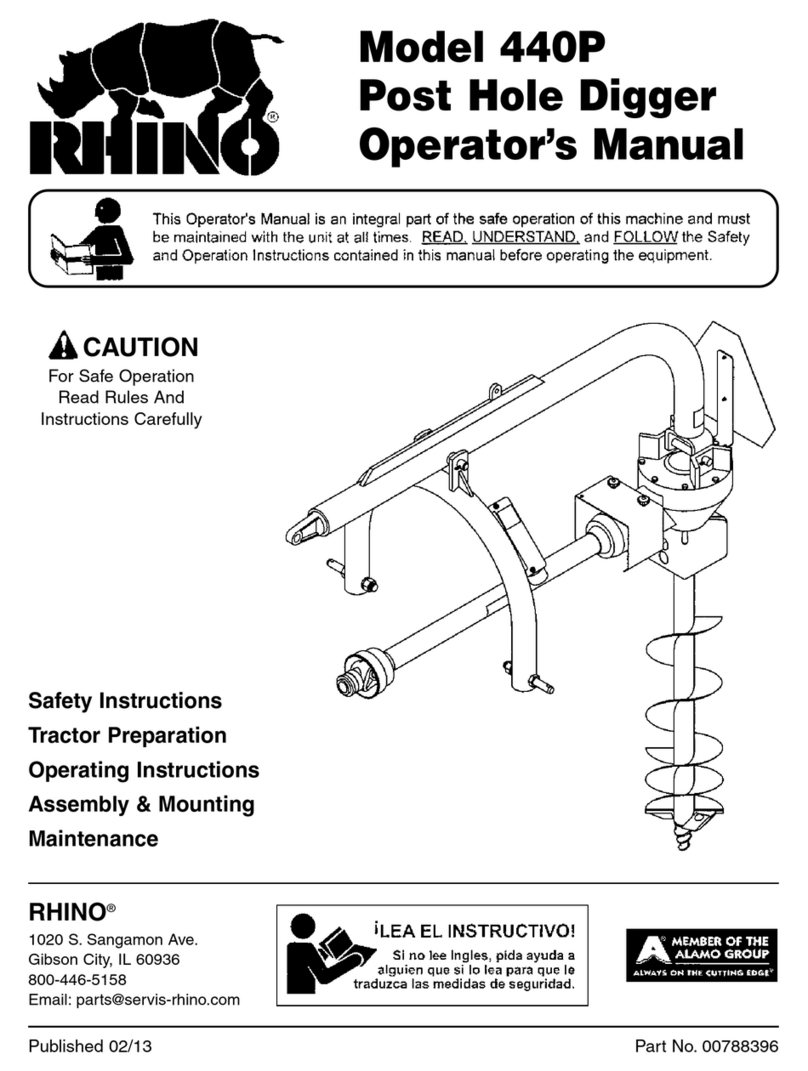

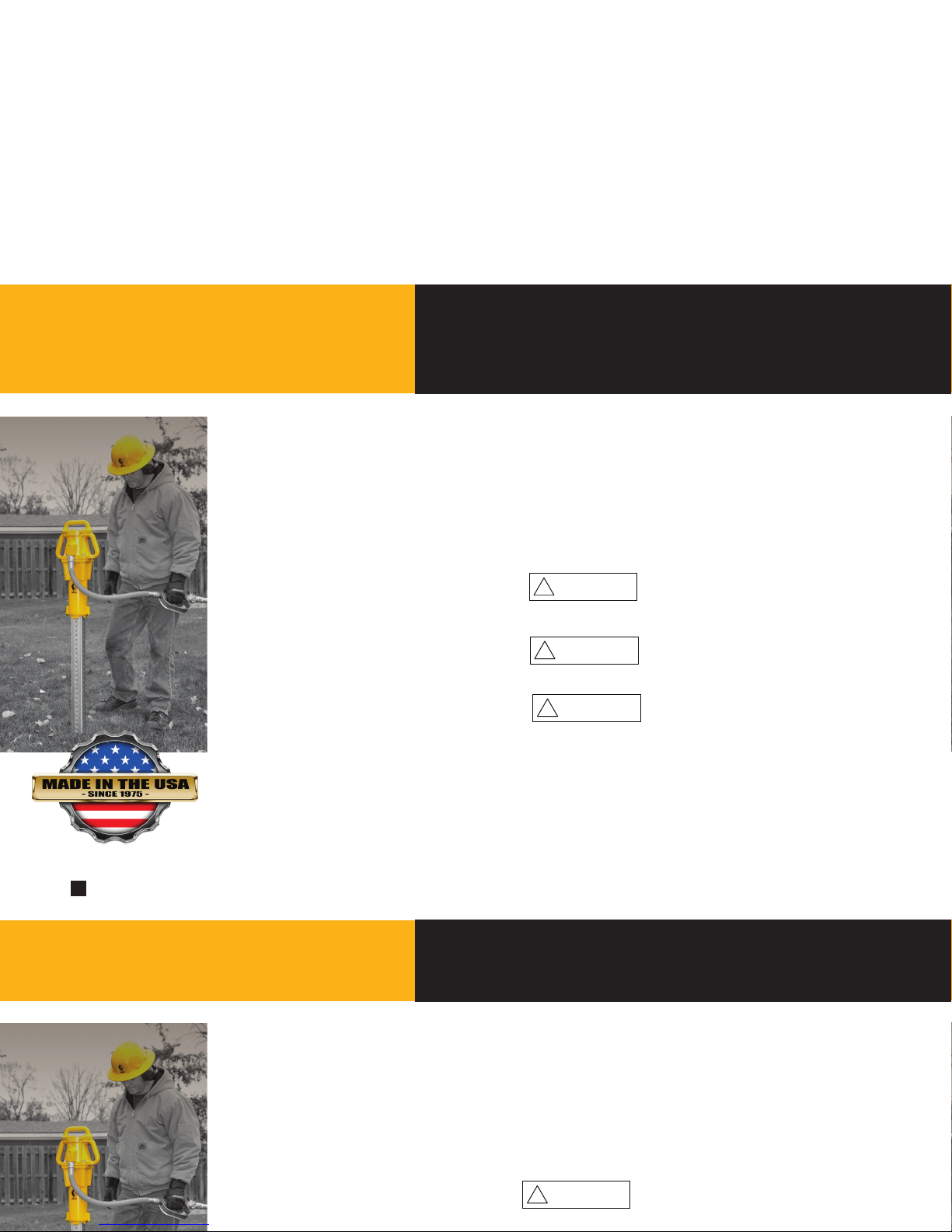

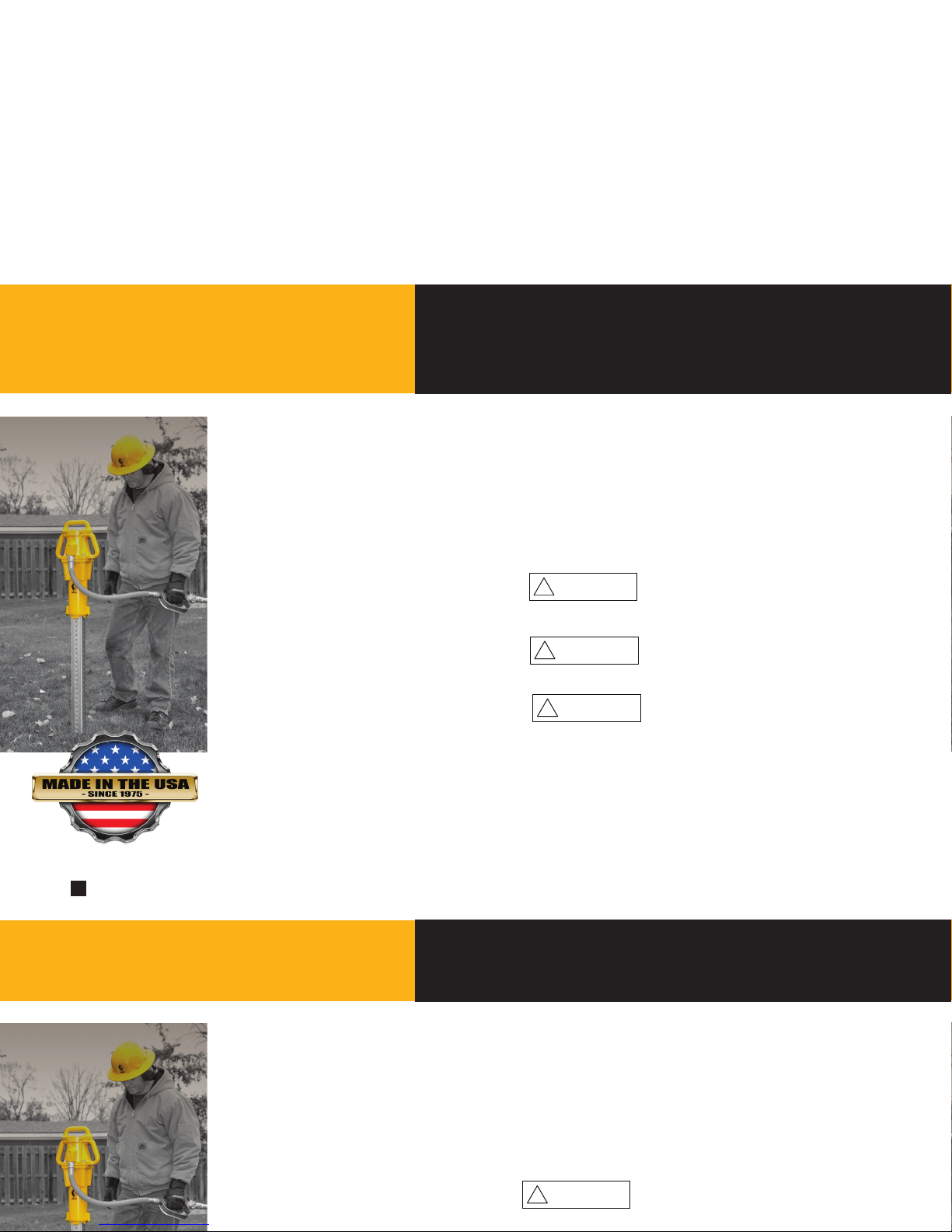

Your safety, and the safety of oth-

ers, is very important. The proper

and safe use of your Rhino® post

driver is an important responsibility

and should be taken seriously.

Keep this owner’s manual avail-

able, so you can refer to it at

any time. This owner’s manual is

considered a permanent part of the

post driver and should remain with

the post driver if resold.

The information and specications

included in this publication were

in eect at the time of approval

for printing. Rhino Tool Company,

Inc. reserves the right, however,

to discontinue or change

specications or design at any time

without notice and without incurring

any obligation whatever. No part of

this publication may be reproduced

without written permission from:

Rhino Tool Company

Your safety, and the safety of oth-

ers, is very important. The proper

and safe use of your Rhino® post

driver is an important responsibility

and should be taken seriously.

Keep this owner’s manual avail-

able, so you can refer to it at

any time. This owner’s manual is

considered a permanent part of the

post driver and should remain with

the post driver if resold.

The information and specications

included in this publication were

in eect at the time of approval

for printing. Rhino Tool Company,

Inc. reserves the right, however,

to discontinue or change

specications or design at any time

without notice and without incurring

any obligation whatever. No part of

this publication may be reproduced

without written permission from:

Rhino Tool Company

!DANGER

!CAUTION

IMPORTANT

NOTE

This book contains important safety information.

Please read it carefully.

Call your local dealer, service center or Rhino Tool

Company for more assistance with your post driver

i

To help you make informed decisions about safety, you

will nd important safety information in a variety of forms,

including:

• Safety Labels on the post driver

• Safety Messages Preceded by a safety alert

symbol and one of three signal words, DANGER,

WARNING, or CAUTION. These signal words mean:

Immediate hazards that will result in

severe personal injury or death.

Hazards or unsafe practices that could

result in personal injury.

Hazards or unsafe practices that could

result in injury, product or property

damage.

• Safety Headings such as IMPORTANT SAFETY

INFORMATION.

• Safety Section such as POST DRIVER SAFETY.

• Instructions how to use this post driver correctly

and safely.

TAKE SAFETY SERIOUSLY TROUBLE SHOOTING

!DANGER

!CAUTION

IMPORTANT

NOTE

This book contains important safety information.

Please read it carefully.

Call your local dealer, service center or Rhino Tool

Company for more assistance with your post driver

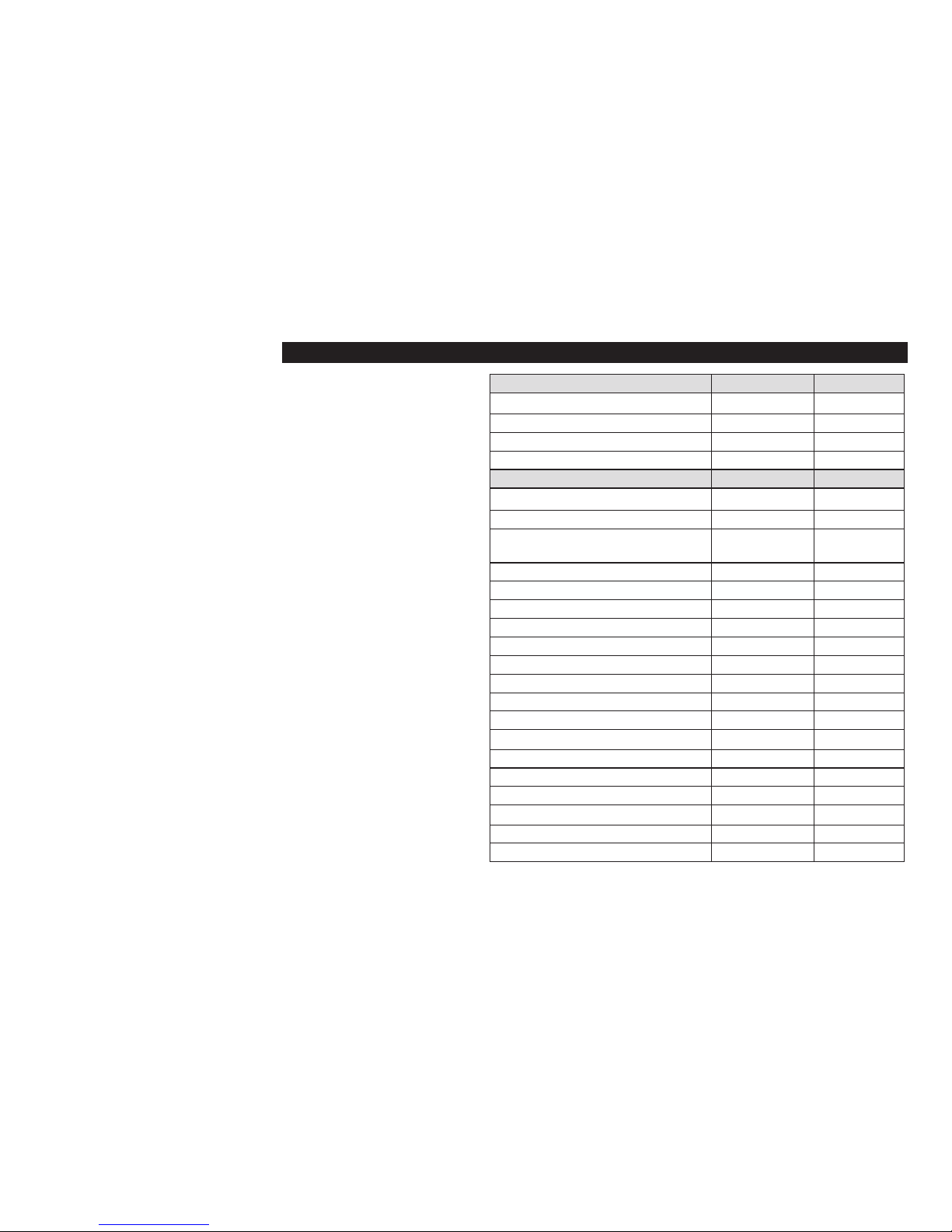

Symptom Explanation/Procedure

Post lodged in the

driver

1. Remove the 2 bolts that secure the adapter and separate the driver from the adapter.

2. Slide the adapter down the post to expose the top of the post. With the proper cutting tool for the type of post, cut

through the post below the ared portion.

3. Once the deformed portion is removed, slide the adapter off the post and reassemble it to the driver. Please follow

bolt tightening procedure.

Drives post slow

or sluggish

performance

1. Inspect the chuck to see if there is any foreign material blocking the piston.

2. Check to see if piston is moving freely by disconnecting the driver from air, tipping upside down and back upright.

You should be able to hear the piston moving freely.

3. Check to ensure the rate of lubrication is adequate.

4. If using a FRL, inspect the lter on the FRL, if impacted with residue replace with new lter.

5. Inspect the lter on the Throttle. If clogged, blow off debris with air hose, or clean with a common cleaning solvent.

6. Check to see if air pressure is correct

7. Check output on compressor

8. In temperatures under 40ºF (4ºC) or high humidity conditions check air lines and tool for icing.

Noticeable air passing

through driver or

“blow by”

To conrm this condition exists, connected to air source, place driver on a post, while activating the throttle lift the

driver slightly if the piston increases in activity blow by is conrmed. This indicates there is most likely damaged or

worn parts inside the driver. In this event the driver should be sent to Rhino Tool Company to be inspected and we

will report if the driver is repairable.

Other problems or

technical questions

Other problems or technical questions: Document your serial number and contact Rhino Tool Company. Phone:

309.853.5555 or Toll Free 866-707-1808, Fax:309.856.5905, Email: [email protected]. In Europe contact Eurogate Int. F: (0031) (0) 523 638286, M: (0031) (0) 610 502607.

Symptom Explanation/Procedure

Post lodged in the

driver

1. Remove the 2 bolts that secure the adapter and separate the driver from the adapter.

2. Slide the adapter down the post to expose the top of the post. With the proper cutting tool for the type of post, cut

through the post below the ared portion.

3. Once the deformed portion is removed, slide the adapter off the post and reassemble it to the driver. Please follow

bolt tightening procedure.

Drives post slow

or sluggish

performance

1. Inspect the chuck to see if there is any foreign material blocking the piston.

2. Check to see if piston is moving freely by disconnecting the driver from air, tipping upside down and back upright.

You should be able to hear the piston moving freely.

3. Check to ensure the rate of lubrication is adequate.

4. If using a FRL, inspect the lter on the FRL, if impacted with residue replace with new lter.

5. Inspect the lter on the Throttle. If clogged, blow off debris with air hose, or clean with a common cleaning solvent.

6. Check to see if air pressure is correct

7. Check output on compressor

8. In temperatures under 40ºF (4ºC) or high humidity conditions check air lines and tool for icing.

Noticeable air passing

through driver or

“blow by”

To conrm this condition exists, connected to air source, place driver on a post, while activating the throttle lift the

driver slightly if the piston increases in activity blow by is conrmed. This indicates there is most likely damaged or

worn parts inside the driver. In this event the driver should be sent to Rhino Tool Company to be inspected and we

will report if the driver is repairable.

Other problems or

technical questions

Other problems or technical questions: Document your serial number and contact Rhino Tool Company. Phone:

309.853.5555 or Toll Free 866-707-1808, Fax:309.856.5905, Email: [email protected]. In Europe contact Eurogate Int. F: (0031) (0) 523 638286, M: (0031) (0) 610 502607.

© 2013, 2015, 2017 Rhino Tool Company Inc., - All Rights Reserved

© 2013, 2015, 2017 Rhino Tool Company Inc., - All Rights Reserved