BCM 1220 BATTERY CHARGER

PM004 Rev 2 00/09/21 Thomson Technlogy

3

3.2. "EQUALIZE" VOLTAGE ADJUSTMENT

NOTE: Set "float" before proceeding with equalize adjustment.

3.2.1. Switch the charger to the "equalize" mode with switch.

3.2.2. Wait until the battery voltage stabilizes. (The output current should be almost

zero, unless a load is also connected to the battery. This may take many hours!)

3.2.3. If the voltage is incorrect, adjust equalize potentiometer located on the printed

circuit card. Turn the adjusting screw clockwise to increase voltage, and

counterclockwise to reduce voltage. Adjust in small increments, allowing voltage

to stabilize after each adjustment. When properly set, return the switch to "float".

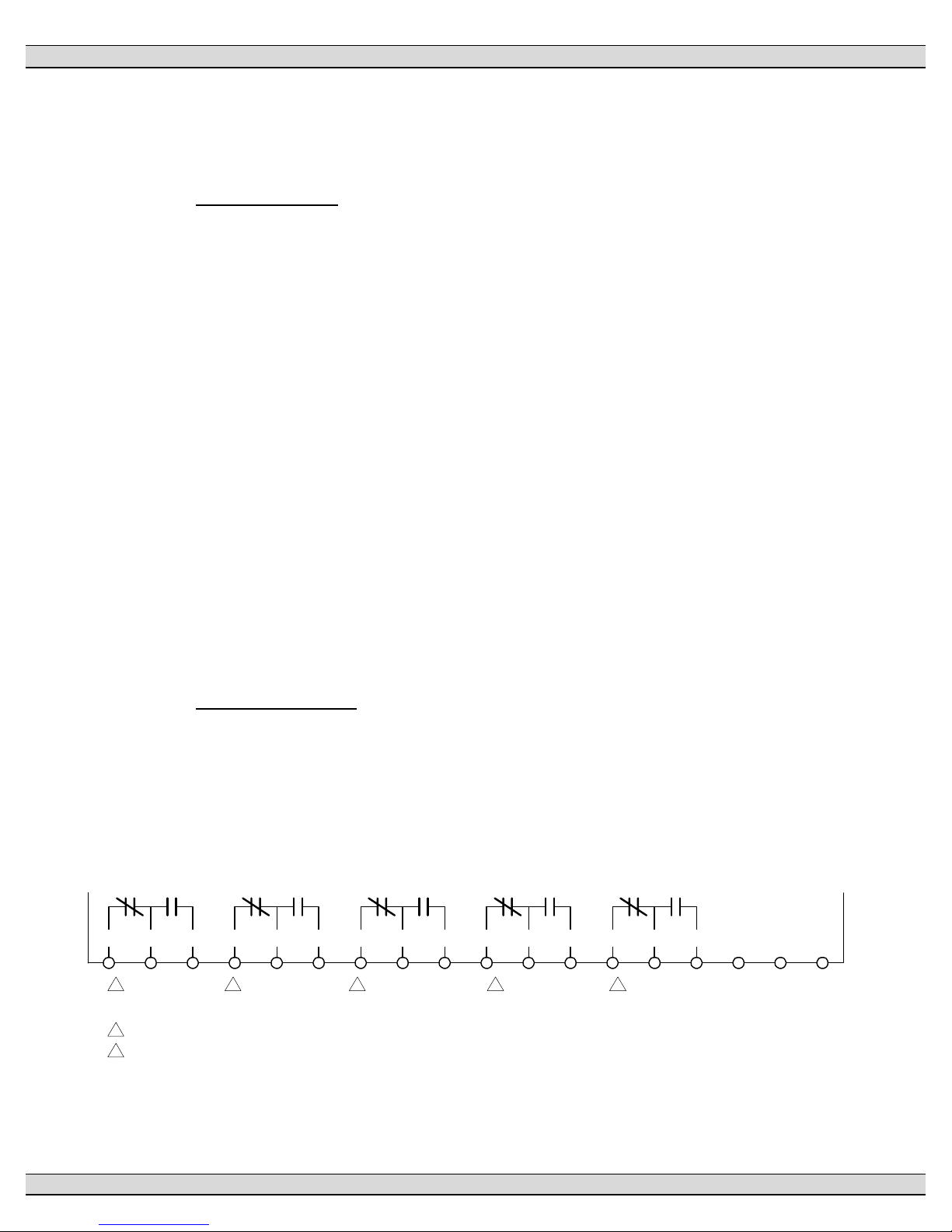

3.3. "CURRENT LIMIT" ADJUSTMENT

NOTE: The "current limit" potentiometer is located on the printed circuit card. It is factory set at

100% of the nameplate rating. Do not exceed this setting or damage to the charger may

result.

During any testing or adjustment of the charger, observe the charging current. In the event that

the current exceeds the nameplate rating, current limit adjustment is required before further

operation.

3.3.1. It is necessary to connect the charger to a lower than nominal voltage load. This

may be accomplished by either:

- Cranking the engine, preferably with the engine disabled to prevent it

from cranking, or;

- Connecting the charger to a partial battery (if inter-cell jumpers are

exposed) or one of a lower voltage (eg. 12 volt battery for 24 volt

charger).

3.3.2. Observe the output current. If the current is within 10% of the nameplate rating,

adjustment is not required.

3.3.3. To adjust current limit, turn the potentiometer on the printed circuit board

(clockwise to decrease). Do not energize the AC supply, except momentarily,

until you are sure the current limit is not set too high.

4. DISCONNECTING THE BATTERY (e.g. For Engine Servicing)

Always turn off the AC supply before disconnecting the battery. This will prevent sparks, and will

ensure that electrical circuits are not fed by the charger alone, which could cause damage.