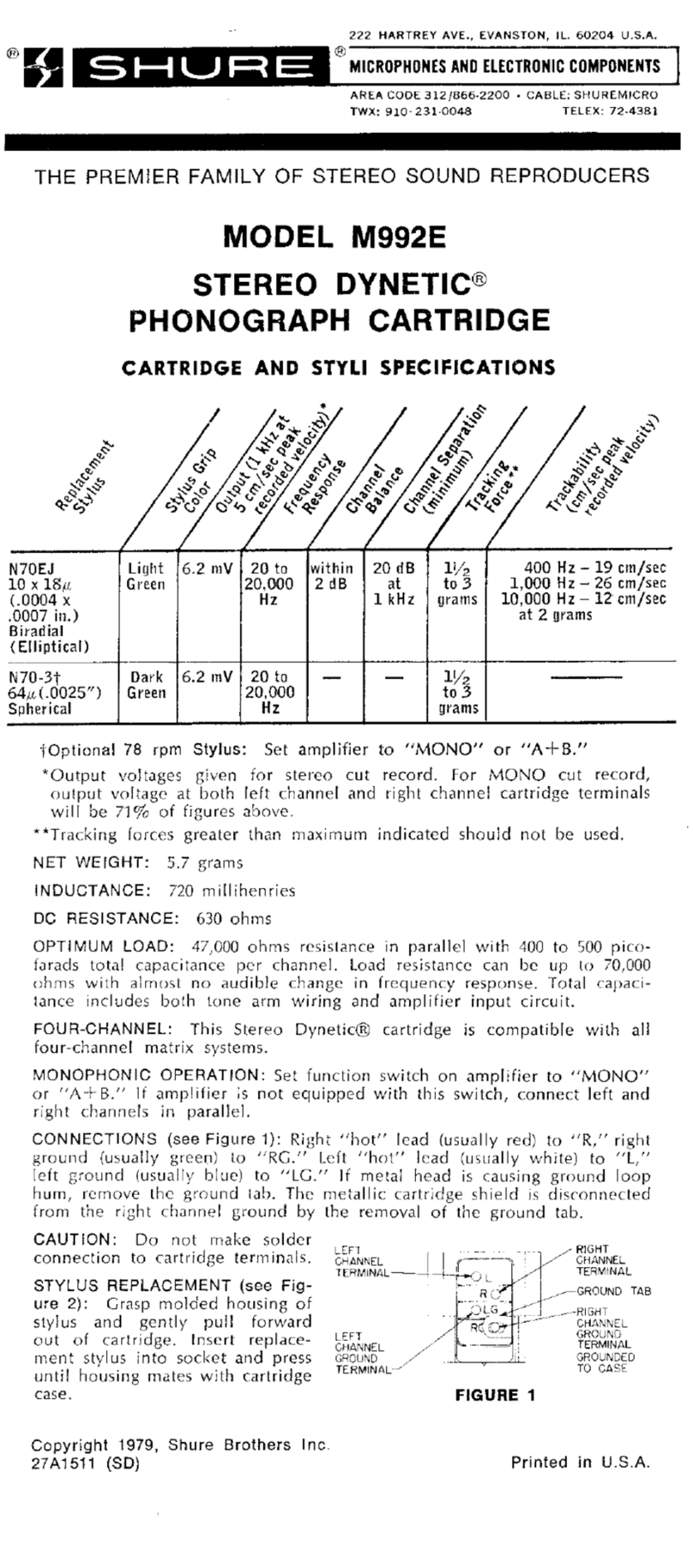

Bif

d/Figure 14

IV. TrackingForceAdjustment

10mN

(milliNewton)

= 1

p

(pond)=1

g

(gramweight)

Beforethe trackingforce can be set, the tone arm

with

thecartridge

mustbebalanced

as

follows.

Movethe knurledtracking

force dial to the zero end

of the scale.Turn on the turntable

(see Section

VIII). Turnthe liftknobto the play position

-V-thus

loweringthe tone arm lift platform.

Position

the arm

between

the arm rest and the turntable

platter.

For

balancing,

loosenthe

knurledscrewon

thecounterweight.

While maintainingthe lateral position

of the arm

with the left hand to avoid damagingthe stylus,

slide the counterweight

until the stylus hoversat

record

playing

level.

Tightenthe knurledscrew and

recheckthebalance.

Note: The counterweight

of the TP 16 Mk III is

designed

for use with lightweight

pickupcartridges

(up

toabout8.5

grams).

Heaviercartridgesrequire a heavier counterweight,

available

through

your

dealer

fromTHORENS.

The adjustment

dial may now be set to the desired

tracking

force,in grams.

As indicated

in Figure

14,

the selectedforce is that value corresponding

with

theindentation;

intermediate

valuesare

indicatedbythe

white

points

betweenthe

numbers.

The tracking force may be initiallychosen accord-

ingtotherecommendationsofthecartridge

manufacturer.

Thissetting

willoftenbe correct;

however,

it shouldbe

noted

thatsuch

prescribed

tracking

forcesarefrequently

basedon ideal

playing

conditions,

i.e.,

using

records

containingonly

moderate

signal

modulationsandexhibit-

ingno

surface

warps.

In practice,

the conditions

for accurately

tracking

a

record

groove

areoften

moredemanding.

The

presence

of

audible

distortion

in both

reproductionchannels

during

loud passages

may indicatethe presence

of tracking

distortion,

whichcan be eliminated

by increasing

the

tracking

forceby0.25

or 0.5grams.

This

measurewill

actuallyextend

thelife

expectancy

oftherecord

played,

since

tracking

distortion

is invariablyaccompanied

by

groove

deformation

and

hence

premature

wear.

Distortion

in onlyone channel

maybe caused

by an

incorrectly

adjustedantiskating

force,

treated

in Section

It is necessarythat the stylus tip be kept free of I

residuesto

insureoptimumtracking

performance;

useonly I

astylus

brush

madefor

cleaning

purposes. I

v. Antiskatingadjustment

The angularhead geometry

of the TP 63 cartridge

wandresults

inminimalradialtracking

errors;

however

it

also

produces

asocalledskating

force,

which

presses

the

stylusonto

the

inner

side

ofthe

record

groove

and,

unless

remedied,

may

cause

distortion

in

one

stereochannel.

This

forceisproduced

bythetracking

frictionofthestylus

tip

with the mooving

groove;

a pull is exerted

on the

tone arm bearingsthat can be resolved into two

force components,

one longitudinaland the other

directed

inward,

perpendicular

to the tone arm, as

shown

inFigure

15.Thisinward

perpendicular

action

isthe

skating

forceFs;witha

lightly

balanced

tonearm,

it

can

lift

thestylus

outofthe

groove

andsend

itskating

acrossthe

recordsurface

towardthe centerof the turntable.

To

counteract

thistendency,

africtionless

magneticassem-

bly

inthe

THORENS

TP 16 MkIII tonearm

appliesan

antiskating

force, directedoutward as illustrated

in

the figure.

Since

the skating

forceis proportional

to

tracking

friction,theantiskating

force

must

beselected

in

proportion

tothe

factorscontributingtothis

friction.

The adjustmentscale on the TP 16 Mk III has

beencalibrated

to include

consideration

of the stylus

tracking

forceandtipconfiguration

forawetordry

record

surface.

The symbolson the calibrationscale representthe

followingtracking

conditions:

wet record surface (producedby

simultaneous

liquid

groove

clean-

ing, preferred by some users,

especially

inEurope

I

I

o spherical

stylus

1

o ellipticalstylus

J

o spherica.l

stvlusl I dryrecordsurface

(normar)

o ellipticalstylus

I I