Thorne BEES ON A BUDGET W.B.C. BEEHIVE User manual

Thornes are committed to providing excellent quality beekeeping equipment. We have been making

beehives for over 100 years now and are in our third, fourth and fifth generations. Many of our staff are

enthusiastic beekeepers with years of knowledge and experience in the industry. All our full size hives

are made from Canadian Western Red Cedar and the Budget range usually from British Western Red

Cedar. Whilst Cedar does not require preservative, having its own camphor type oils, we recommend the

use of an insecticide free Wood Paint, especially designed for beehives. As an alternative, you can use

exterior oil. Whether treated or not, your new Thorne beehive should give you many years of trouble-free

service.

We also have a dedicated email address if you need help or advice, specifically with beekeeping.

CONGRATULATIONS ON BUYING A

BEES ON A BUDGET W.B.C. BEEHIVE

The complete W.B.C. beehive comprises of:

• Solid Floor and Entrance Slides

• Cavity Lath

• Brood Body

• 10 x DN4 frames with standard wired foundation

• Dummy board

• Slotted Steel Queen Excluder

• 2 x Supers

• 22 x SN4 frames with standard wired foundation

• 3 x pairs of runners

• Crownboard with two porter bee escapes

• 3 x Lifts (1 x with porch)

• Plastic cone escapes and brass name plate

• Gabled roof

• All nails, screws, pins and glue

PART LIST FOR THORNE’S BUDGET W.B.C. BEEHIVE

We have a YouTube channel: www.youtube.com/thornebeehives

This shows videos on how to assemble your beehive as well as many other useful videos.

Our website is also full of hints tips and PDF documents on how to assemble each part of your beehive.

You can find them at: www.thorne.co.uk/assembly-instructions

REMEMBER DO NOT GLUE OR NAIL ANYTHING UNTIL YOU ARE SURE THE HIVE PART HAS

BEEN PUT TOGETHER CORRECTLY.

ASSEMBLY INSTRUCTIONS

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

BEES ON A BUDGET W.B.C. BEEHIVE

Once all the hive parts have been assembled, the hive can be put together as follows:

The solid floor with legs, brood, queen excluder,

super/s and crowboard go together on top of

each other as shown here. Then the lifts go over

these, first the one with the porch, then two

more, and your roof on top.

WHAT BIT GOES WHERE IN THE HIVE?

We also have a YouTube video demonstrating this. Follow this link

https://youtu.be/u43U0y1nD74 or snap the QR code.

If you do have any queries about assembling your hive or beekeeping in general please call us on 01673

Crownboard

Super

Queen Excluder

Brood

Solid Floor

WHERE TO GET YOUR FIRST COLONY

There are several ways to get your first colony of bees. Local beekeepers can provide bees which will

be well adapted to the area and they should make sure they are reasonable to handle and free from

disease. Commercial breeders and equipment suppliers select for yield and docility and will also take

care to ensure that colonies are free from disease. In either case, it is recommended that you start

with a nucleus (a small colony with 6 frames of bees). Because it is small, there are fewer bees and it is

easier to manage. As it grows during the season, so should your confidence. You can purchase bees on

our website here: www.thorne.co.uk/bees

If you are offered a swarm to start beekeeping, you should treat them with caution. Swarms can carry

disease and may have poor temperament.

CHOOSING AN APIARY SITE

Most beekeepers keep a few hives ‘at the bottom of the garden’. This may be convenient for the

beekeeper but might not be the best place for the bees. Factors worth considering when choosing an

apiary site:

• Is there sufficient forage to support the bees and produce a surplus?

• Is the location adjacent to a public thoroughfare?

• Is the site protected from the prevailing wind, frost and flooding?

• Is the site easily accessible at all times?

• Is there an adequate supply of water close by?

• Is there sufficient space for expansion?

INSTALLING BEES IN YOUR NEW HIVE

1. Prepare the site and make sure all hive parts are ready for the bees.

2. Place the travelling box (that the bees came in) onto the floor with the entrance facing in the desired

direction and remove the entrance seal. Leave the box for at least 24 hours for the bees to settle to

their new location.

3. Choose a fine, warm day to transfer the bees to their new hive. Light your smoker and put on your

protective clothing.

4. Move the box with the bees to the side. Place the floor and brood body from your new hive onto the

stand. Any flying bees will start to return to the original site and will go into the hive.

5. Remove the lid from the travelling box. Smoke gently. Check the bees on the underside of the lid in

case the queen is there (unlikely but possible) and then shake the bees off the lid into the new hive.

Place the lid to one side.

6. Remove a frame from one side of the travelling box, taking care to avoid crushing bees. Put the

frame into the new hive at one side. Remove each of the remaining frames from the box and transfer

them into the hive. Keep the frames in the same order and orientation. It is best to transfer the six

frames into the centre of the brood body.

7. Once all the frames have been transferred, give the travelling box a sharp shake over the hive to

transfer any bees remaining in the box to the hive. Place frames with foundation either side of the

frames with bees, filling the hive with a dummy board at one side and then put the crownboard in

place.

8. Feed the bees a sugar water syrup 1kg sugar to 1litre water using a feeder on top of the hive. The

colony will have to draw out the foundation into complete honeycombs which can then be used for

brood rearing or food storage.

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

BEES ON A BUDGET W.B.C. BEEHIVE

FIRST YEAR – SEASONAL GUIDE

January – Check mouseguards are still in place and that there is ventilation. Check for woodpecker

damage. Check on stored combs for wax moth. Pay subscription to local Beekeepers Association. Look

for details on our winter sale.

February – Carry out repairs before season starts. Heft the hives to check for stores and give them

fondant (not syrup) if they are short.

March – Remove mouseguards. Continue checking for stores. Watch for early pollen being gathered and

feed pollen pattie if scarce. If warm enough, feed 1:1 sugar syrup.

April – First full inspection, check for worker brood, eggs and young larvae. Do a disease inspection.

Mark queen. Remove old combs and replace with foundation. Put supers on hives before honey flow.

May – Monitor varroa levels and apply control methods as necessary to reduce mite numbers. Begin

swarm control inspections and carry out control. Extract oil seed rape honey.

June – Check colonies do not get hungry during ‘June Gap’. Feed if necessary. Continue varroa

monitoring.

July – Usually height of honey flow. Put on supers. Harvest the crop.

August – Speak to local association about coordinating varroa treatment.

September – Feed each colony with strong syrup (2 parts sugar to 1-part water). Do a disease

inspection.

October – Check colony is ready for winter with a good queen, plenty of young workers, good health

and plenty of stores. Ensure hives are weathertight. Fit mouseguards.

November – Protect stored combs against wax moth by fumigating with Sulphur strips.

December – Put your feet up and read a beekeeping book. Try candlemaking for Christmas. Heft

colonies to check for weight and feed fondant if necessary. Treat with oxalic acid when colonies are

broodless.

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

BEES ON A BUDGET W.B.C. BEEHIVE

Newburgh

Rand

Windsor

Stockbridge

South Molton

THORNES OF SCOTLAND

Newburgh Industrial Estate

Cupar Road

Newburgh

Fife

KY14 6HA

01337 842596

THORNES OF DEVON

Quince Honey Farm

Aller Cross

South Molton

EX36 3RD

01769 573086

THORNES OF WINDSOR

Oakley Green Farm

Oakley Green

Windsor

Berkshire

SL4 4PZ

01753 830256

THORNES OF STOCKBRIDGE

Chilbolton Down Farm

Chilbolton Down

Stockbridge

Hampshire

SO20 6BU

01264 810916

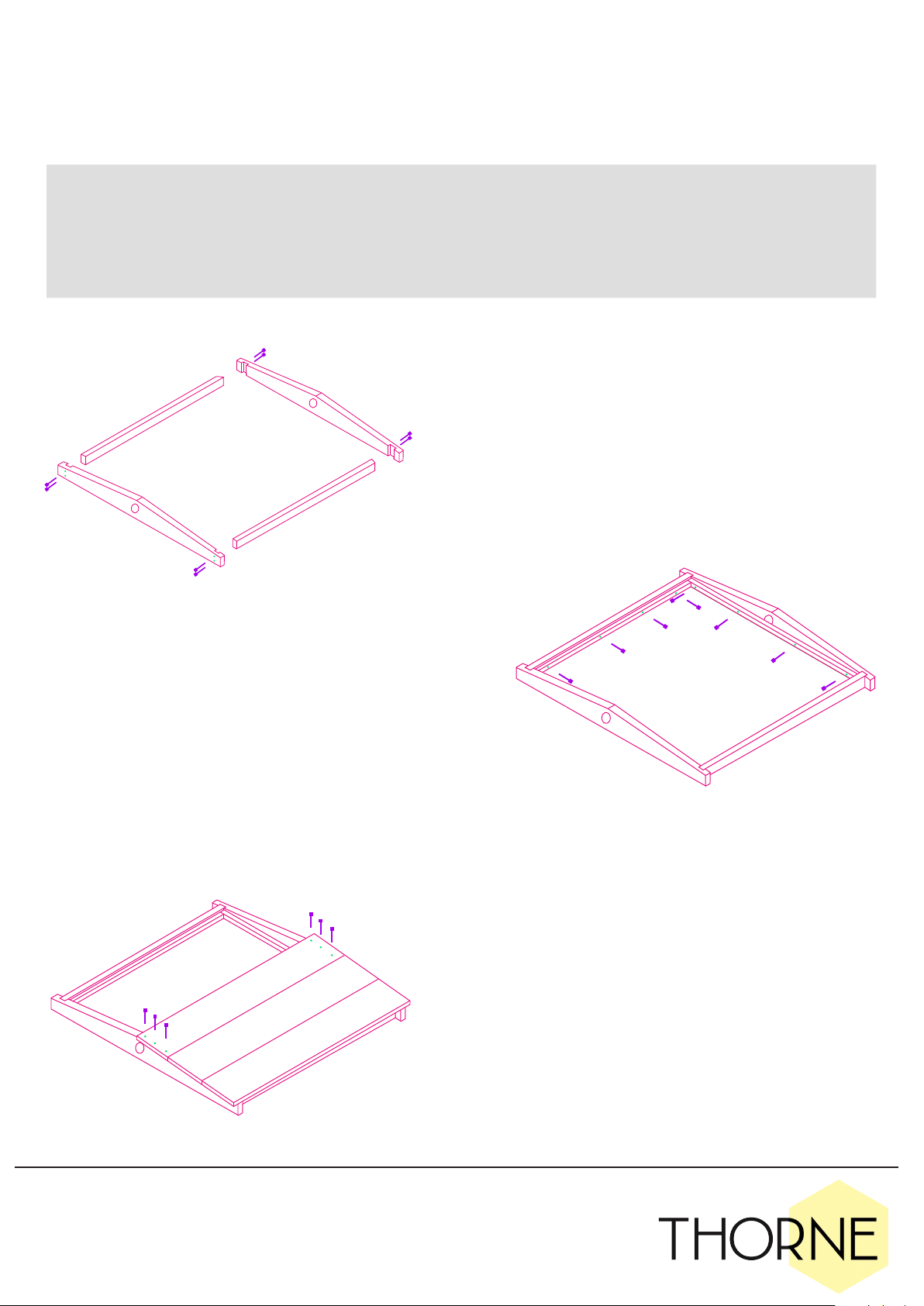

ASSEMBLY INSTRUCTIONS

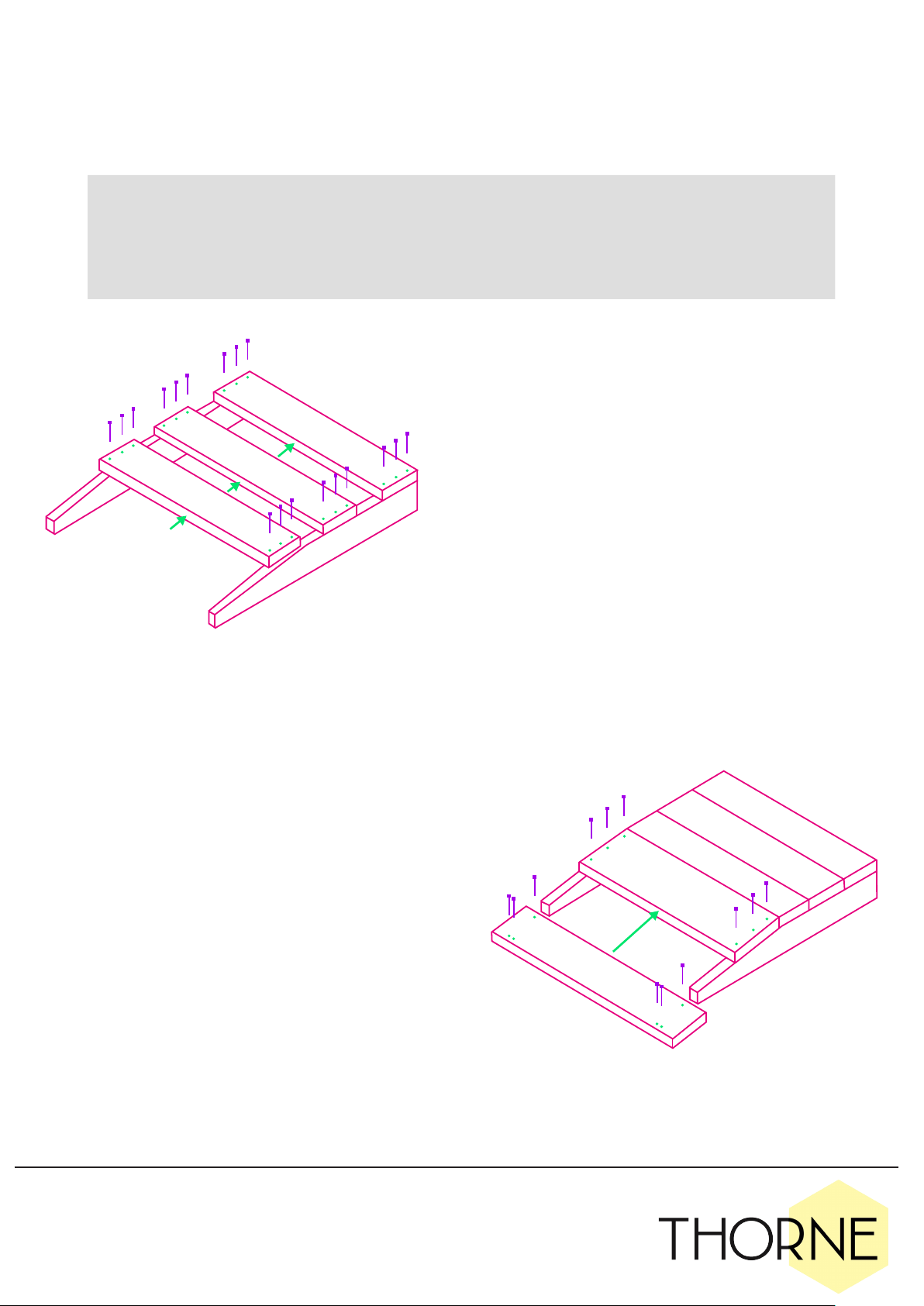

BUDGET W.B.C. FLOOR

Included: 5 x Floorboards, 2 x Joists, 2 x Wedges, 2 x Stays, 4 x Legs,

Glue, 14 x 1” Nails, 34 x 1½” Nails, 4 x 2” Nails, 8 x Screws

Tools needed: Hammer, Punch/Rampin, Set Square, Drill,

Electric Screwdriver, Tape Measure, Pencil

2.

2A. This next step requires the 2 remaining

floorboards. You will also need another 8 x 1½”

nails and 4 x 1” nails.

2B. Starting with the narrower floorboard,

one edge will be beveled, this beveled edge

will butt up to the last board you attached to

the joists. Glue and nail in place as with the

previous 3 boards.

2C. The last board you are left with will be

wider than the others. Make sure you leave

equal over hang either side and nail as shown

in diagram. 1 x 1½” nail either side at the top,

and then 2 x 1” nails to attatched the board to

the end of the joist underneath.

1A. For this first step you will need 18 x 1½” nails,

the 2 joists and the 3 smaller floorboards.

1B. Start by placing the joists on a flat surface,

as pictured, and apply glue along the top of

the joist. Starting at the higher end, and place

on the first floorboard. Nail in your first nail on

each side and make sure everything is square

before continuing. Once you are sure it is

square, carry on nailing so you have a total of 3

nails in each side of your first floorboard.

1C. Move onto the next floorboard, making sure

you apply glue to the joist and the floorboard

you have just attatched that this one will

butt up to. Nail in 3 nails on each end of the

floorboard. Repeat this one more time for the

third floorboard.

1.

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

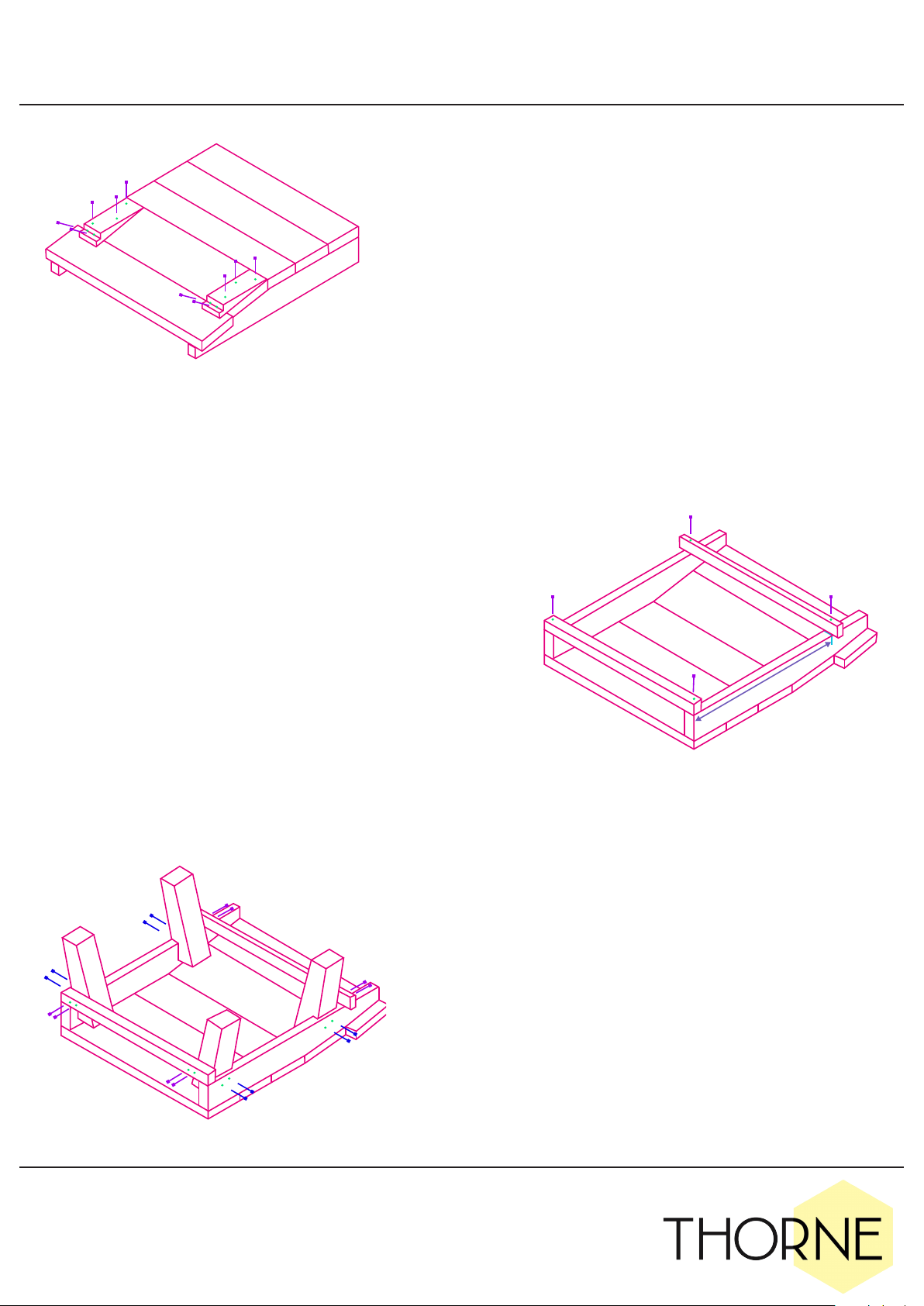

3. 3A. You will need the 2 wedges, 10 x 1” nails and a

rampin or nail punch also.

3B. Line up the wedges as shown in the diagram

making sure they are the right way round and flush

with the join between the third and forth board. Glue,

then nail 3 nails in the top of each wedge, making

sure not to hit nails you have already inserted, and

that the nails do not pretrud on the underneath.

3C. Then nail 2 nails into each the rebates as show

in the diagram. This is easily done with a rampkin, or

part nail in with a hammer and finish with a punch.

4.

4A. For this step you will need the 2 stays and 4 x 2”

nails.

4B. Glue and nail the shorter, square stay at the

back, in line with the end of the joists, 1 x 2” nail in

each end.

4C. Then measure from the back of the floor along

the joist 18” (457mm) and mark on both joists. Line

up the longer, recangular stay with these marks and

glue and nail into place so overhang lines up with

wider floorboard.

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

5. 5A. This last step requires 4 x legs, 8 x 1½” nails and

8 x screws.

5B. Now you have your stays in place, each leg

should slot into the corners. Use 2 screws to

attached each leg, it might be easier to pre-drill

the holes in the joist.

5C. Once the legs are screwed in place, nails 2 x

1½” nails through the stays and into the legs as show

in the diagram.

BUDGET W.B.C. FLOOR continued...

ASSEMBLY INSTRUCTIONS

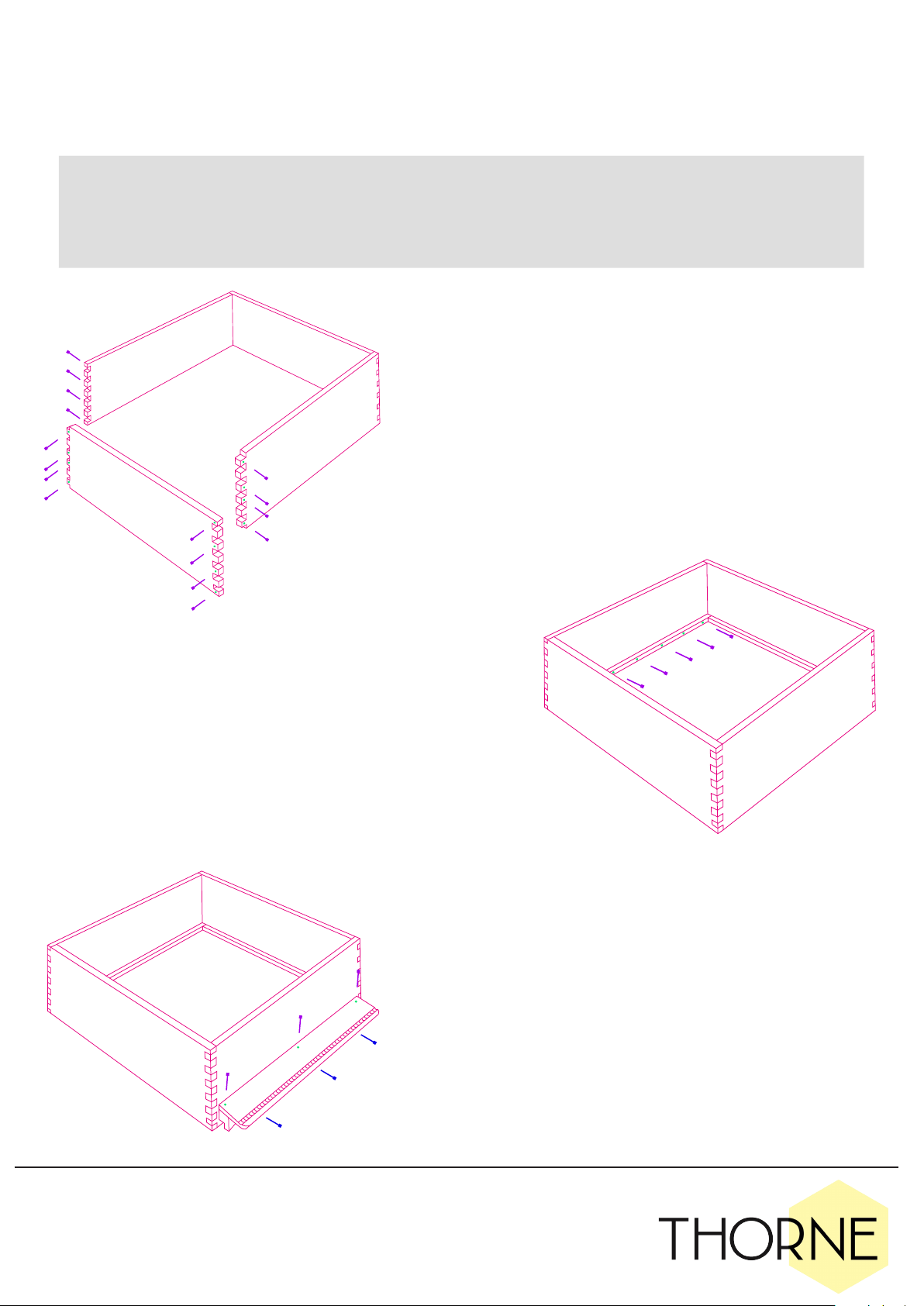

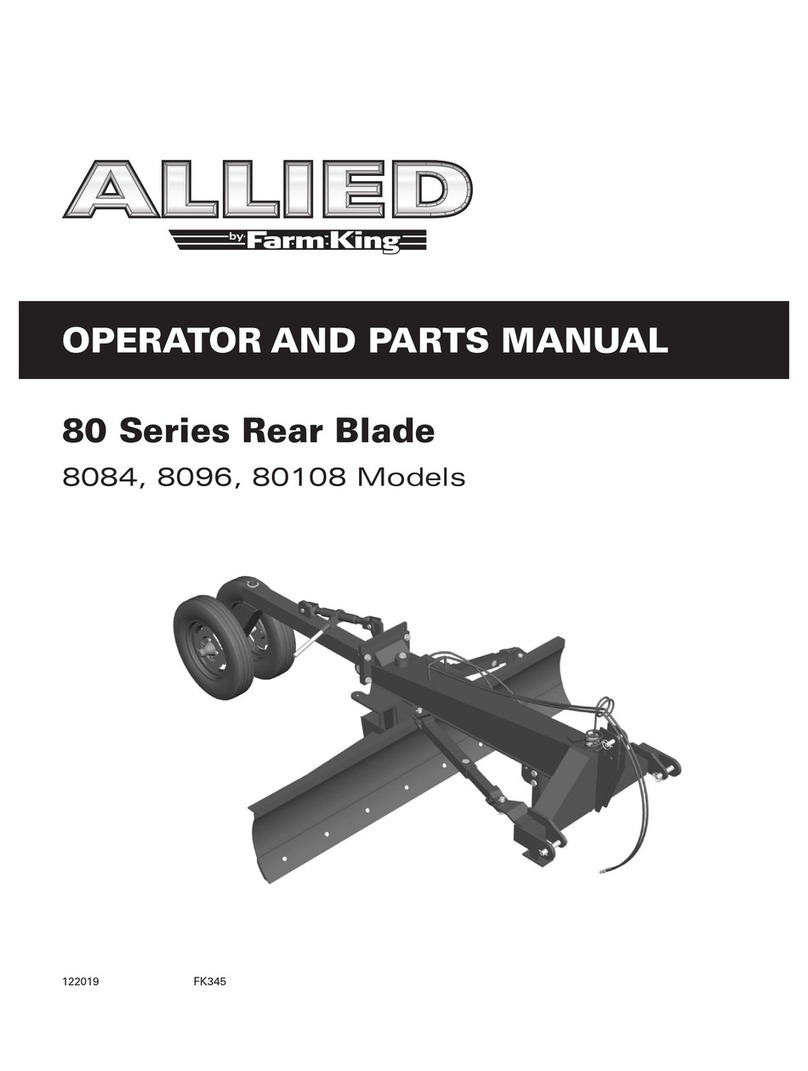

BUDGET W.B.C. LIFT & PORCH

Included: 4 x Walls, 4 x Laths, 1 x Porch, 1 x Porch Roof, Thorne Name Plate,

Glue, 20 x 1” Nails, 35 x 1½” Nails, 3 x Screws, 6 x Brass Pins

Tools needed: Hammer, Set Square, Electric Screwdriver

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

1A. For this first step you will need 32 x 1½” nails and

4 x walls. The walls will all have a slope to them with

bevelled top and bottom edges. Make sure you you

have these the right way round so they are sloping in

toward the top of the lift and thus ensuring the tops

and bottoms are horizontal.

2B. Slot the walls together and nail into place with 8

x 1½” nails on each corner in the configuration shown

in the diagram.

CHECK THE BOX IS SQUARE BEFORE MOVING ONTO

THE NEXT STEP.

1.

3A. Lastly, you will add the porch and porch roof

to one of the lifts. You will need both parts of the

porch, 3 x screws and 3 x 1½” nails. Start with your

lift on a flat surface, line up the porch flat inline

with the bottom of the lift, so it is centered, and

screw into place.

3B. Next take the porch roof piece, so that the rain

channel is facing up, place onto the porch so it is

inline with it and butt up to the wall of the lift, and

nail into place with 3 x 1½” nails.

3C. Finish off the lift and porch with the Thorne

name plates, fixing it with 6 x brass pins.

3.

2. Next you will need 20 x 1” nails and 4 x laths.

These laths should be nailed inside the lift, a laths

depth (½”) up from bottom of the lift wall. You can

use one of the laths as a guide. Tuck the first lath

into one of the corners, so that the next lath can

tuck into that one, and so on round the inside of

the lift. Nail these in place with 5 x 1” nails per

lath.

2.

REPEAT STEPS 1 AND 2 UNTIL YOU HAVE 3 LIFTS

ASSEMBLY INSTRUCTIONS

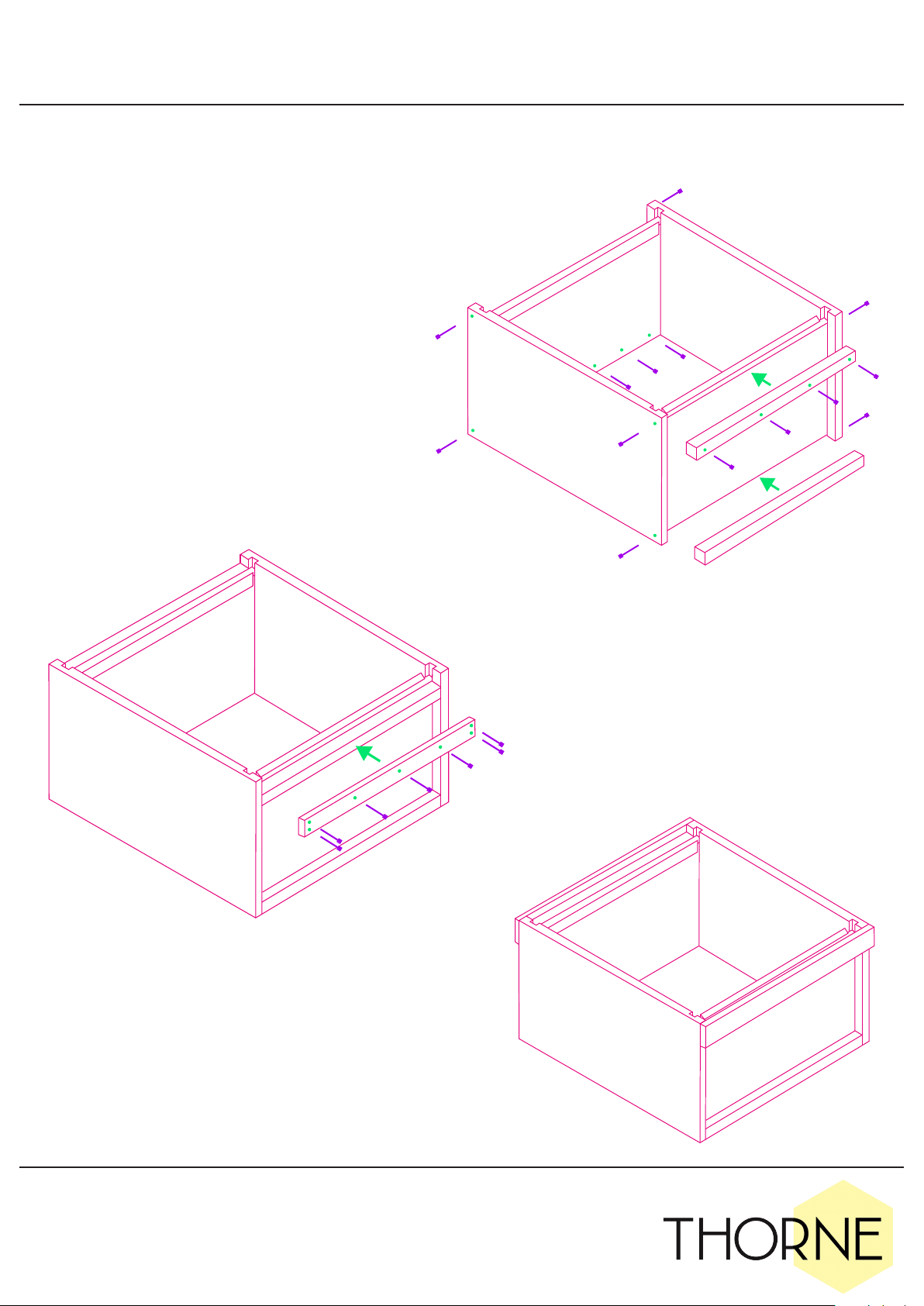

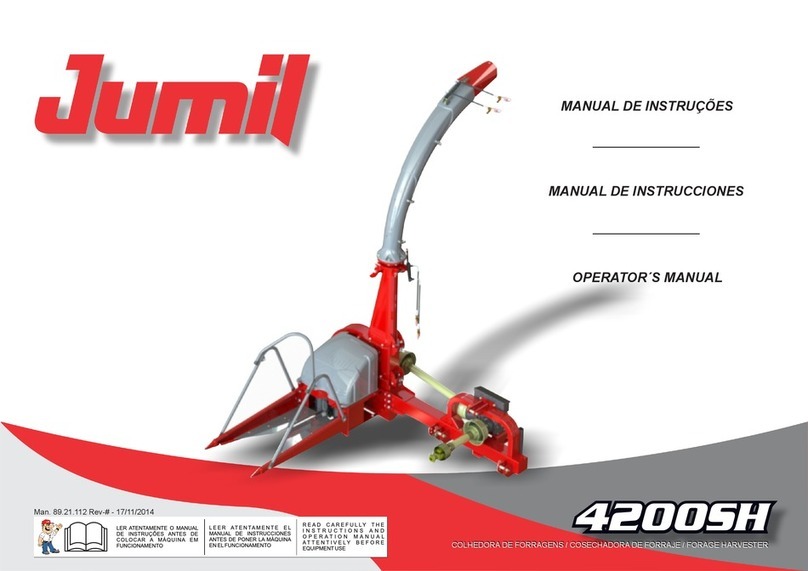

BUDGET W.B.C. BROOD OR SUPER

Included: 2 x Outer Walls, 2 x Inner Walls, 4 x Square Laths, 2 x Rectangular

Laths, 2 x Runners, Glue, 10 x Brass Pins, 24 x 1” Nails, 32 x 1½” Nails

Tools needed: Hammer, Set Square, Tape Measure, Pencil

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

1. 1. Firstly you need 2 x runners, 10 x pins and 2 x inner walls. The inner

walls are the smaller ones without the grooves. Attach one runner to

each wall along one of the longer sides, like shown in the diagram,

using 5 x pins per runner.

2.

2. Next, take 2 x outside walls, and

measure 7/16” (11mm) down from the

top of each groove and mark.

3A. For this step you will need 16 x 1½” nails

and all 4 walls. Run a line of glue down

the grooves and attach the inner walls to

the outer walls, making sure the top of the

runners line up with the marks you made in

step 2.

3B. Fix these together by nailing through

the outer wall, into the end of inner wall,

with 1½” nails. Use 4 nails per corner on the

brood, and 3 nails for a super.

CHECK THE BOX IS SQUARE BEFORE

MOVING ONTO THE NEXT STEP.

3.

4.

4A. You will now need 4 x square laths,

8 x 1½” nails and 16 x 1” nails. Glue and

position the laths in the cavities created

by the longer outer wall, the top one in

line with the top of the inner wall, and the

bottom one in line with the outer wall.

4B. Using the 1½” nails, nail through the

outer wall and into the end of the lath,

repeat on each end of each lath.

4C. Next fix the top laths from the outside

using 4 x ” nails for each top lath. Then

nail the bottom laths from the inside,

again using 4 x 1” nails for each lath.

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

BUDGET W.B.C. BROOD OR SUPER continued...

5.

5. The final step for your brood/super

is to fix the rectangular laths onto the

upper outside of the box, so they are

flush with the outside walls. Glue and

fix into place with 7 x 1” nails per lath in

the configuration shown in the diagram.

ASSEMBLY INSTRUCTIONS

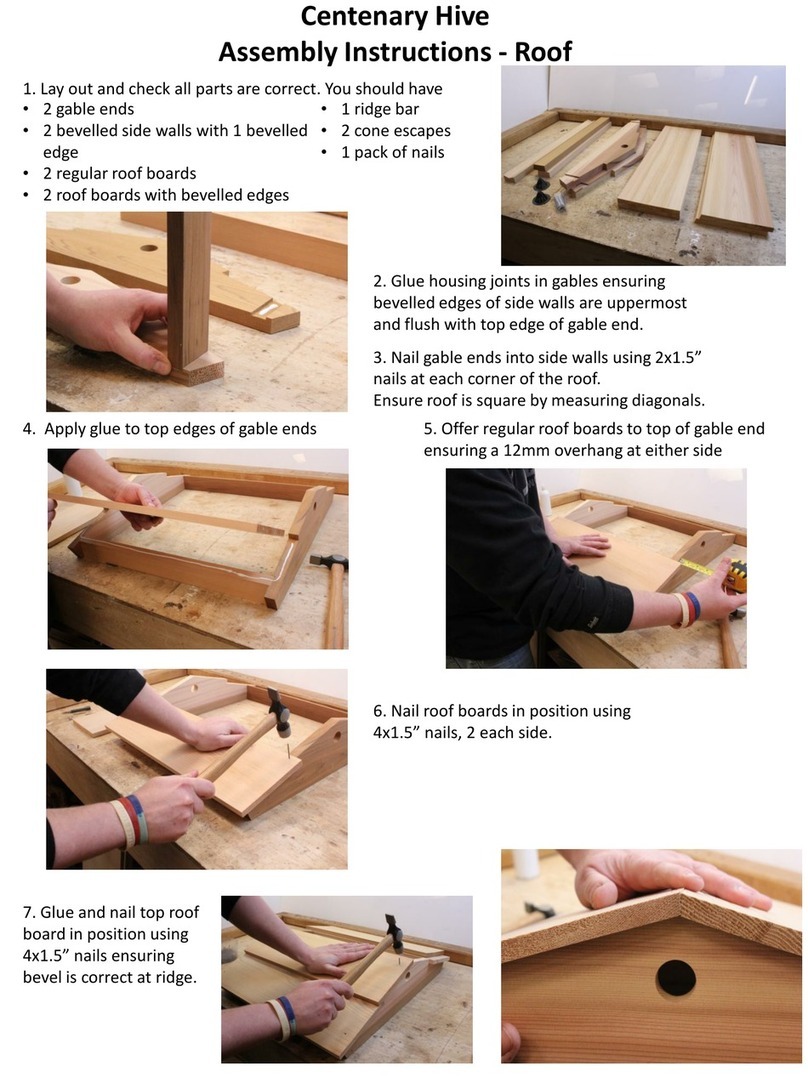

BUDGET W.B.C. ROOF

Included: 2 x Gable Ends, 2 x Joists, 4 x Laths, 4 or 6 x Roof Boards, 2 x

Roof Metals, 1 x Roof Ridge, 2 x Plastic Cone Escapes, Glue, 8 x Escutcheon

Pins, 68 x 1” Nails, 20 x 1” Wire Nails, 8 x 1½” Nails, 4 x 2” Nails

Tools needed: Hammer, Set Square, Punch, Drill, Pencil, Clear Silicone

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

1. 1. Firstly you will need 2 x gable ends, 2 x

joists and 8 x 1½” nails. Make sure you have

the joists the right way round so that the bevel

edge is at the top and in line with the slope of

the gable ends. Glue and nail in place with 2

x 1½” nails per corner. It may be easier to mark

and pre-drill these holes.

2.

3.

2. Next you will need 4 x laths and 16 x 1” nails.

Attach the longer laths to the gable ends a laths

depth (½”) up from bottom using glue then 4 x 1”

nails (make sure these go in at a slight angle).

Then repeat with the other 2 laths onto the joist

side, again a laths depth (½”) up from bottom using

glue and 4 x 1” nails (again at a slight angle).

CHECK THE FRAME IS SQUARE BEFORE

MOVING ONTO THE NEXT STEP.

3A. You now need the roof boards, your hive will

come with either 4 or 6 of these. The diagram

shows the 6 board option, 3 on each side. With

the 6 board option, you will have 2 boards with

a single bevel edge, 2 boards with two straight

sides and 2 boards with the rain channel.

3B. Get the boards with the single beveled

edge and line this up with the apex of the gable

making sure the over hang is equal on each side,

glue and nail into place with 3 x 1” nails each

end. It might be easier to mark a line where you

nails need to go to make sure you are hitting the

gable end underneath. Continued on next page...

E.H. THORNE (Beehives) Ltd.

Beehive Business Park, Rand, Nr. Wragby, Lincolnshire, LN8 5NJ

BUDGET W.B.C. ROOF continued...

4.

5.

3. 3C. Now attached the board with the two straight

edges, again gluing (including along the edge of

the board you just fixed down) and nail with 3 x 1”

nails at each end.

3D. The last board will be the one with the rain

channel, the rain channel should be facing down

and at the edge of the roof. Glue and nail in place

with 3 x 1” nails at each end, plus 4 x 1” nails along

the edge, as shown in the diagram. Again it might

be easier to measure and draw a pencil line where

these nails need to go to hit the joist underneath.

3E. Repeat on the other side. Once you have all

roof boards in place, run a bead of clear silicone

along the apex on the top and underneath.

4. You now need the 2 x roof metals and 20 x 1” wire

nails. Position the metals one at a time onto the roof

boards and nail into place. You will find it easier to

use a rampin to create dents for your nails. (If you

have opted for the copper roof, you may feel the

need to drill the holes) Use 3 x nails on the shorter

ends, and 4 x nails on the longer ends.

5. Next add the roof ridge along the apex of the

roof, nail into place with 2 x 2” nails at each end

making sure you miss the circular holes and still

hit the gable end underneath, again you might

find it easier to measure and mark where the nails

should go.

6A. Once you have the roof ridge in place, nail

the ridge from the underneath with 8 x 1” nails.

6B. Lastly, attach the cone escapes in place over

the circular holes using 4 x escutcheon pins per

escape.

6.

Other Thorne Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Farm King

Farm King Allied 80 Series Operator and parts manual

Jumil

Jumil 4200SH Operator's manual

Original inside

Original inside EUROTOP 701 A Operator's manual

CrustBuster

CrustBuster 4600 Series Operation maintenance manual & parts list

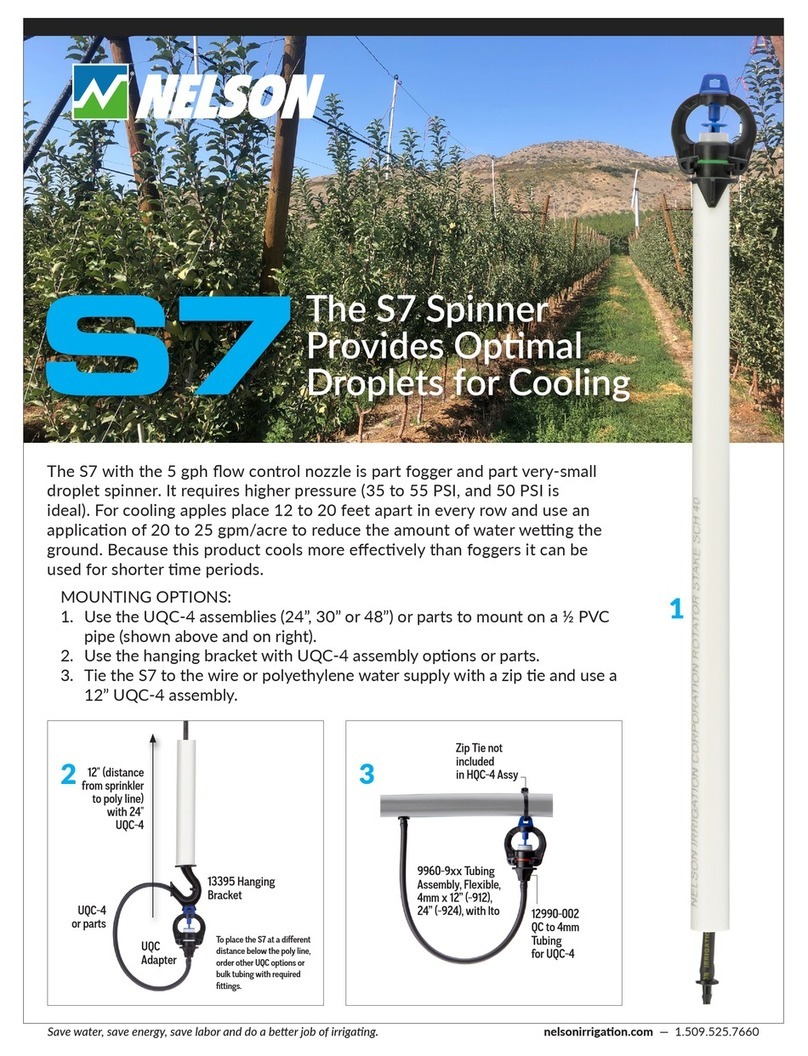

Nelson

Nelson S7 instructions

aivituvin

aivituvin AIR 18 instruction manual

REIST INDUSTRIES

REIST INDUSTRIES RR48 Operator and parts manual

GREAT PLAINS

GREAT PLAINS Yield-Pro 3PYPA Original instructions

Kubota

Kubota TE8511C Operator's manual

Raven

Raven SmarTrax installation manual

Lipco

Lipco Reversing Harrow UF 80L Translation of the original instructions

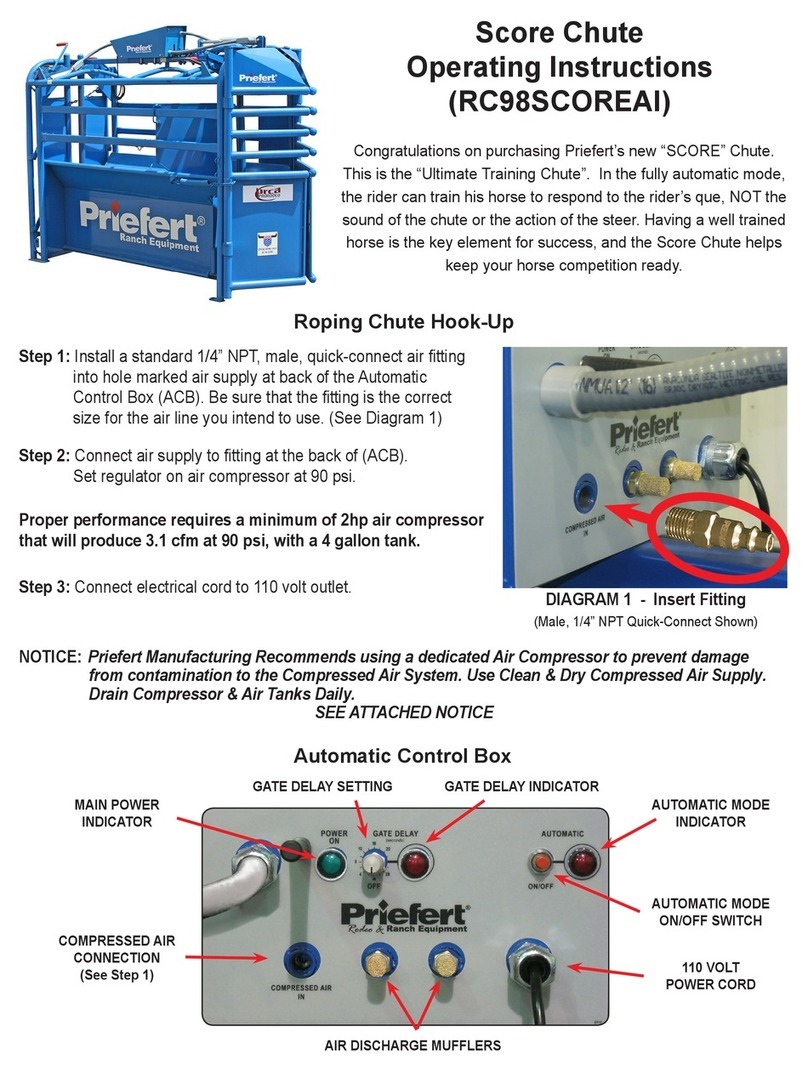

Priefert

Priefert RC98SCOREAI operating instructions