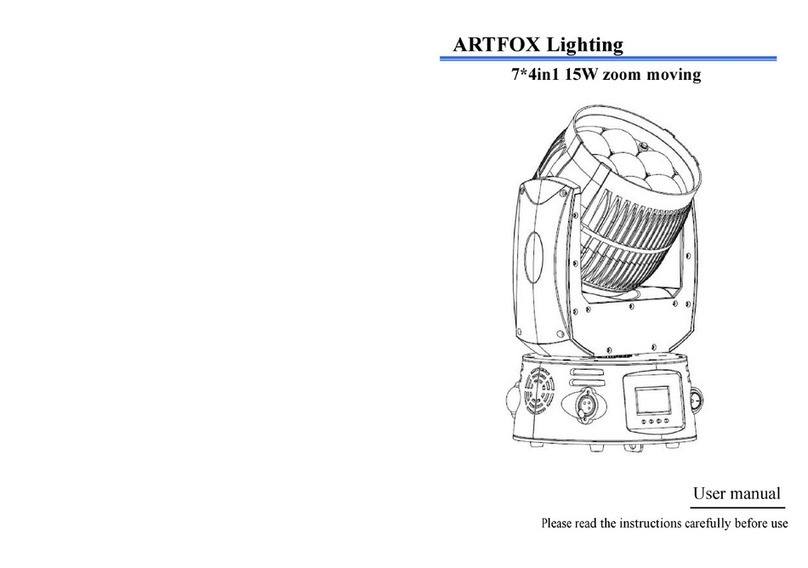

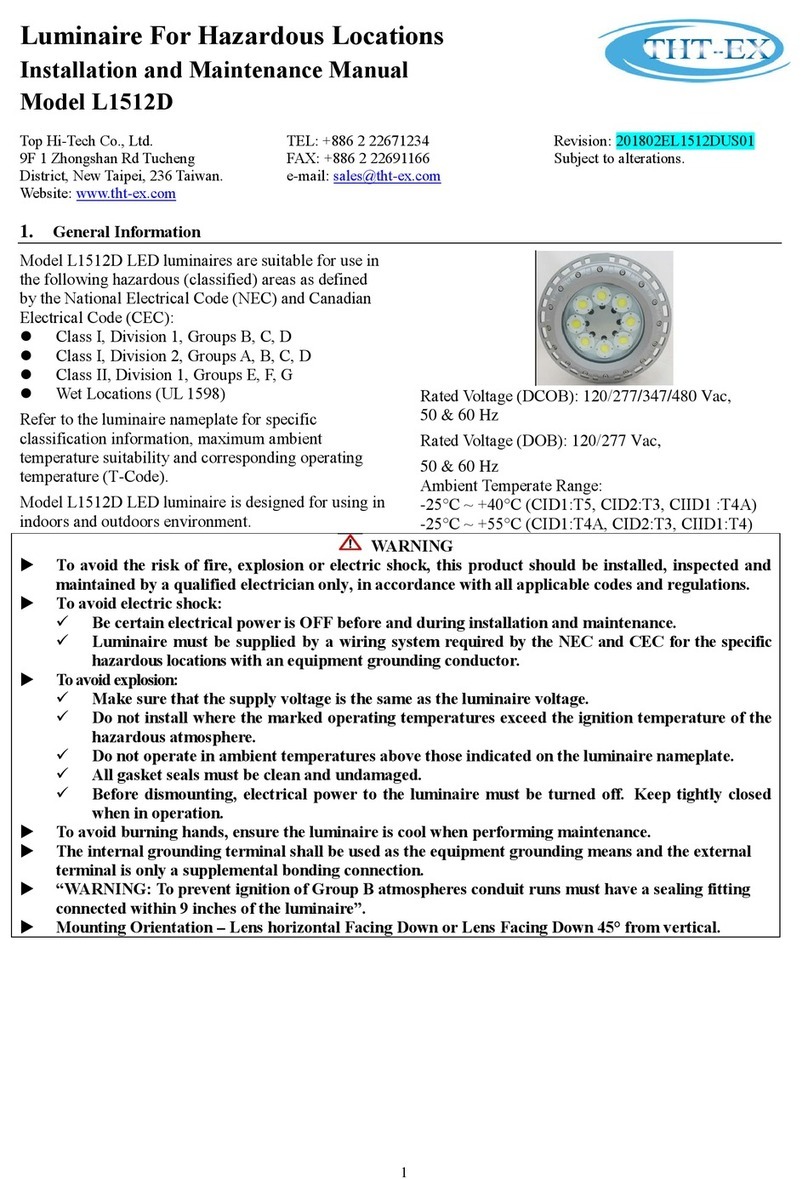

5. Assembly and Installation

5.1 Electrical Connection

5.1.1 Cable Entries through Top Cover

FLoosen the M4 set screw of Top Cover of the

luminaire. (Figure 1)

FLoosen the Top Cover of the luminaire and

remove it.

FThe thread of cable entry hole of Top Cover is

NPT 3/4” or M20.

FAttach the Top Cover to suitable conduit.

FInsert the cable from outside through the conduit

and the cable entry hole of Top Cover.

FIntroduce the wires of the luminaire with wires of

cable by attached closed-end-terminals as

following (Figure 2):

Black-wire connects to Neutral;

Red-wire connects to Live;

Green-wire connects to Ground.

FThread the Top Cover and torque until

wrench-tight.

FTighten the M4 set screw of Top Cover with

torque value 1 N-m.

FCheck the tightness of conduit and Top Cover.

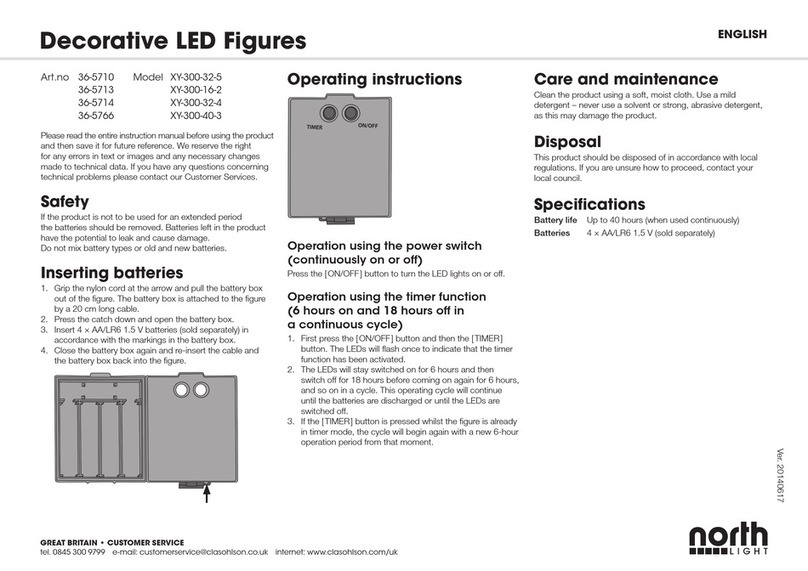

5.1.2 Cable Entries through Entry Hole of Tank

FLoosen the Plug from the Tank and remove it.

(Figure 3)

FThe thread of cable entry hole of Tank is M20.

FAttach the Tank to suitable conduit.

FInsert the cable from outside through the conduit

and the cable entry hole of Tank.

FIntroduce the wires of the luminaire with wires of

cable by attached closed-end-terminals as

following (Figure 2):

Black-wire connects to Neutral;

Red-wire connects to Live;

Green-wire connects to Ground.

FThread the conduit and torque until wrench-tight

with torque value 40 N-m.

FCheck the tightness of conduit.

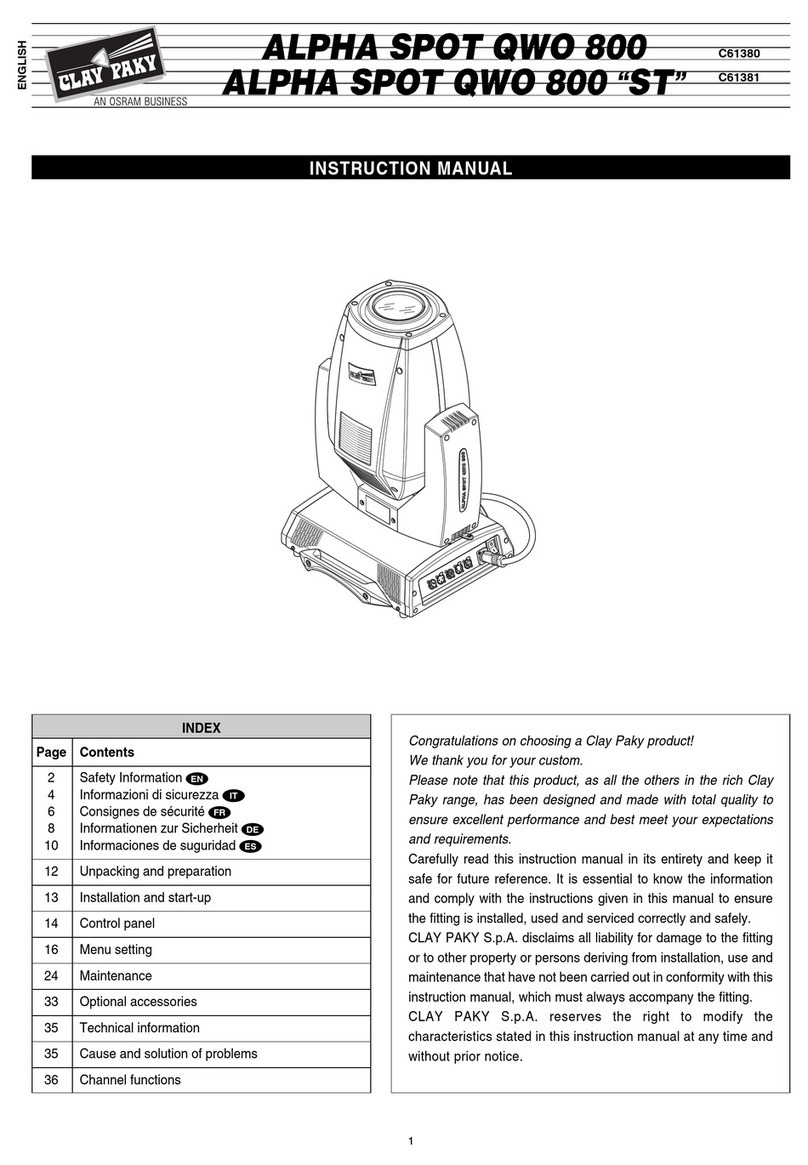

5.2 Mounting Bracket Installation

5.2.1 Wall Mounting & Pendant Mounting Bracket

FThe mounting bracket is both for the use of wall

mounting and Pendant mounting.

FPosition the bracket holders and fix it by means

of the provided M6 screws, 24.5 kgf-cm. (Figure

4)

FSecure the wall/pendant mounting bracket to the

structure by using six fasteners (not provided).

(Figure 5)

FThe lighting can be adjusted up and down by 25°.

(See picture in Technical Data)

5.2.2 Ceiling Mounting Bracket (C90)

FThe mounting bracket is for the use of ceiling

mounting.

FPosition the bracket holders and fix it by means

of the provided M6 screws, 24.5 kgf-cm. (Figure

6)

FSecure the wall mounting bracket to the structure

by using four fasteners (not provided). (Figure 7) Figure 7

Figure 6

Figure 4

Red: Live wire

Green: Ground wire

Black: Neutral wire

Figure 1 Figure 2

Figure 3

Figure 5