THT-EX L1319 User manual

1

Operating Instructions

Universal Explosion Proof LED Lighting

Model L1319

Drawing No: Instructions_L1319_IECEx

Revision Level: 01 Date: 2016-10-28

Top Hi-Tech Co., Ltd.

5F., No. 113, Zhongcheng Rd.,

Tucheng District,

New Taipei City, 236 Taiwan

Website: www.tht-ex.com

TEL: +886 2 22689570

FAX: +886 2 22689571

e-mail: sales@tht-ex.com

Revision: EX-L1319-01

Subject to alterations.

Contents

1. General Safety Instructions ………………………………………………………………..…………….……..1

2. Intended Field of Application ………………………………………………………………………………..…1

3. Technical Data ……………………………………………………………….……….……………..……….....2

4. Model Code …………………………………………………………………………………………...…….….2

5. Dimension ……………………………………………………………………………………….………….......3

6. Assembly and Installation ……………………………………………………………………….......................3

7. Maintenance …………………………………………………………………………………………………….5

8. Accessories and Spare Parts …………………………………………………………………………………....5

9. Transport, Storage and Disposal ……………………………………………………….……………………….5

1. General Safety Instructions

1.1 Before assembly/commissioning:

FRead through the operating instructions.

FGive adequate training to the assembly and

operating personnel.

FEnsure that the contents of the operating

instructions are fully understood by the

personnel in charge.

FThe national installation and assembly

regulations (e.g. IEC/EN 60079-14) apply.

1.2 When operating the device:

FEnsure the operating instructions are made

available for the person in charge on

location at all times.

FObserve these instructions, other working

instructions and national safety regulations.

FVerify the implementation of safety

instructions.

2. Intended Field ofApplication

The Universal Explosion Proof LED Lighting, Model L1319 is intended for using in gas explosive

atmospheres (Zone 1 and Zone 2 according to IEC60079-10-1) and dust explosion hazards (Zone 21 and Zone

22 according to IEC60079-10-2). The use in other potentially explosive atmospheres does not correspond to

WARNING

This manual contains basic safety instructions to be observed during installation, operation and

maintenance of the apparatus, and for properly and safety run of the apparatus according to its

performance data. Any damage of the apparatus may result explosion protection null and void. This

manual represents the most relevant information about the product, applicable codes and regulations shall

supplement it. Non-observance will endanger persons, plant and the environment. The person in charge is

required to secure its employment in the industrial unit.Any improper usage, as well as non-compliance

with the rules under this manual, shall release the manufacturer’s all responsibilities.

The flameproof joints are not intended to be disassembled or repaired.

WARNING – The luminaire shall not be opened

2

the designated use and is therefore not allowed.

The apparatus is designed for using in indoor and outdoor environments.

3. Technical Data

Item Description

Explosion Protection

IECEx

Gas Explosion Protection

Dust Explosion Protection

ATEX

Gas Explosion Protection

Dust Explosion Protection

Ex db IIC T6 Gb

Ex tb IIIC T85°C Db

II 2 G Ex db IIC T6 Gb

II 2 D Ex tb IIIC T85°C Db

Rated Voltage

120

V

ac

/

2

20

Vac

/277

V

ac

(±

10

%)

, 50 & 60

Hz

;

Note information on type label.

Power Factor

≧0.9

Ambient Temperate Range

-

4

0°

C ~ +

55

°

C

Degree of Protection

IP6

7

Material

Enclosure

:

Aluminum alloy

Glass: Tempered glass

LED Service Life

60,000 hrs

Entrance Hole

3

×

M25

threaded holes

Cable Gland

M25

×

1.

5

mm

, Secure to Top Cover with torque value 65 N

-

m.

Fitting Cable

Size of

Sealing Ring

Fitting

Cable

ID:

Ø

8.5

,

Ø

9.0

,

L=

15

mm

OD:

Ø

7.5~

Ø

9

Mounting Type / Weight

(Net Lighting Weight: 7.4 kg)

Ceiling mounting

Wall

&

Hanging

mounting

7.73

kg

7.96 kg

Stanchion mounting

25°

Pendant mounting

8.84 kg

7.83 kg

4. Model Code

THT

E

1319

Z

C

C

C

2

D0

-

S25

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(

10

)

(1) Brand name, THT = Top Hi-Tech Co., Ltd

(2) Category of product, E = Explosion proof lighting fixtures

3

(3) Model name, 1319 = Model L1319 series

(4) Sub-series designation , Z = No sub-series under this model

(5) Designates type of Top Cover, C = Top Cover with opening

(6) Designates type of LED module, C = LED bar

(7) Designates C.C.T of LED, C = Cool white, W = Warm white

(8) Designates voltage, 2 = 220 Vac, 1 = 110 Vac

(9) Designates wattage of LED lighting, D0 = 40W

(10) Mounting type, W90 = Wall mounting

H90 = Hanging mounting

C90 = Ceiling mounting

S25 = Stanchion mounting 25°

P90 = Pendant mounting

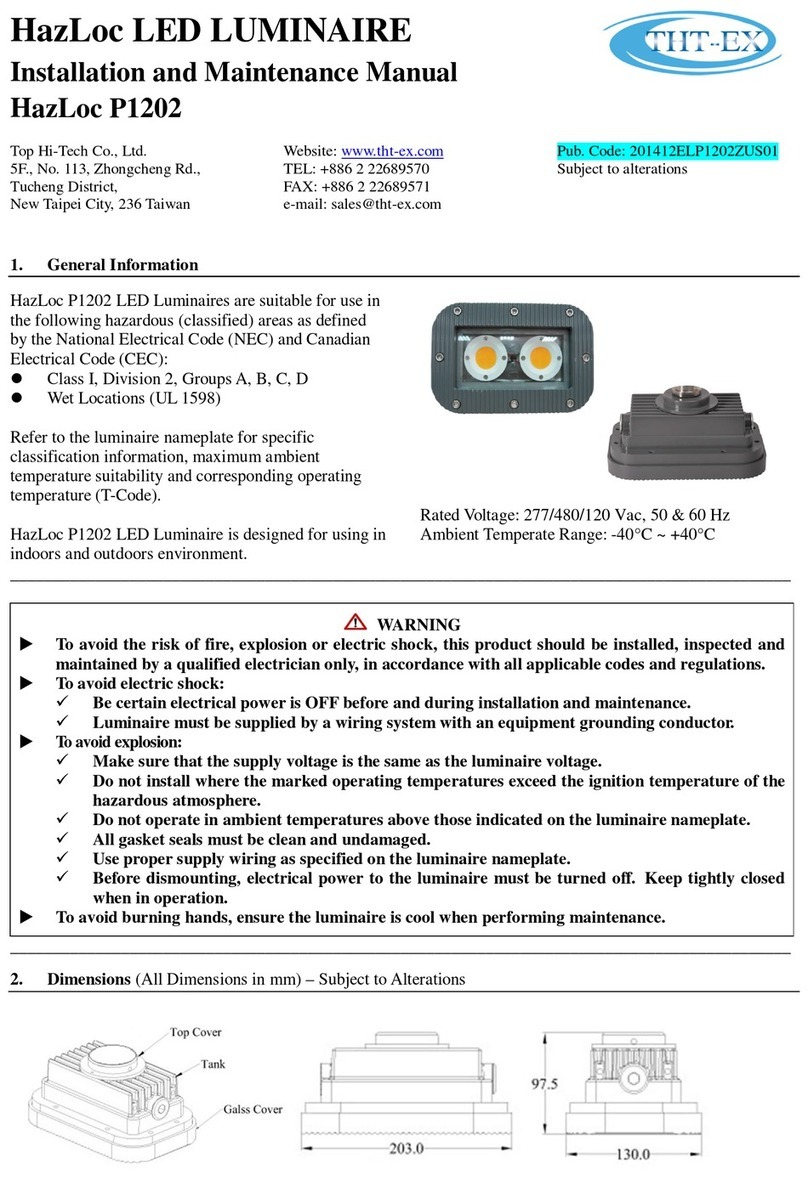

5. Dimensions (All Dimensions in mm) – Subject to Alterations

6. Assembly and Installation

6.1 Electrical Connection

Overview

1

: Junction Box ( Provide by customer)

2

:

Cable

(Length(min):1.5

m)

3

:

L1319 Lighting

Electrical Connection

1. Insert the cable (2) of the luminary into the Ex certified Junction Box (1).

2. Fix and Introduce the wires of luminary with the terminal post of Junction Box (White-wire connects to

Neutral; Red-wire connects to Live; Green-wire connects to Ground.)

Attention:

1. The Junction Box must be pass the Ex db/Ex tb certification that approved by IECEx/ATEX.

2. The minimum diameter of suitable cable for cable gland is 7.5 mm.

3. The cable types are: SJTW or SOOW, 18/3C AWG, 1 m length.

4

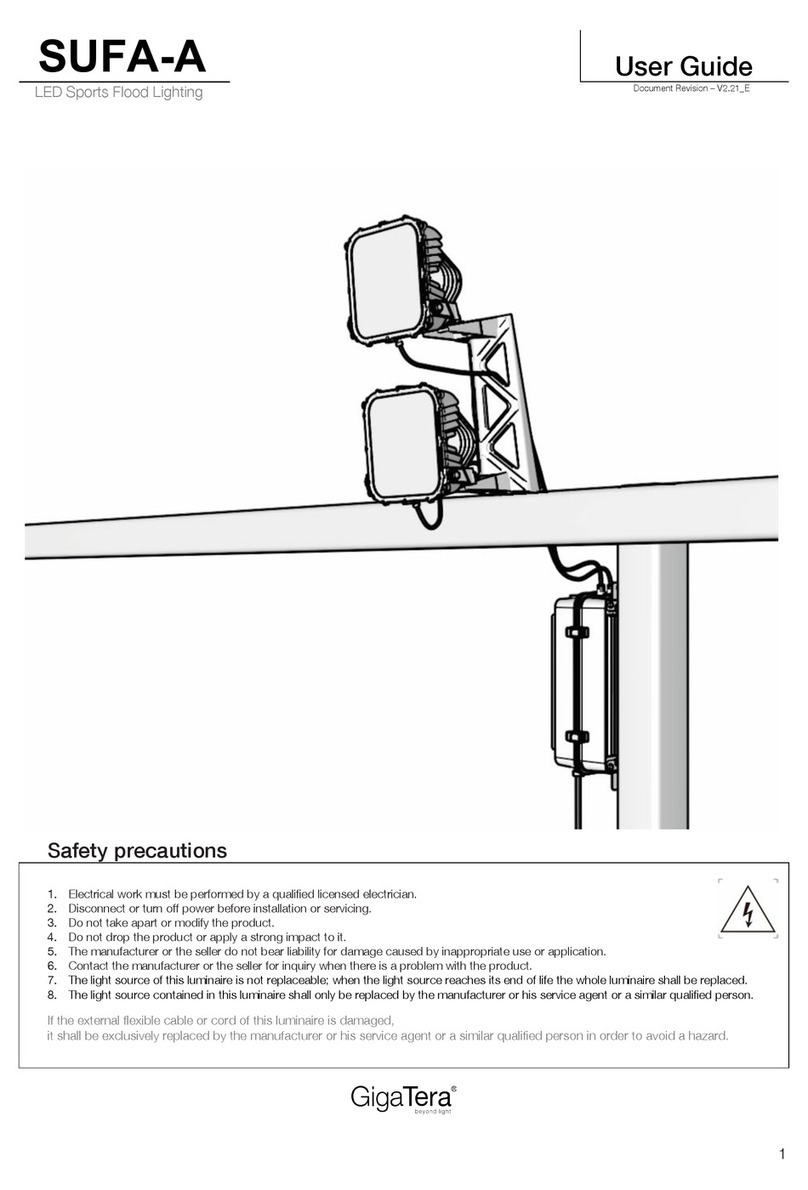

6.2 Mounting Bracket Installation

6.2.1 Wall & Hanging Mount Bracket

FThe mount bracket is for the use of both Wall

mount (Figure 1) and Hanging mount (Figure 2).

FPosition the bracket holders and fix it by means of

the provided M8 screws, 61 kgf-cm.

FSecure the Wall/Hanging mounting bracket to the

structure by using four fasteners (not provided).

FThe angle of lighting fixture can be adjusted.

6.2.2 Ceiling Mount

FThe mounting bracket is for the use of Ceiling

mounting.

FPosition the bracket holders and fix it by means of

the provided M6 screws, 24.5 kgf-cm. (Figure 3)

FSecure the wall mounting bracket to the structure

by using four fasteners (not provided).

6.2.3 Pendant mounting

FThe mounting type is for the use of bending tube

mounting (Figure 4).

FTube mounting thread is NPT 3/4”.

FThread the tube mounting on conduit and torque

until wrench-tight as requirement, 2700 kgf-cm.

6.2.4 Stanchion mounting 25°

FThe mounting types are for the use of bending

tube mounting (Figure 5). Tube mounting thread

is NPT 1-1/2”

FThread the tube mounting on conduit and torque

until wrench-tight as requirement, 6600 kgf-cm.

6.3 Ground wire

FExternal earth screw location as showing in the

Red Circle of right pictures.

FThe external earth ground wire installation and

terminal type as show the right pictures.

FGround wire cross-sectional area=4mm²,max

LED current=1A; @V=110Vac-10%.

FBoth ground screw and washer material is

stainless steel.

FScrew hole spec: M5.

FTorque requirement: 14.5 kgf.cm.

FEnsure wire is tied assured.

Figure 4

Figure 1 Figure 2

Figure 5

Figure 3

5

6.4 Putting into Service

Before putting into operating, it’s necessary to ensure that:

Fthe lighting is correctly installed.

Fthe connection has been correctly made.

Fthe cable has been inserted correctly.

Fthe voltage is correctly

7. Maintenance

Regular Maintenance

FConsult the relevant national regulations (e.g. IEC/EN 60079-17) to determine the type and extent of

inspections.

FArrange the plan of regular inspection with the equipment, one time per 3-month at least, so that any defects

in the equipment which may be anticipated are promptly detected.

To check as part of the maintenance schedule as following:

FCracks or damages on the glass cover and/or on the enclosure.

FCondition of the connecting cables.

FScrews of the mounting bracket are tightened.

8. Accessories and Spare Parts

9. Transport, Storage and Disposal

FTransport and storage is only allowed in the original packaging, on the way pointed out on the carton

box.

FTransport – Shock-free in its original carton, do not drop, and handle carefully.

FStore – Store in a dry place in its original packaging.

FDisposal – Ensure environmentally friendly disposal of all components according to the legal

regulations.

WARNING

uTo avoid dangers due to energized parts, all connections and wiring must be disconnected from the

power supply. Secure the connections against unauthorized activation.

uTo avoid risk of burn to hands, let the housing, the cable gland and the protective glass cool down for

approximate 30 minutes before touching them.

uMaintenance work is not permitted on flameproof enclosures. Repairs are only to be carried out by

the manufacturer. Unauthorized repair shall cause the manufacturer’s liability and warranty

expires.

WARNING

Use only original THT-EX accessories and spare parts. For accessories and spare parts, see data sheet at

www.tht-ex.com.

Table of contents

Other THT-EX Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Heitronic

Heitronic Bedlight Installation and operating instructions

Anslut

Anslut 002518 operating instructions

Chauvet Professional

Chauvet Professional STRIKEARRAY2 user manual

MELINERA

MELINERA 351847 2007 Operation and safety notes

Stairville

Stairville LC-48 owner's manual

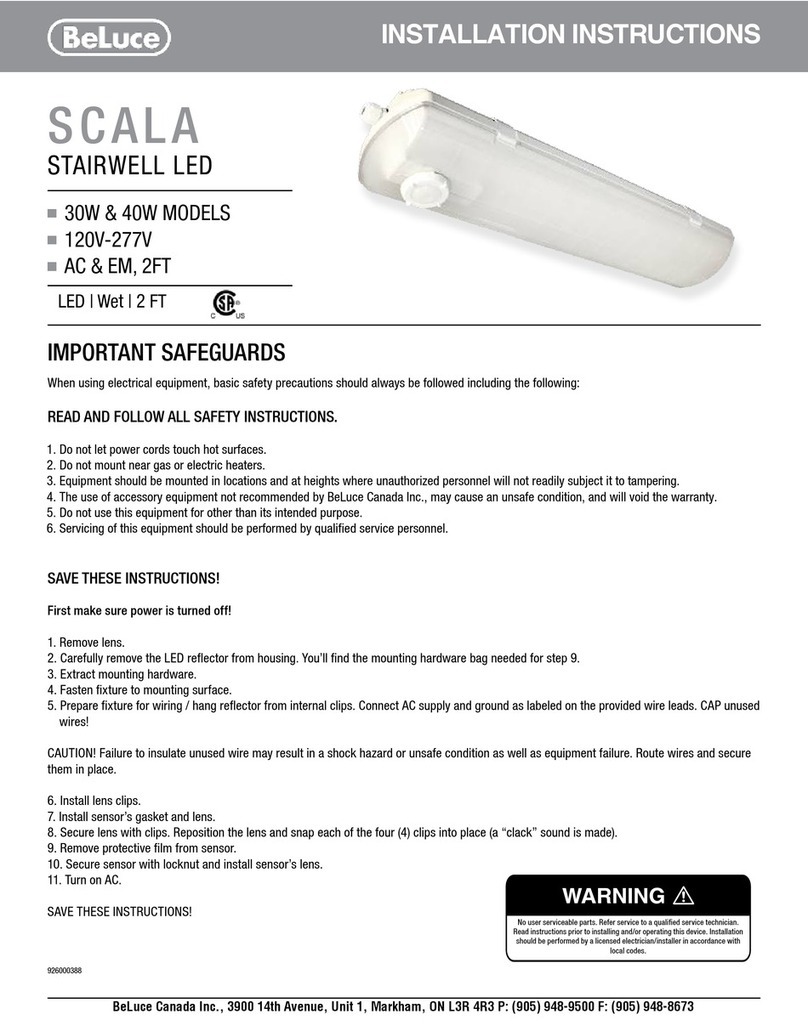

BeLuce

BeLuce SCALA installation instructions