Thytronic NVA100X User manual

NVA100X - Getting started - 01 - 2018

—Packaging

ProNext devices must be stored within the required temperature limits; the relative humidity should

not cause condensation or formation of frost.

It is recommended that the devices are stored in their packaging; in the case of long storage, especial-

ly in extreme climatic conditions, it is recommended that the device is supplied with power for

some hours before the commissioning, in order to bring the circuits to the rating conditions and to

stabilize the operation of the components.

—Contents

• Getting started

• Test report

• Screws

—Technical support

Full documentation is available on the www.thytronic.it website; for information and purchase of licen-

ses for oscillographic recording function please contact THYTRONIC.

TABLE OF CONTENTS

Packaging ...................................................................................................................................................................................................................1

Contents .....................................................................................................................................................................................................................1

Technical support......................................................................................................................................................................................................1

INSTALLATION 2

Mounting.....................................................................................................................................................................................................................2

Flush mounting...........................................................................................................................................................................................................2

I/O diagram .................................................................................................................................................................................................................4

Electrical connections..............................................................................................................................................................................................5

Output relays ..............................................................................................................................................................................................................6

Binary Inputs ..............................................................................................................................................................................................................6

Ethernet Ports ............................................................................................................................................................................................................7

Local Port....................................................................................................................................................................................................................7

RS485 port...................................................................................................................................................................................................................8

PROGRAMMING AND SETTINGS 9

MMI Password management..................................................................................................................................................................................9

MMI (Man Machine Interface).............................................................................................................................................................................11

Reading variables (READ)......................................................................................................................................................................................11

Setting modifying (SET) ..........................................................................................................................................................................................12

TEST...........................................................................................................................................................................................................................13

COMMUNICATION ..................................................................................................................................................................................................13

Circuit breaker commands.....................................................................................................................................................................................13

MMI menu structure...............................................................................................................................................................................................14

NVA100X#P2J00TE0

In5A

UAUX 110-230 Vac/dc

100V

100V

IEn

UEn

Un

1A 1A

5A 1A

5A

Flush mounting

Inductive CTs-VTs

ThySensor inputs versions

Rack mounting with

MAR support

20 kV

UNP

630 A

NVA100X#P2000TE2

Inp

UAUX 110-230 Vac/dc

IEn 1A 1A 5A

GETTING STARTED

NOTE This document does not replace the instruction manual.

Some functions described may be not available in all NVA100X models.

NVA100X

THE COMPREHENSIVE SOLUTION FOR FEEDERS AND UTILITIES PROTECTION

2NVA100X - Getting started - 01 - 2018

INSTALLATION

MOUNTING

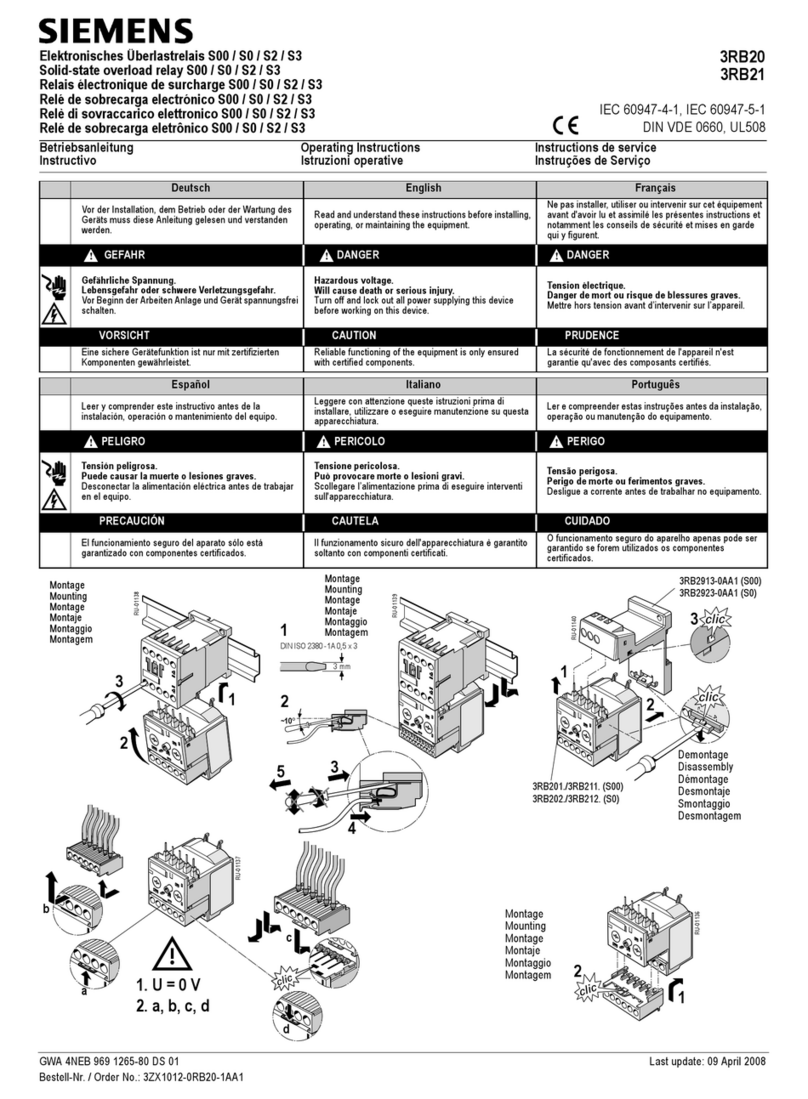

—Flush mounting

The fixed case, fitted with special fastening brackets, is mounted on the front of electric control board,

previously drilled as indicated in the drawing. In case of side-by-side mounting of several relays the

minimum drilling distance is determined by the front dimensions indicated in the overall dimensions

drawing, increased by 3 mm, to ensure an adequate tolerance and gasket space between adjacent

relays. The depth dimension, as indicated in the drawing, must be increased by as much as needed to

allow room for the wiring.

DRILLING TEMPLATE

SIDE VIEW

RACK MOUNTING

FRONT VIEW REAR VIEW

177

252

225 20

210 ±0.3

164.4

158.0 ±0.3

189

94.5

N.4 holes ø 4.2

N.4 holes ø 4.2

156

164.4

177

207

189

215

10

9

A

B

IN2D IN1C OC1E OC2F

NVA100X#JA2MM00

In5A

UAUX 110-230 Vac/dc

100V

100V

IEn

UEn

Un

1A 1A

5A 1A

5A

177 (4U)

101.6

482.6

465

3

NVA100X - Getting started - 01 - 2018

• Remove the two vertical frames for access the holes for the fi xing screws; the frames are snapped.

• Insert the device into the slot.

• Fit the device to the panel with four screws..

• Replace the vertical frames.

4NVA100X - Getting started - 01 - 2018

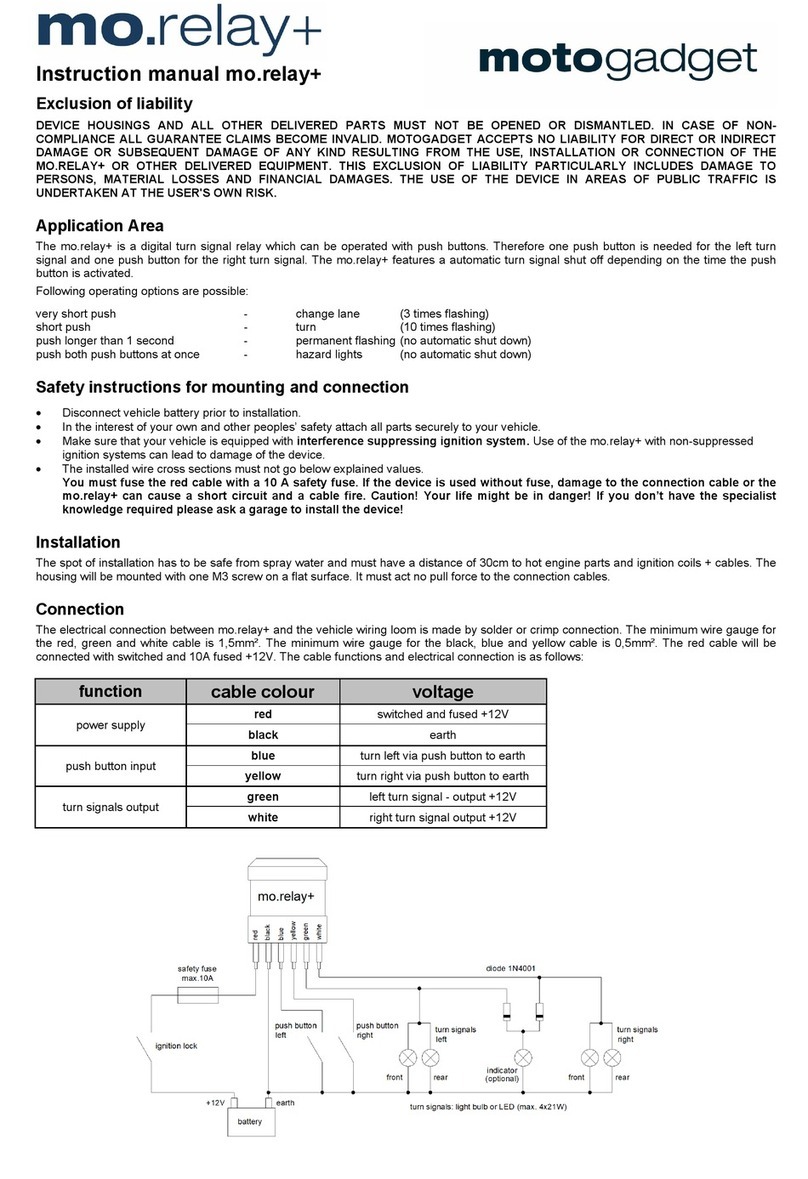

I/O DIAGRAM

Note [1]

two redundant ports with hw-sw switching selectable from TX (RJ45) + FX

(optical fiber), TX + TX or FX + FX. A version with two simultaneously active

Ethernet FX ports with RSTP protocol is available.

Note [2]

A version with 10 indipendent input is available.

UL1

UL2

UL3

UE

VOLTAGE INPUTS

9

10

7

8

5

6

3

4

BLOCK IN

3

4

1

IL1

IL2

IL3

IE

CURRENT INPUTS

2

3

4

5

6

7

8

Local Ethernet

X

1

2

BLOCK OUT

BLOUT-

BLOUT+

RS485

5

6

A+

B-

X

UAUX

1≅

2

B1

B

A

IN1C [2]

11

12

13

14

15

16

17

18

19

20

BINARY INPUTS

1IN1-1

IN1-2

IN1-3

IN1-4

IN1-5

IN1-6

IN1-7

IN1-8

IN1-9

IN1-10

IN1-11

IN1-12

IN1-13

IN1-14

IN1-15

IN1-16

2

3

4

5

6

7

8

9

10

OUTPUT RELAYS

1

3

2

18

20

19

9

10

11

12

13

14

OC1E

KC1-1

4

6

5

KC1-2

7

8

KC1-3

KC1-4

KC1-5

KC1-6

15

17

16

KC1-7

KC1-8

1

3

2

18

20

19

9

10

11

12

13

14

OC2F

KC2-1

4

6

5

KC2-2

7

8

KC2-3

KC2-4

KC2-5

KC2-6

15

17

16

KC2-7

KC2-8

IN2D

11

12

13

14

15

16

17

18

19

20

BINARY INPUTS

1IN2-1

IN2-2

IN2-3

IN2-4

IN2-5

IN2-6

IN2-7

IN2-8

IN2-9

IN2-10

IN2-11

IN2-12

IN2-13

IN2-14

IN2-15

IN2-16

2

3

4

5

6

7

8

9

10

NVA100X

4-20 mA

Mis.1

+

-

3

1

2

# / ∩

4

Mis.2

+

-

7

5

6

# / ∩

8

Mis.3

+

-10

9

# / ∩

Mis.4

+

-

13

11

12

# / ∩

14

Mis.5

+

-

17

15

16

# / ∩

18

Mis.6

+

-19

20

# / ∩

OPTIONS

TA-TV ThySensor

TX [1]

TX [1]

FX [1]

FX [1]

ETHERNET

Pt100

1

2

3

PT1

MPT1

T1

4

5

6

PT2

GND2

GND3

GND4

GND5

GND6

GND7

GND8

GND1

MPT2

T2

7

8

9

PT3

MPT3

T3

10

11

12

PT4

MPT4

T4

13

14

15

PT5

MPT5

T5

16

17

18

PT6

MPT6

T6

19

20

21

PT7

MPT7

T7

22

23

24

PT8

MPT8

T8

ThySensor INPUTS

IL1-UL1

IL2-UL2

IL3-UL3

P1

P2

UE

B5

B6

IE

B9

B10

UAUX

B1 ≅

B2

IRIG-B

AM IRIG-B IN

IRIG-B/1PPS IN

1PPS OUT

IRIG-B OUT

5

NVA100X - Getting started - 01 - 2018

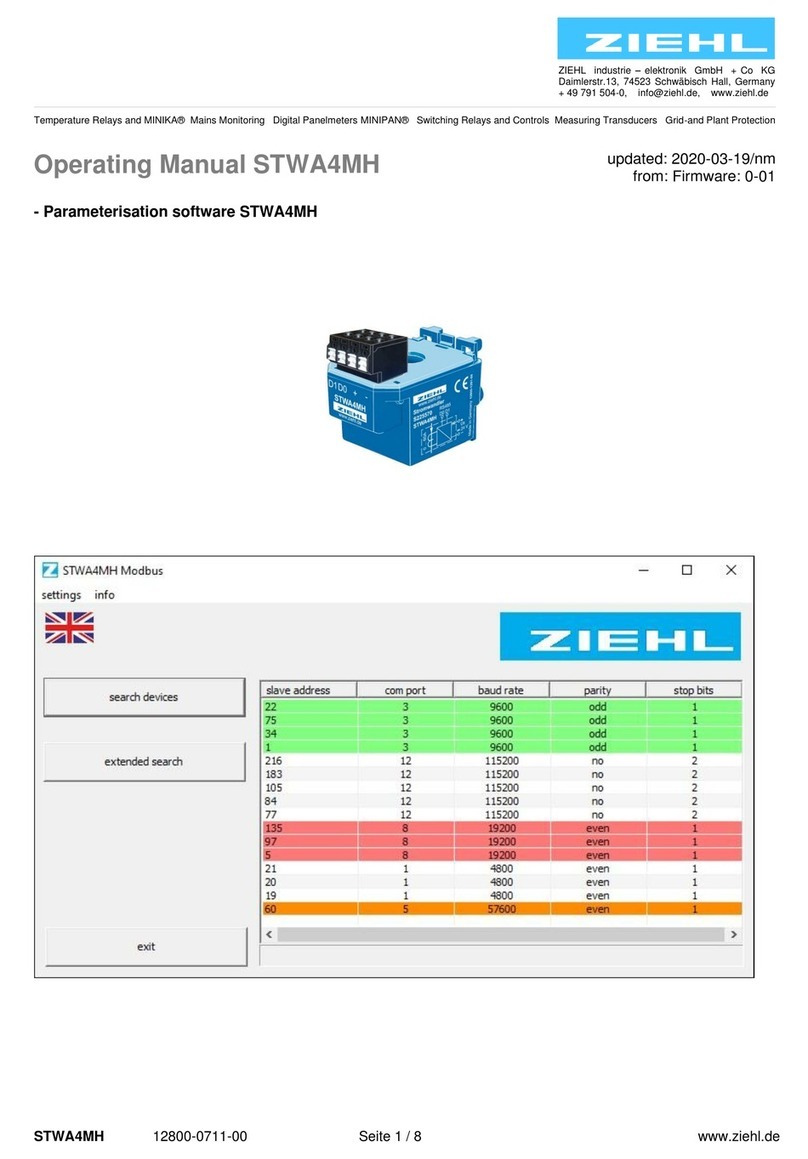

ELECTRICAL CONNECTIONS

Electrical connections should be made by referring to the connection diagram;

CT-VT input versions

For the A1...A8 and B1...B10 , screw terminals with following characteristics are available:

• Nominal cross section: 0.2 to 4 mm2(AWG 24...10) for single conductor

0.2 to 1.5 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 7 mm

For the IN1C-1...16, IN2D-1...16, OC1E-1...16 and OC2F-1...16 connections, screw terminals

with following characteristics are available:

• Nominal cross section: 0.14 to 2.5 mm2(AWG 26...16) for single conductor

da 0.14 to 0.75 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 8 mm

For the X1...X6 (RS485 and blocks) connections, screw terminals with following characteristics are

available:

• Nominal cross section: 0.2 to 2.5 mm2(AWG 24...12) for single conductor

0.2 to 1.5 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 10 mm

A protective ground connection is required, which must be connected to the suitable screw with a

separate lead of at least 4 mm2.

Amperometric inputs

In case of replacement of the relay or checks on the amperometric circuits is essential to provide

appropriate support to achieve the secondary circuit shorting. For security reasons it is advisable to

operate in the absence of line current.

When making the current connections, attention must be paid to not exceeding the performance of

the line current transformers. To be exact, the total load, constituted by the NA80 protective relay,

any other protective relays or measuring instruments and the resistance of the connections, must

not exceed the line CT performance.

In particular, consumption of the relay input circuit must not exceed 0.2 VA while the load (expressed

in VA) constituted by the conductors is given by:

0.018 × L × In2/ S where:

L the overall length, expressed in m, of the two conductors in relation to each phase;

Innominal current of the line CT expressed in A;

S cross sectional area of the current conductors expressed in mm2.

Devices must be installed by qualified personnel only.

No liability is accepted from Thytronic due to improper use.

CAUTION

If the secondary of a CT carrying primary current is open circuited, a high voltage can be developed

across the CT terminals.

CAUTION

Voltage inputs

Auxiliary power supply

Amperometric inputs

X1...X4 Block2

X5, X6 RS485

10

9

A

B

IN2D IN1C OC1E OC2F

Ground connection screw

Binary inputs

Output relays

NVA100X#JA2MM00

I

n5A

U

AUX

110-230 Vac/dc

100V

100V

I

En

U

En

U

n

1A

1A

5A

1A

5A

6NVA100X - Getting started - 01 - 2018

ThySensor inputs

(NVA100X#P)

The inputs current and voltage connections are made through pre-wired L1, L2 and L3 RJ45 plug.

For the A1, A2 and U1, U2 screw terminals with following characteristics are available:

• Nominal cross section: 0.2 to 4 mm2(AWG 24...10) for single conductor

0.2 to 1.5 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 7 mm

For the IN1C-1...16, IN2D-1...16, OC1E-1...16 and OC2F-1...16 connections, screw terminals with fol-

lowing characteristics are available:

• Nominal cross section: 0.14 to 2.5 mm2(AWG 26...16) for single flexible conductor

0.14 to 0.75 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 8 mm

For the X1...X6 (RS485 and blocks) connections, screw terminals with following characteristics are

available:

• Nominal cross section: 0.2 to 2.5 mm2(AWG 24...12) for single flexible conductor

0.2 to 1.5 mm2for two conductors with same cross section

• Tightening torque: 0.5-0.6 Nm

• Stripping length: 10 mm.

—Output relays

The device may be confi gured with:

• Two boards with eight command relays KC1-1...KC1-8 and KC2-1...KC2-8 (SPDT, tipo C e SPST-

NO,type A)

• One board with eight command relays KC1-1...KC1-8 and one boardwith with sixteen signalling relay

KS1-1...KS1-16 (SPST-NO, type A with four commons)

It is advisable to verify that the technical characteristic of the contacts be suitable for the applied load

(about current, nominal voltage, make and break current , etc..).

All contacts are shown in de-energized state for standard reference.

—Binary Inputs

The input circuits are voltage-free; activation requires the application of a power source, preferably

the same auxiliary voltage present in the switchboard.

The inputs are dimensioned for a wide range of operation and does not require any hw and / or sw

Voltage and amperometric

inputs from ThySensor

Residual voltage

input

Binary inputs

Output relays

L1

B

L2

L3

IN2D IN1C OC1E OC2F

Auxiliary power supply 1

2

5

6

Residual current

input

9

10

X1...X4 Block2

X5, X6 RS485

Ground screw

10

9

7

NVA100X - Getting started - 01 - 2018

programming.

AUX-IN external modules allow the thresholds setting for the binary inputs activation.

The digital inputs switching threshold can be set during installation so that the command voltage is

comparable to the supply voltage.

The inputs are immune to transitory interferences, however the following recommendation must be

considered in high disturbed environments:

• Position input wiring away from high energy sources.

• Set a debounce timer (tON and/or tOFF) to alloy the transient to decay.

• Use shielded cables with ground connection on only one end (preferably at the relay side.

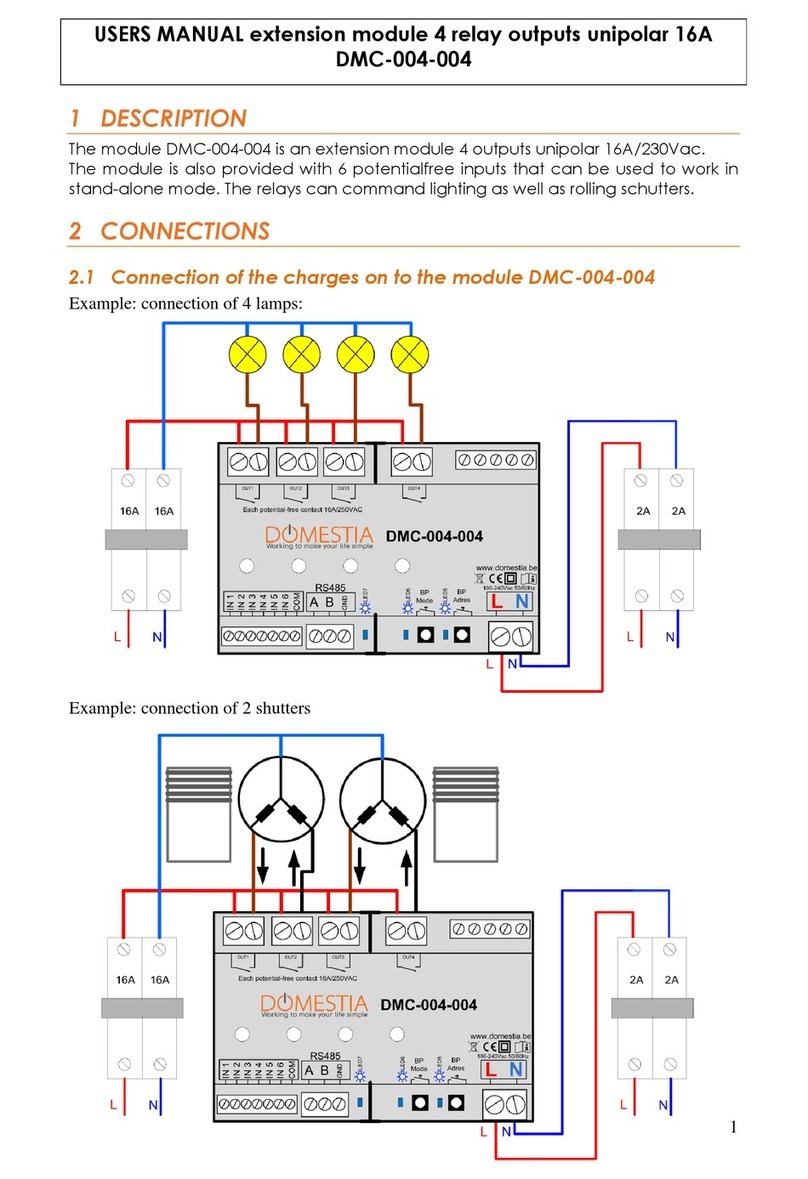

—Ethernet Ports

Pro_NX relays are supplied with two Ethernet ports with TX (RJ45) or FX (fi ber optic) connection, and

ModBus / TCP or IEC 61850 protocol.

The following options are available:

A) TX + FX ports [1]

B) TX + TX ports [1]

C) FX + FX ports [1]

D) FX + FX + RSTP [2]

Connections to TX ports (RJ45) must be made with shielded cable FTP Cat.5e category or higher.

The link must be enabled by means ThySetter sw and local connection:

• Set the IP address (Host IP address and IP net mask) n order that the NVA100X and PC parame-

ters are matched.

• Set to OFF parameters Autonegotiation on relay.

Parameters are inside the Communication \ Ethernet submenu. Dopo aver eseguito le modifiche, af-

finché le nuove impostazioni relative alla comunicazione Ethernet siano attive, è necessario togliere

l’alimentazione ausiliaria e successivamente rialimentare il relè.

—Local Port

A cross cable must be used for connection between computer and local port.

Nota 1 The TX (RJ45) and FX (fi bra ottica) Ethernet port are multiplexed (single IP address). Under normal conditions, the primary port is active, while the

secondary port is activated in the event of failure of the primary port or by means of hw-sw switching command.

Note 2 Two simultaneously active Ethernet ports with RSTP protocol

ethernet-wiring.ai

4

6

5

2

1

3

x

NETWORK

3V3

TX

TX

LINK2

LINK1

4

6

5

2

1

3

x

NETWORK

3V3

FX

TX

LINK2

LINK1

4

6

5

2

1

3

x

NETWORK

3V3

FX

LINK2

LINK1

Var. A) Var. B) Var. C)-D)

Ingressi logici

+UAUX

-UAUX

ABIN1C IN2D

BINARY INPUTS

1

IN1-1

IN1-2

IN1-3

IN1-4

2

3

4

5

BINARY INPUTS

1

IN2-1

IN2-2

IN2-3

IN2-4

2

3

4

5

8NVA100X - Getting started - 01 - 2018

When used the local port takes priority over the Ethernet port.

—RS485 port

RS485 communication circuit connections must be made using screened twisted pair cable observing

the polarities; screening must only be connected to a single end.

It is recommended to terminate the line at the extremities of the same; this must be performed on the

RS485 line control unit and on the ProNext device placed at the furthest point

serial1-sch.ai

Connector RJ45

RS485

120 Ω

120 Ω

SUPERVISION UNIT

A+

B-

X5

X6

NVA100X

UAUX

≅

ETH-1

ETH-2

ETHERNET

1 - DTR

2 - GND

3 - RX

4 - TX

RS232

RS485

A+

B- X5

X6

NVA100X

UAUX

≅

ETH-1

ETH-2

ETHERNET

1 - DTR

2 - GND

3 - RX

4 - TX

RS232

RS485

A+

B-

4

6

5

2

1

3

x

NETWORK

3V3

FX

TX

LINK2

LINK1

RS485

B-

A+

9

NVA100X - Getting started - 01 - 2018

PROGRAMMING AND SETTINGS

All relay programming and adjustment operations may be performed through

• MMI (keyboard and display)

• a Personal Computer with the aid of the ThySetter software

—MMI Password management

Preamble

For security purpose, is possible to password-protect modification to the settings of relays by mean of

the MMI (keyboard and display).

Is possible to select:

• OFF - modification of the settings by means of MMI (keyboard and display) are permanently disabled,

• ON - modification of the settings by means of MMI (keyboard and display) are permanently enabled,

• By Password - modification of the settings by means of MMI (keyboard and display) are enabled only after typing of password.

Default setting is ON (modification enabled). Setting can be changed using Thysetter only on level 1 (

menu (Preference / Session Level).

ThySetter

Setting Parameter Setting Enable is in menù Set / MMI.

Note: to make any changes with Thysetter you need to start change settings, change the setting and end change settings.

MMI

If the By password mode is selected a new menu PASSWORD is inserted at the top of the display

menu. Press the key ENTER PASSWORD message is displayed followed by Password

not ok >>; press the key you can enter the personal password with the usual procedure (de-

fault password is 0000):

• Press the (Enter) button for a few seconds; the modification in progress status is highlighted by

flashing of the START and TRIP LEDs and by appearance of the pointer on the bottom

• Change the parameters by means the or moving to the next character with .

• Press the (Enter) button; the cursor and the LED TRIP turn off (the LED START keeps flashing)

• Press the (Enter) button for a few seconds; new message appears: Confirm settings?

• Answer to the message ENTER: YES to confirm changes or RESET: NO to abort.

• After entering the current password correctly, the message ENTER PASSWORD and PAS-

SWORD OK >> appears on display.

If password is correct, from this moment is possible to change settings.

After some minutes of inactivity, reported by turning off the display backlight, Dopo alcuni minuti di

inattività, segnalati dallo spegnimento della retroilluminazione del display, possibility of modification is

disabled and therefore it is necessary to re-enter the password.

If you continue navigating the menus without entering the password, you can view all settings, but it

WARNING For safety reasons, a change of the rated values (Set \ Base menu) parameters become active

only after an hw reset

10 NVA100X - Getting started - 01 - 2018

is impossible to make any modification (keeping pressed for some seconds the key (Enter) modi-

fication procedure is disabled (LED START, TRIP and curson under the parameters to be modified).

Changing password

After correct insertion of password is displayed this message: ENTER PASSWORD and

PASSWORD OK >>; pressing the key is shown the message CHANGE PASSWORD

>> and pressing button you access the relative menu where you can enter the new password.

Lost password

To change password current one must be entered. If the password is lost, neither the password nor

any parameter from MMI can be changed and the changes can only be made by ThySetter.

To enable modification from MMI without password is needed to disable password lock connecting a

PC with Thysetter setting ON parameter Parameters setting enable available in menu Set / MMI.

If password is lost and password lock must be enabled, device database must be reset using the com-

mand Set default setting available in the menu Command \ Default setting. (double click on Default

Setting, click on Set default setting, right click --> Send Command).

Note:

The command Set default settings restores the factory settings, all user- defined

adjustments are cleared.

Be carefully to enter the correct parameter !

The device serial number should be set to avoid IP address conflicts for devices con-

nected to the Ethernet network.

11

NVA100X - Getting started - 01 - 2018

MMI (MAN MACHINE INTERFACE)

On the front panel there are eight buttons which allow the user to perform all the settings, reading and

modification operations.[1]

The adjustment of the settings and the operation mode of the output relays must be performed while

the unit is electrically powered. All preset values are permanently stored in the nonvolatile memory.

The buttons take the following operations:

- (Up) move the cursor upwards to the preceding menu options

- (Down) move the cursor downwards to the subsequent menu options

- (Left) move the cursor upwards to the preceding menu options

- (Right) move the cursor downwards to the subsequent menu options

- (Enter) access to the selected menu with the option of modifying any given parameter

- (Reset) abort the current changes and/or accessing the previous menu

- Circuit breaker Open command

- Circuit breaker Close command

At power-up, the display shows the text:

“THYTRONIC

PRO-NVA100X-VM00-a

date and time: (01/01/2000 00:00”

The ON green Led points out the auxiliary power supply voltage (permanent lighted) and possible

faults (blink lighted).

The display backlight is automatically activated when any key switch is set.

By means of the (Up) or (Down) buttons, it is possible to cyclically browse through the menu

options: READ, SET, COMMUNICATION, TEST

Having identifi ed the sub-menu of interest, it is possible to gain access by using the (Right) button

and then analogously, run through the relevant options by using the (Up) or (Down) buttons.

The full menu tree and some examples are showed in the following pages (numerical values and

settings are pointed out as examples and does not agree with real situations).

—Reading variables (READ)

All data (measure, settings, parameters, etc...) can be displayed; they are arranged in functional

group submenus::

“SELF TEST >>”

“SERIAL NUMBER >>”

“INFO >>”

“MEASURES >>”

“ACTIVE PROFILE >>”

“PROTECTIONS >>”

“PLC >>”

“CIRCUIT BREAKER SUPERVISION >>”

“DELAYED INPUTS IN1-1...IN1-16 >>”

“INTERNAL STATES >>”

“RELAYS KC1-1...KC1-8 >>”

“PARTIAL COUNTERS >>”

“TOTAL COUNTERS >>”

“SELF-TEST >>”

“PILOT WIRE DIAGNOSTIC >>”

“SELECTIVE BLOCK BLOCK2 >>”

“INTERNAL ELECTIVE BLOCK BLOCK4 >>”

“FAULT RECORDING >>”

“EVENTS RECORDING >>”

Note 1 LSetting changes are enabled when the Enabling setting by MMI parameter is set

OPEN CB

CLOSE CB

Label_LED

LEDs

Input 1 board LEDs

L1-1...L1-8 user

programmable

Input 1 MMI board

LEDs L1-1...L1-8

user programmable

ON e Diagnostic

Start

Trip

12 NVA100X - Getting started - 01 - 2018

—Setting modifying (SET)

For safety reason is sometime required that modification of settings using MMI (keyboard and display)

is disabled; in this way only qualified personell can modify settings using software Thysetter.

All changes in the setting parameters are carried out through MMI only if the Enable setting by MMI

parameter is ON. (ENABLE SETTING BY MMI submenu inside the SET menu).

To effect a change, having identified the parameter intended for change, the following procedure must

be performed:

• Select the parameter going through the menus by means the , and keys

• Press the (Enter); button for a few seconds; the modification in progress status is highlighted by

flashing of the START and TRIP LEDs and by appearance of the pointer on the bottom.

• Move the cursor over the parameter intended for change using the (Enter) button,.

• Change the parameters by means the (increment) or (decrement) buttons.

• Press the (Enter) button to move the cursor over the last parameter in the display.

• Press the (Enter) button once again; the cursor and the LED TRIP turn off (the LED START keeps

flashing).

• Press the (Enter) button for a few seconds; new message appears: “Conrm settings?”

• Answer to the message ENTER: YES to confi rm changes or RESET: NO to abort.

The end of the START LED blinking points out the end of procedure; the changes become right now

active.

The abort command may be used to abandon changes (prior to use of the ENTER: YES); the same

effect is achieved by removing the auxiliary power supply to the relay.

As example, to set the operating mode of the KC1-1 output relay as ENERGIZED, LATCHED, the following

procedure must be issued:

• Select menu Set “SET >>”by mean of the button (Down).

• Press the (Right) button to enter; the following submenu title is displayed: “BASE >>”

• Scroll menus by means (Down) button

“INPUT SEQUENCE >>”

“POLARITY >>”

“LINE >>”

“ENABLE VECTOR JUMP >>”

“INPUTS IN1-1...IN1-16 >>”

“RELAYS KC1-1...KC1-8 >>”

“LEDs ON MMI >>”

“LEDs LED1-1...LED1-8 >>”

“SELF-TEST RELAY >>”

“MMI >>”

“AUTO-RECLOSE 79 >>”

“PROFILE SELECTION >>”

“PROFILE A >>”

“PROFILE B >>”

“PLC >>”

“CIRCUIT BREAKER SUPERVISION 52 >>”

“VT SUPERVISION 74VT >>”

“CT SUPERVISION 74CT >>”

“FAULT LOCATOR FL >>”

“REMOTE TRIPPING >>”

“PILOT WIRE DIAGNOSTIC >>”

“DEMAND MEASURES >>”

• Select the Set menu “RELAYS KC1-1...KC1-8 >>”, the “KC1-1 relay Setpoints >>”

is displayed.

• Press the (Right) button to enter; the following messages are displayed:

“Logic DE-ENERGIZED Mode NO LATCHED”

• Press the (Enter) button for a few seconds; the modification in progress status is highlighted by

the both START and TRIP flashing.

• Move the cursor over the parameter intended for change using the (Enter), button, (in our case

on the message “Logic DE-ENERGIZED”,

• Change the parameters by means the o “Logic ENERGIZED”,

• Premere il pulsante (Enter) momentaneamente per posizionare il cursore in corrispondenza del-

l’ultimo parametro visualizzato sul display, “Mode NO LATCHED”,

• Modificare il parametro mediante i pulsanti (increment) or (decrement) buttons, “Mode LA-

TCHED”,

• Press the (Enter) button once again; the cursor and the LED TRIP turn off (the LED START keeps

flashing),

• Press the (Enter) button for a few seconds; new message appears: “Conrm settings?”

• Answer to the message ENTER: YES to confirm changes or RESET: NO to abord

The end of the LED START blinking points out the end of procedure.

13

NVA100X - Getting started - 01 - 2018

—TEST

The operational tests with command of the selected output relays may be activated.

By means of (Up) or (Down) buttons it is possible to browse the main menu till the “ “TEST”

message; to enter you must press the (Right) button. [1] The display message “Test state:

OFF” shows the test state (OFF or test in progress).

By means of (Down) button is possible to browse menu to select:

• Stop test

• Start test

• Test KC1-1

• Test KC1-2

• Test KC1-3

• Test K...

As example, to start the test of KC1-1, the following procedure must be issued::

• Select the Start test menu “Start test? >>”.

• Press the (Right) button to start; the test in progress status is highlighted by activation of all LEDs.

• Come back by pressing the (Left) .

• SelecttherelaytobetestedKC1-1bymeans or

untilthemessage“Test KC1-1? >> isdisplayed.

• Press the (Right) button to start the test on KC1-1.

• To terminate the test, it is necessary to select the “Stop test? >>” message and press the

(Right). button to end the test. In any case the test will be automatically terminated after a delay of

one minute.

—COMMUNICATION

Inside the COMMUNICATION menu it is possible to read/modify the setting data of the RS485 Protocol

and Ethernet parameters. Since newer versions Ip Address can be modified only in Commands \ Set

Params \ Set not resettable parameter.

By means of (Up) or (Down) buttons it is possible to browse the main menu till the “RS485

Protocol >>”, “Ethernet Local Parameters >>” or“Ethernet Remote

Parameters >>”; to enter you must press the (Right) button.

As example, to select the address 12 for the ModBus protocol, the following procedure must be issued:

• Select the Communication menu“COMMUNICATION >>”.

• By means (Down) button select the “RS485 Protocol >>”.

• Press the (Right) button to enter; the following message is displayed:

“Protocol MODBUS”

“Address 1”

“9600 baud”

• Start the procedure to effect a change explained in the Setting modifying (SET) paragraph

• Press the (Enter); button for a few seconds; the modifi cation in progress status is highlighted by

the both START and TRIP flashing.

• Move the cursor over the parameter intended for change using the (Enter), button, (in the exam-

ple on the 1 address),

• Change the parameters by means the (increment) button (up to 12 address),

• Press the (Enter) button to move the cursor over the last parameter in the display.

• Press the (Enter) button once again; the cursor and the LED TRIP turn off (the LED START keeps

flashing),

• Press the (Enter) button for a few seconds; new message appears: “Conrm settings?”

• Answer to the message ENTER: YES to confirm changes or RESET: NO to abort.

The end of the LED blinking points out the end of procedure.

—Circuit breaker commands

By means of the (open) and (close) keys, the circuit breaker commands may be issued.

The committed output relays must be enabled inside the Circuit Breaker supervision \

LEDs-relays allocation menu.

Note 1 Instantly all the relays are switched in rest state, including relays programmed as “normally energized”

14 NVA100X - Getting started - 01 - 2018

MMI MENU STRUCTURE

READ

NVA100X_menuread1.ai

Profile A

ACTIVE PROFILE >>

PROCEED READ MENU’

State N.Open OFF

State SumI OFF

State SumI^2t OFF

State tbreak OFF

SumIL1 0 In

SumIL2 0 In

SumIL3 0 In

SumIL1^2t 0 In^2s

SumIL2^2t 0 In^2s

SumIL3^2t 0 In^2s

CIRCUIT BREAKER

SUPERVISION >>

CB COMMANDS >>

CB POSITION >>

CB DIAGNOSTIC >>

CB-OPEN Cmd OFF

CB-CLOSE Cmd OFF

CB state ?

Binary IN1-1 OFF

Binary IN1-2 OFF

Binary IN1-3 OFF

..................

Binary IN1-16 OFF

DELAYED INPUTS

IN1-1...IN1-16 >>

VIN01 Status OFF

VIN01 Timeout ON

VIN02 Status OFF

VIN02 Timeout ON

..................

VIN032 Status OFF

VIN032 Timeout ON

VIN >>

VOUT01: OFF

VOUT02: OFF

VOUT03: OFF

..................

VOUT16: OFF

VOUT >>

INFO >>

Code NVA100X-VM00-a

Ver.sw 1.00

DSP fw Rel 1.00

SERIAL NUMBER >> Serial number

237

IEC61850 >> Code NVA100X-VM00-a

Sw Release 1.30

SELF TEST >>

Protection

ON SERVICE

Global self-test

OK

System OK

Data-base:

boot OK

run-time OK

DAta BUS:

heavy OK

minor OK

DSP:

..................

MODULES >>

MMI board ON

SING1 board ON

SING2 board OFF

SRC1 board ON

------------------

<< No Yes >>

Disable

27-27V1-37?

DISABLE 27-37

FUNCTIONS

BY OPERATOR >>

PROTECTIONS >> SEE NEXT PAGES

THYTRONIC

PRO-NVA100X-VM00-a

DATE: 19/06/2013

TIME: 17:29:59

PLC >>

PLC State 1: 0

PLC State 2: 0

PLC State x: 0

..................

PLC State 32: 0

User SW name: xxx

Ver.:

DATE: 01/08/2007

PLC state: OFF

PLC version: 01.40

Error: none

Warning: none

PLC States >>

CLOCK ADJUST >>

HOUR: 14

MINUTE: 25

SECONDS: 0

<< Confirm >>

DAY: 11

MONTH: 7

YEAR: 2013

<< Confirm >>

START

SYNCHRO CHECK >>

Start Synchro check?

<<No Yes>>

MEASURES >>

IL1 0.000 In

IL2 0.000 In

IL3 0.000 In

IE 0.000 IEn

UL1 0.000 En

UL2 0.000 En

UL3 0.000 En

UL4 0.000 Un4

UE 0.000 UEn

U12 0.000 Un

U23 0.000 Un

U31 0.000 Un

UEC 0.000 UECn

ILmax 0.000 In

ILmin 0.000 In

IL 0.000 In

ULmax 0.000 En

UL 0.000 Un

U 0.000 Un

PhiL1 0 deg

PhiL2 0 deg

PhiL3 0 deg

Alpha1 0 deg

Alpha2 0 deg

Alpha3 0 deg

PhiE 0 deg

PhiEC 0 deg

DTheta 0 DThetaB

I1 0.000 In

I2 0.000 In

I2/I1 0.000 In

U1 0.000 En

U2 0.000 En

U/f 0.000 Un/fn

P 0.000 Pn

Q 0.000 Qn

S 0.000 An

CosPhi 1.000

PL1 0.000 Pn

QL1 0.000 Qn

CosPhiL1 1.000

PL2 0.000 Pn

QL2 0.000 Qn

CosPhiL2 1.000

PL3 0.000 Pn

QL3 0.000 Qn

CosPhiL3 1.000

IL1-2nd 0.000 In

IL2-2nd 0.000 In

IL3-2nd 0.000 In

IL1-3rd 0.000 In

IL2-3rd 0.000 In

IL3-3rd 0.000 In

IE-3rd 0.000 IEn

UE-3rd 0.000 UEn

IL1-4th 0.000 In

IL2-4th 0.000 In

IL3-4th 0.000 In

IL1-5th 0.000 In

IL2-5th 0.000 In

IL3-5th 0.000 In

f 0.000 Hz

fUL1 0.000 Hz

fUL4 0.000 Hz

DV 0.000 Un4

DF 99.99 Hz

PhiL14 0 deg

df/dt 0.000 Hz/s

IL1FIX 0.000 In

IL2FIX 0.000 In

IL3FIX 0.000 In

PFIX 0.000 Pn

QFIX 0.000 Qn

IL1ROL 0.000 In

IL1ROL 0.000 In

IL2ROL 0.000 In

IL3ROL 0.000 In

PROL 0.000 Pn

QROL 0.000 Qn

IL1MAX 0.000 In

IL2MAX 0.000 In

IL3MAX 0.000 In

PMAX 0.000 Pn

QMAX 0.000 Qn

IL1MIN 0.000 In

IL2MIN 0.000 In

IL3MIN 0.000 In

PMIN 0.000 Pn

QMIN 0.000 Qn

EA+ 0 kWh

EA- 0 kWh

EQ+ 0 kvarh

EQ- 0 kvarh

EA 0 kWh

EQ 0 kvarh

INTERNAL STATES

>>

LEDs reset OFF

Prof. switch OFF

Block1: OFF

Block2 Generic OFF

Block2 50 OFF

Block2 50N OFF

TCS1 OFF

TCS2 OFF

Ext.trip BF OFF

Remote trip OFF

Fault trig OFF

52a OFF

52b OFF

CB OPEN Cmd OFF

CB CLOSE Cmd OFF

CB Monitor OFF

79 Enable OFF

79 Block OFF

79 Ext. OFF

Reset Demand OFF

Reset Energy OFF

Reset count. OFF

Thermal image init

OFF

74VT ext. OFF

MCB VT OPEN OFF

TCP >>

MULTICAST >>

SERVER >>

RPC >>

CLIENT01: OFF

CLIENT02: OFF

CLIENT03: OFF

..................

CLIENT08: OFF

CLIENT01: OFF

CLIENT02: OFF

CLIENT03: OFF

..................

CLIENT08: OFF

CON. TCP: 0

CON. MCAST: 0

NOTA I menù illustrano tutte le funzioni di protezione

Le funzioni effettivamente presenti dipendono dalla versione di NVA100X-x (x = B, V, P, G o C)

15

NVA100X - Getting started - 01 - 2018

NVA100X_menuread1a.ai

PROTECTIONS

27 >>

Start U< OFF

Trip U< OFF

BLK1 U< OFF

Start U<< OFF

Trip U<< OFF

BLK1 U<< OFF

27V1 >>

Start U1< OFF

Trip U1< OFF

BLK1 U1< OFF

37 >>

Start I< OFF

Trip I< OFF

BLK1 I< OFF

37P >>

Start P1< OFF

Trip P1< OFF

BLK1 P1< OFF

Start P2< OFF

Trip P2< OFF

BLK1 P1< OFF

Start IE> OFF

Trip IE> OFF

CLP IE> OFF

BLK1 IE> OFF

BLK2IN IE> OFF

BLK4IN IE> OFF

Start IE>> OFF

Trip IE>> OFF

CLP IE>> OFF

BLK1 IE>> OFF

BLK2IN IE>> OFF

BLK4IN IE>> OFF

Start IE>>> OFF

Trip IE>>> OFF

CLP IE>>> OFF

BLK1 IE>>> OFF

BLK2IN IE>>> OFF

BLK4IN IE>>> OFF

50N/51N-87NHIZ >>

Start IEC> OFF

Trip IEC> OFF

CLP IEC> OFF

BLK1 IEC> OFF

BLK2IN IEC> OFF

BLK4IN IEC> OFF

Start IEC>> OFF

Trip IEC>> OFF

CLP IEC>> OFF

BLK1 IEC>> OFF

BLK2IN IEC>> OFF

BLK4IN IEC>> OFF

Start IEC>>> OFF

Trip IEC>>> OFF

CLP IEC>>> OFF

BLK1 IEC>>> OFF

BLK2IN IEC>>> OFF

BLK4IN IEC>>> OFF

50N(C)/51N(C) >>

37Q >>

Start P1< OFF

Trip P1< OFF

BLK1 P1< OFF

Start P2< OFF

Trip P2< OFF

BLK1 P1< OFF

32P >>

Start P1> OFF

Trip P1> OFF

BLK1 P1> OFF

Start P2> OFF

Trip P2> OFF

BLK1 P2> OFF

32Q >>

Start Q1> OFF

Trip Q1> OFF

BLK1 Q1> OFF

Start Q2> OFF

Trip Q2> OFF

BLK1 Q2> OFF

49MG >>

Alarm DThAL OFF

BLK1 DThAL OFF

BLK2IN DThAL OFF

Trip DTh> OFF

BLK1 DTh> OFF

BLK2IN DTh> OFF

Alarm DThAL1 OFF

BLK1 DThAL1 OFF

BLK2IN DThAL1 OFF

BLK4IN DThAL1 OFF

Alarm DThAL2 OFF

BLK1 DThAL2 OFF

BLK2IN DThAL2 OFF

BLK2IN DThAL2 OFF

BLK4IN DThAL2 OFF

Trip DTh> OFF

BLK1 DTh> OFF

BLK2IN DTh> OFF

BLK4IN DTh> OFF

CLP DTh OFF

49LT >>

79 >>

ActiveMode 79 OFF

Run 79 OFF

CycleState 79 Rest

Residual-time 79

0 s

LastEvent 79

No events

EnableState 79 OFF

Start(U/f)AL OFF

Trip (U/f)AL OFF

BLK1 (U/f)AL OFF

Start(U/f)> OFF

Trip (U/f)> OFF

BLK1 (U/f)> OFF

Start(U/f)>> OFF

Trip (U/f)>> OFF

BLK1 (U/f)>> OFF

24 >>

Synchro Avv OFF

Synchro ControlOFF

Synchro Trip OFF

Synchro diagnostic

State V1-SYNC OFF

State V4-SYNC OFF

State f1-RANGE OFF

State f4-RANGE OFF

State V1>SYNC OFF

State V4>SYNC OFF

State V1<SYNC OFF

State V4<SYNC OFF

State df-net OFF

State df-SYNC OFF

State dphi-SYNCOFF

25 >>

I2/I1 >>

Start I21> OFF

Trip I21> OFF

BLK1 I21> OFF

CLP I21> OFF

46M >>

Start I2> OFF

Trip I2> OFF

CLP I2> OFF

BLK1 I2> OFF

BLK2IN I2> OFF

Start I2>> OFF

Trip I2>> OFF

CLP I2>> OFF

BLK1 I2>> OFF

BLK2IN I2>> OFF

Start I> OFF

Trip I> OFF

CLP I> OFF

BLK1 I> OFF

BLK2IN I> OFF

BLK4IN I> OFF

Start I>> OFF

Trip I>> OFF

CLP I>> OFF

BLK1 I>> OFF

BLK2IN I>> OFF

BLK4IN I>> OFF

Start I>>> OFF

Trip I>>> OFF

CLP I>>> OFF

BLK1 I>>> OFF

BLK2IN I>>> OFF

BLK4IN I>>> OFF

50/51 >>

PROCEED READ MENU’

Start I2AL> OFF

Trip I2AL> OFF

BLK1 I2AL> OFF

Start I2>> OFF

Trip I2>> OFF

BLK1 I2>> OFF

46G >>

47 >>

Start US1< OFF

Start US> OFF

Trip 47 OFF

BLK1 47 OFF

55 >>

Start CPhi1< OFF

Trip CPhi1< OFF

BLK1 CPhi1< OFF

Start CPhi2< OFF

Trip CPhi2< OFF

BLK1 CPhi2< OFF

46LT >>

Start I2> OFF

Trip I2> OFF

CLP I2> OFF

BLK1 I2> OFF

BLK2IN I2> OFF

Start I2>> OFF

Trip I2>> OFF

CLP I2>> OFF

BLK1 I2>> OFF

BLK2IN I2>> OFF

16 NVA100X - Getting started - 01 - 2018

NVA100X_menuread1b.ai

PROTECTIONS

74VT >>

Block 74VT OFF

Alarm 74VT OFF

BLK1 74VT OFF

74CT >>

Start I* OFF

Trip S< OFF

BLK1 S< OFF

59 >>

Start IED> OFF

Trip IED> OFF

CLP IED> OFF

BLK1 IED> OFF

BLK2IN IED> OFF

BLK4IN IED> OFF

Start IED>> OFF

Trip IED>> OFF

CLP IED>> OFF

BLK1 IED>> OFF

BLK2IN IED>> OFF

BLK4IN IED>> OFF

Start IED>>> OFF

Trip IED>>> OFF

CLP IED>>> OFF

BLK1 IED>>> OFF

BLK2IN IED>>> OFF

BLK4IN IED>>> OFF

Start IED>>>> OFF

Trip IED>>>> OFF

CLP IED>>>> OFF

BLK1 IED>>>> OFF

BLK2IN IED>>>> OFF

BLK4IN IED>>>> OFF

67N >>

BF >>

Trip Int/Ext OFF

Start IBF> OFF

Start IEBF> OFF

Start BF OFF

Trip BF OFF

BLK1 BF OFF

74VTint67 State

OFF

74VText67 State

OFF

Start IPD> OFF

Trip IPD> OFF

CLP IPD> OFF

BLK1 IPD> OFF

BLK2IN IPD> OFF

BLK4IN IPD> OFF

Start IPD>> OFF

Trip IPD>> OFF

CLP IPD>> OFF

BLK1 IPD>> OFF

BLK2IN IPD>> OFF

BLK4IN IPD>> OFF

Start IPD>>> OFF

Trip IPD>>> OFF

CLP IPD>>> OFF

BLK1 IPD>>> OFF

BLK2IN IPD>>> OFF

BLK4IN IPD>>> OFF

Start IPD>>>> OFF

Trip IPD>>>> OFF

CLP IPD>>>> OFF

BLK1 IPD>>>> OFF

BLK2IN IPD>>>> OFF

BLK4IN IPD>>>> OFF

67 >>

Start U> OFF

Trip U> OFF

BLK1 U> OFF

Start U>> OFF

Trip U>> OFF

BLK1 U>> OFF

59N >>

Start UE> OFF

Trip UE> OFF

BLK1 UE> OFF

Start UE>> OFF

Trip UE>> OFF

BLK1 UE>> OFF

VECTOR JUMP >>

Start dphi> OFF

Trip dphi> OFF

BLK1 dphi> OFF

Enphi state OFF

Start 74TCS OFF

Trip 74TCS OFF

BLK1 74TCS OFF

Start I2ndh> OFF

2ndh-REST >>

74TCS >>

59V2 >> Start U2> OFF

Trip U2> OFF

BLK1 U2> OFF

66 >>

Trip 66 OFF

BLK1 66 OFF

ATST 0 s

ANST 0

AtIN 0 s

81O >>

Start f> OFF

Trip f> OFF

BLK1 f> OFF

Start f>> OFF

Trip f>> OFF

BLK1 f>> OFF

81U >>

Start f< OFF

Trip f< OFF

BLK1 f< OFF

Start f<< OFF

Trip f<< OFF

BLK1 f<< OFF

Start f<<< OFF

Trip f<<< OFF

BLK1 f<<< OFF

Start f<<<< OFF

Trip f<<<< OFF

BLK1 f<<<< OFF

81R >>

Start df> OFF

Trip df> OFF

BLK1 df> OFF

Start df>> OFF

Trip df>> OFF

BLK1 df>> OFF

Start df>>> OFF

Trip df>>> OFF

BLK1 df>>> OFF

Start df>>>> OFF

Trip df>>>> OFF

BLK1 df>>>> OFF

PROCEED READ MENU’

PREVIOUS READ MENU’

17

NVA100X - Getting started - 01 - 2018

READ

PREVIOUS READ MENU’

PROCEED READ MENU’

PARTIAL COUNTERS SEE NEXT PAGES

TOTAL COUNTERS SEE NEXT PAGES

NVA100X_menuread2.ai

NVA100X_menuread1.ai

KC1-1 relay OFF

KC1-1 coil OK

KC1-2 relay OFF

KC1-2 coil OK

KC1-3 relay OFF

KC1-3 coil OK

KC1-4 relay OFF

KC1-4 coil OK

KC1-5 relay OFF

KC1-5 coil OK

KC1-6 relay OFF

KC1-6 coil OK

KC1-7 relay OFF

KC1-7 coil OK

KC1-8 relay OFF

KC1-8 coil OK

RELAYS

KC1-1...KC1-8

Fault 0

(last) >>

Fault 1

>>

Fault ...

>>

Fault 10

>>

FAULTS RECORDING

>>

PILOT WIRE

DIAGNOSTIC >>

BreakedBLIN1 OFF

ShortedBLIN1 OFF BLOCK2IN-IPh OFF

BLOCK2IN-IE OFF

tb timeout OFF

Fault 0 Cause: -

Operating phase: -

Date:

Time:

IL1r: 0.000 In

IL2r: 0.000 In

IL3r: 0.000 In

UL1r: 0.000 Un

UL2r: 0.000 Un

UL3r: 0.000 Un

U12r: 0.000 Un

U23r: 0.000 Un

U31r: 0.000 Un

IEr: 0.000 IEn

IECr: 0.000 IEn

UEr: 0.000 UEn

UECr: 0.000 UECn

PhiL1r: 0 deg

PhiL2r: 0 deg

PhiL3r: 0 deg

Alpha1r: 0 deg

Alpha2r: 0 deg

Alpha3r: 0 deg

PhiEr: 0 deg

PhiECr: 0 deg

DTheta-r: :

0.000 DThetaB

U1r: 0.000 En

U2r: 0.000 En

U/fr: 0.000 Un/fn

Pr: 0.000 Pn

Qr: 0.000 Qn

CosPhir: 0.000

fr: 0.000 fn

dfr: 0.000 Hz/s

dphir: 0 deg

Binary inputs

IN1-16...IN1-1:

0000000000000000

IN2-16...IN2-1:

0000000000000000

Relay

KC1-8...KC1-1:

00000000

KC2-8...KC2-1:

00000000

ST-IPh-BLK2 OFF

ST-IE-BLK2 OFF

BLK2OUT-IPh OFF

BLK2OUT-IE OFF

BLK2OUT-IPh/IE OFF

SELECTIVE BLOCK

BLOCK2

BLOCK2 INPUT >>

BLOCK2 OUTPUT >>

INTERNAL

SELECTIVE BLOCK

BLOCK4 >>

ST-IPh-BLK4 OFF

ST-IE-BLK4 OFF

BLK4OUT OFF

Event 0 (last)

Power up

17/06/2013

06:48:27:254

Event 1

Settings

18/06/2013

06:48:27:254

Event 2

Power down

18/06/2013

08:00:27:137

Event ...

Settings

18/06/2013

06:48:27:254

Event 299

Settings

18/06/2013

06:48:27:254

EVENTS RECORDING

>>

18 NVA100X - Getting started - 01 - 2018

ParStU<cnt 0

ParTrU<cnt 0

ParBk1U<cnt 0

ParStU<<cnt 0

ParRtU<<cnt 0

ParBk1U<<cnt 0

ParStI>cnt 0

ParTrI>cnt 0

ParBk1I>cnt 0

ParBk2I>cnt 0

ParStI>>cnt 0

ParTrI>>cnt 0

ParBk1I>>cnt 0

ParBk2I>>cnt 0

ParStI>>>cnt 0

ParTrI>>>cnt 0

ParBk1I>>>cnt 0

ParBk2I>>>cnt 0

ParSt-P1>cnt 0

ParTr-P1>cnt 0

ParBk1-P1>cnt 0

ParSt-P2>cnt 0

ParRt-P2>cnt 0

ParBk1-P2>cnt 0

ParSt-P1<cnt 0

ParTr-P1<cnt 0

ParBk1-P1<cnt 0

ParSt-P2<cnt 0

ParRt-P2<cnt 0

ParBk1-P2<cnt 0

ParSt-Q1<cnt 0

ParTr-Q1<cnt 0

ParBk1-Q1<cnt 0

ParSt-Q2<cnt 0

ParRt-Q2<cnt 0

ParBk1-Q2<cnt 0

ParSt-Q1>cnt 0

ParTr-Q1>cnt 0

ParBk1-Q1>cnt 0

ParSt-Q2>cnt 0

ParRt-Q2>cnt 0

ParBk1-Q2>cnt 0

ParStU1<cnt 0

ParTrU1<cnt 0

ParBk1U1<cnt 0

ParSt(U/f)ALcnt 0

ParTr(U/f)ALcnt 0

ParBk1(U/f)ALcnt 0

ParSt(U/f)>cnt 0

ParTr(U/f)>cnt 0

ParBk1(U/f)>cnt 0

ParSt(U/f)>>cnt 0

ParTr(U/f)>>cnt 0

ParBk1(U/f)>>cnt 0

79 Counters >>

24 Counters >>

ParRR79cnt 0

ParSR79cnt 0

ParDR79cnt 0

ParFR79Pcnt 0

ParFR79Ecnt 0

25 Counters >>

27 Counters >>

32P Counters >>

32Q Counters >>

27V1 Counters >>

ParTr-47cnt 0

ParBk1-47cnt 0

47 Counters >>

ParStI<cnt 0

ParTrI<cnt 0

ParBk1I<cnt 0

37 Counters >>

37P Counters >>

37Q Counters >>

ParTr25cnt 0

ParStUE>cnt 0

ParTrUE>cnt 0

ParBk1UE>cnt 0

ParStUE>>cnt 0

ParRtUE>>cnt 0

ParBk1UE>>cnt 0

49MG Counters >>

55 Counters >>

67 Counters >>

67N Counters >>

81O Counters >>

81U Counters >>

CB Counters >>

74TCS Counters >>

74VT Counters >>

74CT Counters >>

BF Counters >>

50/51 Counters >>

ParStU>cnt 0

ParTrU>cnt 0

ParBk1U>cnt 0

ParStU>>cnt 0

ParRtU>>cnt 0

ParBk1U>>cnt 0

59 Counters >>

59N Counters >>

50N/51N Counters >>

51V Counters >>

40 Counters >>

49LT Counters >>

ParAlDthAL1cnt 0

ParBk1DthAL1cnt 0

ParBk2DthAL1cnt 0

ParAlDthAL2cnt 0

ParBk1DthAL2cnt 0

ParBk2DthAL2cnt 0

ParTrDth>cnt 0

ParBk1Dth>cnt 0

ParBk2Dth>cnt 0

46M Counters >>

ParAlDthAL1cnt 0

ParBk1DthAL1cnt 0

ParBk2DthAL1cnt 0

ParAlDthAL2cnt 0

ParBk1DthAL2cnt 0

ParBk2DthAL2cnt 0

ParTrDth>cnt 0

ParBk1Dth>cnt 0

ParBk2Dth>cnt 0

50N(C)/51N(C

Counters >>

ParStIPD>cnt 0

ParTrIPD>cnt 0

ParBk1IPD>cnt 0

ParBk2IPD>cnt 0

ParStIPD>>cnt 0

ParTrIPD>>cnt 0

ParBk1IPD>>cnt 0

ParBk2IPD>>cnt 0

ParStIPD>>>cnt 0

ParTrIPD>>>cnt 0

ParBk1IPD>>>cnt 0

ParBk2IPD>>>cnt 0

ParStIPD>>>>cnt 0

ParTrIPD>>>>cnt 0

ParBk1IPD>>>>cnt 0

ParBk2IPD>>>>cnt 0

ParStIED>cnt 0

ParTrIED>cnt 0

ParBk1IED>cnt 0

ParBk2IED>cnt 0

ParStIED>>cnt 0

ParTrIED>>cnt 0

ParBk1IED>>cnt 0

ParBk2IED>>cnt 0

ParStIED>>>cnt 0

ParTrIED>>>cnt 0

ParBk1IED>>>cnt 0

ParBk2IED>>>cnt 0

ParStIED>>>>cnt 0

ParTrIED>>>>cnt 0

ParBk1IED>>>>cnt 0

ParBk2IED>>>>cnt 0

ParBk1-74CTcnt 0

ParTr74CTcnt 0

ParStBFcnt 0

ParTrTrcnt 0

ParBk1BFcnt 0

2ndh-REST

Counters >> ParStI2ndh>cnt 0

N.OpenCBcnt 0

ParBk1-74VTcnt 0

ParTr74VTcnt 0

ParBk1-74TCScnt 0

ParTr74TCScnt 0

I2/I1 Counters >>

ParStI21>cnt 0

ParTrI21>cnt 0

ParBk121>cnt 0

46LT Counters >>

ParStI2>cnt 0

ParTrI2>cnt 0

ParBk1I2>cnt 0

ParBk2I2>cnt 0

ParStI2>>cnt 0

ParTrI2>>cnt 0

ParBk1I2>>cnt 0

ParBk2I2>>cnt 0

ParStIE>cnt 0

ParTrIE>cnt 0

ParBk1IE>cnt 0

ParBk2IE>cnt 0

ParStIE>>cnt 0

ParTrIE>>cnt 0

ParBk1IE>>cnt 0

ParBk2IE>>cnt 0

ParStIE>>>cnt 0

ParTrIE>>>cnt 0

ParBk1IE>>>cnt 0

ParBk2IE>>>cnt 0

ParStIEC>cnt 0

ParTrIEC>cnt 0

ParBk1IEC>cnt 0

ParBk2IEC>cnt 0

ParStIEC>>cnt 0

ParTrIEC>>cnt 0

ParBk1IEC>>cnt 0

ParBk2IEC>>cnt 0

ParStIEC>>>cnt 0

ParTrIEC>>>cnt 0

ParBk1IEC>>>cnt 0

ParBk2IEC>>>cnt 0

59V2 Counters >> ParStU2>cnt 0

ParTrU2>cnt 0

ParBk1U2>cnt 0

55 Counters >> ParStCPhi<cnt 0

ParTrCPhi<cnt 0

ParBk1CPhi<cnt 0

66 Counters >> ParTr66cnt 0

ParBk1-66cnt 0

ParSt-f>cnt 0

ParTr-f>cnt 0

ParBk1-f>cnt 0

ParSt-f>>cnt 0

ParTr-f>>cnt 0

ParBk1-f>>cnt 0

VECTOR JUMP

Counters >>

ParSt-dpi>cnt 0

ParTr-dpi>cnt 0

ParBk1-dpi>cnt 0 ParSt-f<cnt 0

ParTr-f<cnt 0

ParBk1-f<cnt 0

ParSt-f<<cnt 0

ParTr-f<<cnt 0

ParBk1-f<<cnt 0

ParSt-f<<<cnt 0

ParTr-f<<<cnt 0

ParBk1-f<<<cnt 0

ParSt-f<<<<cnt 0

ParTr-f<<<<cnt 0

ParBk1-f<<<<cnt 0

81R Counters >>

ParSt-df>cnt 0

ParTr-df>cnt 0

ParBk1-df>cnt 0

ParSt-df>>cnt 0

ParTr-df>>cnt 0

ParBk1-df>>cnt 0

ParSt-df>>>cnt 0

ParTr-df>>>cnt 0

ParBk1-df>>>cnt 0

ParSt-df>>>>cnt 0

ParTr-df>>>>cnt 0

ParBk1-df>>>>cnt 0

PARTIAL COUNTERS

NVA100X_menuread3.ai

46G Counters >>

ParStI2AL>cnt 0

ParTrI2AL>cnt 0

ParBk1I2AL>cnt 0

ParStI2>>cnt 0

ParTrI2>>cnt 0

ParBk1I2>>cnt 0

TotStI-I/U>cnt 0

TotTrI-I/U>cnt 0

TotBk1I-I/U>cnt 0

TotBk2I-I/U>cnt 0

TotStI-I/U>>cnt 0

TotTrI-I/U>>cnt 0

TotBk1I-I/U>>cnt 0

TotBk2I-I/U>>cnt 0

ParSt40ALcnt 0

ParTr40ALcnt 0

ParBk140ALcnt 0

ParStXC1XD1cnt 0

ParTrXC1XD1cnt 0

ParBk1XC1XD1cnt 0

ParStXC2XD1cnt 0

ParTrXC2XD1cnt 0

ParBk1XC2XD2cnt 0

TotStI-I/U>cnt 0

TotTrI-I/U>cnt 0

TotBk1I-I/U>cnt 0

TotBk2I-I/U>cnt 0

TotStI-I/U>>cnt 0

TotTrI-I/U>>cnt 0

TotBk1I-I/U>>cnt 0

TotBk2I-I/U>>cnt 0

19 NVA100X - Getting started - 01 - 2018

TOTAL COUNTERS

NVA100X_menuread4.ai

TotStU<cnt 0

TotTrU<cnt 0

TotBk1U<cnt 0

TotStU<<cnt 0

TotRtU<<cnt 0

TotBk1U<<cnt 0

TotStI>cnt 0

TotTrI>cnt 0

TotBk1I>cnt 0

TotBk2I>cnt 0

TotStI>>cnt 0

TotTrI>>cnt 0

TotBk1I>>cnt 0

TotBk2I>>cnt 0

TotStI>>>cnt 0

TotTrI>>>cnt 0

TotBk1I>>>cnt 0

TotBk2I>>>cnt 0

TotSt-P1>cnt 0

TotTr-P1>cnt 0

TotBk1-P1>cnt 0

TotSt-P2>cnt 0

TotRt-P2>cnt 0

TotBk1-P2>cnt 0

TotSt-P1<cnt 0

TotTr-P1<cnt 0

TotBk1-P1<cnt 0

TotSt-P2<cnt 0

TotRt-P2<cnt 0

TotBk1-P2<cnt 0

TotSt-Q1<cnt 0

TotTr-Q1<cnt 0

TotBk1-Q1<cnt 0

TotSt-Q2<cnt 0

TotRt-Q2<cnt 0

TotBk1-Q2<cnt 0

TotSt-Q1>cnt 0

TotTr-Q1>cnt 0

TotBk1-Q1>cnt 0

TotSt-Q2>cnt 0

TotRt-Q2>cnt 0

TotBk1-Q2>cnt 0

TotStU1<cnt 0

TotTrU1<cnt 0

TotBk1U1<cnt 0

TotSt(U/f)ALcnt 0

TotTr(U/f)ALcnt 0

TotBk1(U/f)ALcnt 0

TotSt(U/f)>cnt 0

TotTr(U/f)>cnt 0

TotBk1(U/f)>cnt 0

TotSt(U/f)>>cnt 0

TotTr(U/f)>>cnt 0

TotBk1(U/f)>>cnt 0

79 Counters >>

24 Counters >>

TotRR79cnt 0

TotSR79cnt 0

TotDR79cnt 0

TotFR79Pcnt 0

TotFR79Ecnt 0

25 Counters >>

27 Counters >>

32P Counters >>

32Q Counters >>

27V1 Counters >>

TotTr-47cnt 0

TotBk1-47cnt 0

47 Counters >>

TotStI<cnt 0

TotTrI<cnt 0

TotBk1I<cnt 0

37 Counters >>

37P Counters >>

37Q Counters >>

TotTr25cnt 0

TotStUE>cnt 0

TotTrUE>cnt 0

TotBk1UE>cnt 0

TotStUE>>cnt 0

TotRtUE>>cnt 0

TotBk1UE>>cnt 0

49MG Counters >>

55 Counters >>

67 Counters >>

67N Counters >>

81O Counters >>

81U Counters >>

CB Counters >>

74TCS Counters >>

74VT Counters >>

74CT Counters >>

BF Counters >>

50/51 Counters >>

TotStU>cnt 0

TotTrU>cnt 0

TotBk1U>cnt 0

TotStU>>cnt 0

TotRtU>>cnt 0

TotBk1U>>cnt 0

59 Counters >>

59N Counters >>

50N/51N Counters >>

51V Counters >>

40 Counters >>

49LT Counters >>

TotAlDthAL1cnt 0

TotBk1DthAL1cnt 0

TotBk2DthAL1cnt 0

TotAlDthAL2cnt 0

TotBk1DthAL2cnt 0

TotBk2DthAL2cnt 0

TotTrDth>cnt 0

TotBk1Dth>cnt 0

TotBk2Dth>cnt 0

46M Counters >>

TotAlDthAL1cnt 0

TotBk1DthAL1cnt 0

TotBk2DthAL1cnt 0

TotAlDthAL2cnt 0

TotBk1DthAL2cnt 0

TotBk2DthAL2cnt 0

TotTrDth>cnt 0

TotBk1Dth>cnt 0

TotBk2Dth>cnt 0

50N(C)/51N(C

Counters >>

TotStIPD>cnt 0

TotTrIPD>cnt 0

TotBk1IPD>cnt 0

TotBk2IPD>cnt 0

TotStIPD>>cnt 0

TotTrIPD>>cnt 0

TotBk1IPD>>cnt 0

TotBk2IPD>>cnt 0

TotStIPD>>>cnt 0

TotTrIPD>>>cnt 0

TotBk1IPD>>>cnt 0

TotBk2IPD>>>cnt 0

TotStIPD>>>>cnt 0

TotTrIPD>>>>cnt 0

TotBk1IPD>>>>cnt 0

TotBk2IPD>>>>cnt 0

TotStIED>cnt 0

TotTrIED>cnt 0

TotBk1IED>cnt 0

TotBk2IED>cnt 0

TotStIED>>cnt 0

TotTrIED>>cnt 0

TotBk1IED>>cnt 0

TotBk2IED>>cnt 0

TotStIED>>>cnt 0

TotTrIED>>>cnt 0

TotBk1IED>>>cnt 0

TotBk2IED>>>cnt 0

TotStIED>>>>cnt 0

TotTrIED>>>>cnt 0

TotBk1IED>>>>cnt 0

TotBk2IED>>>>cnt 0

TotBk1-74CTcnt 0

TotTr74CTcnt 0

TotStBFcnt 0

TotTrTrcnt 0

TotBk1BFcnt 0

2ndh-REST

Counters >> TotStI2ndh>cnt 0

N.OpenCBcnt 0

TotBk1-74VTcnt 0

TotTr74VTcnt 0

TotBk1-74TCScnt 0

TotTr74TCScnt 0

I2/I1 Counters >>

TotStI21>cnt 0

TotTrI21>cnt 0

TotBk121>cnt 0

46LT Counters >>

TotStI2>cnt 0

TotTrI2>cnt 0

TotBk1I2>cnt 0

TotBk2I2>cnt 0

TotStI2>>cnt 0

TotTrI2>>cnt 0

TotBk1I2>>cnt 0

TotBk2I2>>cnt 0

TotStIE>cnt 0

TotTrIE>cnt 0

TotBk1IE>cnt 0

TotBk2IE>cnt 0

TotStIE>>cnt 0

TotTrIE>>cnt 0

TotBk1IE>>cnt 0

TotBk2IE>>cnt 0

TotStIE>>>cnt 0

TotTrIE>>>cnt 0

TotBk1IE>>>cnt 0

TotBk2IE>>>cnt 0

TotStIEC>cnt 0

TotTrIEC>cnt 0

TotBk1IEC>cnt 0

TotBk2IEC>cnt 0

TotStIEC>>cnt 0

TotTrIEC>>cnt 0

TotBk1IEC>>cnt 0

TotBk2IEC>>cnt 0

TotStIEC>>>cnt 0

TotTrIEC>>>cnt 0

TotBk1IEC>>>cnt 0

TotBk2IEC>>>cnt 0

59V2 Counters >> TotStU2>cnt 0

TotTrU2>cnt 0

TotBk1U2>cnt 0

55 Counters >> TotStCPhi<cnt 0

TotTrCPhi<cnt 0

TotBk1CPhi<cnt 0

66 Counters >> TotTr66cnt 0

TotBk1-66cnt 0

TotSt-f>cnt 0

TotTr-f>cnt 0

TotBk1-f>cnt 0

TotSt-f>>cnt 0

TotTr-f>>cnt 0

TotBk1-f>>cnt 0

VECTOR JUMP

Counters >>

TotSt-dpi>cnt 0

TotTr-dpi>cnt 0

TotBk1-dpi>cnt 0 TotSt-f<cnt 0

TotTr-f<cnt 0

TotBk1-f<cnt 0

TotSt-f<<cnt 0

TotTr-f<<cnt 0

TotBk1-f<<cnt 0

TotSt-f<<<cnt 0

TotTr-f<<<cnt 0

TotBk1-f<<<cnt 0

TotSt-f<<<<cnt 0

TotTr-f<<<<cnt 0

TotBk1-f<<<<cnt 0

81R Counters >>

TotSt-df>cnt 0

TotTr-df>cnt 0

TotBk1-df>cnt 0

TotSt-df>>cnt 0

TotTr-df>>cnt 0

TotBk1-df>>cnt 0

TotSt-df>>>cnt 0

TotTr-df>>>cnt 0

TotBk1-df>>>cnt 0

TotSt-df>>>>cnt 0

TotTr-df>>>>cnt 0

TotBk1-df>>>>cnt 0

46G Counters >>

TotStI2AL>cnt 0

TotTrI2AL>cnt 0

TotBk1I2AL>cnt 0

TotStI2>>cnt 0

TotTrI2>>cnt 0

TotBk1I2>>cnt 0

TotStI-I/U>cnt 0

TotTrI-I/U>cnt 0

TotBk1I-I/U>cnt 0

TotBk2I-I/U>cnt 0

TotStI-I/U>>cnt 0

TotTrI-I/U>>cnt 0

TotBk1I-I/U>>cnt 0

TotBk2I-I/U>>cnt 0

TotSt40ALcnt 0

TotTr40ALcnt 0

TotBk140ALcnt 0

TotStXC1XD1cnt 0

TotTrXC1XD1cnt 0

TotBk1XC1XD1cnt 0

TotStXC2XD1cnt 0

TotTrXC2XD1cnt 0

TotBk1XC2XD2cnt 0

TotStI-I/U>cnt 0

TotTrI-I/U>cnt 0

TotBk1I-I/U>cnt 0

TotBk2I-I/U>cnt 0

TotStI-I/U>>cnt 0

TotTrI-I/U>>cnt 0

TotBk1I-I/U>>cnt 0

TotBk2I-I/U>>cnt 0

20 NVA100X - Getting started - 01 - 2018

PILOT WIRE

DIAGNOSTIC >>

BreakedBLIN1 OFF

ShortedBLIN1 OFF

INTERNAL

SELECTIVE BLOCK

BLOCK4 >>

ST-IPh-BLK4 OFF

ST-IE-BLK4 OFF

BLK4OUT OFF

BLOCK2IN-IPh OFF

BLOCK2IN-IE OFF

tB timeout OFF ST-IPh-BLK2 OFF

ST-IE-BLK2 OFF

BLK2OUT-IPh OFF

BLK2OUT-IE OFF

BLK2OUT-IPh/IE OFF

SELECTIVE BLOCK

BLOCK2 >>

BLOCK2 INPUT >>

BLOCK2 OUTPUT >>

Fault 0 Cause:

No faults

Operating phase: -

Date:

Time:

IL1r: 0.000 In

IL2r: 0.000 In

IL3r: 0.000 In

UL1r: 0.000 En

UL2r: 0.000 En

UL3r: 0.000 En

U12r: 0.000 Un

U23r: 0.000 Un

U31r: 0.000 Un

IEr: 0.000 IEn

IECr: 0.000 In

UEr: 0.000 UEn

UECr: 0.000 UECn

PhiL1r: 0 deg

PhiL2r: 0 deg

PhiL3r: 0 deg

Alpha1r: 0 deg

Alpha2r: 0 deg

Alpha3r: 0 deg

PhiEr: 0 deg

PhiECr: 0 deg

DTheta-r: DthetaB

U1r: 0.000 En

U2r: 0.000 En

U/fr: 0.000 Un/fn

Pr: 0.000 Pn

Qr: 0.000 Qn

CosPhir: 0.000

fr: 0.000 fn

dfr: 0.000 Hz/s

dphir: 0 deg

Binary Inputs

IN1-16...IN1-1

0000000000000000

Binary Inputs

IN2-16...IN2-1

0000000000000000

Relays

KC1-8...KC1-1

00000000

Relays

KC2-8...KC2-1

00000000

Fault x Cause:

No faults

Operating phase: -

Date:

Time:

IL1r: 0.000 In

IL2r: 0.000 In

IL3r: 0.000 In

UL1r: 0.000 En

UL2r: 0.000 En

UL3r: 0.000 En

U12r: 0.000 Un

U23r: 0.000 Un

U31r: 0.000 Un

IEr: 0.000 IEn

IECr: 0.000 In

UEr: 0.000 UEn

UECr: 0.000 UECn

PhiL1r: 0 deg

PhiL2r: 0 deg

PhiL3r: 0 deg

Alpha1r: 0 deg

Alpha2r: 0 deg

Alpha3r: 0 deg

PhiEr: 0 deg

PhiECr: 0 deg

DTheta-r: DthetaB

U1r: 0.000 En

U2r: 0.000 En

U/fr: 0.000 Un/fn

Pr: 0.000 Pn

Qr: 0.000 Qn

CosPhir: 0.000

fr: 0.000 fn

dfr: 0.000 Hz/s

dphir: 0 deg

Binary Inputs

IN1-16...IN1-1

0000000000000000

Binary Inputs

IN2-16...IN2-1

0000000000000000

Relays

KC1-8...KC1-1

00000000

Relays

KC2-8...KC2-1

00000000

FAULTS RECORDING>>

Fault 0 (last) >>

Fault 1 >>

Fault .... >>

Fault 299 >>

EVENTS RECORDING>>

Event 0 (last):

Power up

21/06/2013

06:50:58:413

Event 1:

Power down

20/06/2013

14:23:38:000

Event 2:

Settings

19/06/2013

06:48:27:584

Event 3:

KC1-2 off

19/06/2013

06:28:52:168

Event 4:

KC1-2 on

19/06/2013

06:28:35:711

Event x:

Power up

xx/xx/xxx

xx:xx:xx:xxx

PROCEED SET MENU’

PREVIOUS READ MENU’

NVA100X_menuread5.ai

Table of contents

Other Thytronic Relay manuals

Thytronic

Thytronic RMT/3 Guide

Thytronic

Thytronic NA10 User manual

Thytronic

Thytronic NV10B User manual

Thytronic

Thytronic RMT/8D Guide

Thytronic

Thytronic Pro-N NVA100X-D User manual

Thytronic

Thytronic NC020 User manual

Thytronic

Thytronic NA30 User manual

Thytronic

Thytronic DTB 49-50 User manual

Thytronic

Thytronic NA20 User manual

Thytronic

Thytronic NA11 User manual