Fig. 6 End position adjustment

1. Loosen threaded sleeve5.

2. Position the slide in the desired end position.

3. Turn the internal cushioning component until the end position is reached.

Observe the maximum torque here èFollowing table.

NOTICE!

The exact slide position must be checked during a test run with compressed

air applied and, if necessary, corrected.

4. Retighten the threaded sleeve with the following tightening torque.

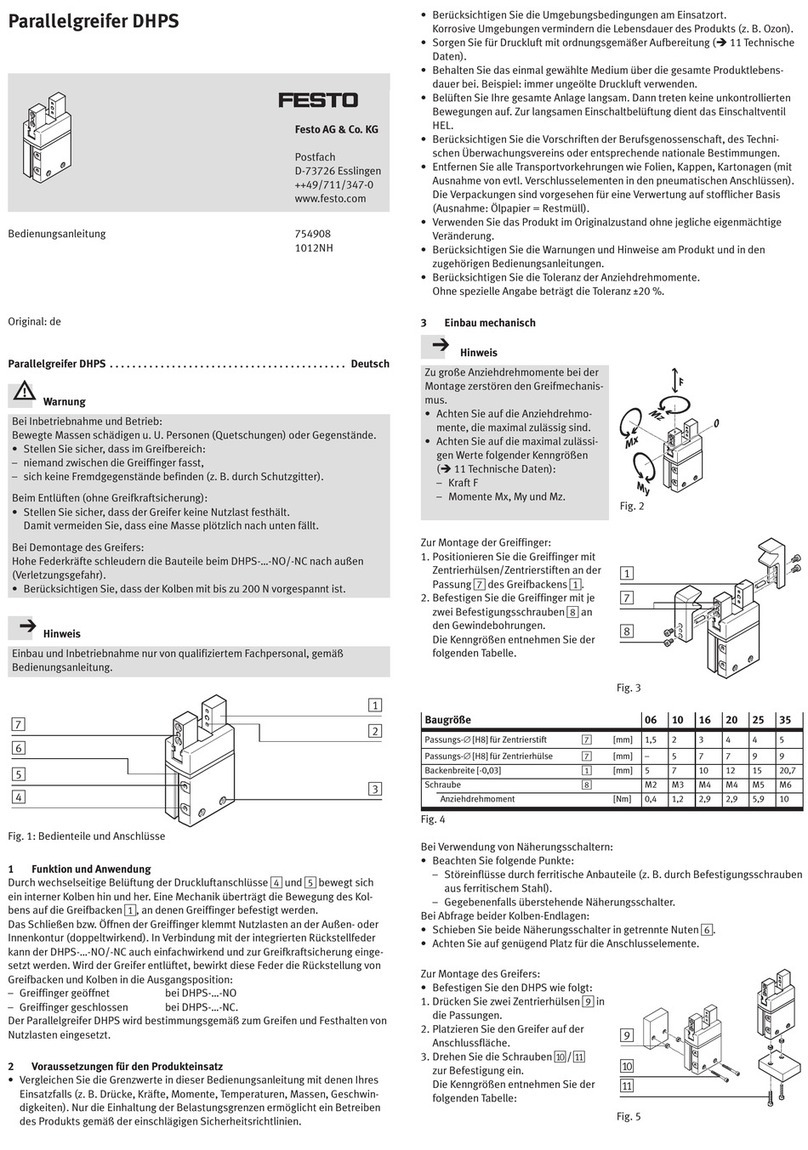

DGST-... 6 8 10 12 16 20 25

Threaded sleeve

Internal hexagon

socket

ß3 4 5 6 8 10 10

Tightening

torque

[Nm] 0.45 0.7 0.9 1.8 2.7 4.5 7

Cushioning component

Internal hexagon

socket DYSS

ß–1) 2 2 2.5 3 4 5

Internal hexagon

socket DYEF

ß1.3 1.5 2 2.5 3 4 4

Max. torque [Nm] 0.1 0.5 0.6 1 3 5 10

1) The cushioning component has a slot instead of an internal hexagon socket.

Tab. 6 Internal hexagon socket and torque

9.2 Execution

NOTICE!

Risk of collision by payloads that protrude through the rotor/slide.

• Only turn adjusting screws while the rotor/slide is stationary.

Fig. 7

1. First of all, close the one-way flow control valves on both sides completely,

then unscrew them one complete turn.

2. Initially exhaust drive simultaneously at both sides.

ÄThis causes the slide to move slightly to a point of balance.

3. Then exhaust the drive on just one side.

ÄThis causes the slide to move into an end position.

4. Start the test run.

5. If needed: correct speed at the one-way flow control valves. The slide should

reach the end positions without striking them harshly or recoiling.

10 Malfunctions

10.1 Fault clearance

Fault description Cause Remedy

Slide moves unequally. One-way flow control valves are

not installed correctly.

Control flow of exhaust air, if

possible (not supply air).

Speed is too high. Reduce the speed.The slide strikes the end posi-

tion harshly. Cushioning is insufficient. – Adjust shock

absorber/fixed stop again

è Preparation for com-

missioning.

– Reduce the speed.

– Check and, if necessary,

replace cushioning com-

ponents.

Fault description Cause Remedy

Missing air cushion. Pressurise both air supply ports

at the same time and then

exhaust at one end.

The shock absorber is faulty. Replace the shock absorber.

The slide strikes the end posi-

tion harshly.

Payload is too great. Reduce payload.

Slide in initial position despite

pressurisation.

Tubing incorrectly connected. Check tubing connection.

The slide speed is too low. Air volume is lacking. – Increase connection cross-

section.

– Check the adjustment of

throttle.

– Connect volume

upstream.

Tab. 7

10.2 Repair

Send the product to the Festo repair service for repair.

– Use the shock absorber paying due regard to environmental protection (use

of problem substances). The shock absorber is filled with hydraulic fluid. Due

to the design, the hydraulic fluid cannot be refilled.

To replace the integrated cushioning components:

1. Observe section on "Adjusting the end positions"è 9.1 Preparation.

2. Loosen the threaded sleeve5 on the cushioning component.

3. Replace cushioning component èwww.festo.com/catalogue:

– DYEF-G8-M_-Y1 at DGST-…-P

– DYSS-G8-…-Y1F at DGST-…-Y12.

4. Adjust the end positions.

5. Lock both cushioning components with the threaded sleeve, observe the

tightening torqueè Tab. 6 Internal hexagon socket and torque.

11 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations èwww.festo.com/sp.

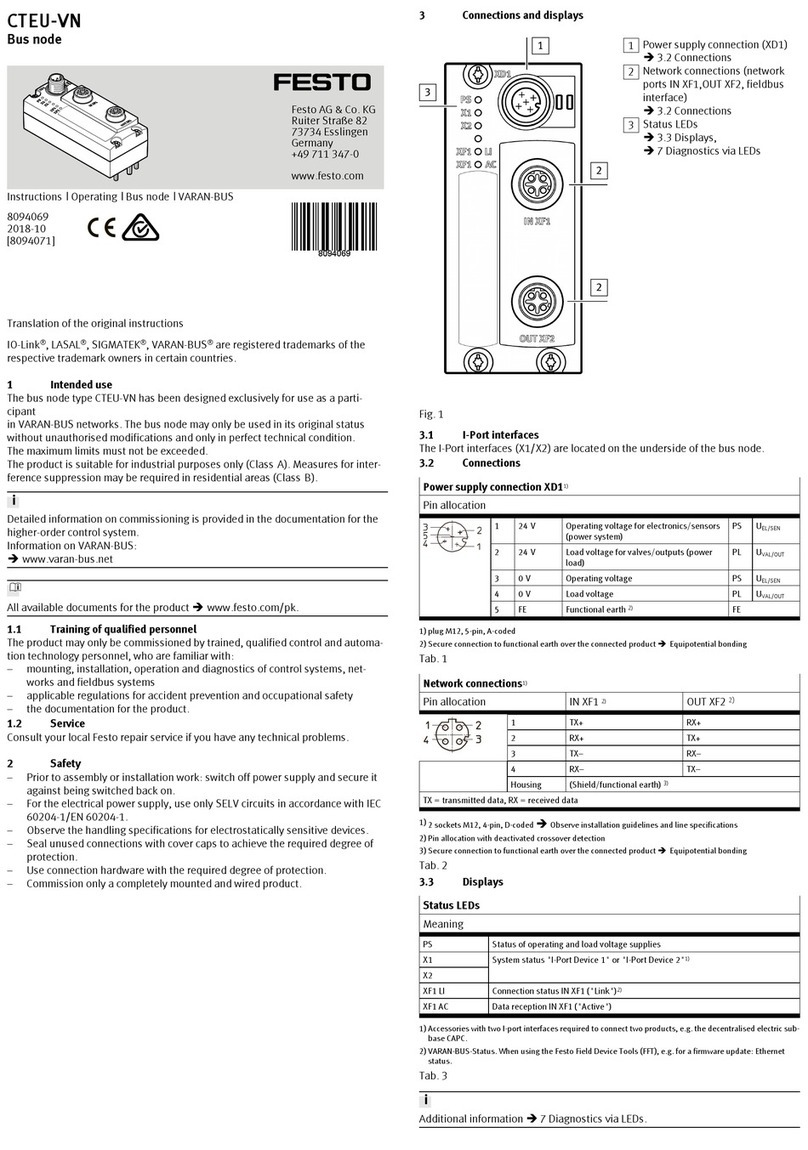

12 Technical data

Size 6 8 10 12 16 20 25

Design Drive with yoke kinematics and

Guide Recirculating ball bearing guide Three-part

cage guide

Mode of operation Double-acting

Pneumatic connection M3 M5 G1/8

Cushioning

– DGST-...-E1 Elastic cushioning, without end-position adjustment, at

both ends

– DGST-...-P Elastic cushioning at both ends, non-adjustable, with

end-position adjustment

– DGST-...-Y12 Shock absorber, self-adjusting on both sides, with end-

position adjustment

Mounting position Any

Max. speed

– DGST-...-E1/Y12 [m/s] 0.5

– DGST-...-P [m/s] 0.5 0.8

Repetition accuracy

– DGST-...-E1/P [mm] £0.3

– DGST-...-Y12 [mm] £0.02

Operating medium Compressed air in accordance with ISO8573-1:2010

[7:4:4]

Note on the operating medi-

um

Lubricated operation possible (in which case lubricated

operation will always be required)

Operating pressure1) [bar] 1.5…8 1…8

Ambient temperature [°C] –10…+60

Theoretical force at 6 bar

(supply)

[N] 34 60 94 136 241 377 589

Theoretical force at 6 bar

(return)

[N] 25 45 79 102 207 317 495

Impact energy at the end positions

– DGST-...-E1 [J] 0.005 0.03 0.05 0.07 0.15 0.2 0.3

– DGST-...-P [J] 0.018 0.05 0.08 0.12 0.25 0.35 0.45

– DGST-...-Y12 (per

stroke)

[J] 0.09 0.18 0.28 0.48 0.85 1.9 3.6

Max. operating frequency at

DGST-...-Y12

[Cycles/-

min]

50 80 80 80 70 50 50

Product weight at 10 mm

stroke with DGST-...-E1

[g] 90 129 247 391 454 978 1463

Product weight at max.

stroke with DGST-...-E1

[g] 172 310 561 988 1402 3275 4803