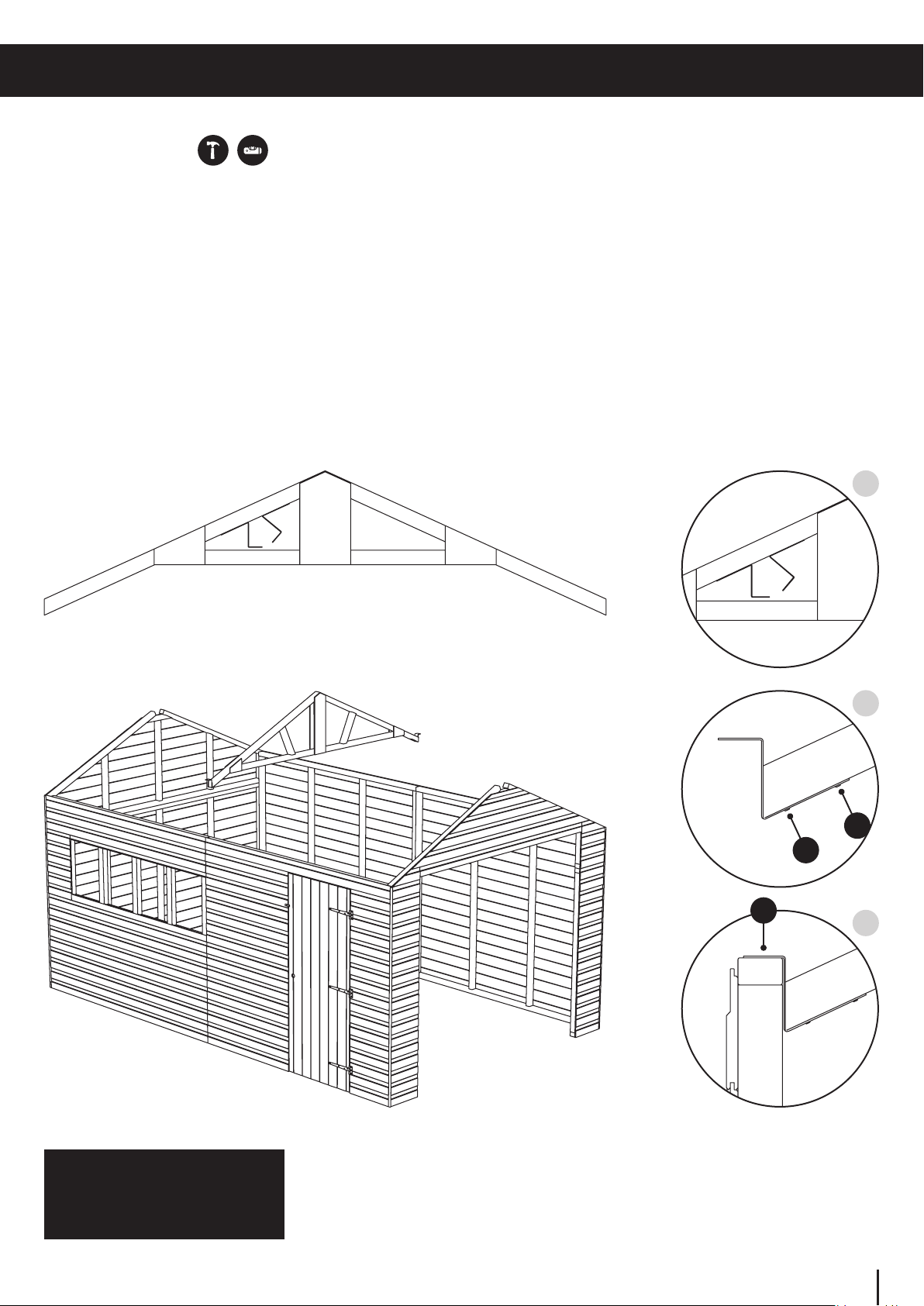

BEFORE YOU GET STARTED

PLEASE READ INSTRUCTIONS CAREFULLY

• Check the pack and make sure you have all the parts listed.

• When you are ready to start, make sure you have the right tools at hand (not supplied).

• Ensure there is plenty of space and a clean dry area for assembly.

TIMBER

As with all natural materials, mber can be aected during various weather condions. For the duraon of

heavy or extended periods of rain, swelling of the wooden panels may occur. Warping of the wood may also

occur during excessive dry spells due to an interior moisture loss. Unfortunately, these processes cannot be

avoided but can be migated. It is suggested that the outdoor building is sprayed with water during extended

periods of warm sunshine and sheltered as much as possible during rain or snow.

To validate your guarantee and ensure longevity of the product, it is ESSENTIAL that your building is treated

with an appropriate high-quality oil or solvent based preservave AFTER assembly, both internally and

externally, and annually thereaer. All glazing units must be sealed (internally and externally) with silicone or

other waterght sealant.

BUILDING A BASE

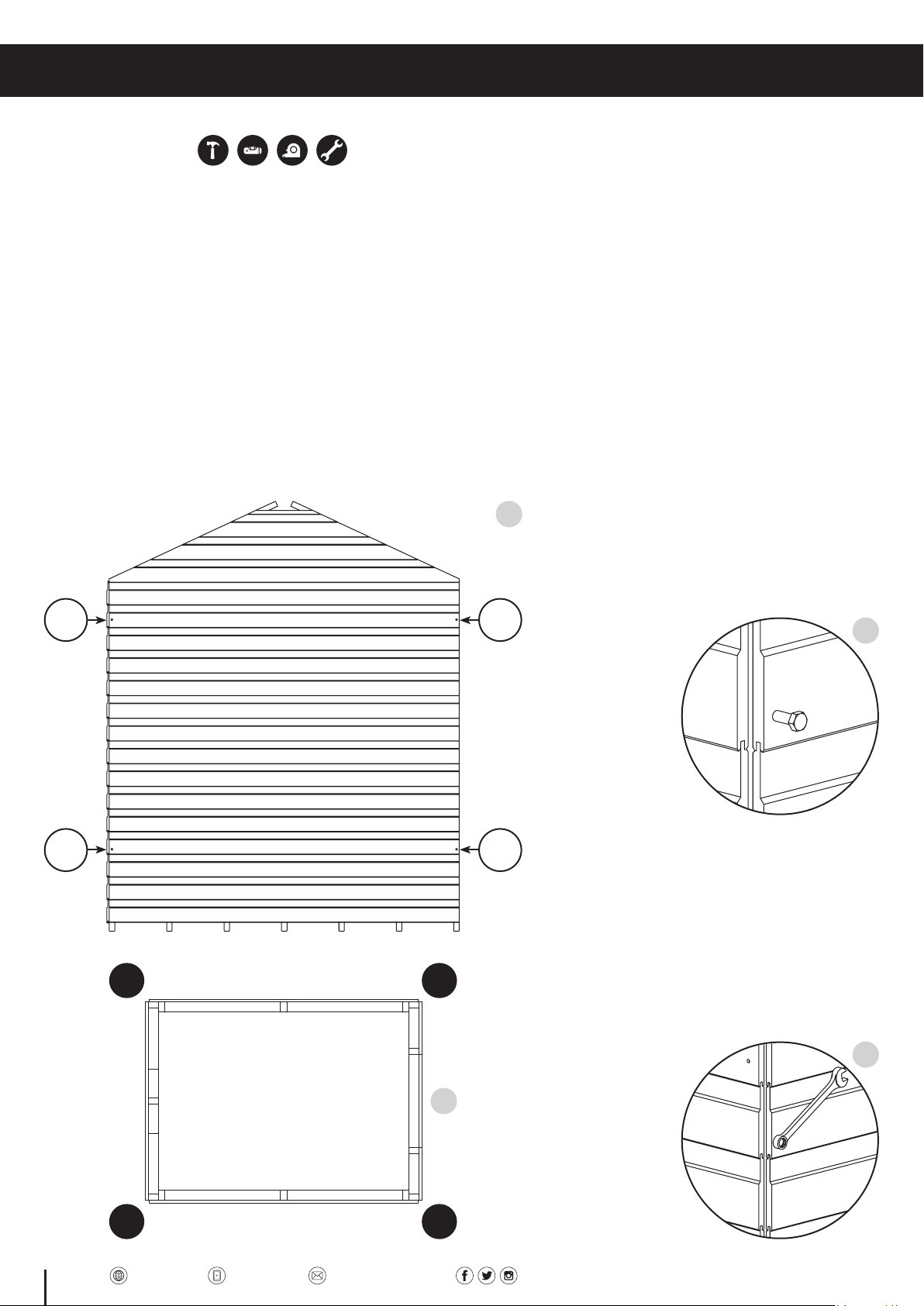

Care must be taken to ensure the product is placed on a suitable base. When thinking about where the building

and base is going to be constructed, ensure that there will be access to all sides for maintenance work and

annual treatment.

Ensure the base is rm and level and is built on rm ground, to prevent distoron.

The constructed base must be at least the size of product as referenced in supplied construct diagram. It is also

recommended that the oor be at least 25mm above the surrounding ground level to avoid ooding.

TYPES OF BASE

• Durable plasc grid*.

• Concrete 75mm laid on top of 75mm hard-core.

• Slabs laid on 50mm of sharp sand.

• Timber Base - Self constructed/Buy pre-made.

*We recommend a Fastt EcoBase for your building. It is durable, lightweight, exible and easy to put in place.

Please see gersheds.com for details.

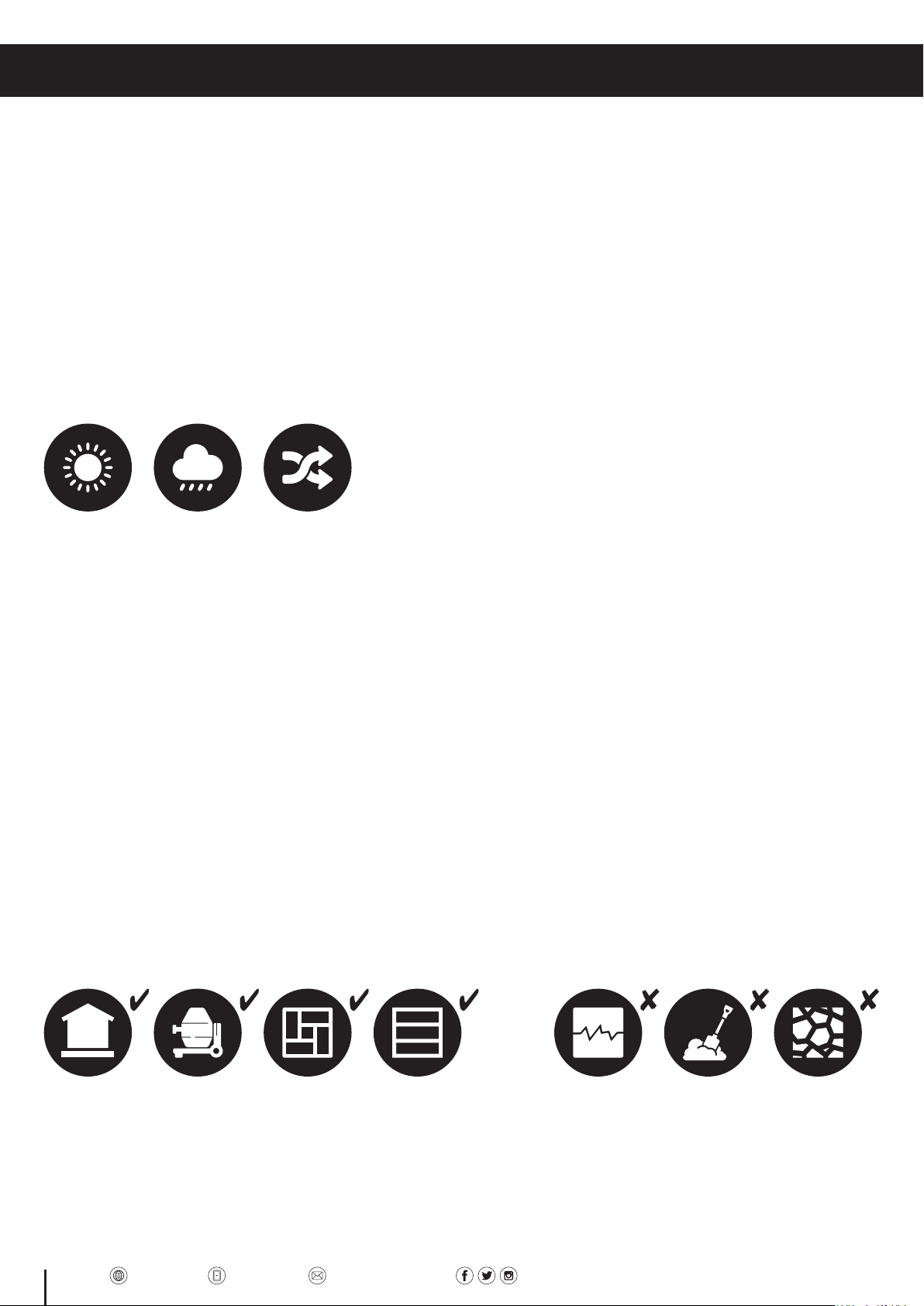

WOOD WARPING

MAY OCCUR

WINTER

EXPANSION

SUMMER

CONTRACTION

PLASTIC BASE SLAB BASE TIMBER BASE BROKEN SLABS BARE SOIL LOOSE GRAVEL

02 gersheds.com 0113 205 4189 sales@gersheds.com

CONCRETE BASE