9

OPERATION

The LVI Pulvimaster is designed to pulverize litter in the poultry house after birds have been taken out of

the house. Please follow these operating suggestions in order to provide maximum eciency of operation

and long life for your machine. Also maintain the machine as suggested.

After attaching the machine to the tractor, verify PTO shaft length is within proper lengths. Adjust tractor

top link so that the Pulvimaster when in the lowered position, the skid shoes are slightly higher in the front

than the rear. This is done to prevent the skid shoes from digging into the poultry house floor.

Adjust the chains on the tail drag lid to allow the lid to move upward to a 45 degree angle while moving

forward. If the chains are adjusted too short the lid will not raise high enough and the pulverized litter will

not be able to exit out the back of the machine. If the pulverized litter cannot exit out the back it will fill

the machine trough and will cause the machine to vibrate and consume more power than necessary. This

situation will vary depending on the depth and moisture of the litter.

Run the tractor PTO at approximately 500 rpm and not greater than 540 rpm. Forward tractor speed

is dependent upon the depth and condition of the litter. At times if the litter has a thick hard crust the

Pulvimaster may need to be run through the litter a second time in order to produce the desired results.

Note: Rocks, stones and other foreign objects can severely damage the machine. Avoid running these

objects into the machine.

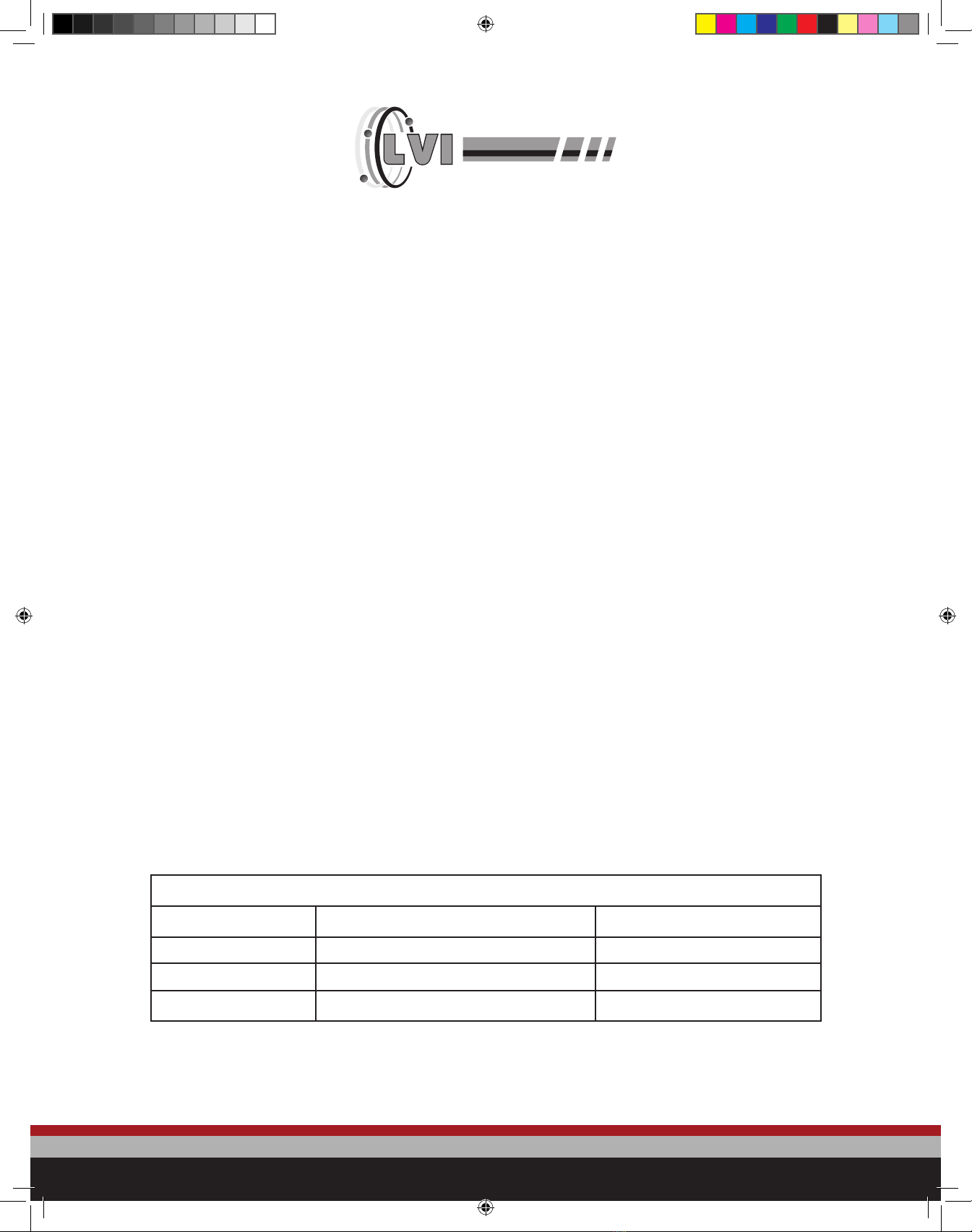

MAINTENANCE SCHEDULE

To ensure the long life for which the processor was designed, it is essential that the proper maintenance

procedures are followed. The following chart indicates the manufacturer’s recommended lubrication/

maintenance schedule.

DESCRIPTION HOURS OF OPERATION SPECIAL INSTRUCTIONS

GEAR BOX CHECK EVERY 6 MONTHS 80-90EP GL-5 GEAR OIL

CHAIN CASE CHECK EVERY 3 MONTHS 80-90EP GL-5 GEAR OIL

PTO SHAFT GREASE EVERY 8 HOURS QUALITY LITHIUM 2 GREASE

BEARINGS GREASE EVERY 8 HOURS QUALITY LITHIUM 2 GREASE

Pullvimast_Owners_Manual_2019.indd 9 1/13/20 9:48 AM